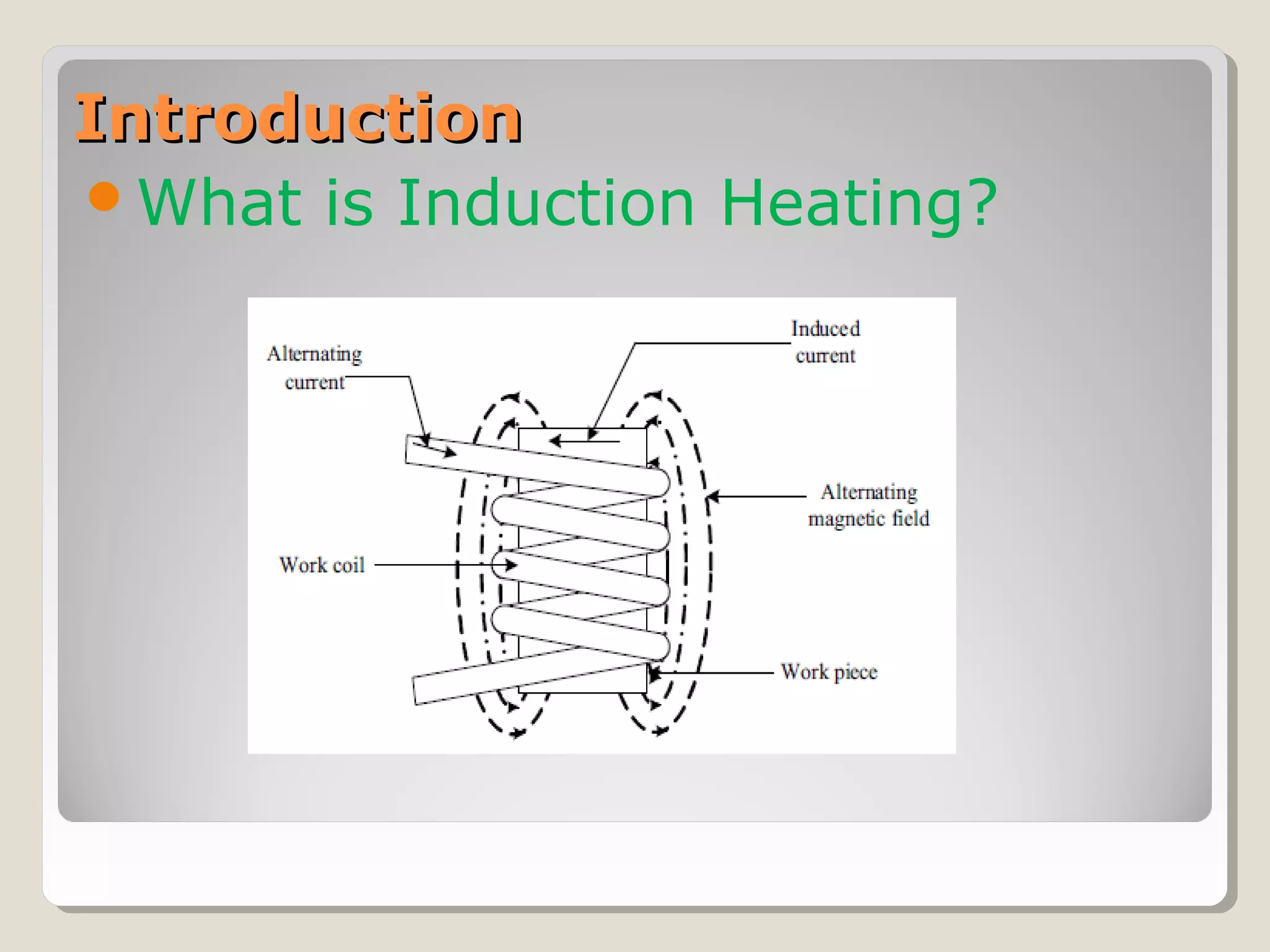

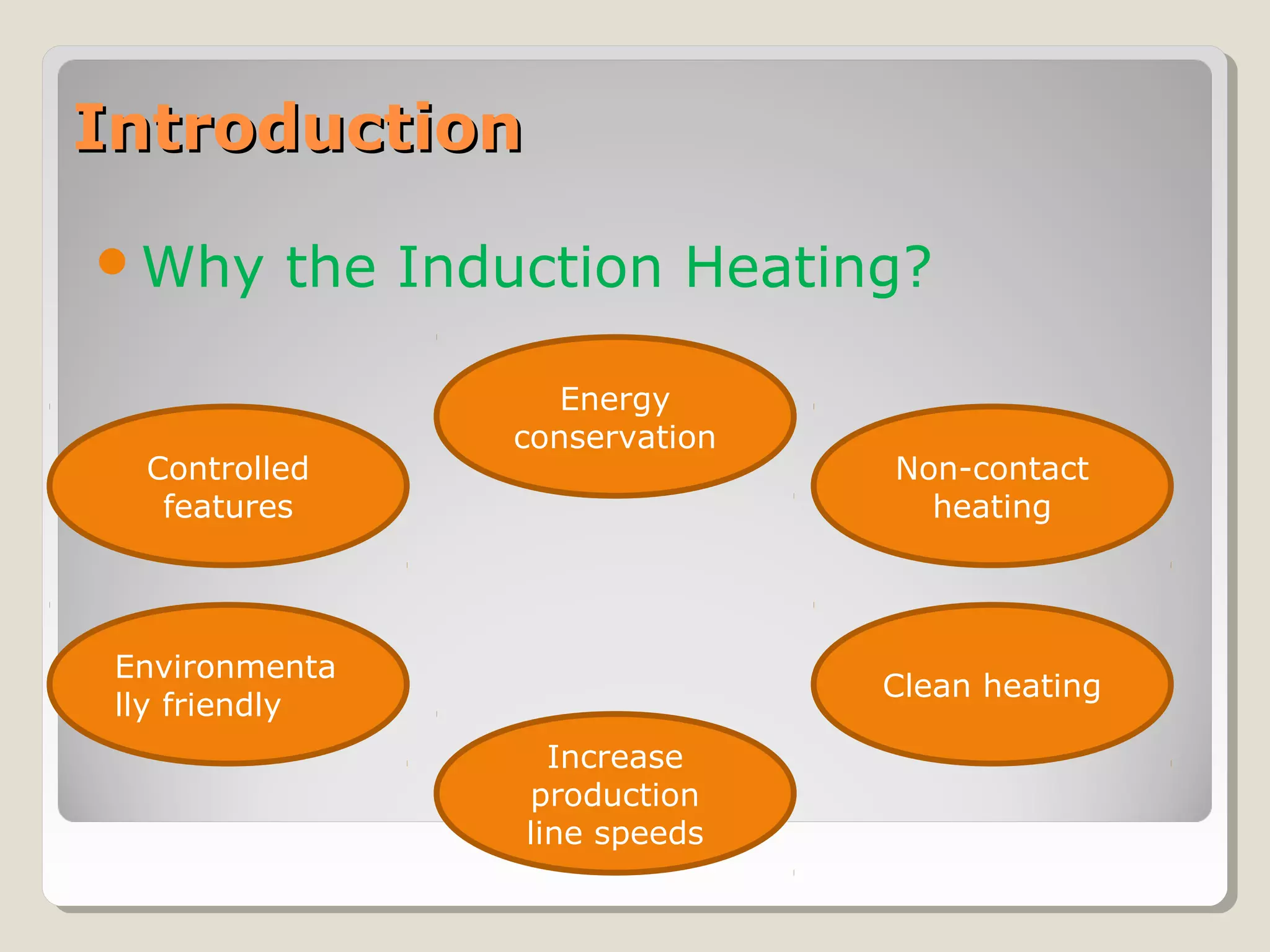

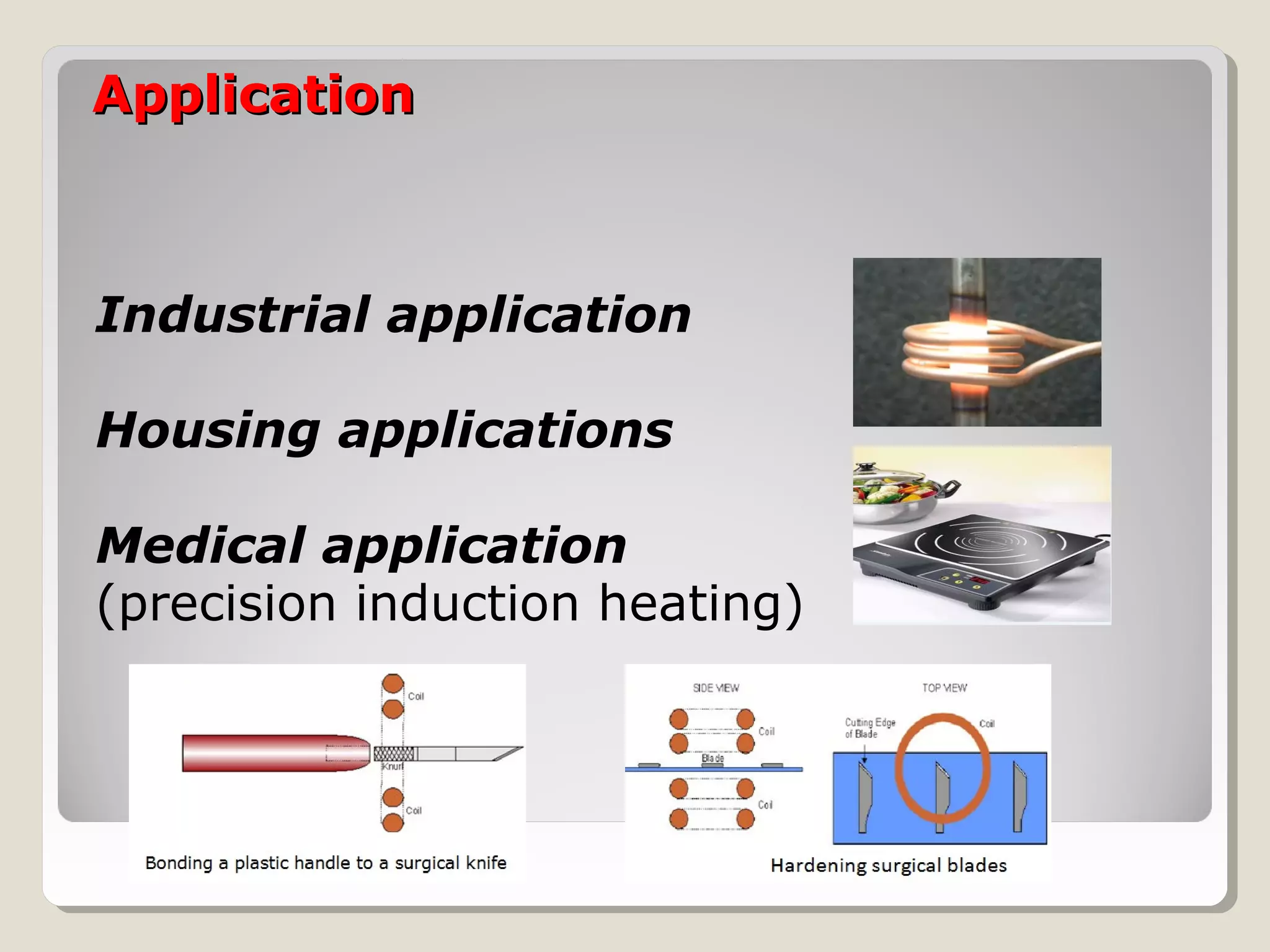

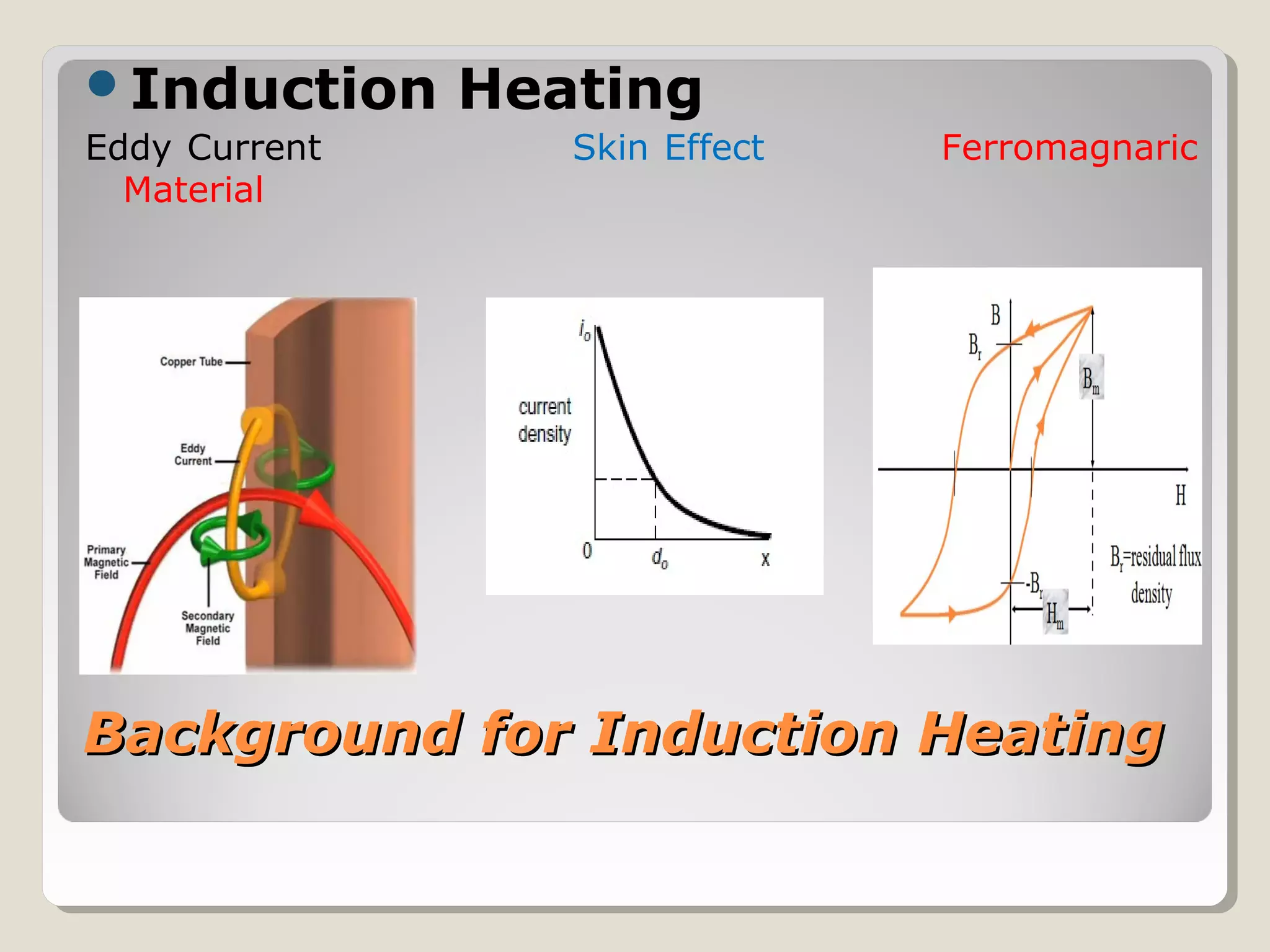

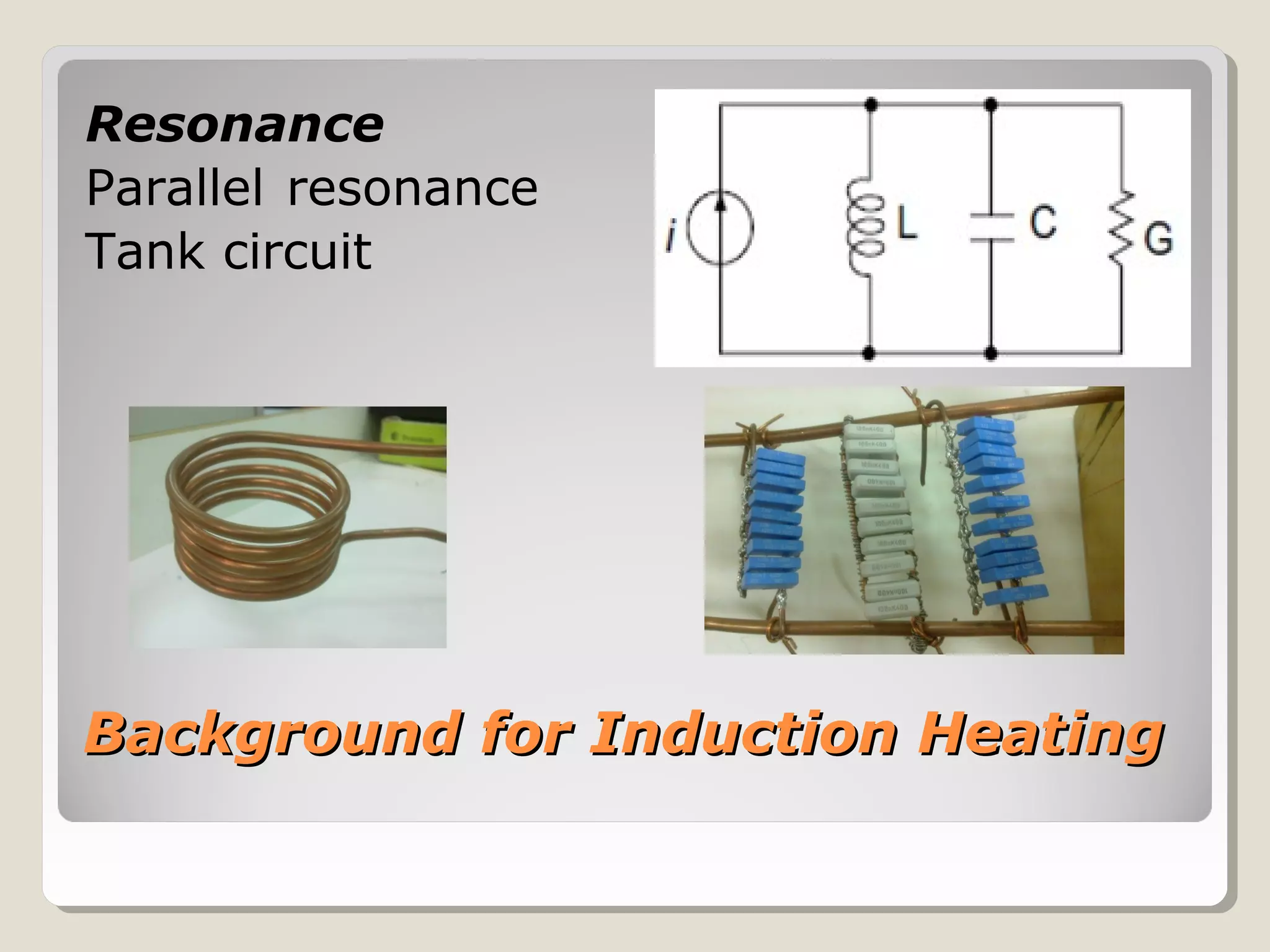

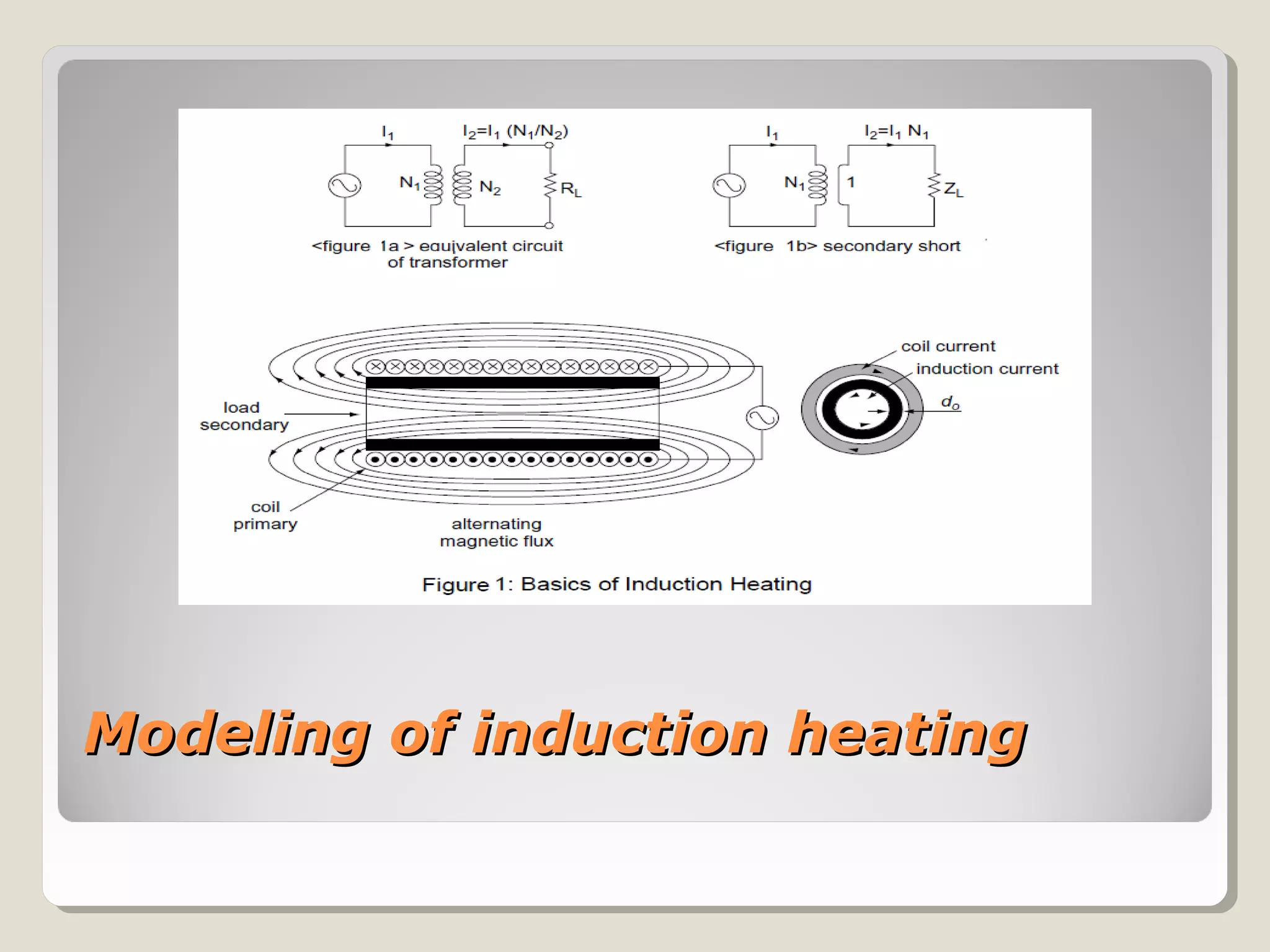

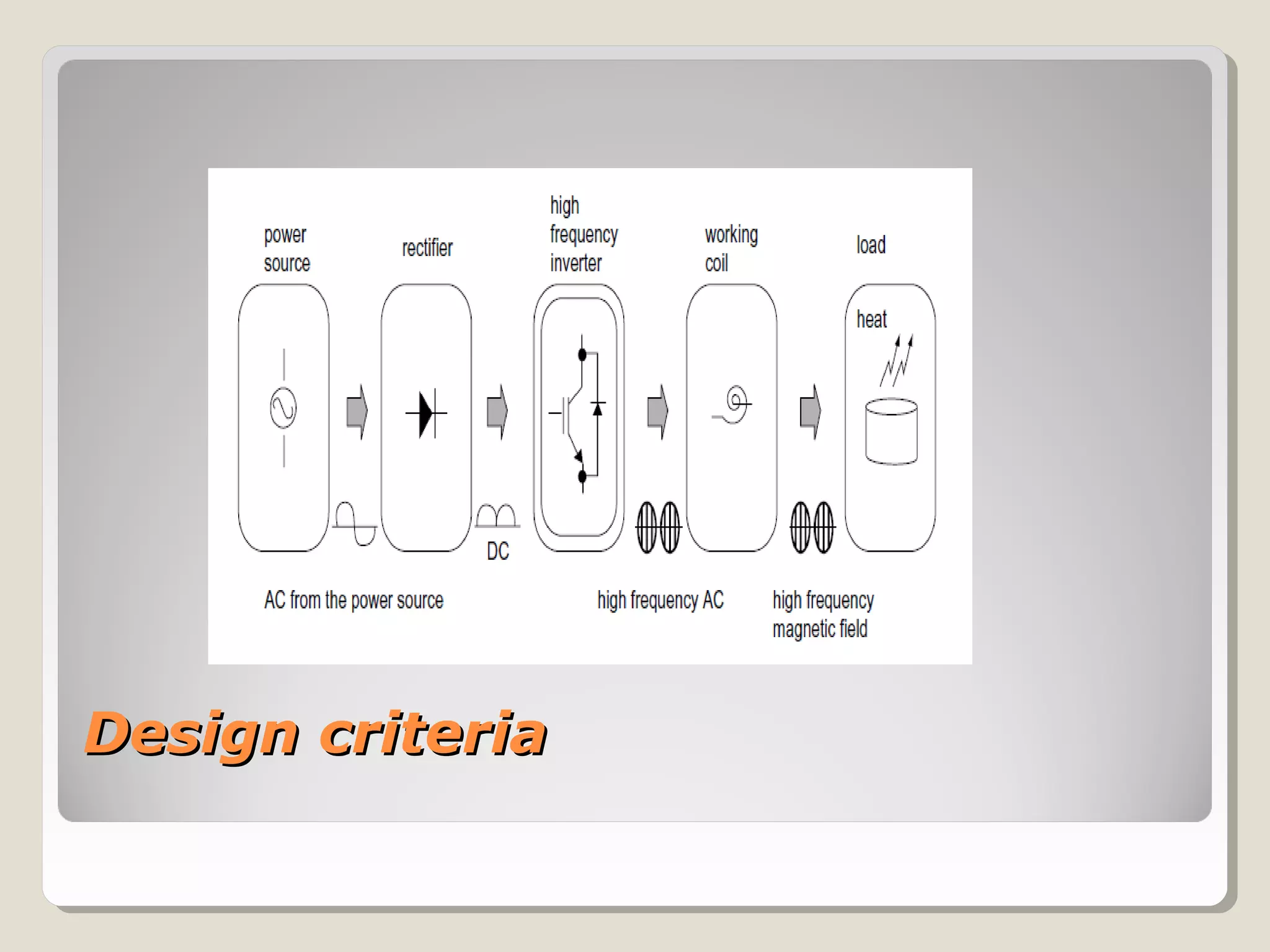

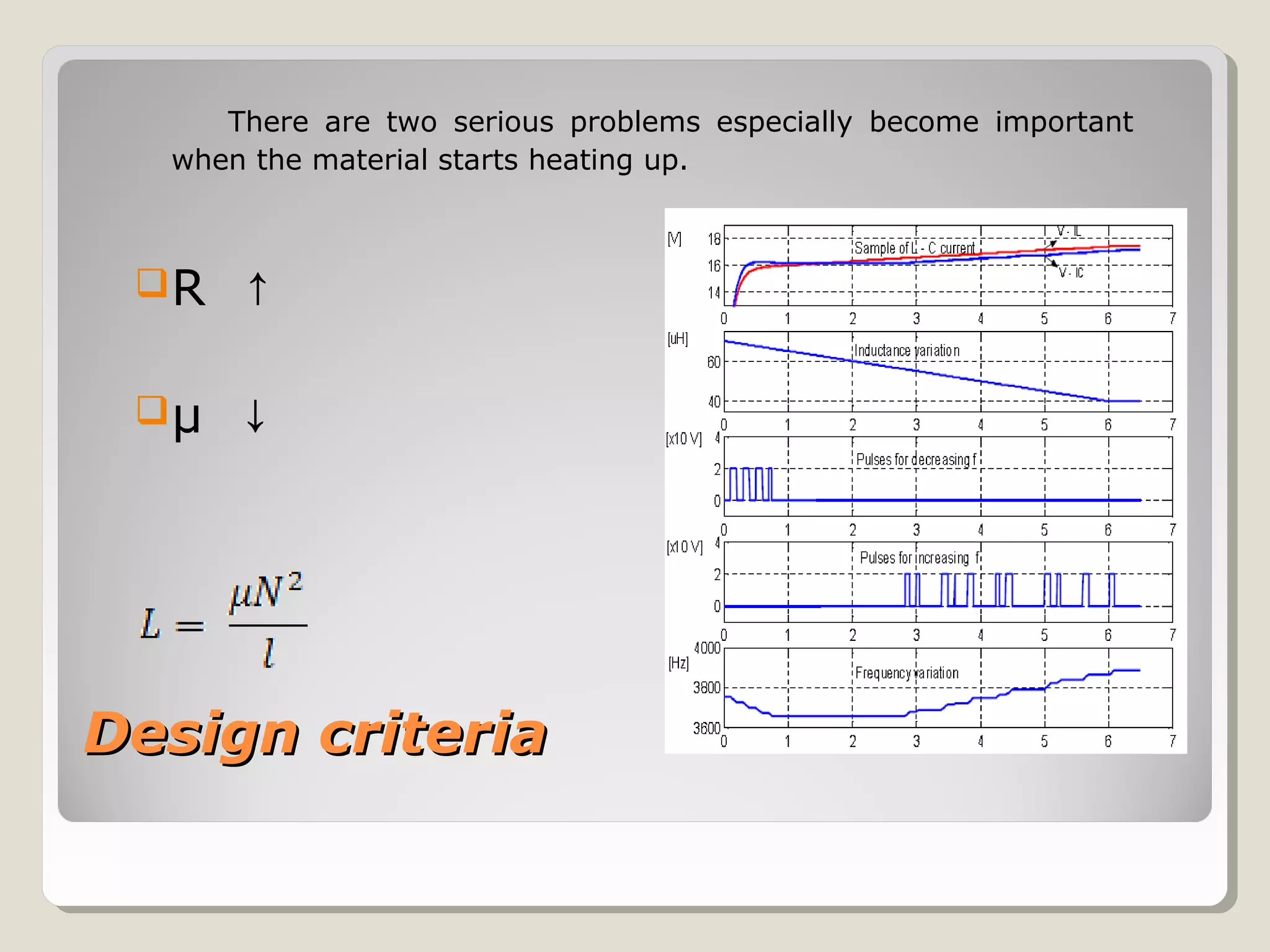

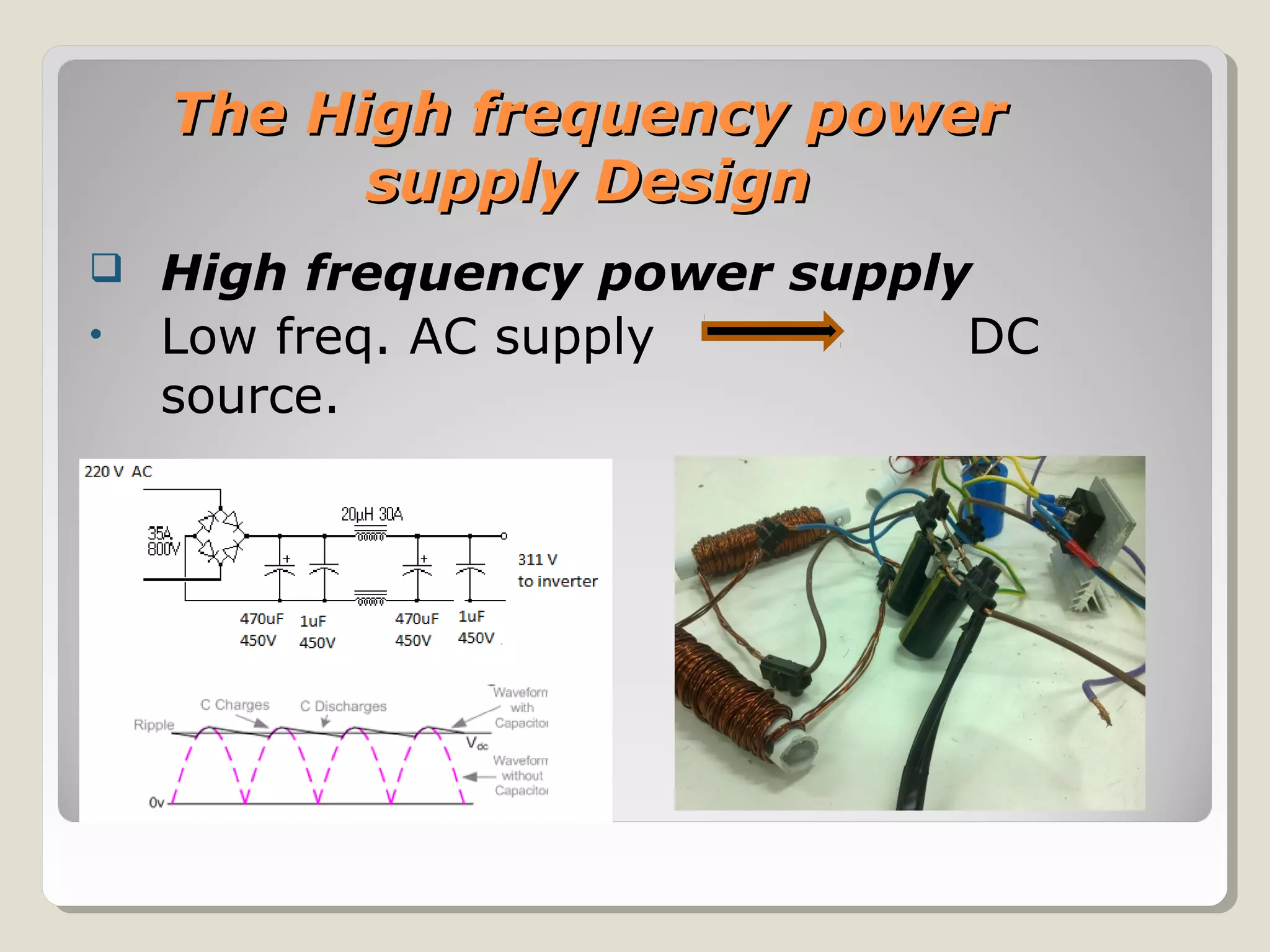

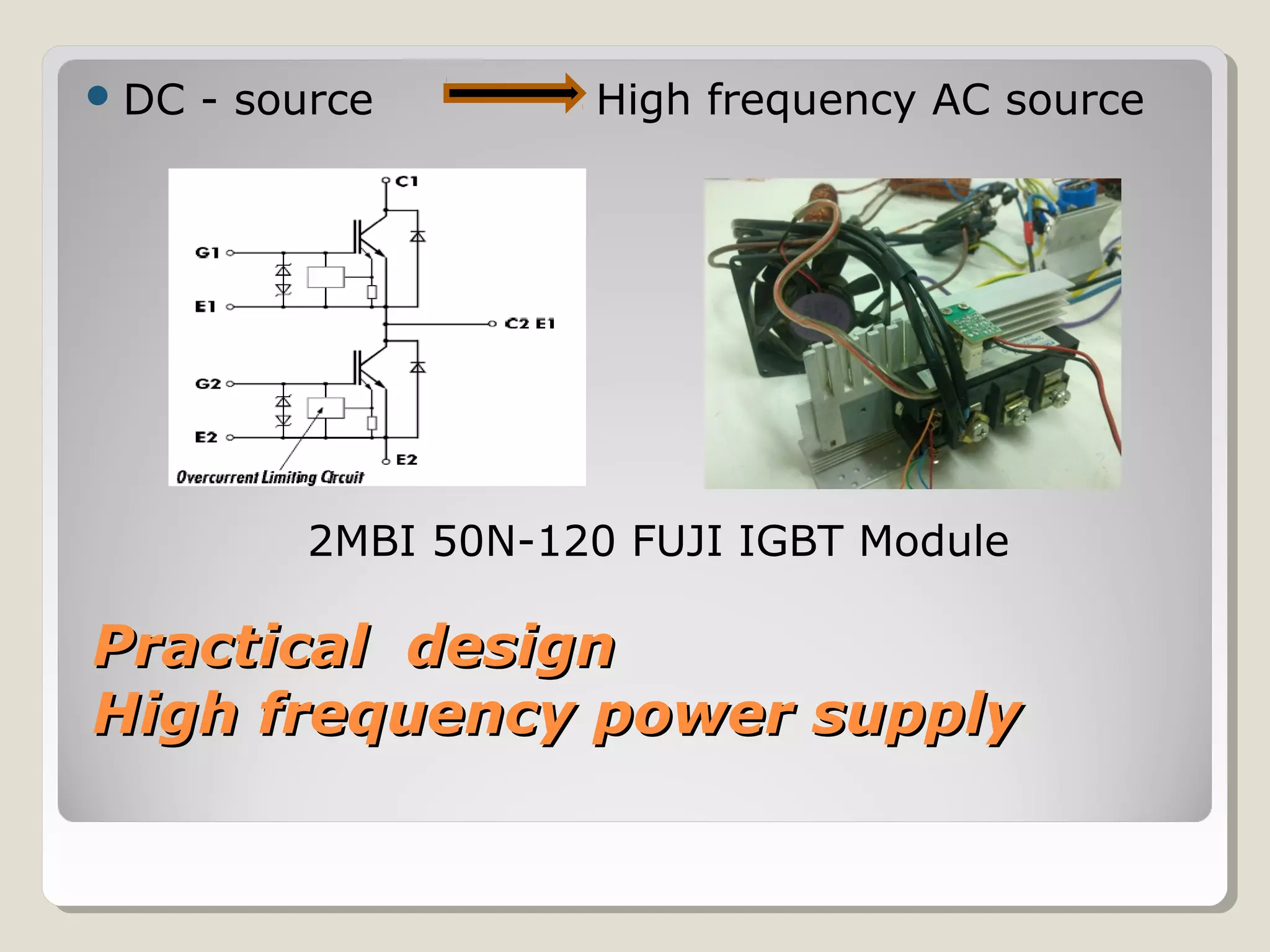

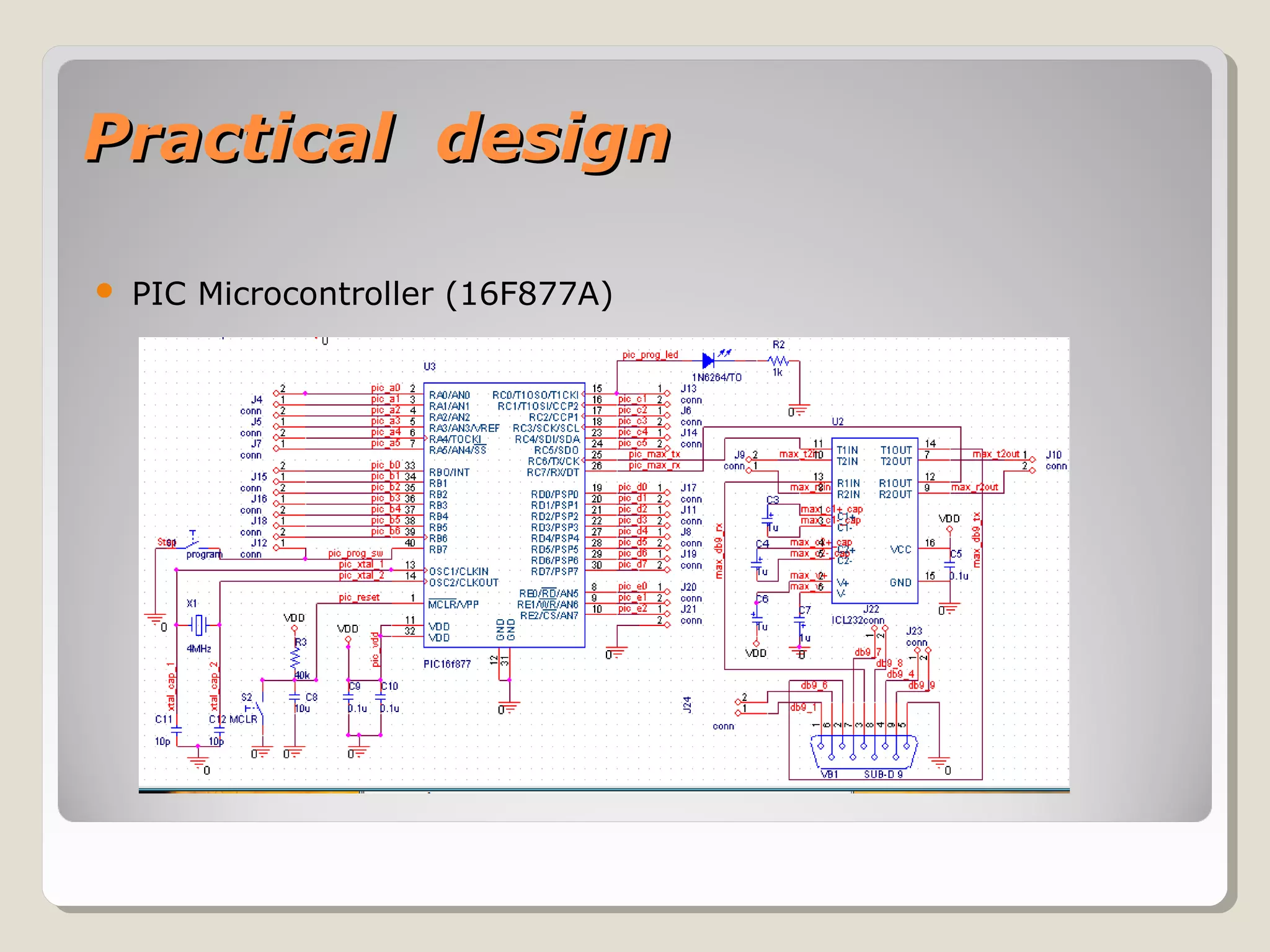

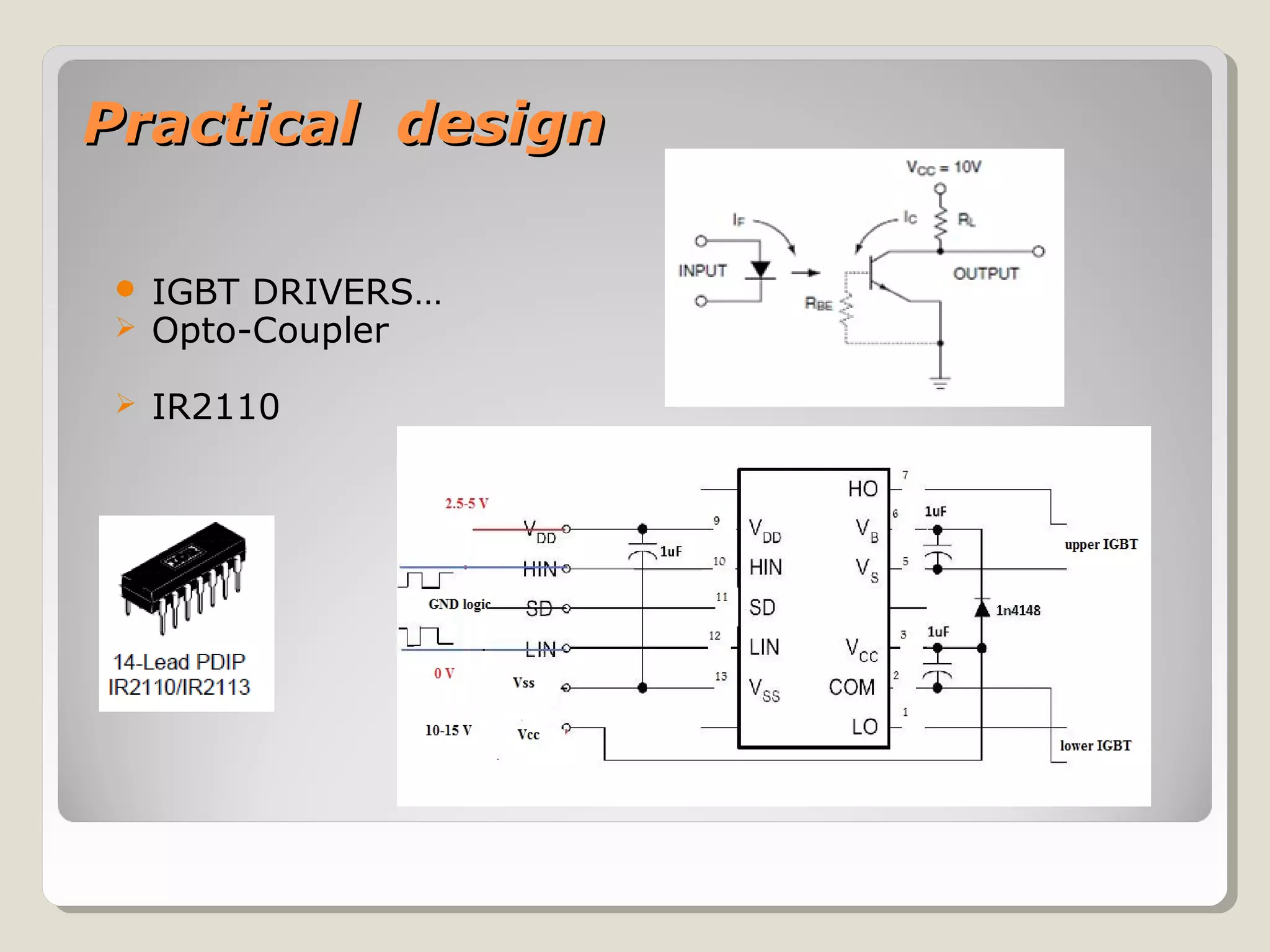

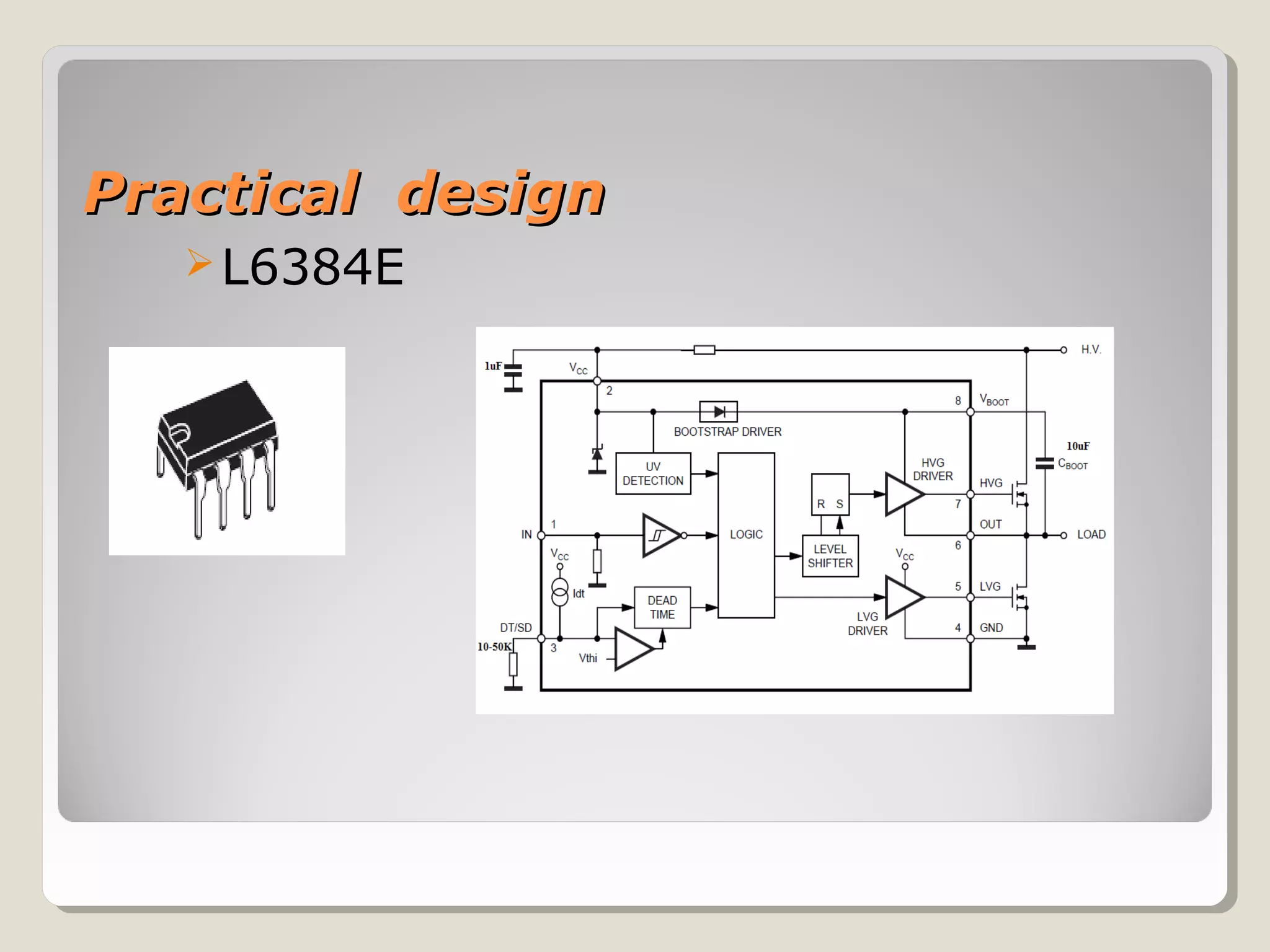

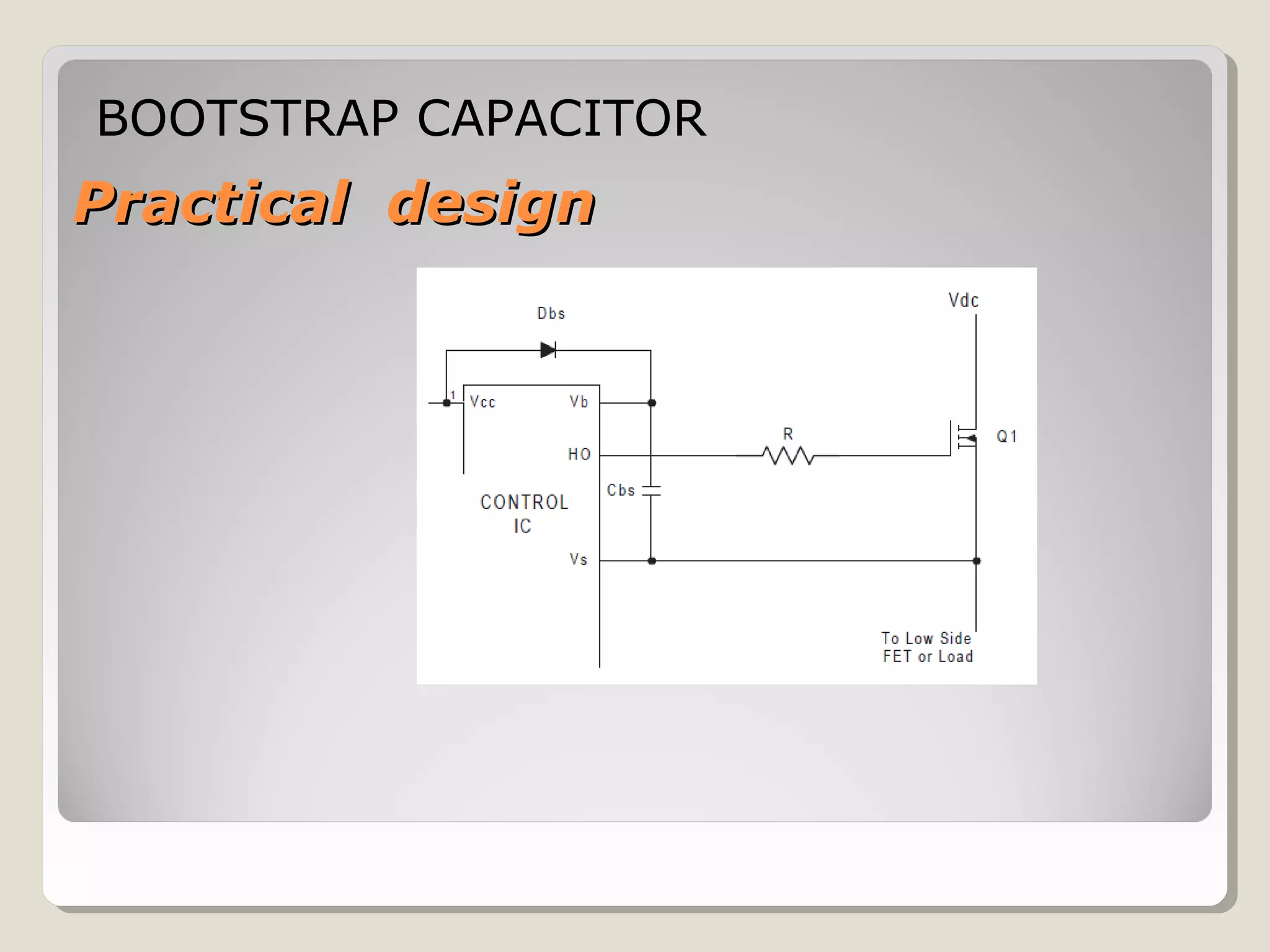

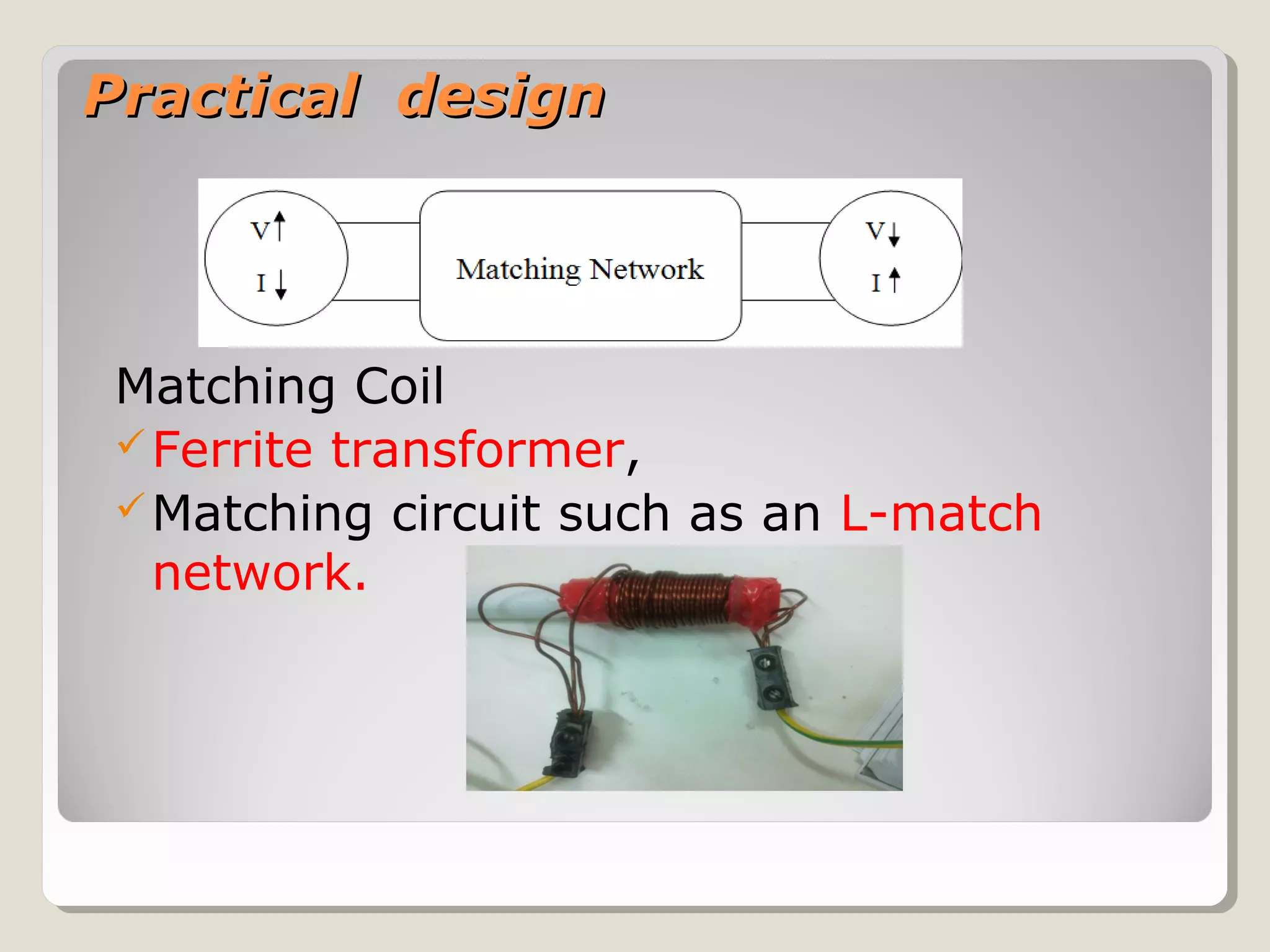

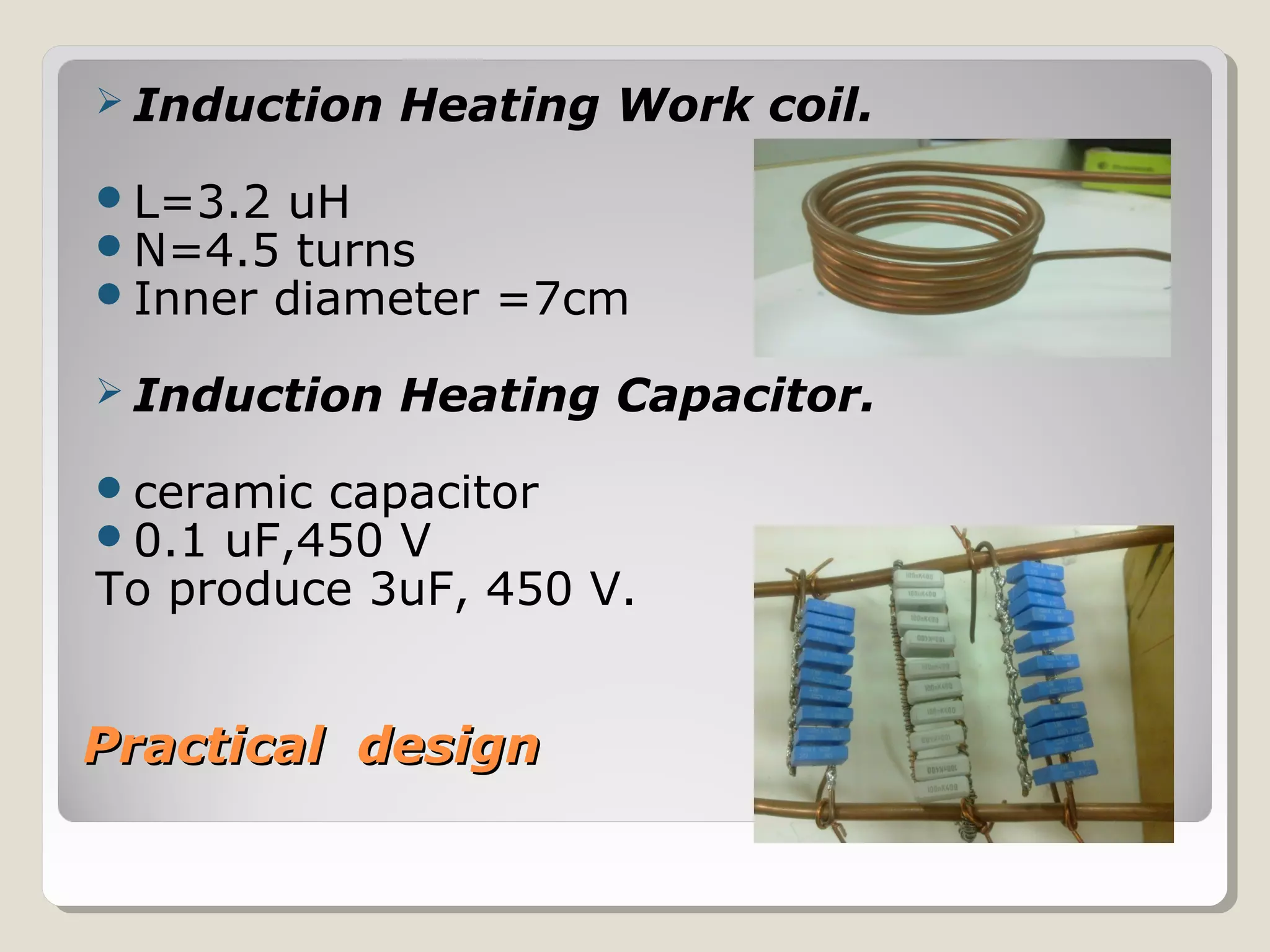

The document introduces induction heating solutions provided by Stead Fast Engineers, emphasizing customization for both ferrous and non-ferrous materials. It outlines the principles of induction heating, its applications, and project goals, including the development of a surface hardening machine. Additionally, it details the practical design elements and challenges faced in creating high-frequency power supply systems for induction heating.