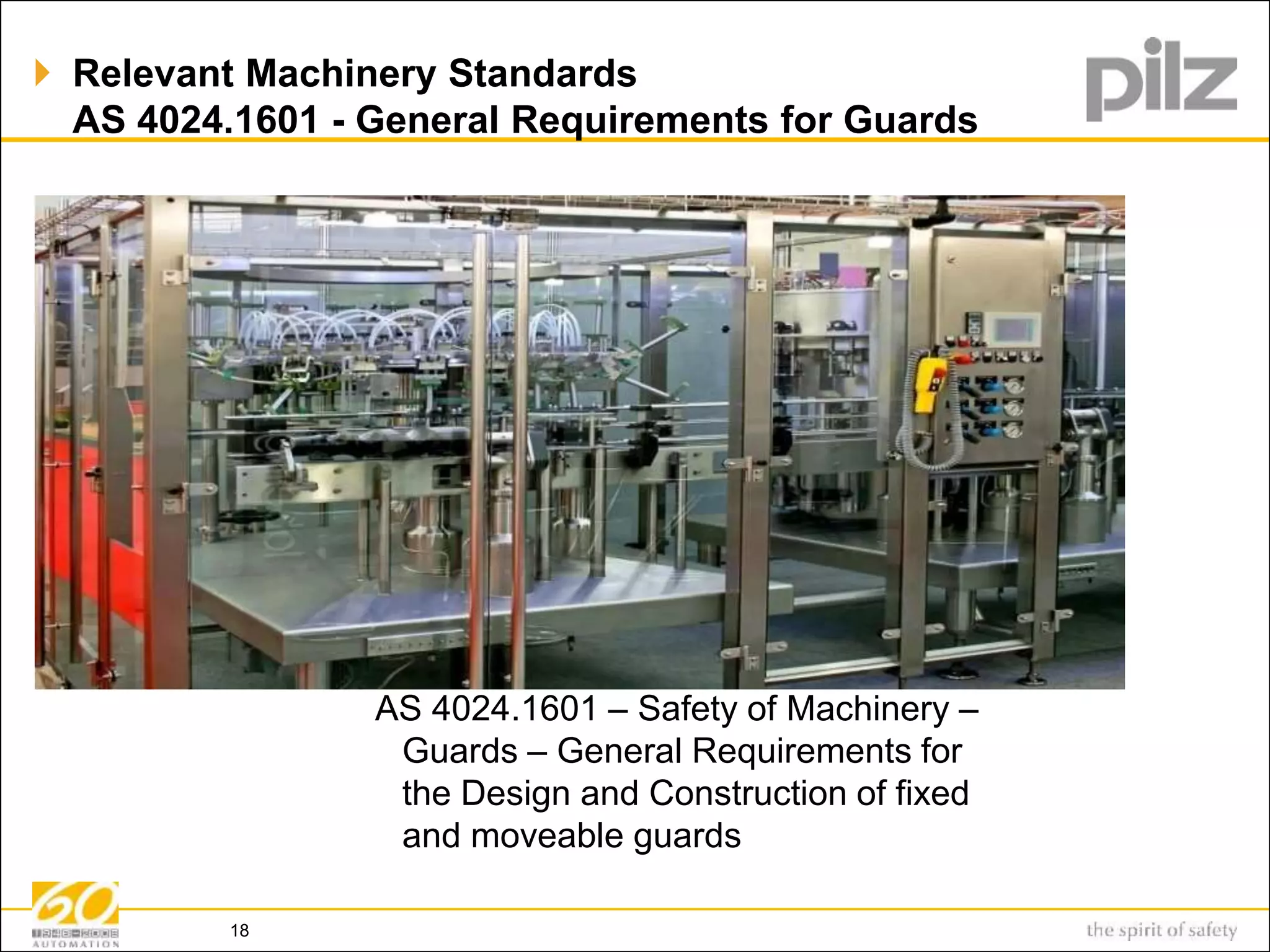

This document provides information about machinery guarding standards and regulations. It discusses findings from WorkSafe inspections that found older machinery often lacked guarding while newer machinery was generally guarded. Standards like AS 4024 provide specifications for machine guarding and safety distances to prevent access to hazard zones. The document outlines various standards regarding risk assessment, guards, safety distances, and safety control systems that are relevant for achieving safe machinery guarding.