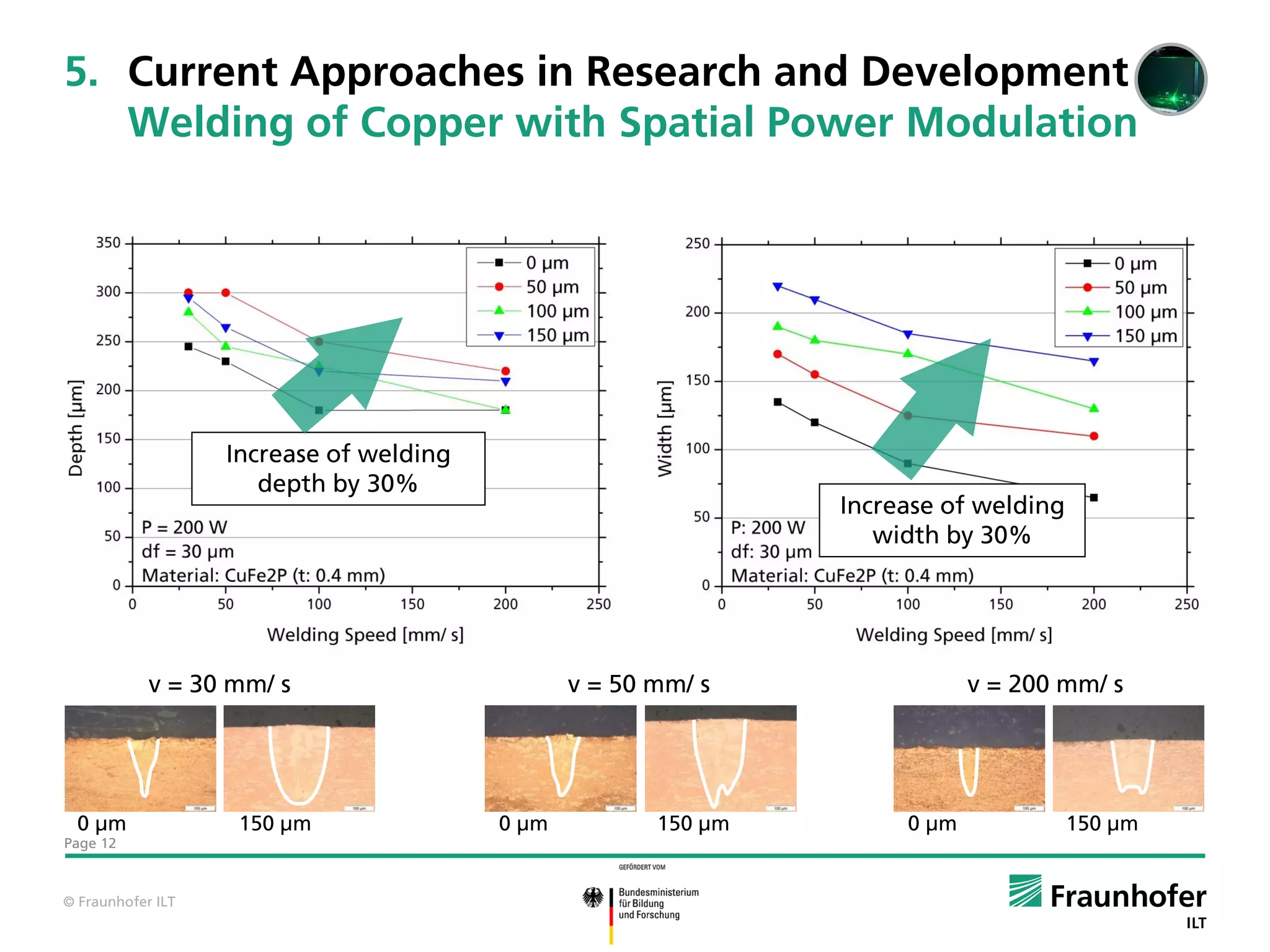

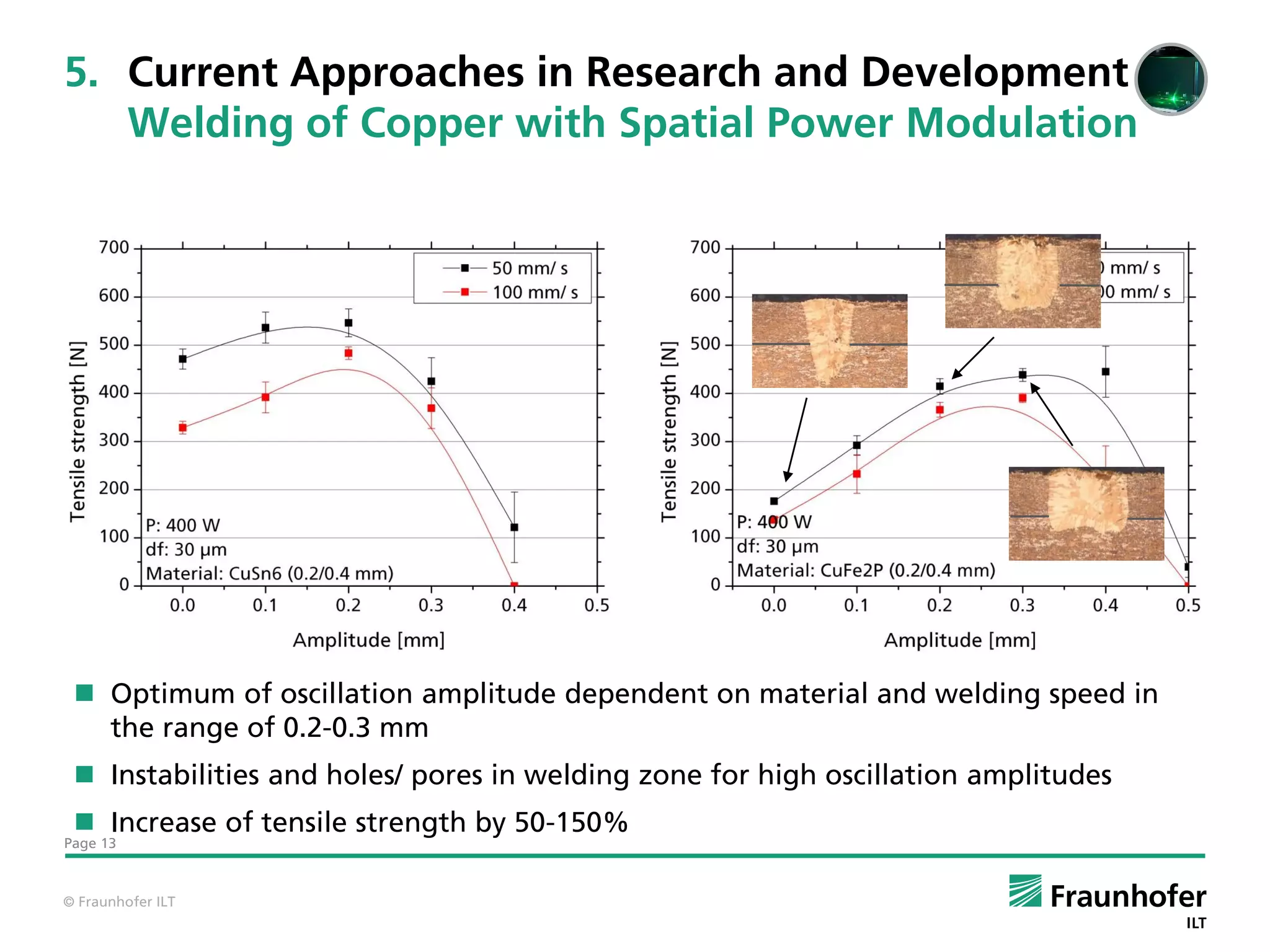

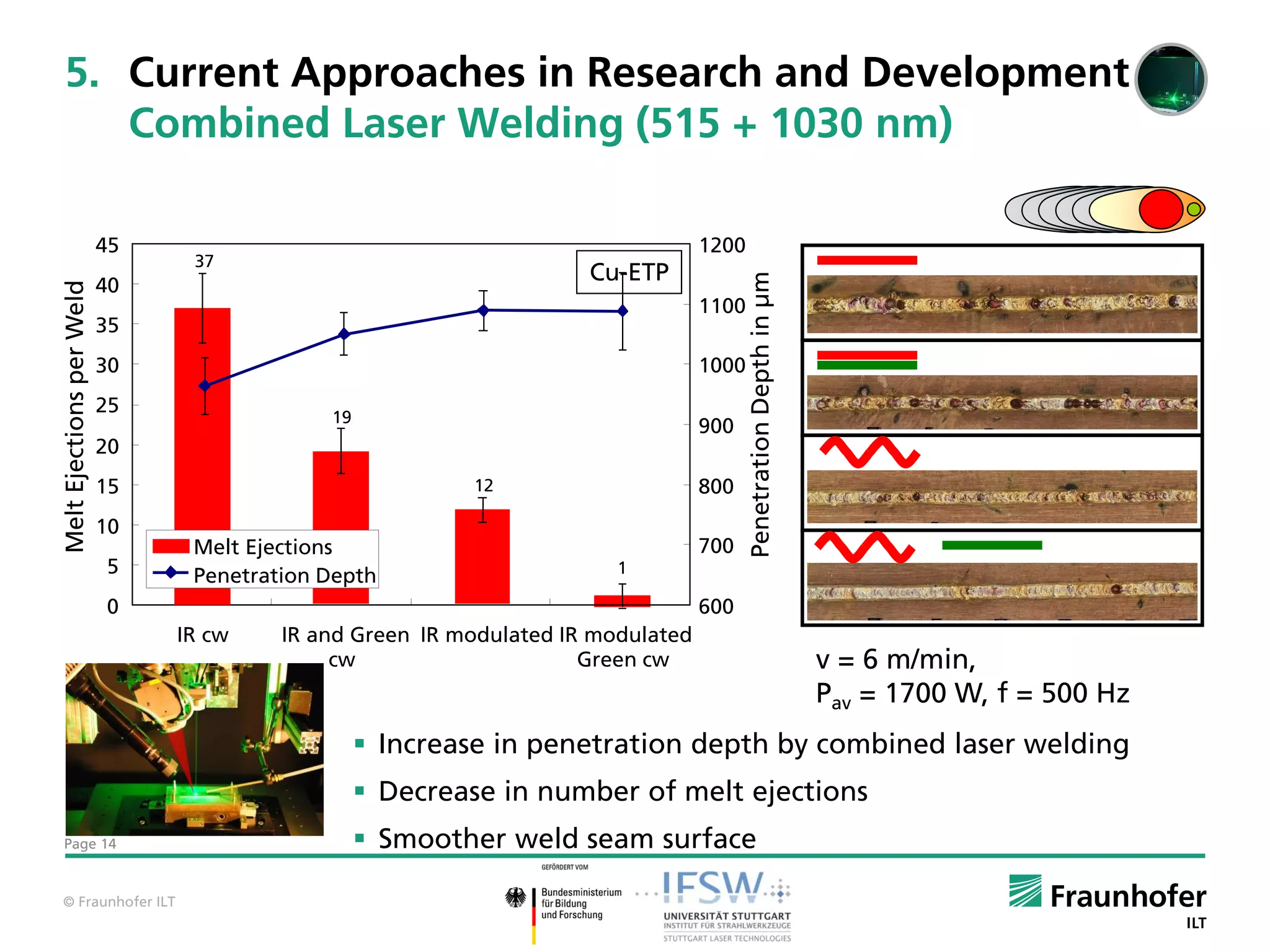

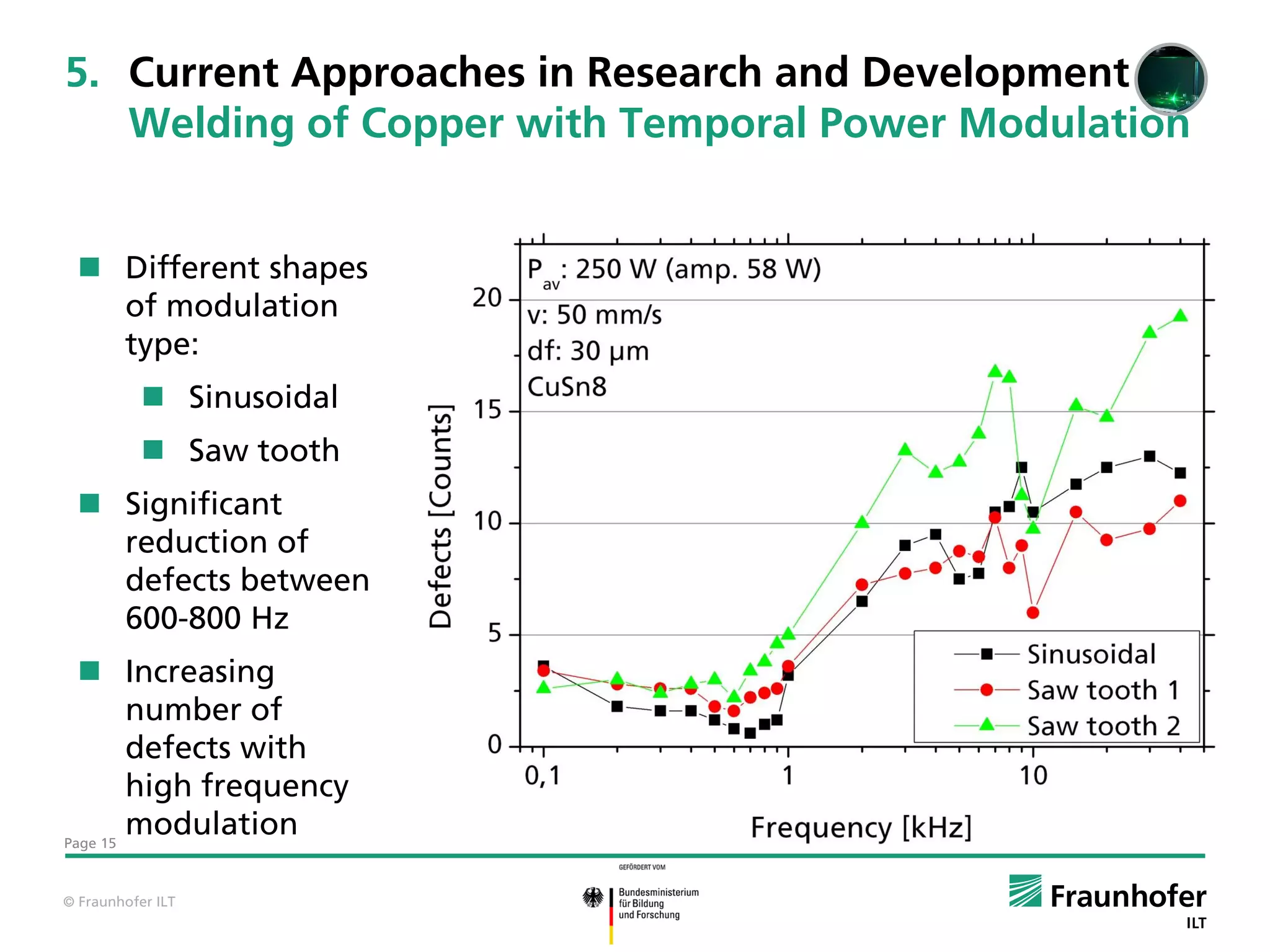

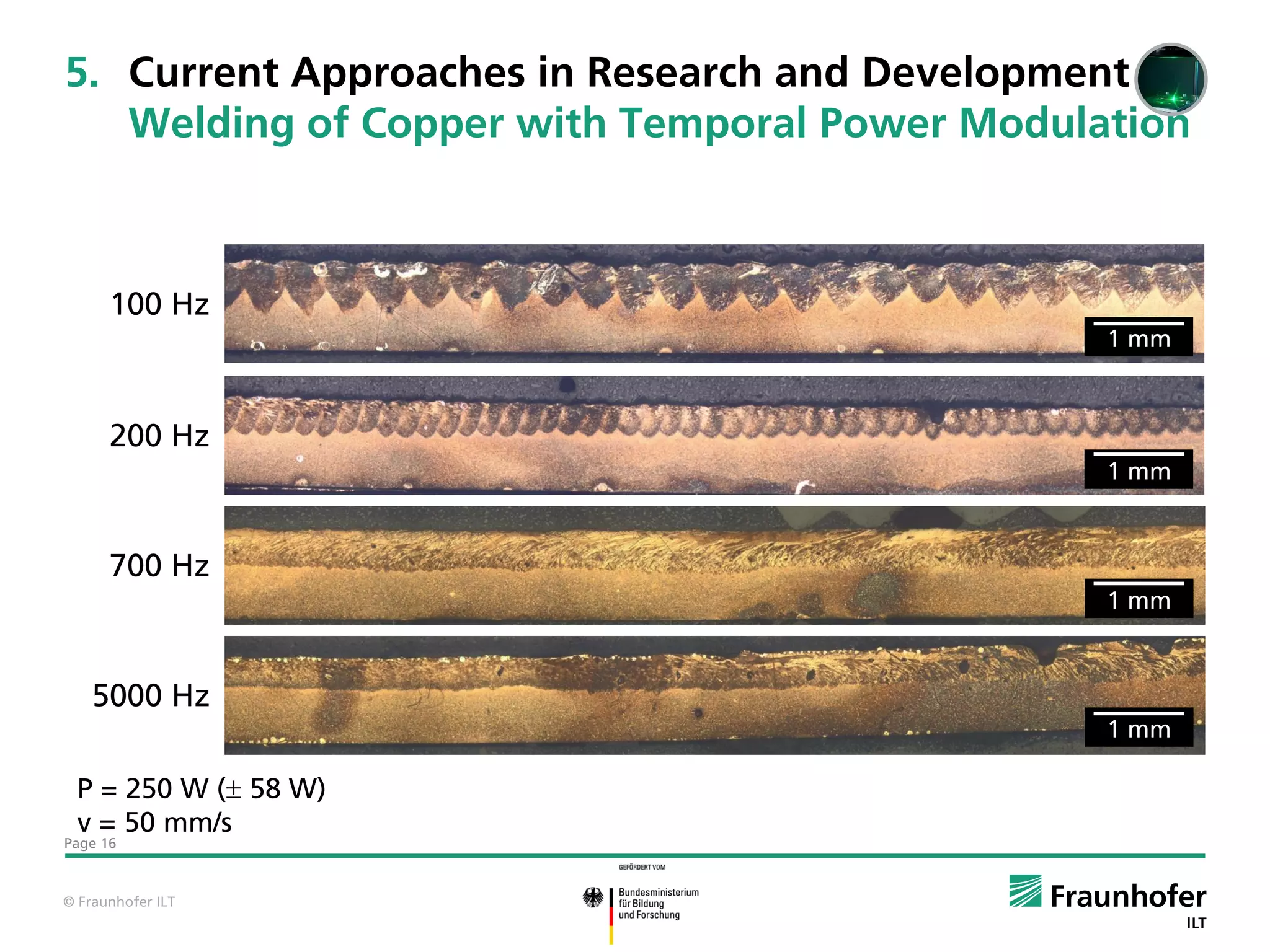

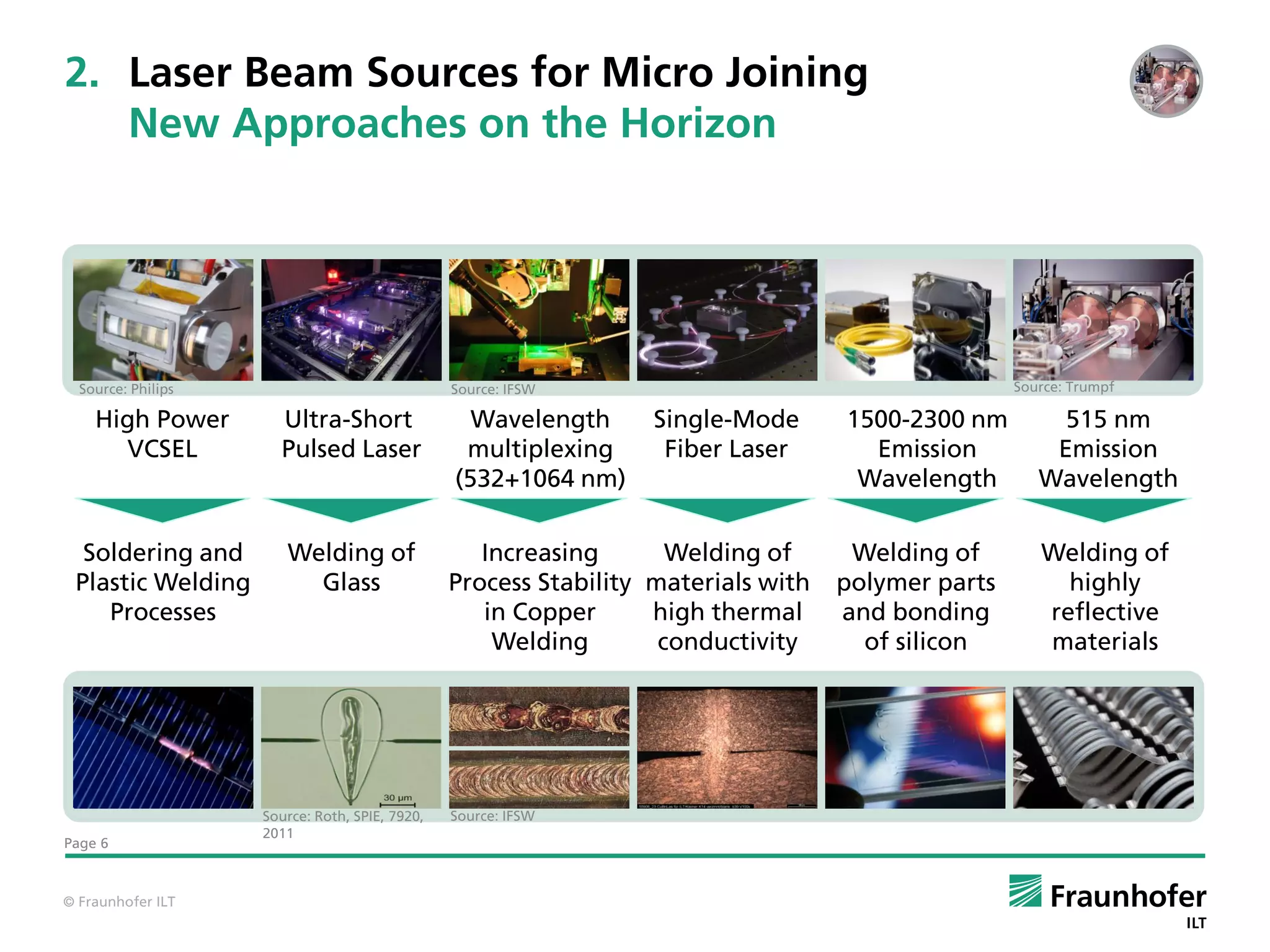

This document discusses laser micro joining processes and applications in research and development. It outlines laser beam sources and beam manipulation strategies used for micro joining applications in energy storage, electronics, and lightweight construction. Current approaches in research include welding copper with spatial and temporal power modulation to increase weld depth and quality. Developments aim to enable precision melt engineering through dynamic beam manipulation and modeling of laser micro joining processes.

![1. Applications for Laser Micro Joining

Energy, Electronics and Lightweight Construction

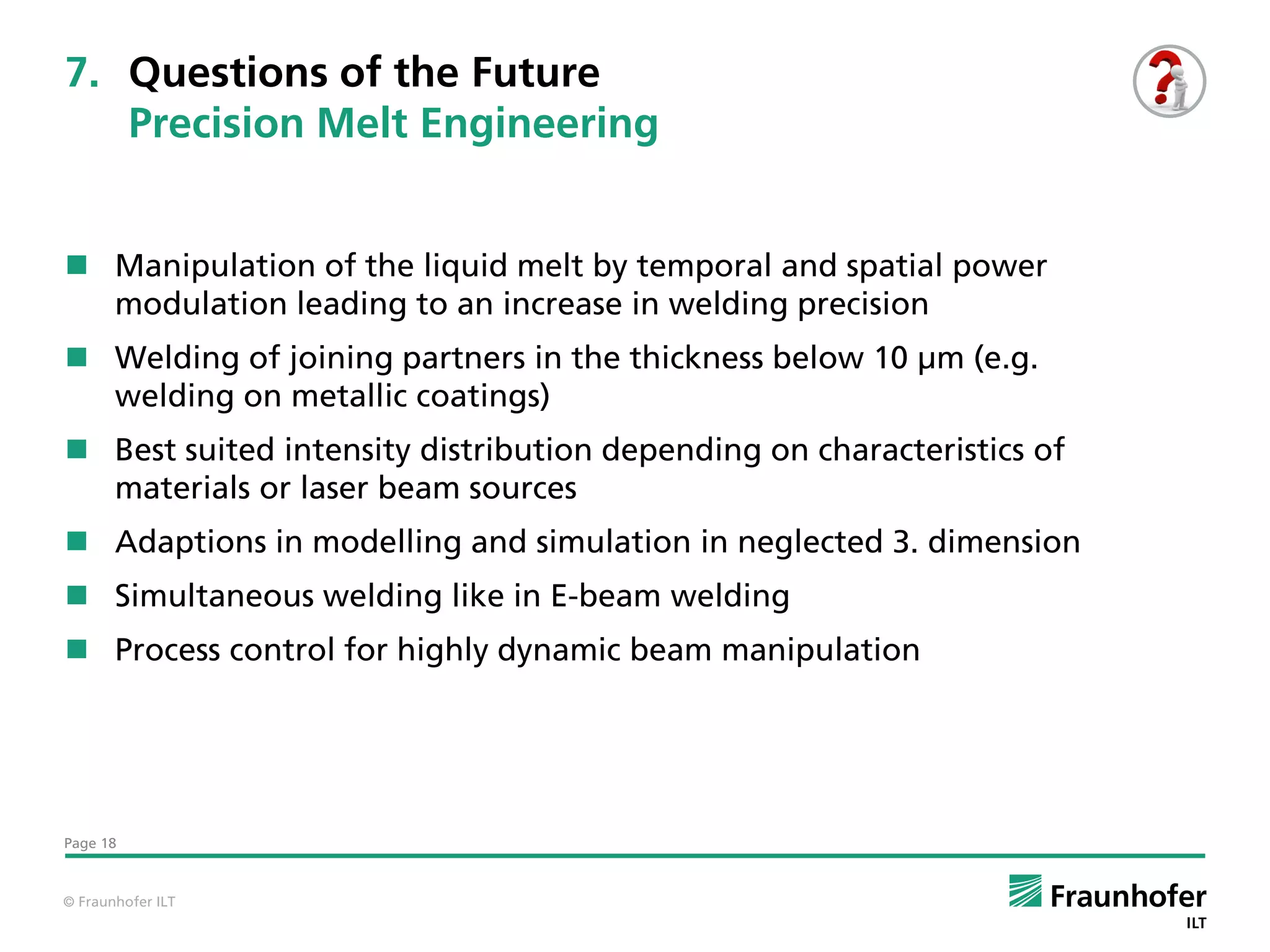

15

Laser Beam

Penetration

Line Energy [J/m m ]

Al 0,5

Conductors 10 Cu 0,3

5

Pouch Cell

Plate Cooler Not Connected

0

0 50 100 150 200

Feed [mm/s]

Welding geometry:

Overlap, Al conductor

top Requirements for welding process

Linear weld seam Stabilized process in small working range

Parameter:

Enlarged cross-section for enhanced conductivity

df = 80 µm

P = 500 - 1 000 W Welding of dissimilar materials

Page 5 v = 50 - 200 mm/s

© Fraunhofer ILT](https://image.slidesharecdn.com/13-00heermehlmann-121212095005-phpapp01/75/Benjamin-Mehlmann-Fraunhofer-Institute-5-2048.jpg)

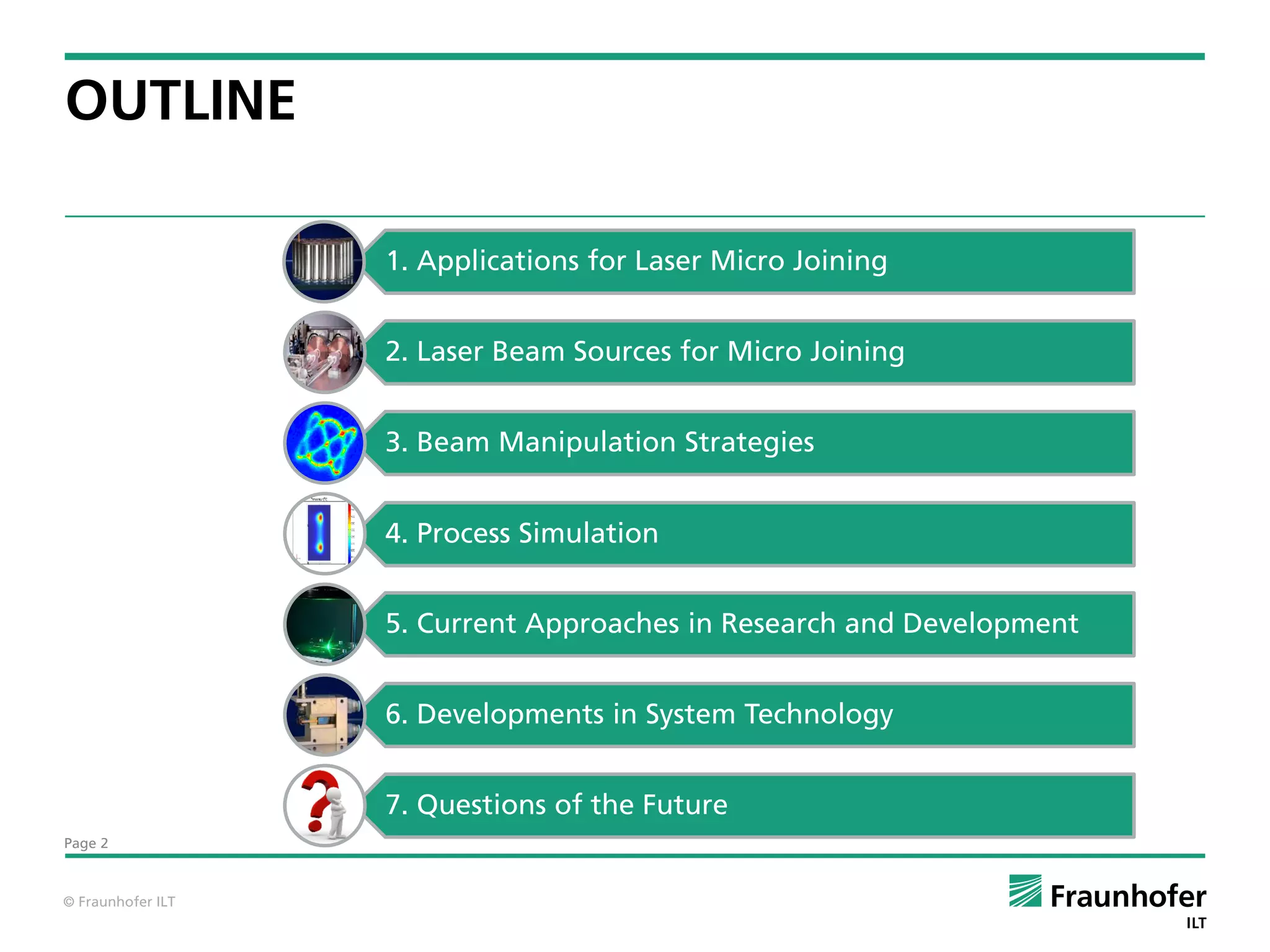

![3. Beam Manipulation Strategies

Variable Intensity Profile in Time and Space

Intensität [W/ cm²] Intensität [W/ cm²]

0,0E+00 0,0E+00

0,2 0,2 2,8E+03 1,9E+03

5,5E+03 3,8E+03

8,3E+03 5,6E+03

1,1E+04 7,5E+03

1,4E+04 9,4E+03

1,7E+04 1,1E+04

y [mm]

y [mm]

1,9E+04 1,3E+04

0,0 0,0 2,2E+04 1,5E+04

2,5E+04 1,7E+04

2,8E+04 1,9E+04

3,0E+04 2,1E+04

3,3E+04 2,3E+04

3,6E+04 2,4E+04

3,9E+04 2,6E+04

-0,2 -0,2 4,1E+04 2,8E+04

4,4E+04 3,0E+04

4,7E+04 3,2E+04

-0,2 0,0 0,2 -0,2 0,0 0,2

x [mm] x [mm]

Beam Shaping Spatial Power Temporal Power

Modulation Modulation

• M-Shape • Fast Beam • Rising Time

• Circle Deflection • Frequency

• Diffractive Optical • Lissajous- • Different

Elements (DOE) oscillation modulation shapes

geometries

• Amplitude

• Frequency

• Amplitude

Page 8

© Fraunhofer ILT](https://image.slidesharecdn.com/13-00heermehlmann-121212095005-phpapp01/75/Benjamin-Mehlmann-Fraunhofer-Institute-8-2048.jpg)