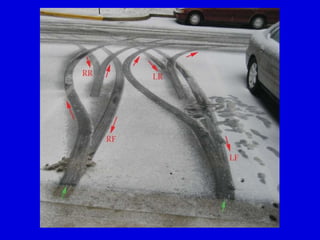

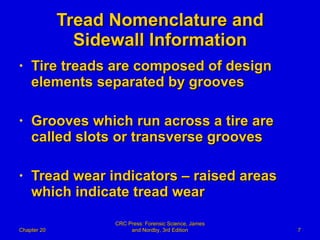

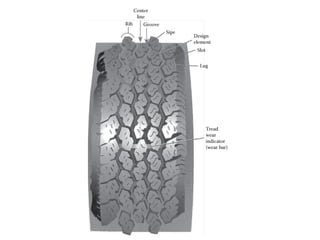

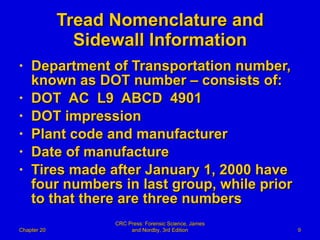

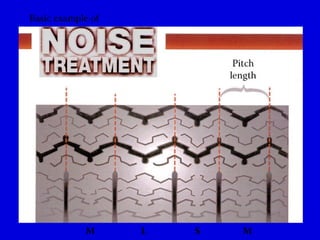

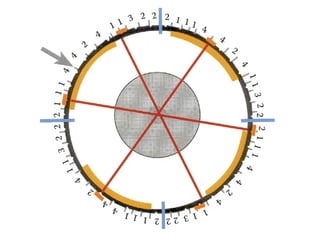

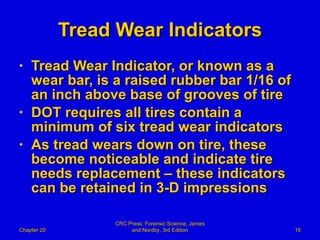

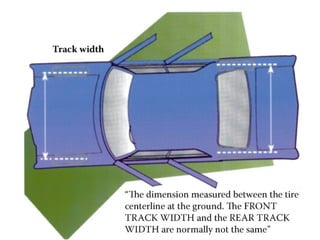

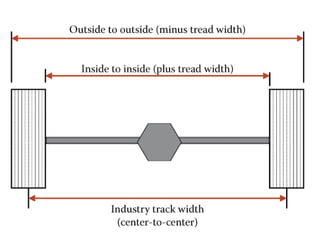

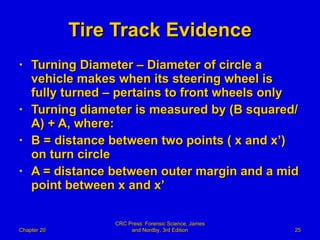

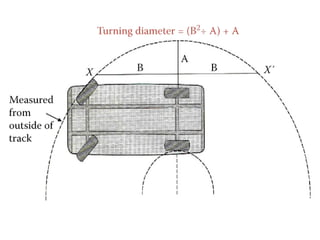

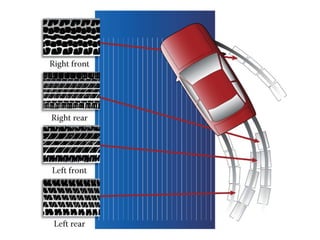

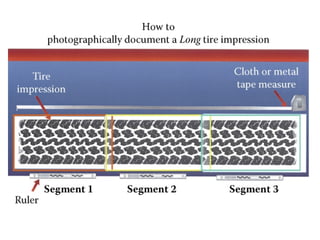

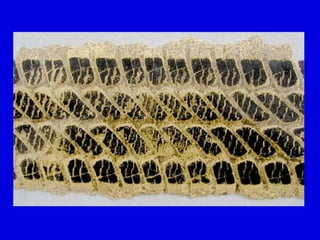

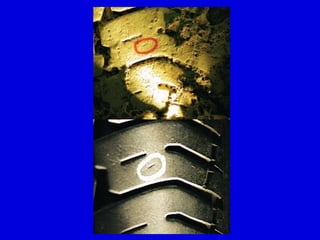

The document discusses forensic analysis of tire tread and tire track evidence. It describes how tire tread patterns can be used to identify individual tires and how track patterns can determine vehicle characteristics like wheelbase. The analysis process involves comparing impressions from a crime scene to tires from suspect vehicles, looking at tread design, wear, and other unique identifying features to see if any matches can be found.