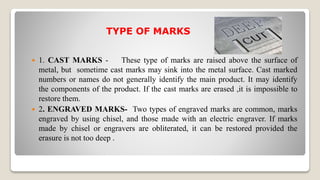

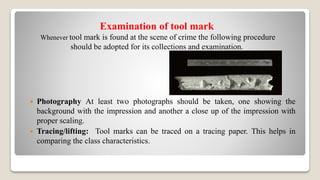

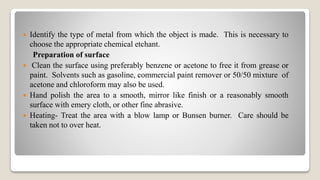

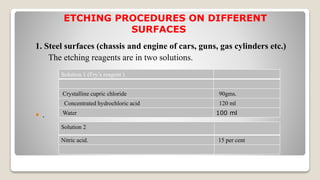

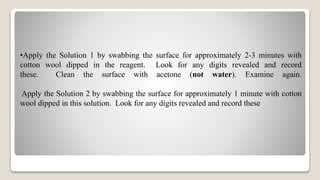

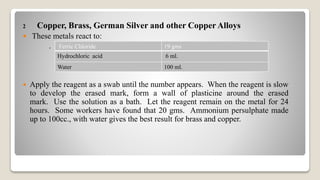

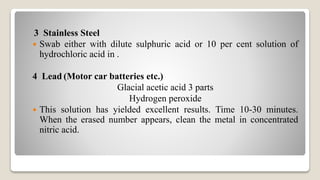

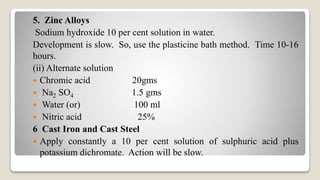

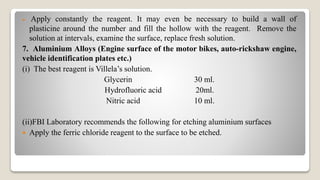

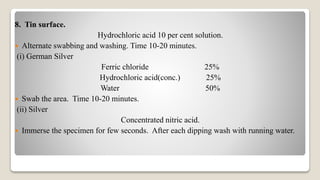

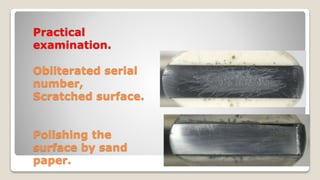

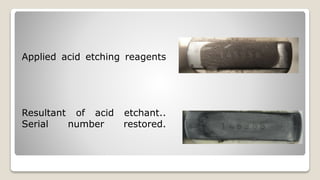

1. The document discusses techniques for restoring obliterated marks on items like vehicles and firearms for identification purposes. 2. It describes different types of marks like cast, engraved, and punched marks and principles of restoration using chemical reagents that dissolve strained metal at different rates. 3. The techniques discussed involve cleaning surfaces, taking photographs, applying etchants like acids selectively to restore serial numbers, and preserving restored marks.