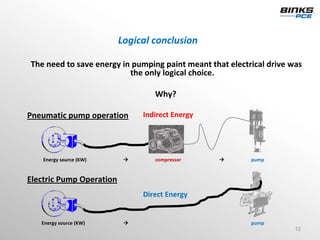

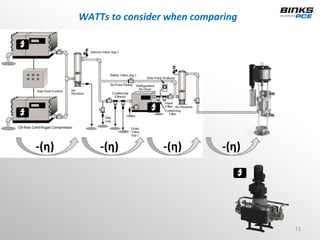

This document discusses the development of smart pump technology that applies artificial intelligence to fluid handling systems. It aims to reduce energy usage by allowing pumps to operate in either an open or closed loop. In open loop, pumps run at a minimum speed and pressure when fluid is being circulated but not used. In closed loop, pumps maintain required pressure but only supply needed flow. This saves significant energy compared to traditional pumping methods. The technology was inspired by turning a tap on and off to minimize water usage. It has benefits like accommodating various materials, preventing paint shear, being low maintenance, and using no consumables. An electric drive pump was chosen over pneumatic due to more direct energy efficiency. Testing confirmed the smart pump saves substantial energy

![ENERGY CONSUMPTION [KW]

MAPLE 30 PNEUMATIC PUMP

15](https://image.slidesharecdn.com/12-itwkaufmann-120423060632-phpapp01/85/Robin-Kaufmann-Bombas-Inteligente-Intelligent-Pumps-15-320.jpg)

![ENERGY CONSUMPTION [KW]

E2‐30 ELECTRIC PUMP

16](https://image.slidesharecdn.com/12-itwkaufmann-120423060632-phpapp01/85/Robin-Kaufmann-Bombas-Inteligente-Intelligent-Pumps-16-320.jpg)