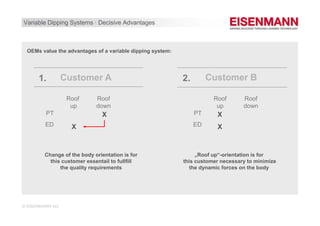

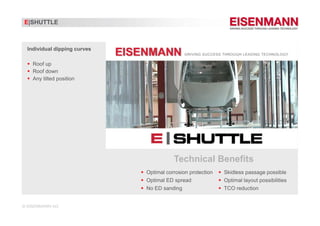

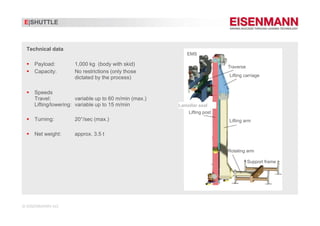

The document discusses conveyor technologies for pretreatment (PT) and electrocoating (ED) systems. It outlines the advantages of variable dipping systems like the E|Shuttle over continuous and discontinuous fixed conveyor systems. The E|Shuttle uses electric monorail technology to allow three degrees of freedom for dipping parts, improving process quality. It has been sold to multiple automakers worldwide for its flexibility, quality, and efficiency. Requirements for conveyor flexibility are increasing due to new body materials and designs, making the E|Shuttle well-suited to meet rising industry demands.