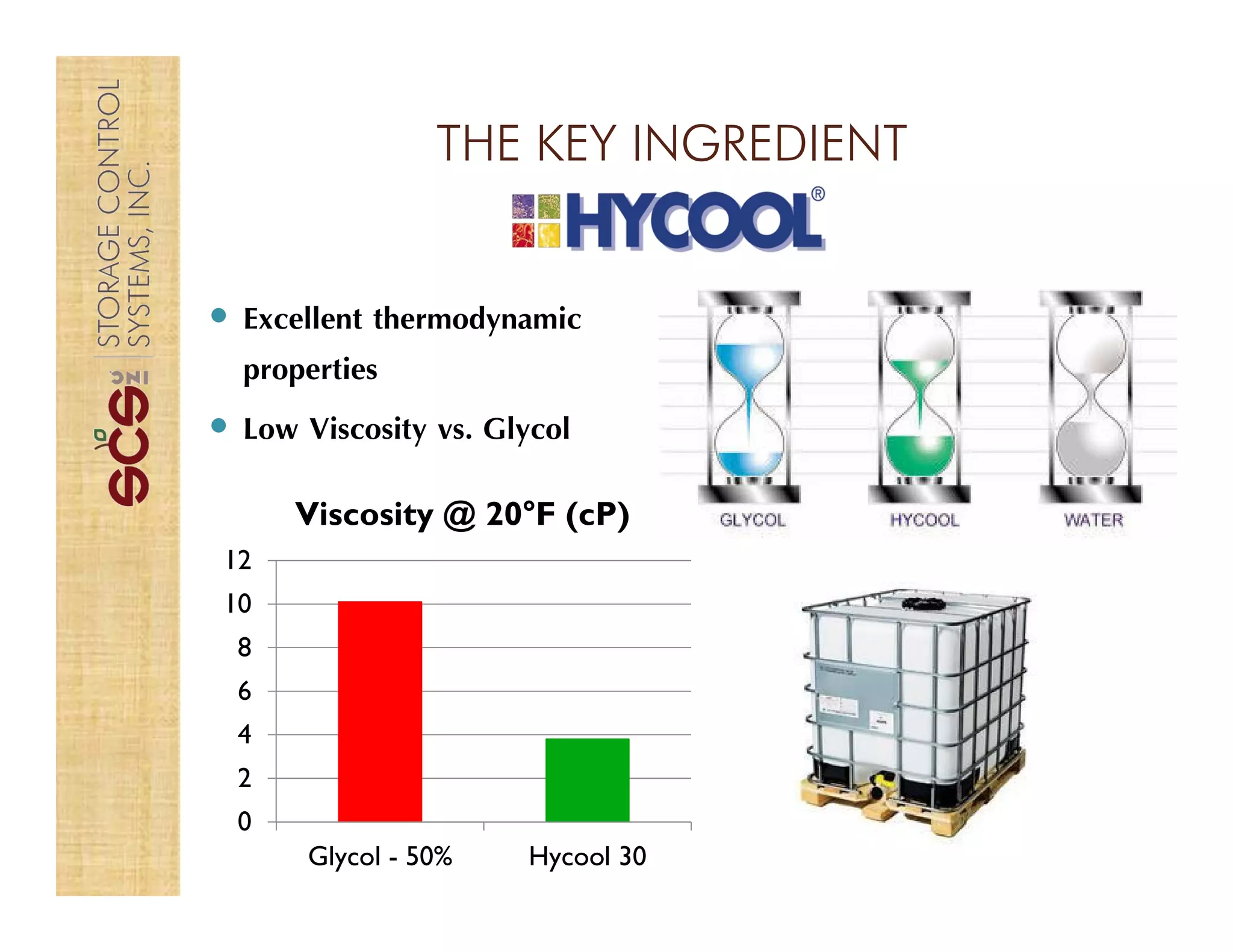

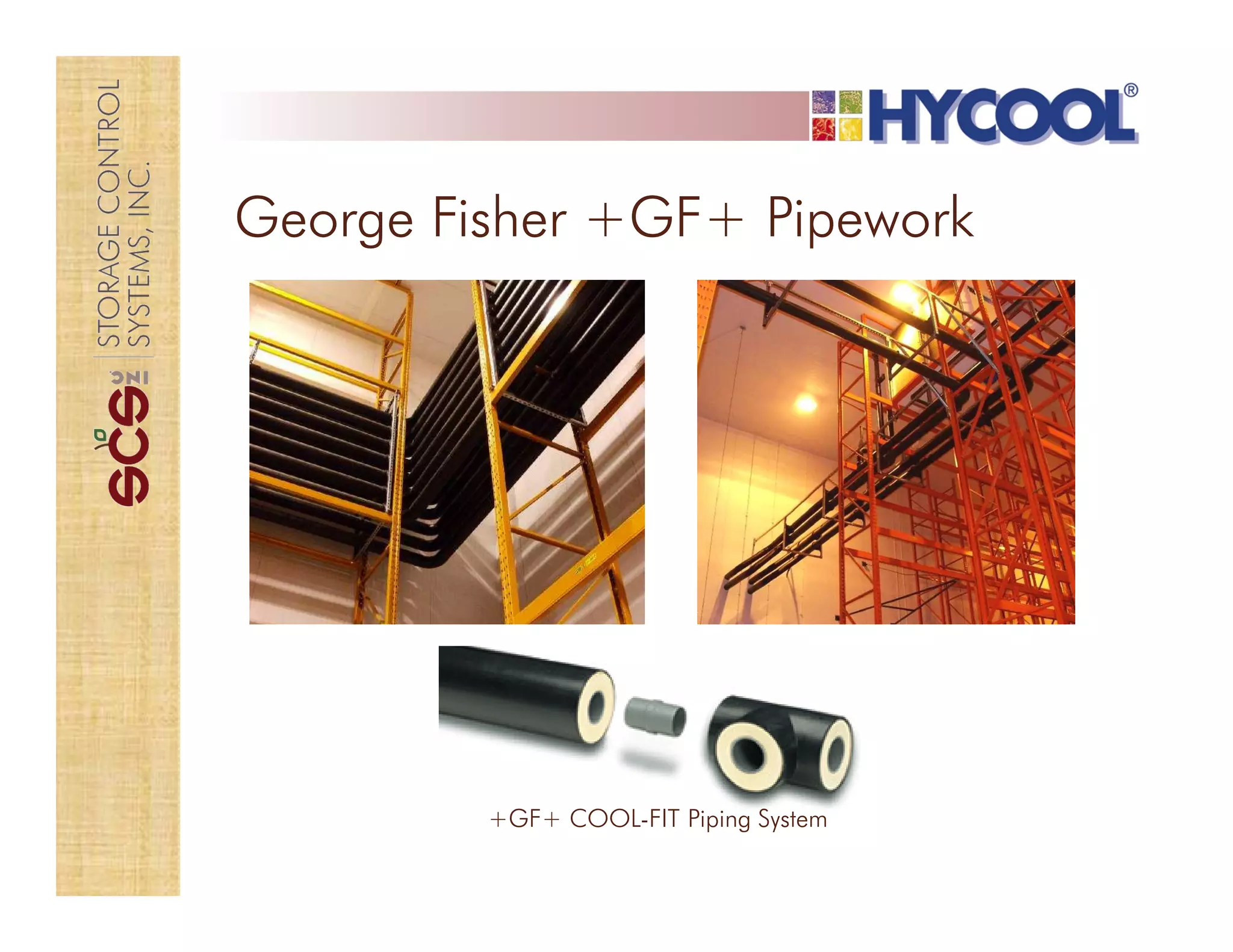

This document summarizes a secondary refrigeration system for food storage. It notes that the system is non-toxic, has no product loss in the event of failure, and uses a simple, safe, low-pressure liquid design. It also claims benefits like lower humidity for less fruit shrinkage, low energy costs, and quality fruit preservation. The system uses a secondary fluid called Hycool that is pumped throughout coils for efficient chilling, replacing direct refrigerant systems. Packaged liquid chillers and control systems are highlighted as providing optimized, low-maintenance solutions.