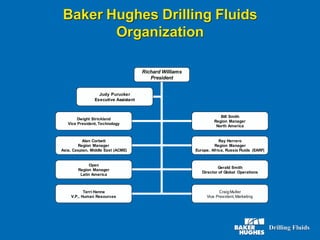

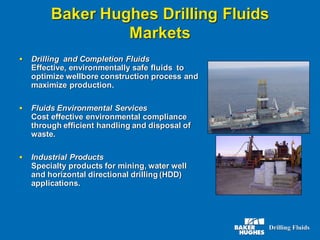

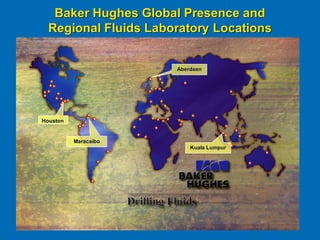

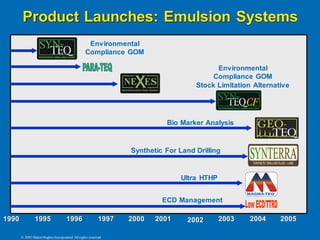

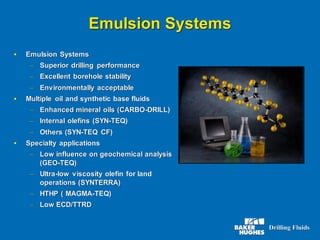

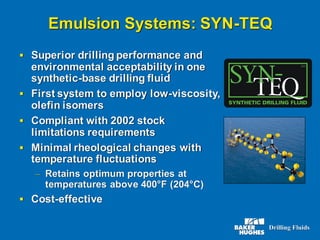

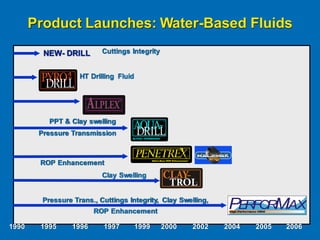

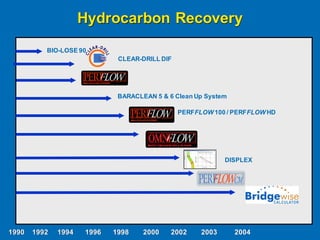

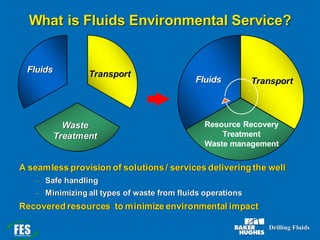

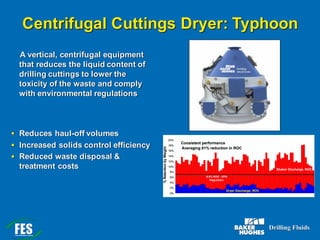

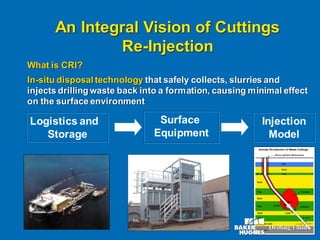

Baker Hughes Drilling Fluids provides organization structure, markets served, region breakdown, product launches, and services for drilling fluids. The organization is led by Richard Williams and serves markets in drilling and completion fluids, environmental services, and industrial products. It has regional managers covering North America, Asia/Middle East, Europe/Africa/Russia, and Latin America. The document outlines various drilling fluid product lines and completion systems to optimize drilling performance and maximize hydrocarbon recovery.