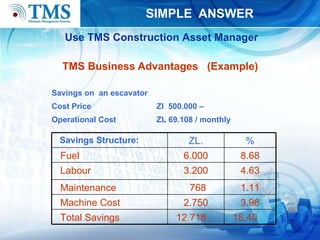

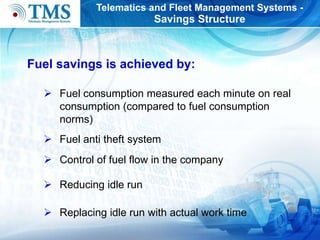

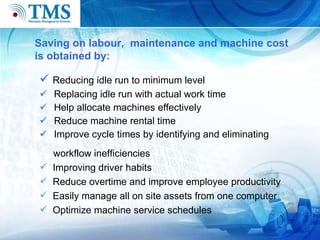

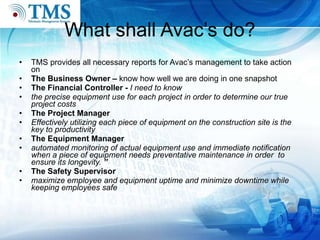

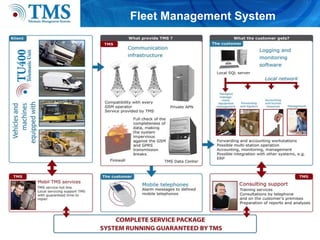

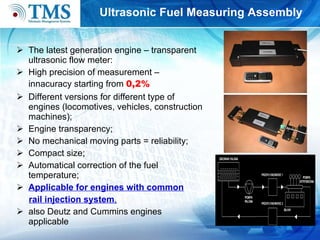

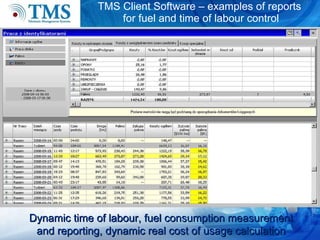

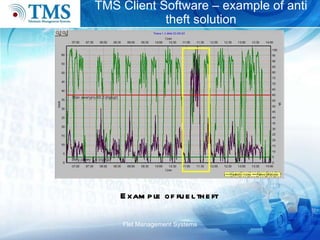

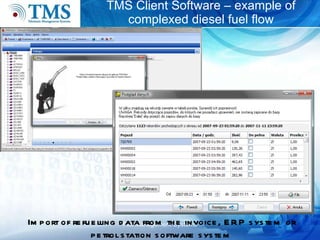

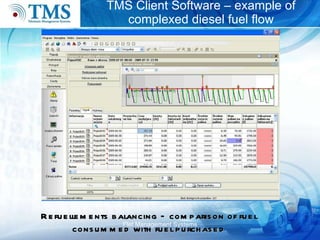

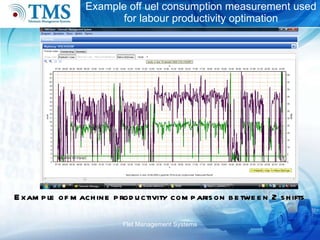

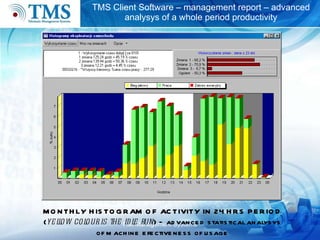

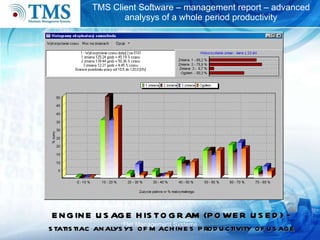

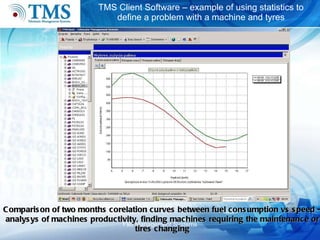

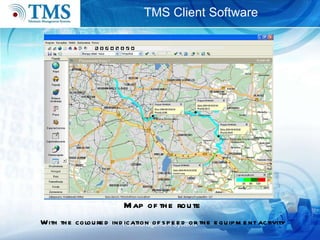

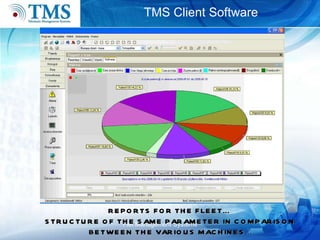

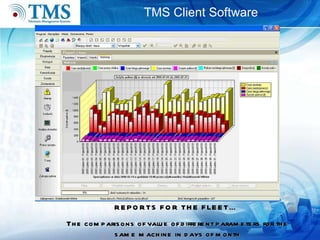

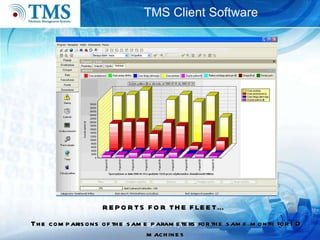

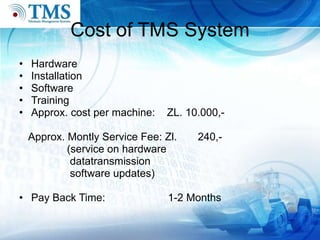

The document discusses how a construction fleet management system called Telematic Management Systems (TMS) can provide benefits to a construction company called JP Avax. TMS allows users to track equipment usage details, location, maintenance needs, and fuel usage. It provides reports to help optimize equipment efficiency, productivity, and costs. Implementing TMS for JP Avax's fleet could result in estimated savings of 4 days on a project and 2,000 liters of fuel. The upfront and ongoing costs of TMS are outlined.