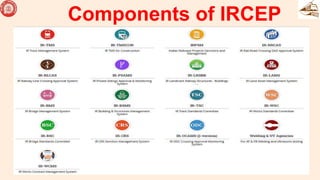

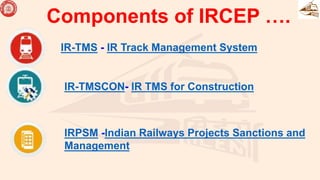

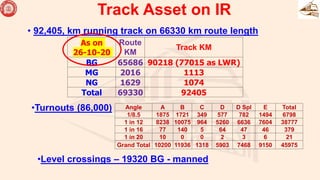

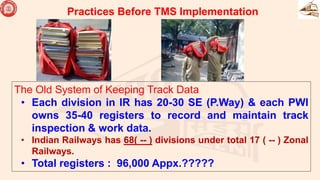

The document describes the Track Management System (TMS) used by Indian Railways to manage track assets and maintenance. Key points:

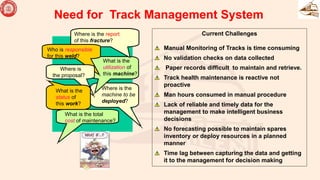

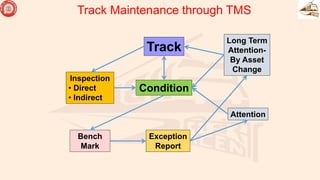

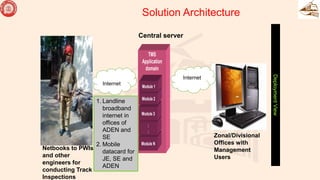

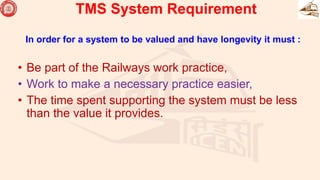

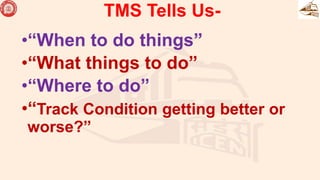

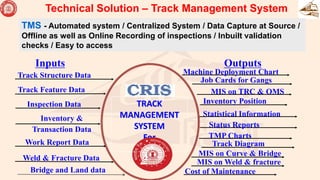

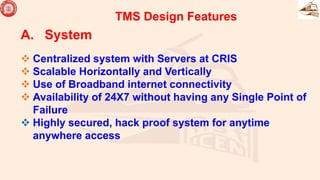

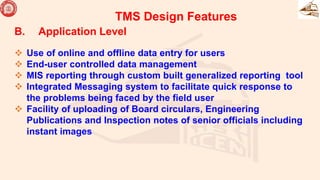

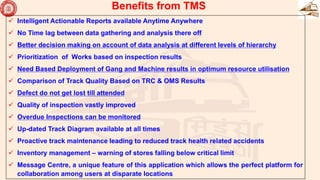

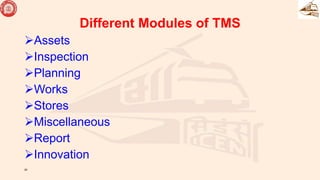

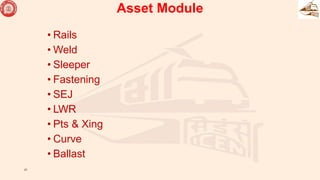

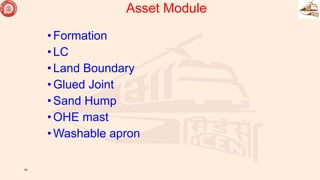

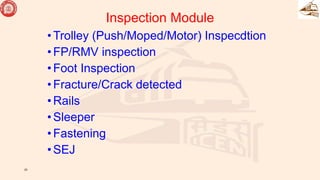

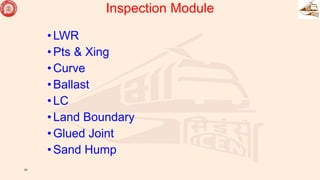

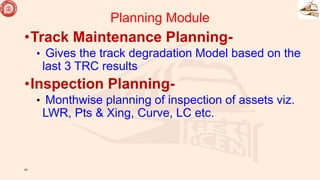

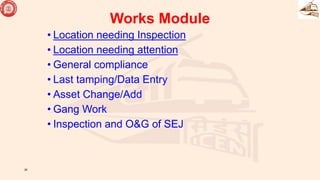

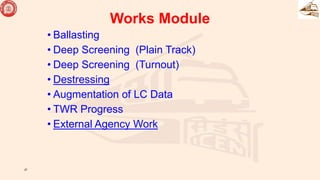

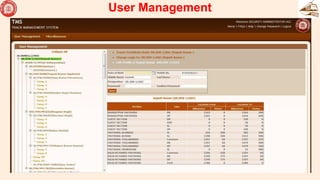

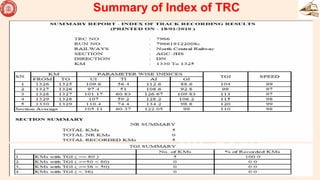

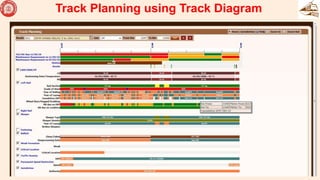

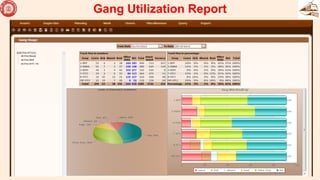

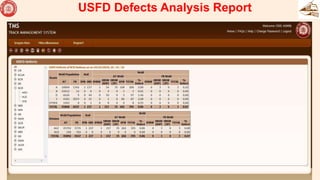

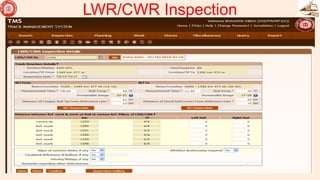

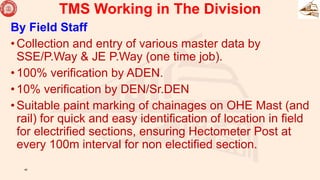

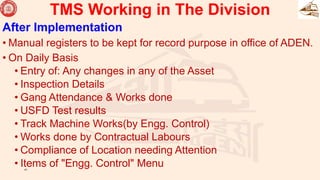

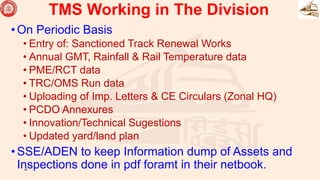

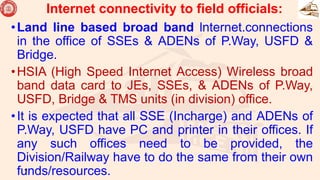

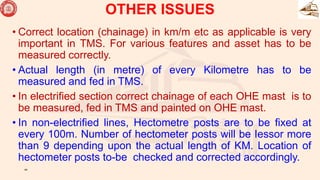

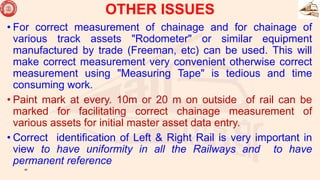

- TMS digitizes paper-based track inspection and maintenance records to improve data collection, analysis and decision making. It has modules for assets, inspections, planning, works and reporting.

- Over 92,000 km of track are managed using around 96,000 paper registers previously. TMS automates this with mobile and web apps.

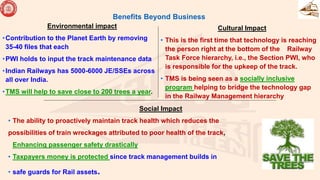

- Benefits include proactive maintenance planning, optimized resource allocation, reduced accidents and improved passenger safety through real-time track condition monitoring.