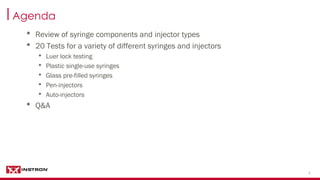

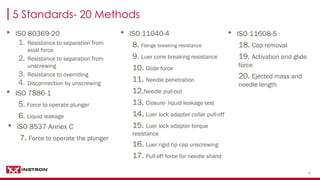

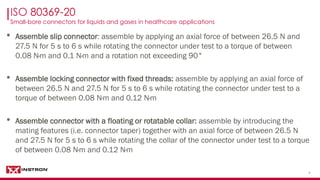

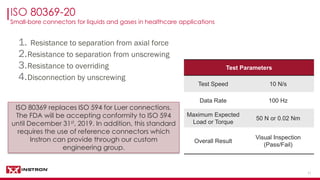

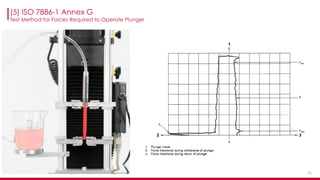

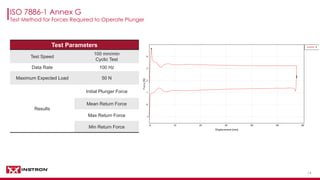

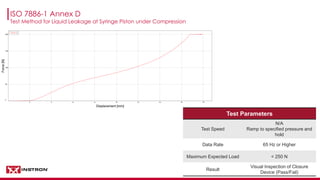

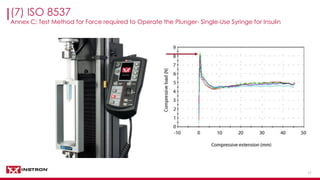

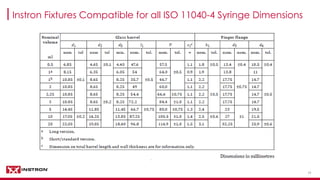

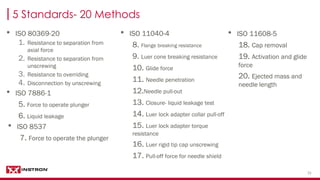

The document outlines a presentation on the testing methods for various types of syringes and injectors, detailing specific tests, standards, and physical parameters involved in ensuring their functionality and safety. It covers standards such as ISO 80369-20 and ISO 7886-1, providing a comprehensive list of 20 distinct tests designed to assess aspects like axial force resistance, liquid leakage, and plunger operation. Additionally, it emphasizes the importance of using reference connectors for compliance with the latest standards.