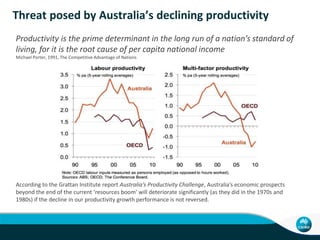

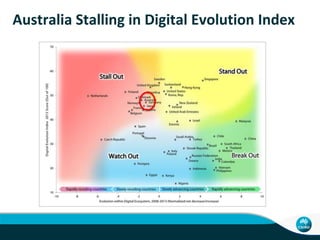

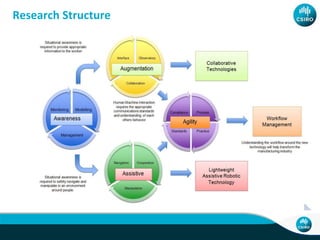

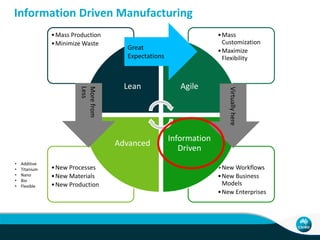

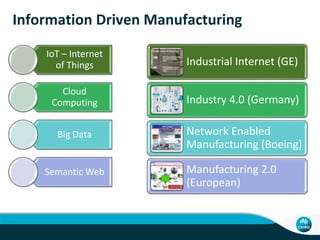

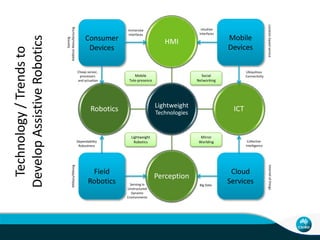

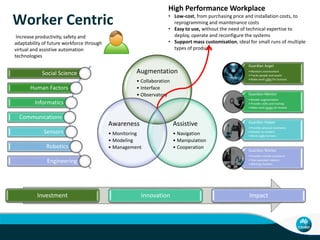

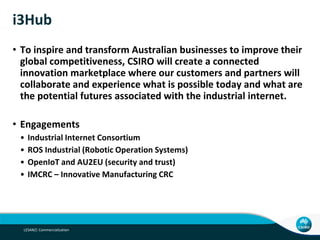

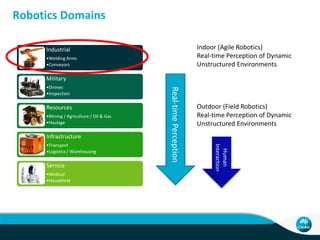

The document outlines a vision for a future where humans and autonomous systems collaborate to enhance productivity, focusing on the development of automated and assistive technologies in Australia. It identifies declining productivity as a key challenge for the nation's economic prospects and proposes innovative strategies through advanced robotics and IoT. The initiative aims to increase safety, adaptability, and competitiveness in various industries by leveraging new manufacturing processes and collaborative technologies.