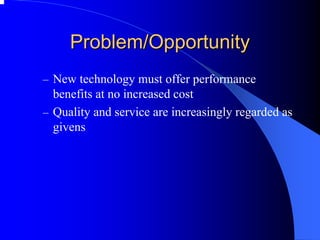

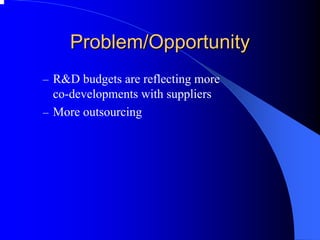

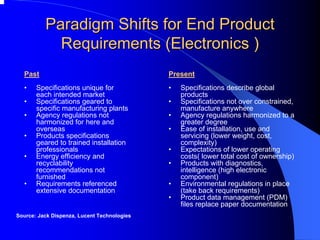

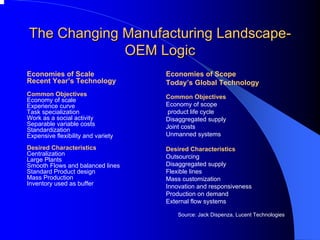

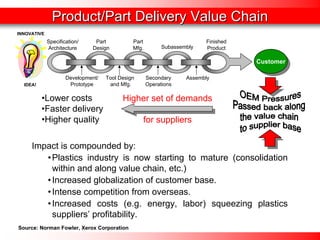

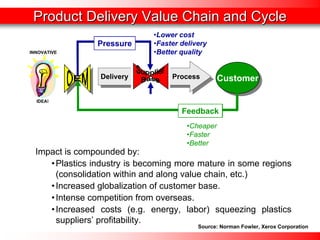

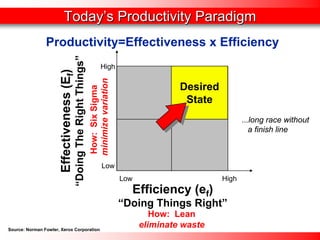

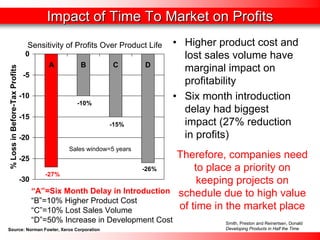

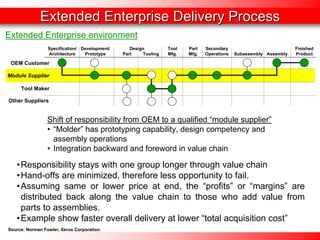

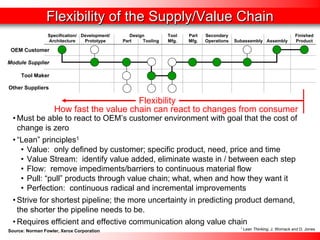

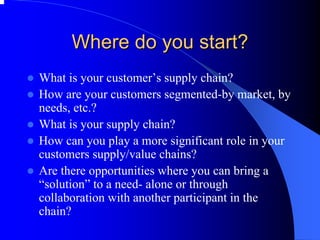

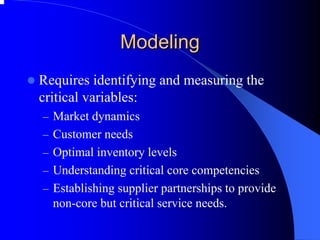

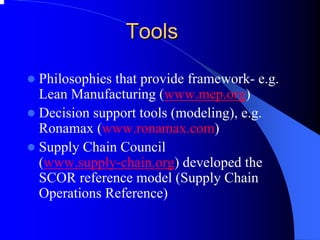

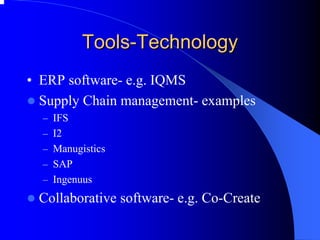

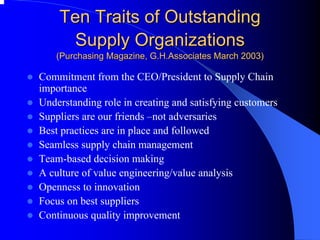

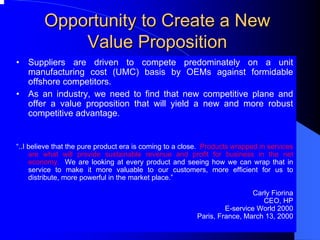

The document discusses how supply chain management can provide competitive advantage. It outlines trends driving companies to outsource more, including globalization and cost pressures. Developing a supply chain strategy requires understanding customer supply chains and how the company can add more value. Implementing lean manufacturing and Six Sigma principles while using information technology tools enables supply chain flexibility and speed to meet customer needs. Managing the supply chain effectively through collaboration and continuous improvement will become a critical competency for most companies.