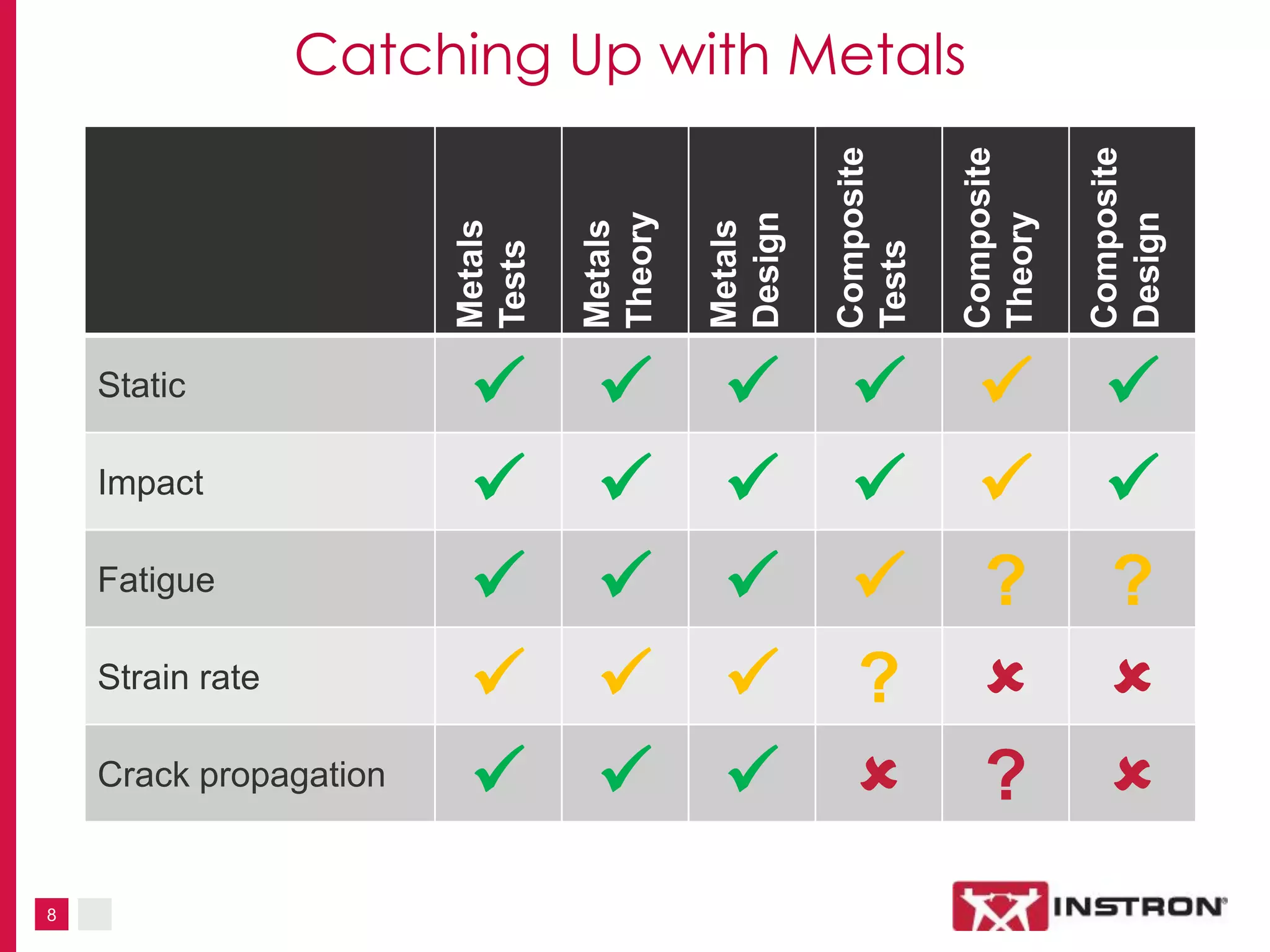

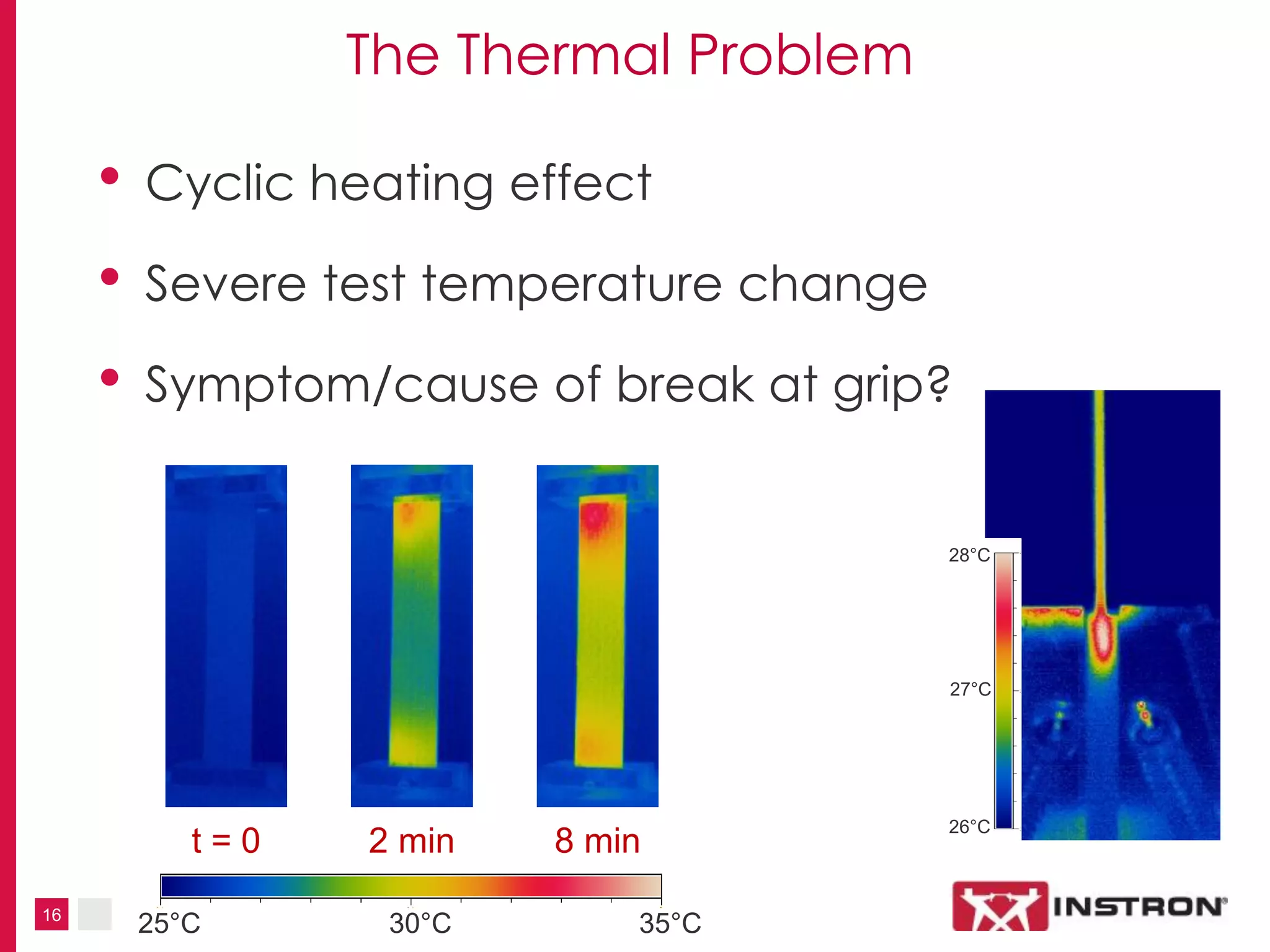

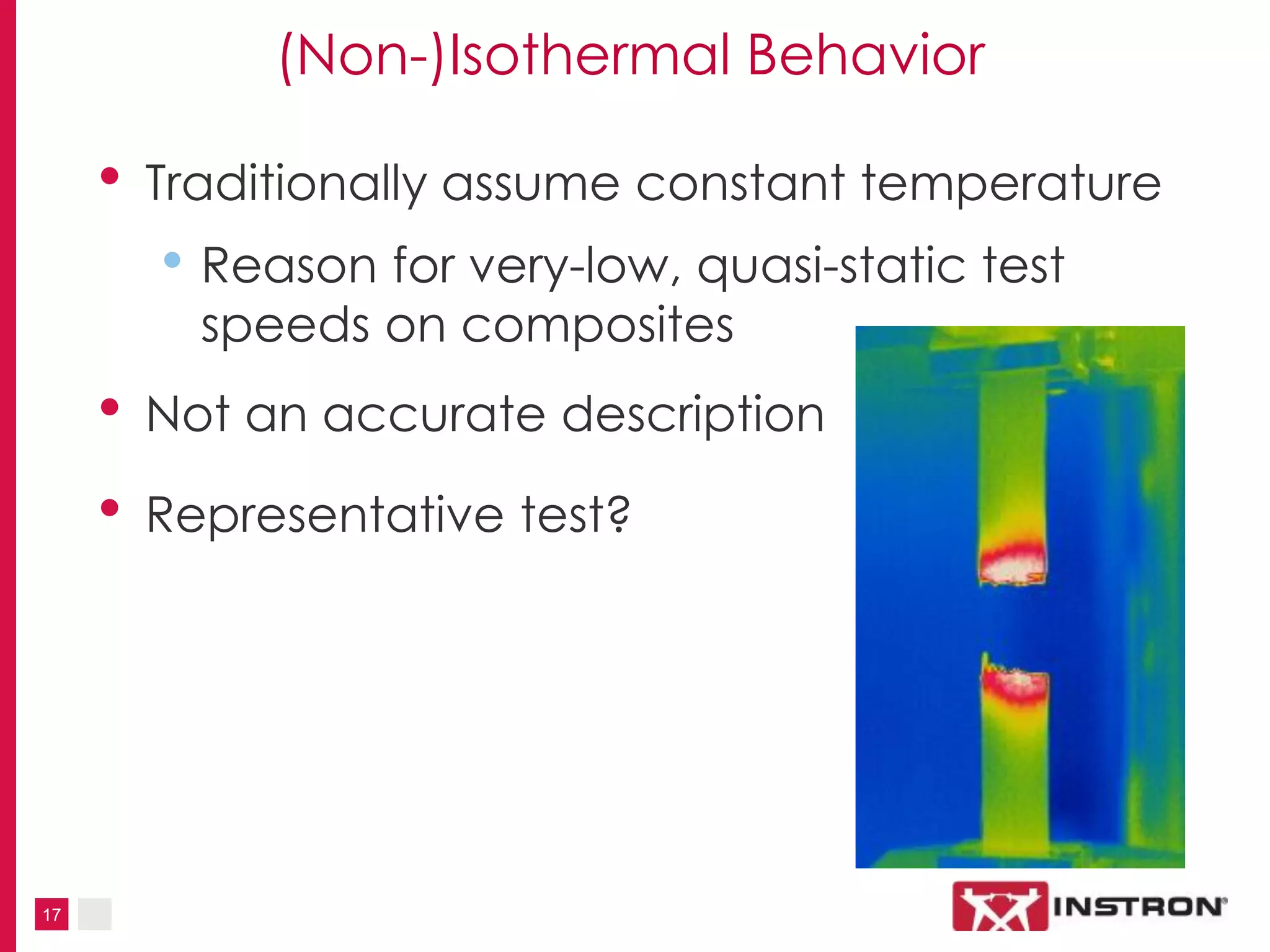

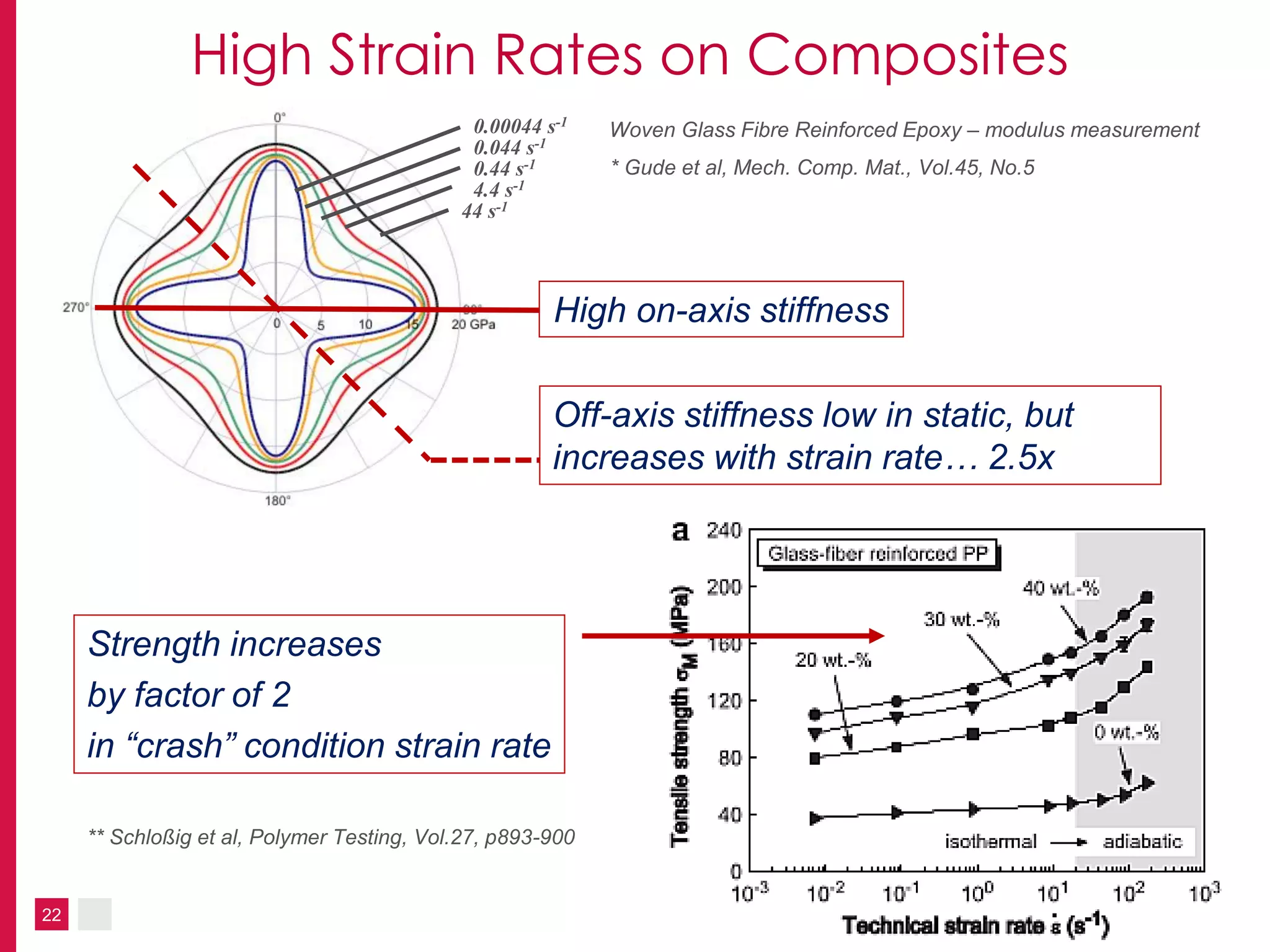

- Dynamic testing of composites is critical for design but still lags behind metals testing. While fatigue testing of composites has begun, it has mostly involved simple tension-tension testing without temperature control. More realistic testing is needed that involves compression, reversed loading, and fixed strain rates.

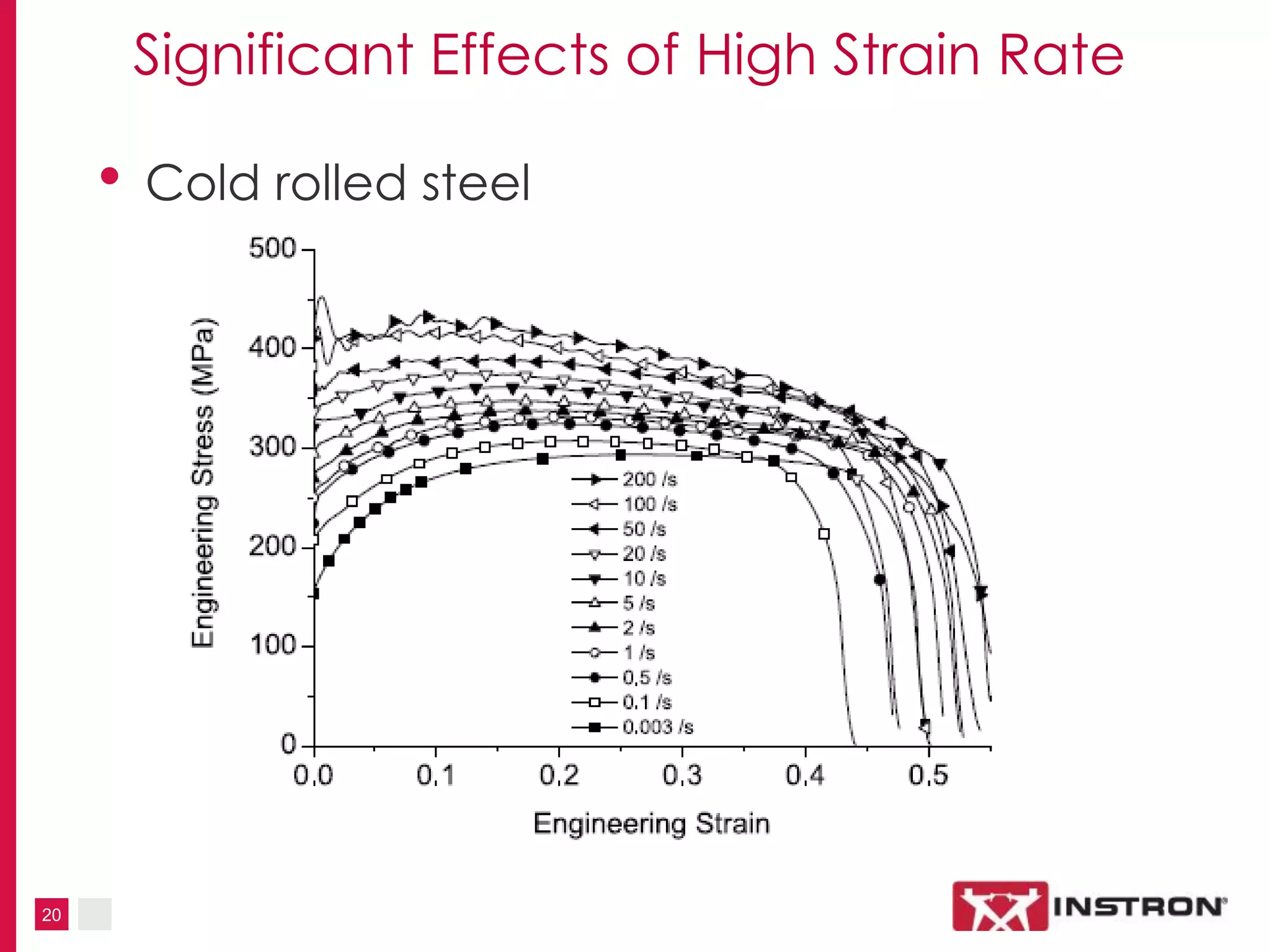

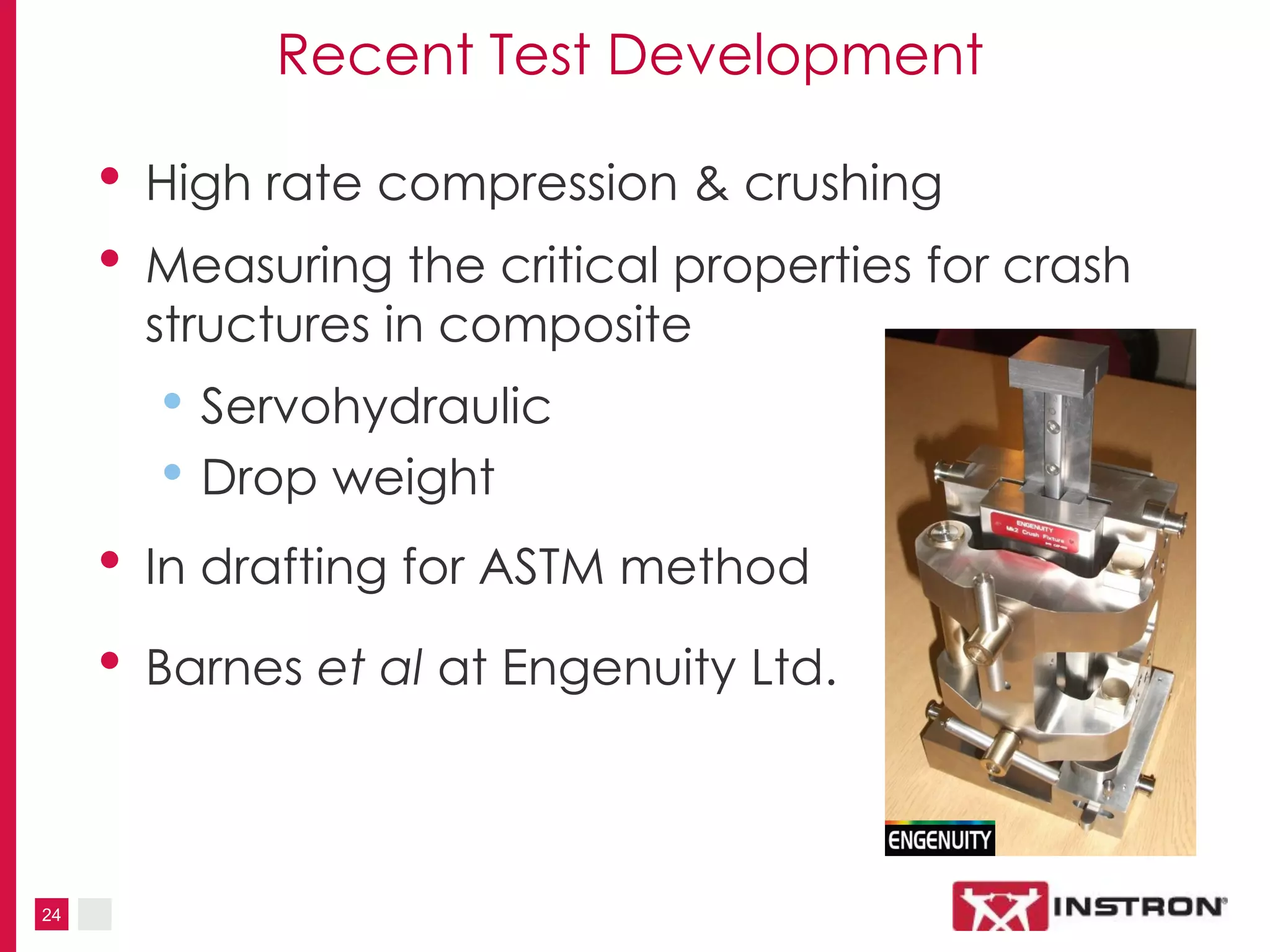

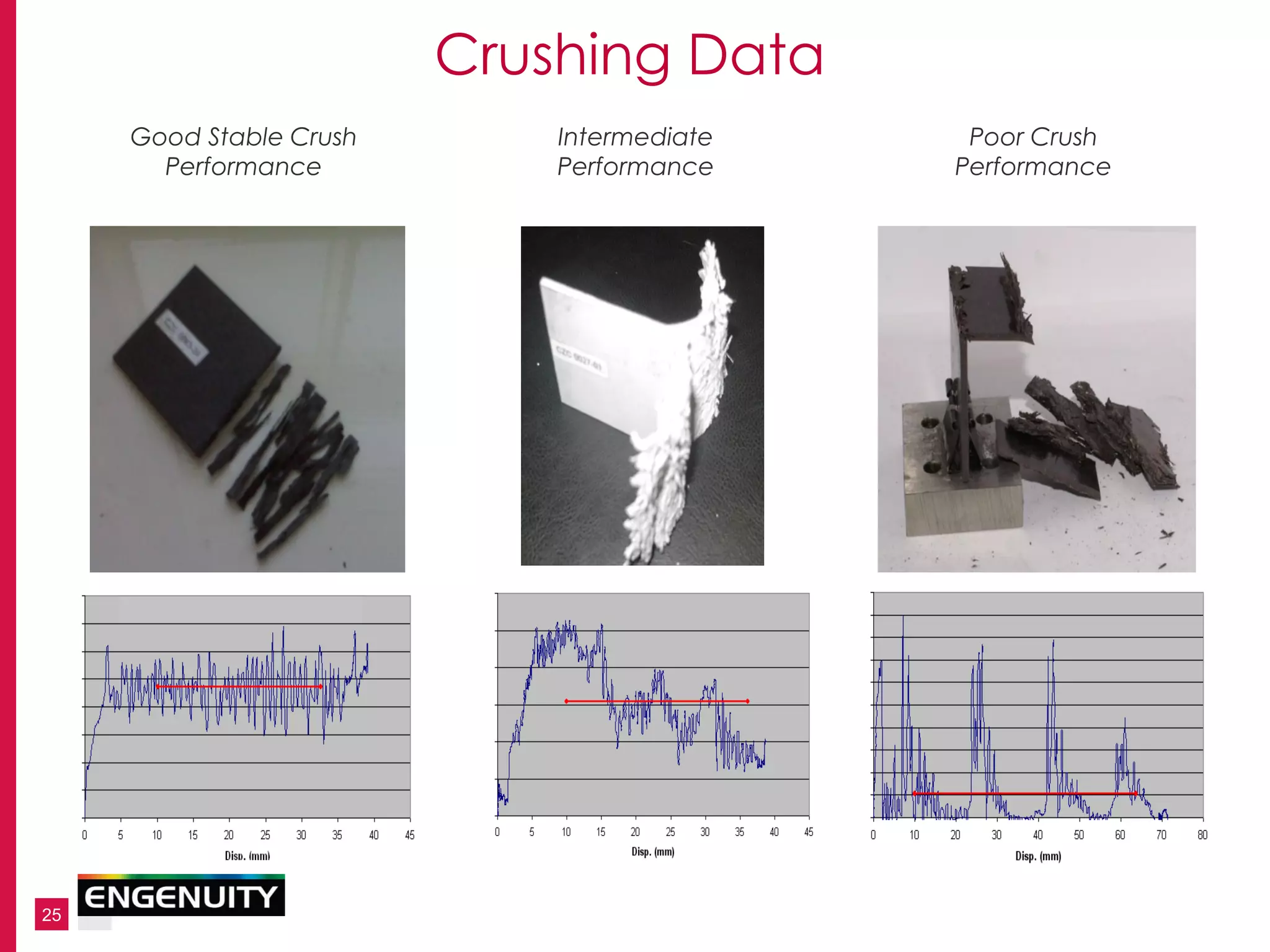

- Strain rate testing is also important as materials behave differently at higher strain rates. Recent work has developed high strain rate compression testing up to 100/s but challenges remain in reducing noise and interpreting results.

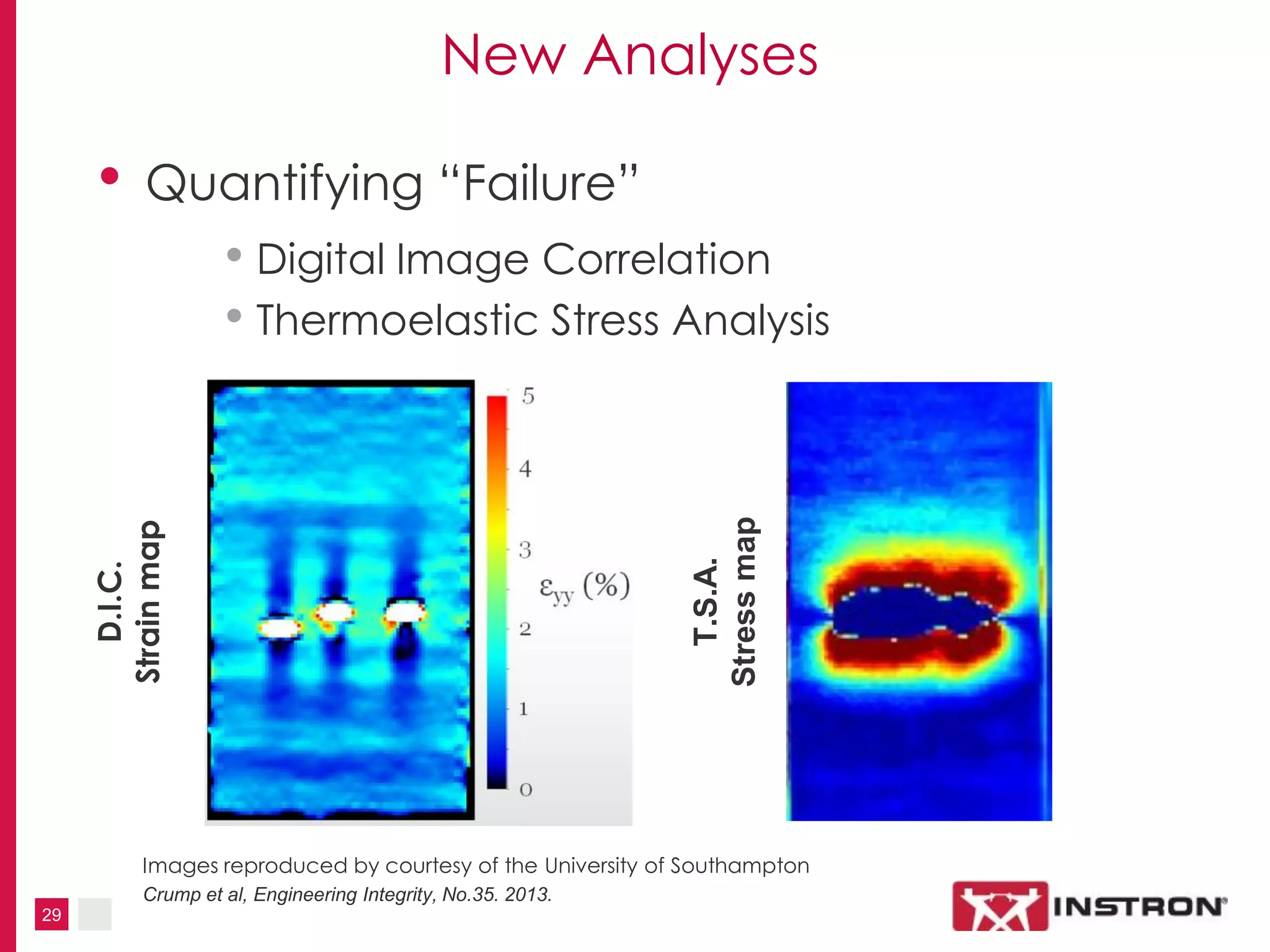

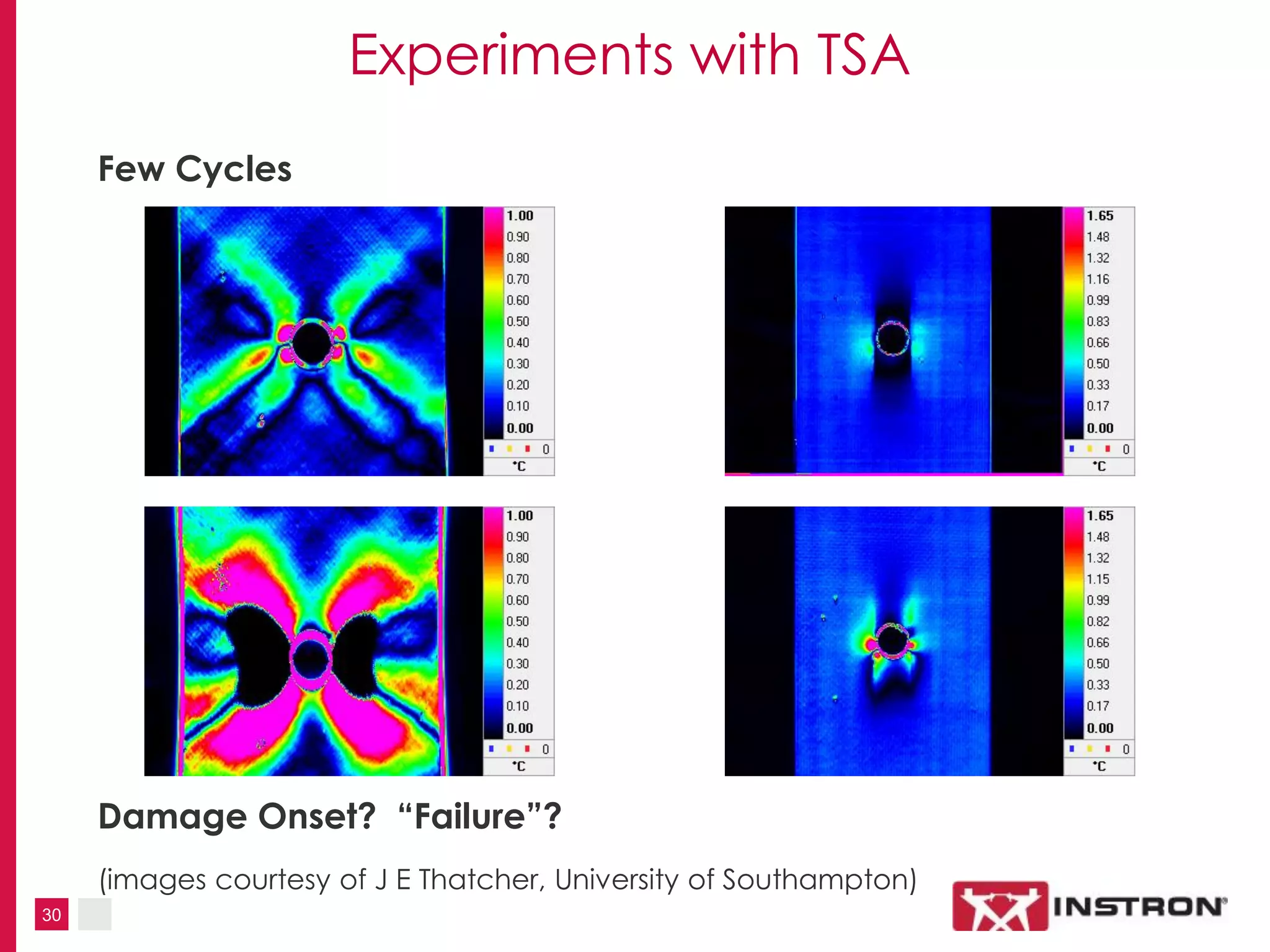

- New analysis tools like digital image correlation and thermoelastic stress analysis allow more data-rich testing of failure modes like crack propagation but composites testing still has headroom for development.