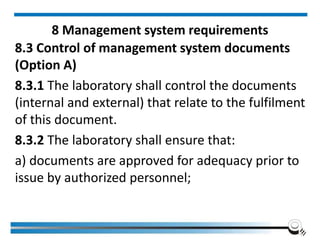

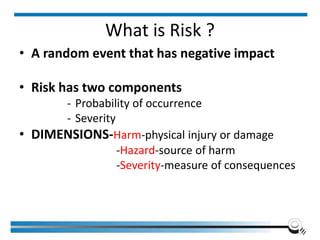

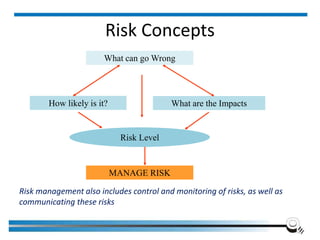

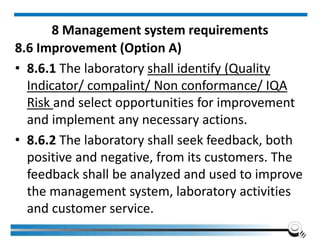

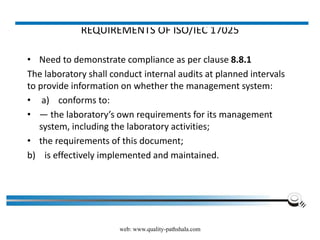

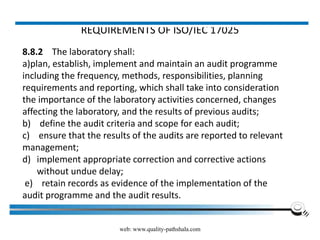

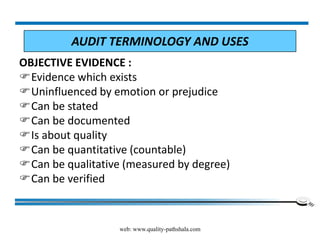

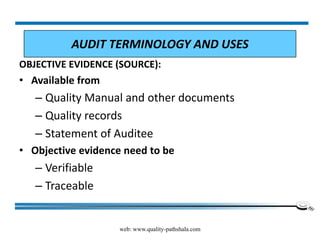

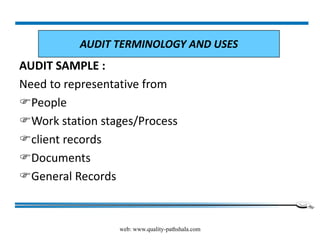

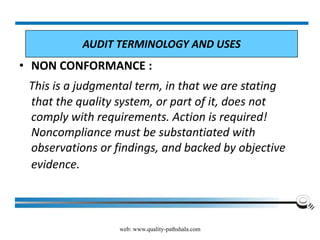

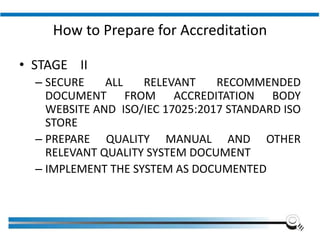

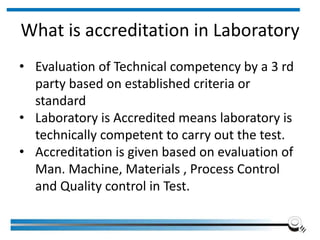

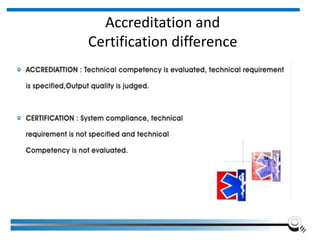

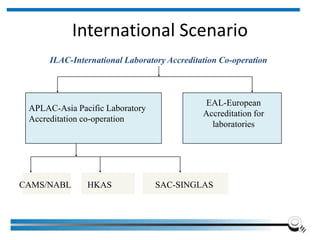

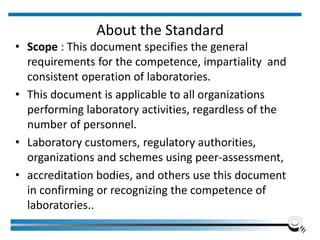

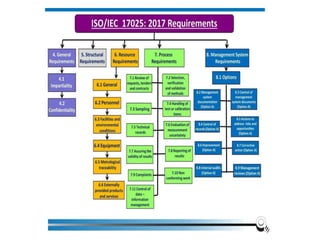

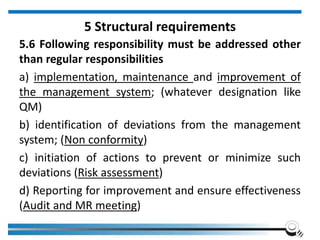

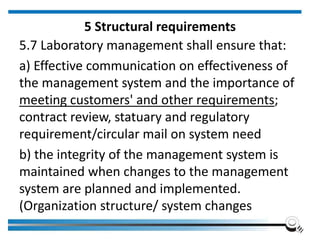

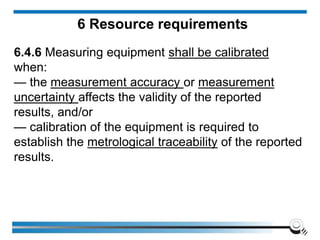

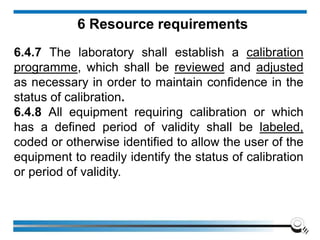

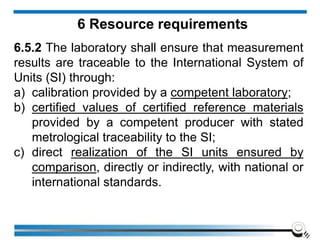

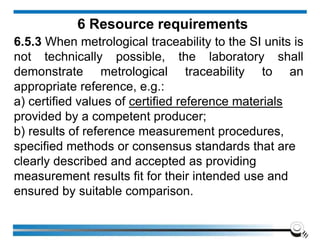

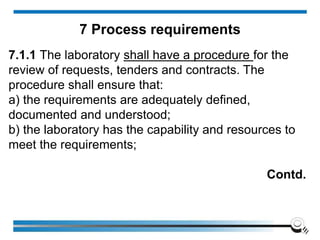

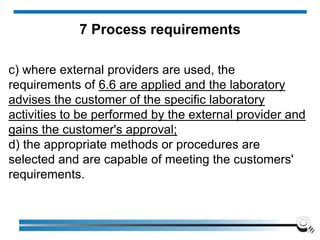

The document discusses the ISO/IEC 17025:2017 requirements related to the competence and quality management of laboratories, emphasizing the importance of impartiality, confidentiality, and precise operation. It outlines the structural, resource, and management system requirements necessary to ensure quality assurance and control, as well as the significance of laboratory accreditation for demonstrating technical competency. Key elements include competency assessments, risk identification, and the need for suitable facilities and equipment to support laboratory activities.

![Equipment Validation Overview

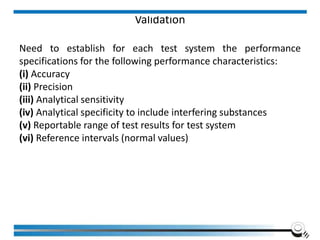

[To establish] documented evidence which provides a high

degree of assurance that a specific process will consistently

produce a product meeting pre-determined specifications and

quality attributes.

Institute of Applied Quality Management 78](https://image.slidesharecdn.com/5-240713063929-59a409d9/85/17025-2017-Training-Manual-for-the-Laboratory-78-320.jpg)

![7.8.8.1 When an issued report needs to be changed,

amended or re-issued, any change of information

shall be clearly identified and, where appropriate, the

reason for the change included in the report.

7.8.8.2 Amendments to a report after issue shall be

made only in the form of a further document, or data

transfer, which includes the statement “Amendment to

Report, serial number... [or as otherwise identified]”, or

an equivalent form of wording.

7 Process requirements](https://image.slidesharecdn.com/5-240713063929-59a409d9/85/17025-2017-Training-Manual-for-the-Laboratory-203-320.jpg)