The document provides an overview of tunneling projects and expertise at Parsons Brinckerhoff (PB). It discusses PB's long history in tunneling beginning with its founder William Barclay Parsons who pioneered cut-and-cover tunneling for the original New York City subway in the early 1900s. PB continues to be a leader in major tunneling projects around the world, with current projects including expansion of the New York City subway system, new tunnels under the Hudson River to New Jersey, and a new rail connection between Long Island and Grand Central Terminal in Manhattan. The document highlights PB's ongoing innovations in tunneling technologies and role in projects that advance the state of the practice.

![© 2010 MIKE SMITH PHOTOGRAPHY

Making it easier to cross the River Tyne in

northern England has been important to the

The first tunnel under the River Tyne was

opened in 1951—a pedestrian and bicycle

route that gave workers better access to

jobs in the shipbuilding industry on both

banks of the river. A 1967 vehicular tunnel,

an engineering marvel in its time, alleviated

congestion on local bridges. Today, the aging

tunnel carries the busy A19 highway beneath

the river, and more capacity is needed.

area’s development throughout history. Currently,

work is under way on The New Tyne Crossing,

a major tunnel project that will greatly enhance

New Tyne Crossing

© 2010 MIKE SMITH PHOTOGRAPHY

TUNNELING TO THE FUTURE IN

NEWCASTLE UPON TYNE

In November 2007, the Tyne and Wear

Integrated Transport Authority engaged a

concessionaire known as TT2 (Tyne Tunnel

2) Limited to develop a new tunnel and

associated toll plazas, interchanges and

highway segments. Work is being executed

under a 30-year design-build-finance-operate-maintain concession financed through

a public-private partnership. The concessionaire is also responsible for refurbishing

and operating the existing A19 tunnel and

operating the pedestrian and bicycle tunnel.

When completed, the two vehicular tunnels

will each have two lanes, with one tunnel

handling northbound vehicles and the other

carrying southbound traffic.

PB is one of three main designers to

the contractor, Bouygues Travaux Publics.

Under the direction of Project Manager

Russell Bayliss, PB’s Newcastle office is

also leading the approvals and consents

and environmental coordination for the

entire project. Other responsibilities include

design of the southern approach tunnel

and existing tunnel refurbishments.

Tunneling Techniques

Space is at a premium, traffic is heavy and

geological conditions are complex along the

tunnel’s alignment, all of which influence

design and construction. The section under

the river will be a 360-meter- (1,181-foot-)

long immersed tunnel—only the second

immersed tunnel in England. The immersed

tunnel will be linked at either end to deep

cut-and-cover tunnel sections. The northern

approach tunnel is 320 meters (1,050 feet)

long and the southern approach tunnel

is 823 meters (2,700 feet) long. The new

northern approach tunnel crosses over the

existing tunnel near the north bank with just

2.8 meters (9 feet) of clearance.

Cut-and-cover sections under the streets north and south of the River Tyne will connect to an immersed

tunnel section beneath the river.

“Most of the approach tunnel sections were constructed using cut-and-cover

techniques and diaphragm walls,” Bayliss

explains. “Trenches are excavated on each

side of the tunnel alignment—as deep as

30 meters [98 feet]—and are temporarily

supported by bentonite slurry. Steel

reinforcement is then lowered

into the trench and concrete is

piped in to replace the bentonite.” After the concrete cures, the

tunnel area between the two

diaphragm walls is excavated.

Temporary props between the

walls help them withstand

the high ground pressures

experienced during

Russell Bayliss

16 • Notes

deep excavation. When the concrete work

on the floor and roof slabs is completed,

the props are removed and the excavation

is backfilled over the tunnel.

To avoid disrupting major utilities—

including gas mains—two short stretches

were bored using umbrella vaults, steel

arches and sprayed concrete lining,

rather than an open excavation.

For the shallower section of

tunnel farther to the south, the

cut-and-cover sections were

constructed using pile and box

techniques. Instead of diaphragm walls, concrete piles

hold open the excavated

area while a reinforced

© 2010 MIKE SMITH PHOTOGRAPHY

mobility in the Newcastle region.

Notes • 17](https://image.slidesharecdn.com/2010-04tunnelingtothefuture-131227222358-phpapp01/85/2010-04-tunneling-to_the_future-10-320.jpg)

![Rehabilitating the Old Tunnel

A cutter suction dredger executed the dredging

operation within strict limits, which protected

migrating salmon and allowed sediment to be

transported by pipeline to infill a dry dock

2 kilometers (1.2 miles) from the site.

When The New Tyne Crossing is completed—scheduled for February 2011—

traffic will be diverted to the new tunnel

and refurbishment of the old tunnel will

begin. Overall completion is anticipated

in early 2012.

Improvements to the existing tunnel include installation of mechanical and

electrical equipment to enhance operations

18 • Notes

© 2010 MIKE SMITH PHOTOGRAPHY

HIVES

“Beyond easing traffic congestion, the

tunnel is part of a major regeneration

scheme to enhance the economic development of the area,” says Paul Littlefair,

PB’s UK Director of Regeneration and

Redevelopment Infrastructure and a native

of Newcastle. “The tunnel will improve

access to jobs and customers, and create

favorable conditions for a public transport

link. The enhanced mobility of goods and

services will make the area more attractive to companies and investors. And more

than 2,000 people have worked on the

project to date, providing immediate economic benefits.” n

Tunnel

indsor

troit-W

De

PB AR

CH

RS

SAILO

DAVID

© 1986

“Despite the range of tunneling techniques

employed, the greatest challenges actually

arise from construction in an urban environment and all the required consenting, statutory and third-party approvals,” says Bayliss.

These include approvals from two

planning authorities—one on either side of

the river—in addition to the government

environmental regulator, port authority and

local departments. Managing approvals

and consents has involved preparation

of detailed documentation, plans and

method statements for the various

construction phases and, Bayliss

notes, ongoing dialogue with the

various entities.

Negotiation and cooperation have been essential in

keeping construction on

track. For example, the

River Tyne is prized

for its salmon and

environmental

Immersed Tunnels

Anchoring Renewal

© 2010 MIKE SMITH PHOTOGRAPHY

Keeping to the Schedule

THE HISTORY OF TUNNELING AT PB

IVES

concrete box is constructed inside. The

final 130 meters (427 feet) of the tunnel

approach is an open-cut box.

Construction began in March 2008; the

approach tunnels have been excavated and

backfilling is under way.

and safety. “This includes ITS [intelligent

transportation systems], SCADA [supervisory

control and data acquisition—a computerized monitoring system], new ventilation

using jet fans, and an advanced fire suppression system, which will be linked to

systems in the new tunnel,” Bayliss says.

“One PB innovation is the addition of a

separate escape passage—a design feature

to be incorporated in both tunnels.”

C

PB AR

© 2010 MIKE SMITH PHOTOGRAPHY

authorities constrained the schedule for

dredging the immersed tunnel trench to

minimize potential impacts to salmon

migration. PB negotiated a slight relaxation

in the six-week dredging window to avoid

major delays to the project. Dredging was

completed in December 2009 and the

immersed tunnel segments were placed in

February 2010.

PB also negotiated a simplified

approval protocol for certain permits, as

well as a phased approvals process, meaning that all approvals did not have to be

secured before construction could begin.

These efforts have been successful in

avoiding approvals-related delays.

ore

Baltim

unnel,

enry T

cH

Fort M

Construction work has to take place near residences and businesses under strict

limitation to prevent nuisance, requiring extensive community consultation and a

great deal of extra care.

An early application of immersed tunneling in the U.S. was the

1.6-kilometer (1-mile) vehicular tunnel between Detroit, Michigan, and

Windsor, Ontario, completed in 1930. The Detroit-Windsor Tunnel

has three sections: open approaches, shield tunneling from the

approaches to the river and an immersed tunnel under the river. The

immersed tunnel segments featured the first use of welded steel

shells and internal steel lining in tunnel construction. It was also the

first tunnel designed and built by PB.

Other immersed tunnels designed by PB included the

Hampto

Baytown Tunnel under the Houston ship

n Road

s

Bridge-T

unnel, V

channel in the early 1950s; a number

irginia

of tunnels in Virginia over a period of

30 years including the first Elizabeth

River Tunnel (also known as the

Downtown Tunnel) connecting Norfolk

and Portsmouth, opened in 1952; the

Midtown Tunnel, completed in 1962; and

the second Downtown Tunnel, opened

in 1982. The standouts, however, were

the PB-designed bridge-tunnel crossings of

Hampton Roads, Virginia, completed in 1957

and 1976, respectively. For those projects,

immersed tunnels were built between two

artificial islands that connected to the mainland via bridges.

Another notable immersed tunnel was

the Fort McHenry Tunnel, completed in 1985,

which was the widest immersed tunnel built at that time and

the first to have double tubes, carrying a total of eight lanes of

traffic, laid immediately side-by-side in a single trench under

Baltimore Harbor.

An immersed tube tunnel under San Francisco Bay constructed in the late 1960s as part of BART was the longest

and deepest immersed tunnel built at that time. It was also

the first immersed tunnel to use cathodic protection for

corrosion control, and to be designed for seismic conditions

using a triaxial seismic joint between the tube and its land connection.

The BART tunnel suffered no damage as a result of the devastating Loma

Prieta earthquake of 1989, and following the disaster was the only direct

means of public transportation between Oakland and San Francisco.

Internationally, PB’s immersed tunnel experience includes Hong

Kong’s first cross-harbor tunnel, linking Hong Kong island to Kowloon,

for which PB in the early 1970s developed a replacement steel design

for a tunnel originally designed as a concrete box. In the 1990s PB

designed an immersed concrete tube for the Western Harbor Crossing,

which was part of an effort to improve access to Hong Kong’s new

international airport. n

Paul Littlefair

Notes • 19](https://image.slidesharecdn.com/2010-04tunnelingtothefuture-131227222358-phpapp01/85/2010-04-tunneling-to_the_future-11-320.jpg)

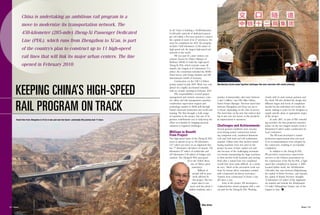

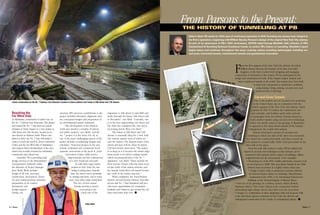

![The Portland CSO’s TBM being

retrieved from below ground.

In Portland, a TBM was delivered to the launch site via barge on the Willamette River.

THE HISTORY OF TUNNELING AT PB

Water conveyance tunnels for which PB has performed design or construction services include:

• The 15-kilometer (9-mile) Boston Harbor outfall and its 55 state-ofthe-art diffusers (completed in 2000), which was part of the effort to

clean up Boston Harbor;

• The recently completed Singapore Deep Tunnel Sewerage System,

a project that replaced that country’s entire wastewater treatment

system, including 48 kilometers (30 miles) of tunnels; and

• The design of water conveyance tunnels of the

Croton water treatment plant in the Bronx, New

York, and the ongoing rehabilitation of 50 kilometers (31 miles) of the New Croton Aqueduct of the

New York City water supply system, which was

built in 1885, the year PB was founded. n

GOOD

MAN

Water Conveyance Tunnels

EL H.

In progress: build out of the Portland East Side CSO lower vortex generaThe tunnel will be 8.8 kilometers

tor at Alder Street.

(5.5 miles) long with an internal

diameter of 6.7 meters (22 feet).

larger East Side CSO tunnel,” says Roy

The project includes seven shafts approxiDealing With 19th Century

Industrialization

Cook, Project Manager for PB’s East Side

mately 15 meters (50 feet) in diameter

CSO design team.

excavated to depths up to 55 meters (180

In addition to the tunnel, near-surface

Furthermore, the tunnel passes seven

feet), approximately 3,700 meters (12,000

pipelines are required as part of the sysmajor bridges crossing the Willamette.

feet) of near-surface pipelines and 13

tem diverting flows from outfalls to the

“One of the most challenging aspects of

diversion structures.

tunnel. One of these pipelines parallels the

the design was selection of an alignment

The challenging tunneling condiriver and was excavated through artificial

through the Sullivan Gulch area,” says

tions—beneath the groundwater table at

fill containing timber piles placed in the

Cook. This deep channel in-filled with

depths up to 50 meters (160 feet) and

19th century to build docks. Despite these

soft sediments is the location for a major

primarily through a very dense gravel

poor conditions, the pipeline was microbridge, an interchange between the I-5

and cobble mixture held in a sand/silt

tunneled as a single drive—930 meters

and I-84 freeways and the main West Coast

matrix—have required the use of a slurry

(3,055 feet) long—the longest microtunnel

north-south railroad tracks. Through this

shield TBM. This type of TBM applies a

to date in the U.S.

area, the tunnel had to avoid deeppositive pressure to the tunnel face by

Cook has found the project rewardpiled foundations for the bridge and

means of bentonite that penetrates the

ing. “It’s been a long process but

then snake through steel H-piles

ground and provides face stability. Slurry

never dull. From the construction

driven to support ramps for

shield tunneling was first used in the

of the deep slurry wall shafts to

the interchange. Investigations

U.S. on the West Side CSO

the slurry shield tunneling to the

showed that deviated piles came

in Portland for a 4-meter

microtunneled pipelines and

within a few feet of the tunnel

(14-foot) diameter tunnel

their associated works, there is

along its originally

also designed by PB. “Its

always something challenging

selected alignsuccess on that project

going on.” n

ment. As a

resulted in the technology being

applied to the

MICA

Demanding Ground

Conditions

result, the tunnel was realigned

to increase clearances.

“The contractor finished

the 6 kilometer- [3.8 mile-]

long TBM drive to the north in

November 2009. The TBM was

retrieved, put on a barge and

floated up river to the main

mining site. Once refurbished,

it will go underground again

to drive south,” explains Cook.

© 2000

This project, now under construction and scheduled for completion in 2011, will significantly improve

water quality in the river, encouraging

its use for recreational activities while

promoting wildlife habitat.

unnel

Deep T

gapore ystem

Sin

age S

Sewer

Roy Cook

Boston

Harbor

Outfall

Notes • 23](https://image.slidesharecdn.com/2010-04tunnelingtothefuture-131227222358-phpapp01/85/2010-04-tunneling-to_the_future-13-320.jpg)

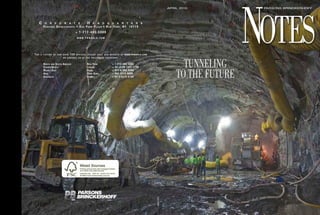

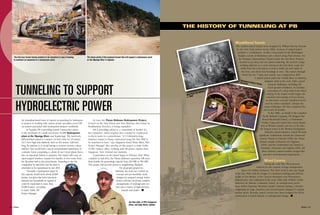

![The Florida Department of Transportation

lengths and will soon be going to great

depths to improve access to and from the

Port of Miami.

IMPROVING PORT ACCESS

IN MIAMI

The Port of Miami is Florida’s main container port and accommodates

4.1 million cruise ship passengers annually.

Construction on the Port of Miami Tunnel

project is expected to begin in May 2010.

As owner’s representative since 2003,

PB has assisted FDOT in the development

of a program to link the Port of Miami—the

cruise capital of the world and cargo gateway of the Americas—with I-95 and I-395 to

alleviate congestion on local Miami streets

and enable the port to remain competitive.

Under the direction of Project Manager Eldon

Abbott and Deputy Project Manager Peter

Donahue, PB’s efforts have included project

management, civil and structural concept

design, tunnel engineering, cost estimating

and scheduling, and preparation of publicprivate partnership (PPP) procurement documents. The firm also supported FDOT during

the contract negotiation process.

Currently, the only route to and from

the Port of Miami, located on the 210-hectare

(518-acre) Dodge Island between Miami and

Miami Beach, is the Port Boulevard Bridge.

Motorists must navigate city streets between

the interstates and the bridge, and regular

traffic backups slow commerce, deter tourism

and negatively impact pedestrian traffic and

local air quality. The solution: Reroute portrelated traffic, particularly trucks and buses,

by providing a direct connection to the Port

of Miami via Florida’s first major tunnel.

Long-Haul Procurement

In 2006, the project was advanced through

a public-private partnership. Following

the request for proposal, the MAT (Miami

Access Tunnel) consortium was selected as

concessionaire in February 2008. Protracted

contract negotiations and the subsequent

pullout in December 2008 of the concessionaire’s original 90 percent equity partner

delayed financial close until October 2009.

The PPP includes FDOT, Miami-Dade

County, the City of Miami, the Federal

Highway Administration and MAT. Under

the PPP contract, MAT will provide finance,

design, build, operate and maintain services over a 35-year period—five years for

design and construction at a cost of $607

million and 30 years for operation and

maintenance with annual payments based

on performance standards.

Mobility Enhancements

In addition to twin-bore tunnels between

Watson and Dodge islands, project com-

24 • Notes

Currently, the only way to reach the Port of Miami is via the Port Boulevard Bridge. A tunnel from Watson

Island to Dodge Island will offer an alternative way to reach the port.

ponents include Port of Miami roadway

connections and the widening of the

MacArthur Causeway to accommodate

the associated growth in traffic. These

enhancements will provide a vital dedicated route to cruise and cargo ships.

Tunnel construction will be especially

challenging due to Florida’s soft, permeable ground conditions. An earth pressure

balance tunnel boring machine (TBM),

with a cutterhead measuring 12.8 meters

(42 feet) in diameter, is being fabricated

to traverse the sand and limestone. Precast

tunnel segments will be placed as the

TBM progresses. Each tube, 1.2 kilometers (0.75 miles) in length and 13 meters

(41 feet) in diameter, will carry two lanes

of traffic at depths up to 37 meters (120

feet) below the navigational channel in

Biscayne Bay.

“Both tubes will be driven from a

single launching pit on Watson Island so

only one area will be required for tunnel

muck outside the portals,” says Donahue.

“When completed, this will be the largest soft-ground bored tunnel in the U.S.”

Each bore is expected to take six months

to complete.

The MacArthur Causeway will be

expanded from three to four lanes in each

direction, and acceleration and deceleration lanes for trucks and buses using the

tunnel will enhance safety. The port’s

roadway system will feature three overlapping bridges to provide improved access

for both cargo and cruise traffic entering

and exiting specific areas of Dodge Island.

En Route to Smoother Sailing

“PB will be reviewing all of the concessionaire’s technical and administrative

submittals for conformance with good

engineering practice and contract terms,”

says Donahue. “In addition to our role

as owner’s representative for permitting,

design and technical assessment, recently

we were tasked with construction engineering and inspection [CE&I] services.”

PB’s Richard Lear and Richard

Monahan are currently managing the

design review process. Following final

design, permitting and utility relocation in

2010, upcoming construction tasks include

excavation for tunnel tubes and port

roadways and bridges in 2011, work on

depressed roadway sections and approaches in 2012, and tunnel finishes and support

facilities efforts in 2013. PB’s Felix Vergara

will manage the CE&I services.

With project completion scheduled

for April 2014, the result will be an infrastructure network that allows for smooth

sailing to and from the

Port of Miami as well

as an improved

downtown and an

enhanced environment for residents

and tourists alike. n

Peter Donahue

© 2006 DAVID SAILORS

(FDOT) and its partners have gone to great](https://image.slidesharecdn.com/2010-04tunnelingtothefuture-131227222358-phpapp01/85/2010-04-tunneling-to_the_future-14-320.jpg)