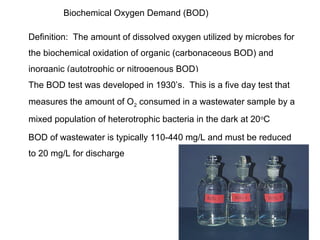

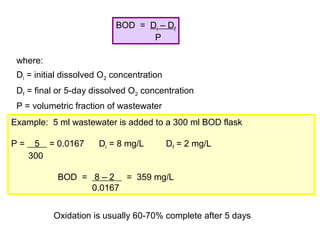

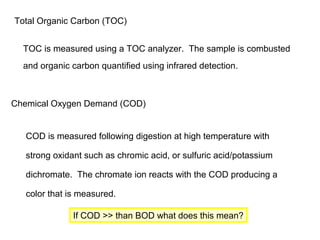

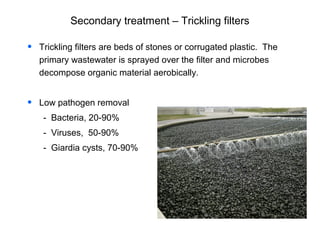

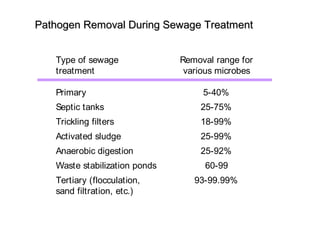

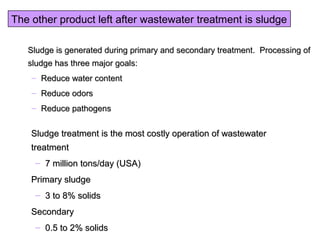

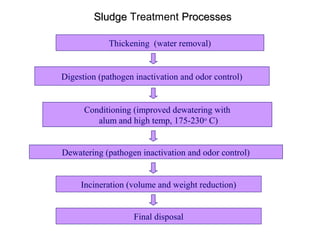

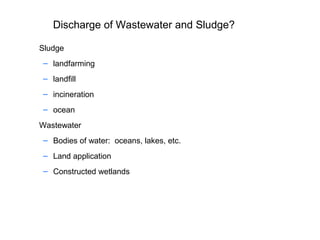

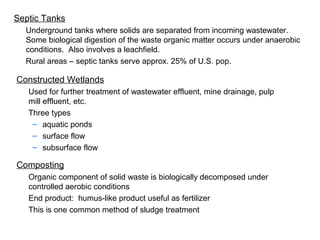

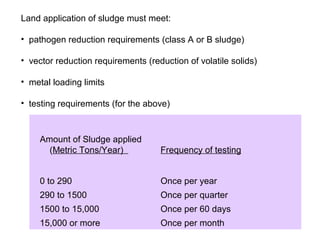

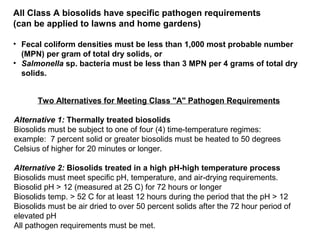

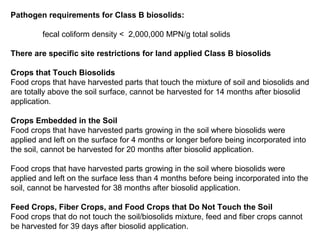

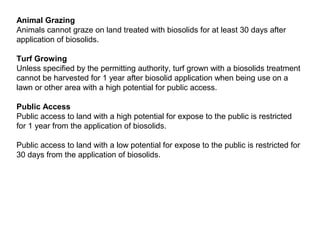

The document summarizes wastewater treatment processes. The objectives are to reduce organic content, remove nutrients like nitrogen and phosphorus, and remove pathogenic microbes. Primary treatment involves physical separation processes. Secondary treatment uses biological processes like activated sludge or trickling filters to reduce organic content like BOD. Tertiary treatment provides further nutrient removal and disinfection. Sludge generated is also treated. Pathogen removal effectiveness varies by treatment process. Land application of sludge and biosolids has requirements to protect public health.