1. Trends in the automotive industry like weight reduction and lower environmental impact are driving changes in pretreatment and electrocoat technologies.

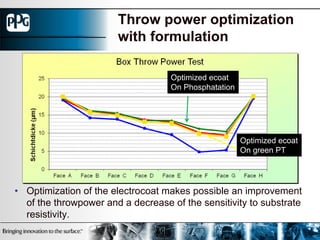

2. Green pretreatments without phosphates are growing but have limitations in corrosion performance; electrocoats need to compensate for the differences in substrate properties.

3. Compact topcoat processes require a robust electrocoat process to avoid sanding and achieve a good appearance; experience has shown several OEMs successfully using PPG electrocoat in these processes.

4. New electrocoat concepts like hyperthrow aim to reduce coating usage and improve throw power, especially for difficult areas, to allow for higher production throughput.