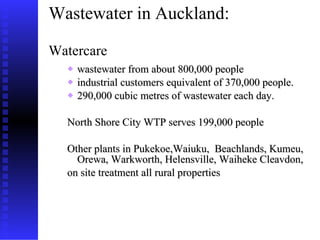

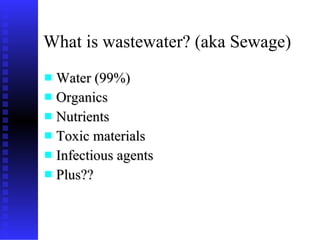

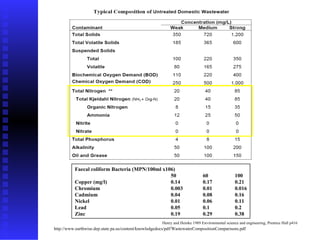

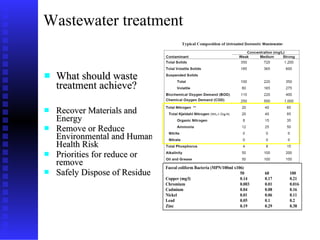

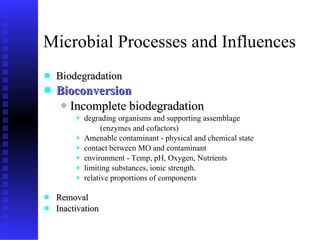

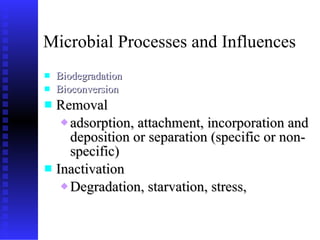

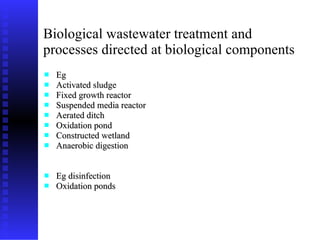

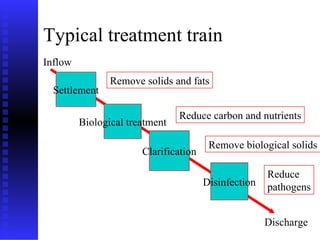

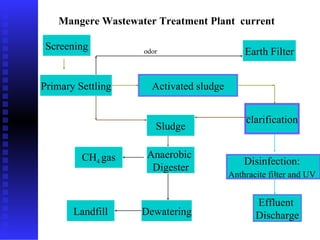

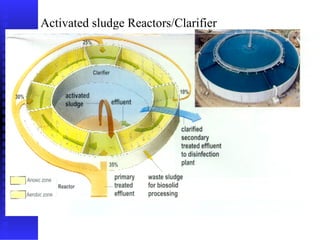

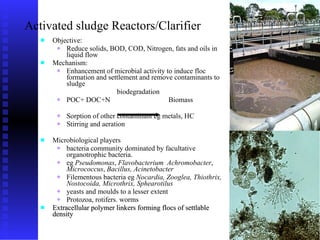

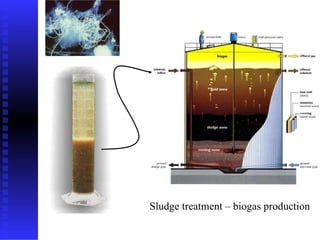

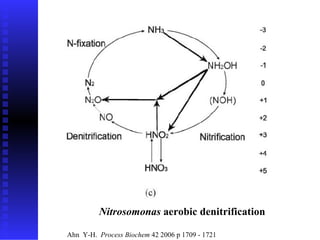

This document provides an overview of municipal and domestic wastewater treatment processes. It discusses the key microbial processes involved, including biodegradation, bioconversion, and removal/separation processes. Common treatment steps like primary settling, biological treatment, clarification and disinfection are outlined. Specific examples of wastewater treatment plants and processes, such as activated sludge reactors and anaerobic digestion, are also described. The document raises questions around optimizing microbial functions in wastewater treatment and recovering resources from wastewater.

![Older reviews: Ahn Y-H Sustainable nitrogen elimination biotechnologies: A Review. Process Biochemistry 41, 2006, 1709 - 1721 Mendoza-Espinosa, Leopoldo Stephenson, Tom. A review of biological aerated filters (BAFs) for wastewater treatment Environmental Engineering Science. 16(3). 1999. 201-216. Stratful, I.; Brett, S. Scrimshaw, M. B.; Lester, J. N.. Biological phosphorus removal, its role in phosphorus recycling Environmental Technology. 20(7). July, 1999. 681-695. Grady, C. P. L., Jr. Filipe, C. D. M. . Ecological engineering of bioreactors for wastewater treatment Water, Air, & Soil Pollution. 123(1-4). October, 2000. 117-132 de-Bashan, Luz E.; Bashan, Yoav Recent advances in removing phosphorus from wastewater and its future use as fertilizer (1997-2003) Water Research. 38(19). November 2004. 4222-4246. Mallick, Nirupama. Biotechnological potential of immobilized algae for wastewater N, P and metal removal: A review. BioMetals. 15(4). December 2002. 377-390. Low, Euan W.; Chase, Howard A.. Reducing production of excess biomass during wastewater treatment Water Research. 33(5). April, 1999. 1119-1132. Aksu, Zumriye. Application of biosorption for the removal of organic pollutants: A review Process Biochemistry. 40(3-4). March 2005. 997-1026. Lazarova, V. ; Savoye, P. Janex, M. L.; Blatchley, E. R., III Pommepuy, M. [Author]. Advanced wastewater disinfection technologies: State of the art and perspectives Water Science & Technology. 40(4-5). Aug.-Sept., 1999. 203-213. Chuichulcherm, S.. An integrated system for the bioremediation of wastewater containing xenobiotics and toxic metals Engineering in Life Sciences. 4(4). August 2004. 354-357. Books that contain helpful sections ( not on close reserve) Fry et al : 1992 Microbial control of pollution: Society for General Microbiology. Gray NF 2004 :Biology of wastewater treatment 2nd ed. Imperial College Press, London. Gerardi M and Zimmerman M :2004 Wastewater Pathogens: Electronic reproduction Somerset, New Jersey : Wiley InterScience, [electronic resource]](https://image.slidesharecdn.com/wastewater-110127023741-phpapp01/85/Wastewater-36-320.jpg)

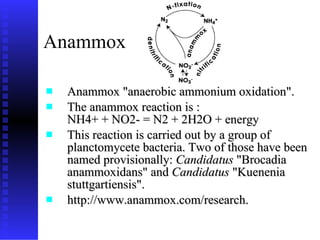

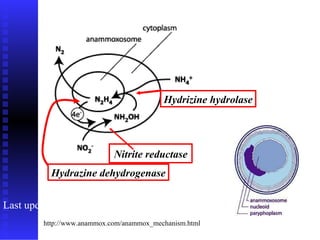

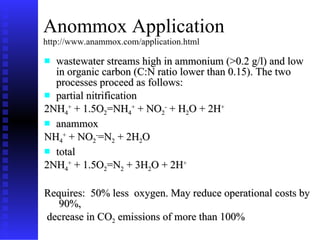

![Suggested Reading Ekama George A [a]; Wentzel Mark C [a]. Difficulties and developments in biological nutrient removal technology and modelling. Water Science & Technology. 39(6). March, 1999. 1-11. ( try via science direct) Fuerhacker M; Bauer H; Ellinger R; Sree U; Schmid H; Zibuschka F; Puxbaum H. Approach for a novel control strategy for simultaneous nitrification/ denitrification in activated sludge reactors. Water Research. 34(9). June, 2000. 2499-2506 Strous Marc; Van Gerven Eric; Zheng Ping; Kuenen J Gijs; Jetten Mike S M [a]. Ammonium removal from concentrated waste streams with the anaerobic ammonium oxidation (Anammox) process in different reactor configurations. Water Research. 31(8). 1997. 1955-1962 Krumins Valdis; Hummerick Mary; Levine Lanfang; Strayer Richard; Adams Jennifer L; Bauer Jan. Effect of hydraulic retention time on inorganic nutrient recovery and biodegradable organics removal in a biofilm reactor treating plant biomass leachate. Bioresource Technology 85. December, 2002. 243-248.](https://image.slidesharecdn.com/wastewater-110127023741-phpapp01/85/Wastewater-37-320.jpg)