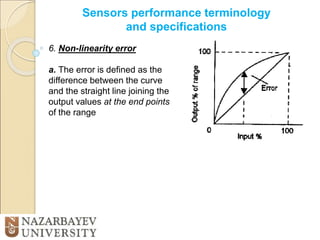

Prashant Kumar Jamwal has extensive experience in academia, having held various teaching positions since 1995. He received his PhD from the University of Auckland, New Zealand and has published papers in international conferences. The summarized document outlines the module "Sensors and Actuators" coordinated by Prashant Jamwal and Nazim Mir-Nasiri. It describes the aims, learning outcomes, topics to be covered, assessment details and provides definitions and specifications for sensors.