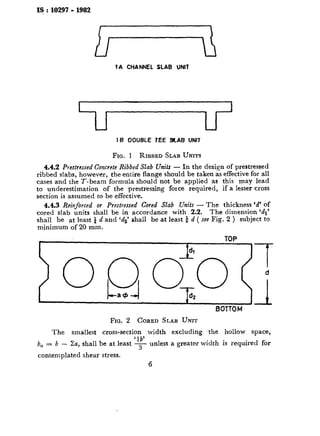

This document provides details on the design and construction of floors and roofs using precast reinforced or prestressed concrete ribbed or cored slab units. It specifies dimensions for the precast units, including widths up to 3000mm for ribbed units and 2100mm for cored units. It also provides requirements for material strengths, structural design considerations, and loads to be accounted for in design according to other relevant Indian Standards.