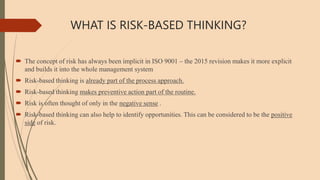

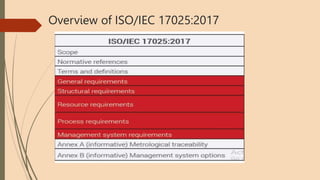

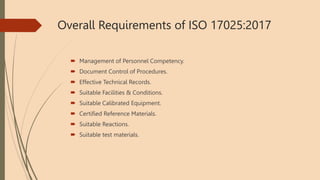

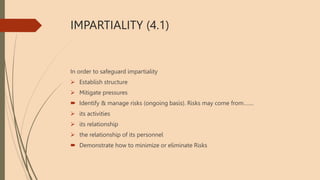

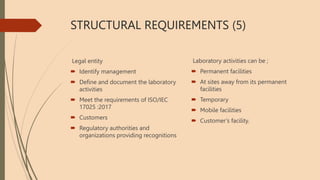

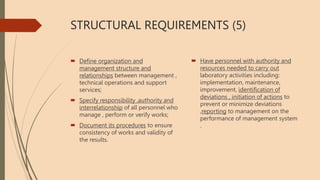

This document provides an overview of the key requirements of ISO/IEC 17025:2017 for testing and calibration laboratories. It discusses the standard's focus on impartiality, competence, consistent operations, and risk-based approaches. Some of the main changes from the previous version include an increased emphasis on performance-based requirements and flexibility. The standard specifies requirements for laboratory management systems, personnel, facilities, equipment, sampling, test and calibration methods, handling of test items, quality control, reporting, and customer complaints in order to ensure the reliability of test and calibration results.