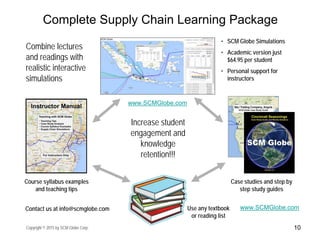

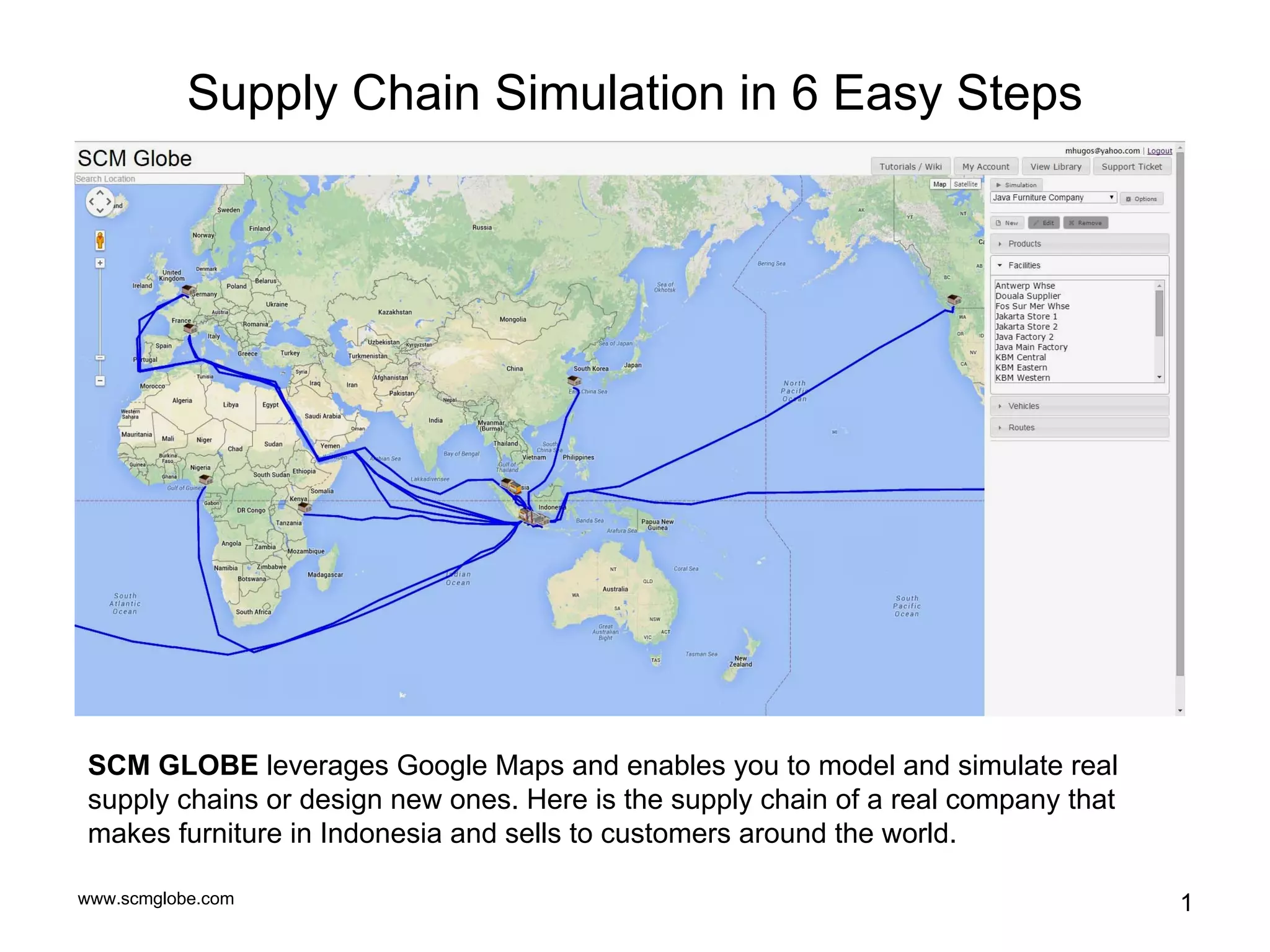

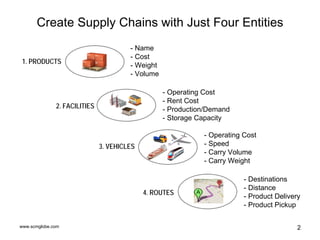

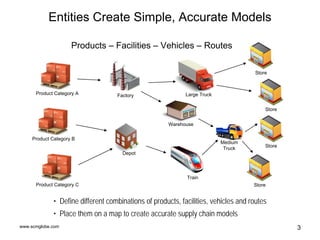

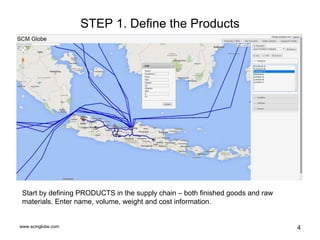

SCM Globe provides a platform for modeling and simulating real supply chains in six easy steps, involving the definition of products, facilities, vehicles, and routes. Users can simulate supply chain performance, identify points of failure, and optimize the system for better efficiency. The service also includes educational resources for students and instructors to enhance learning experiences in supply chain management.

![www.scmglobe.com 5

STEP 2. Define the Facilities

Define the FACILITIES in the supply chain – factories, warehouses, stores etc. – places

where products are made, stored or sold. Enter operating costs, production rates, daily

demand and on-hand inventory [zoom in, switch to satellite view and see actual facilities].](https://image.slidesharecdn.com/instructormodsimslides-151026184755-lva1-app6891/85/Supply-Chain-Modeling-and-Simulation-in-6-Easy-Steps-5-320.jpg)