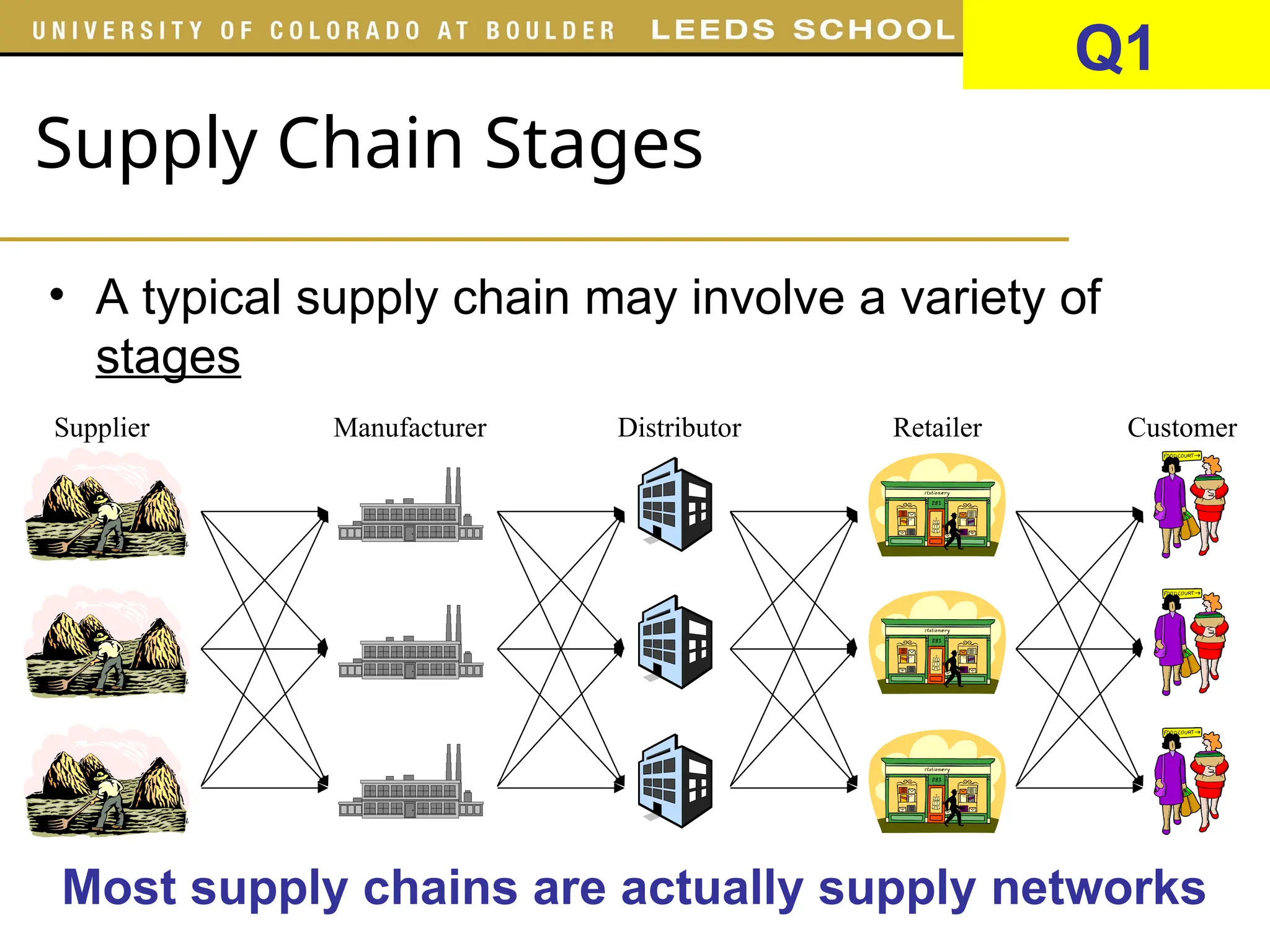

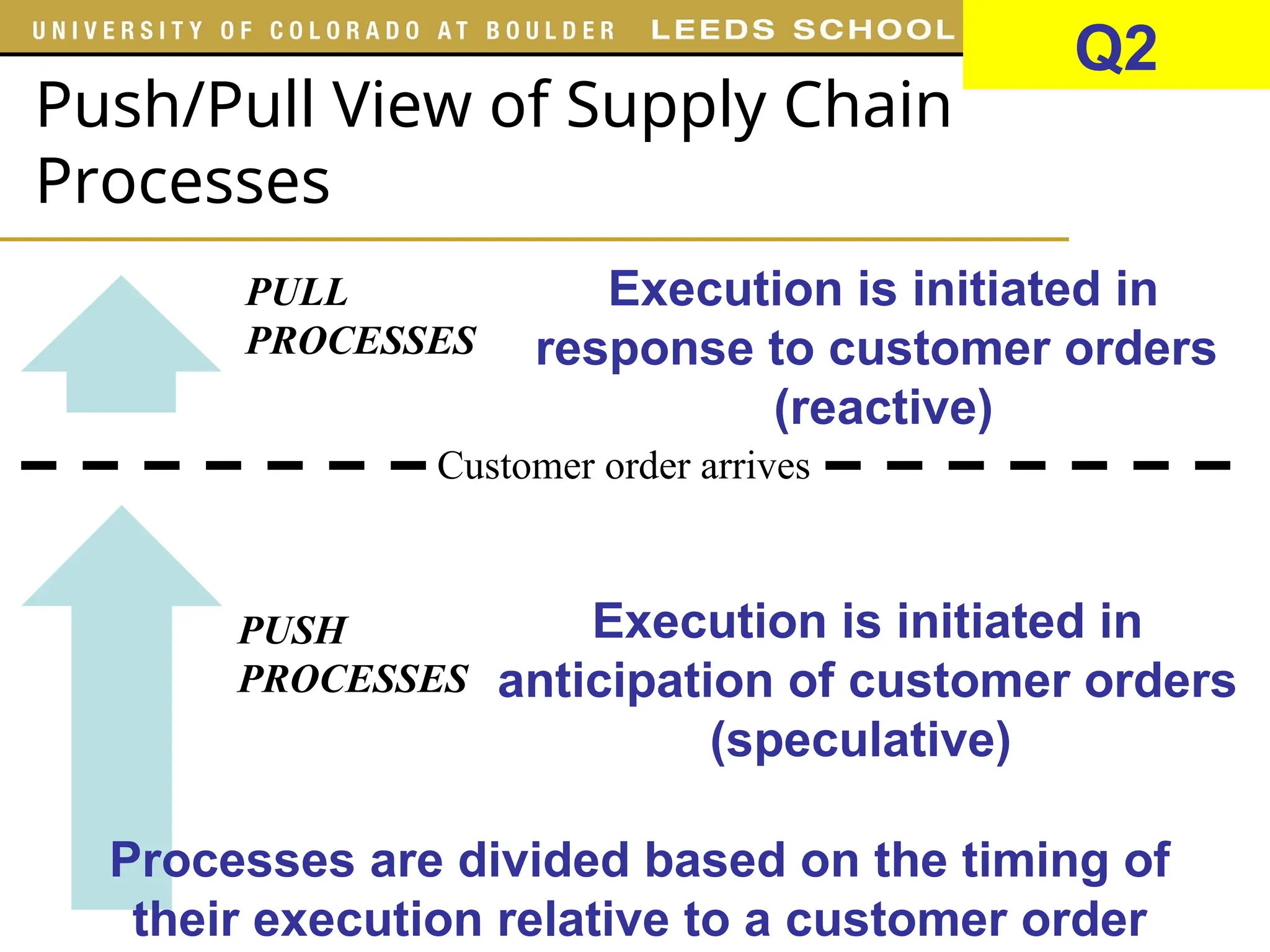

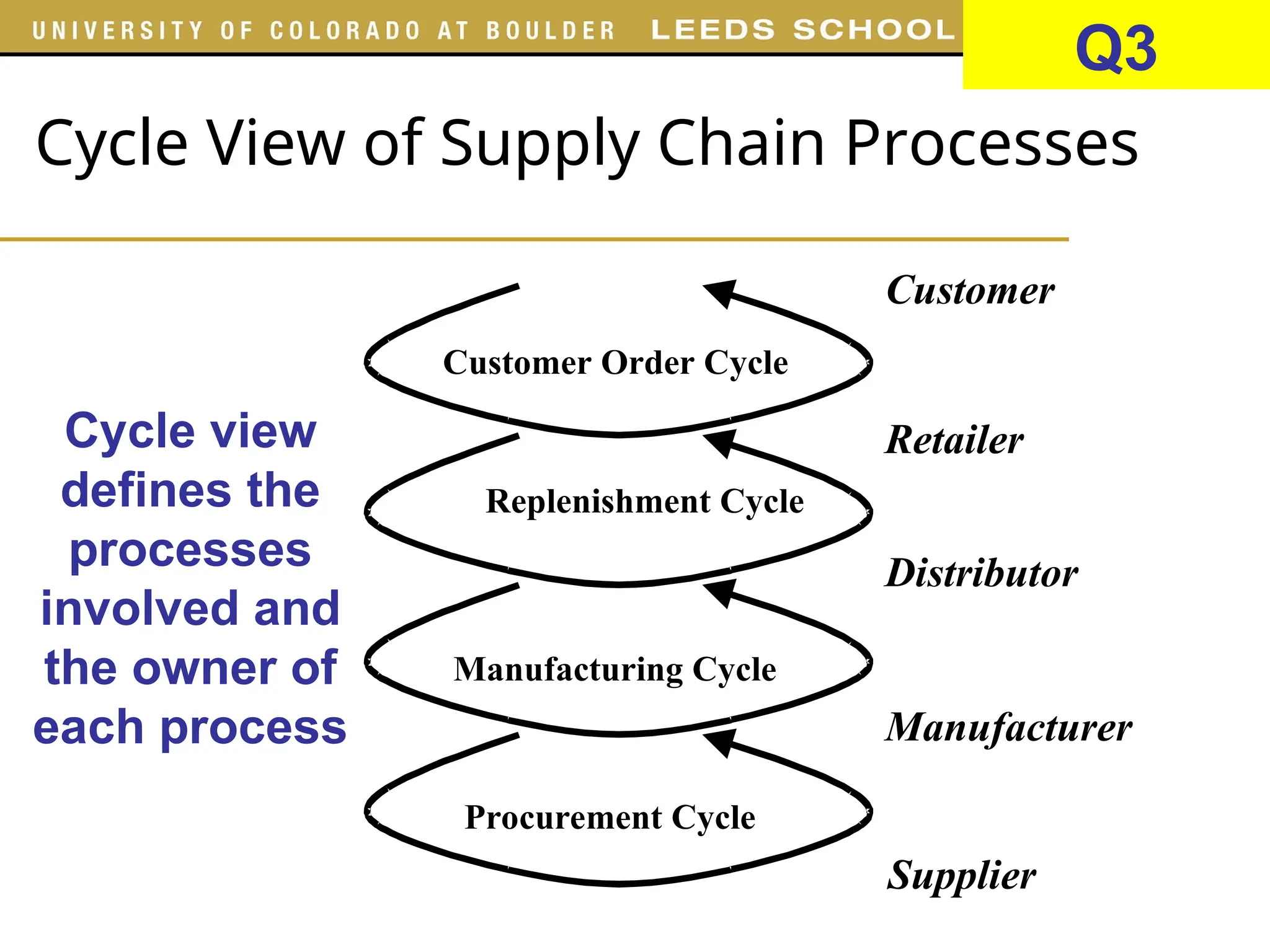

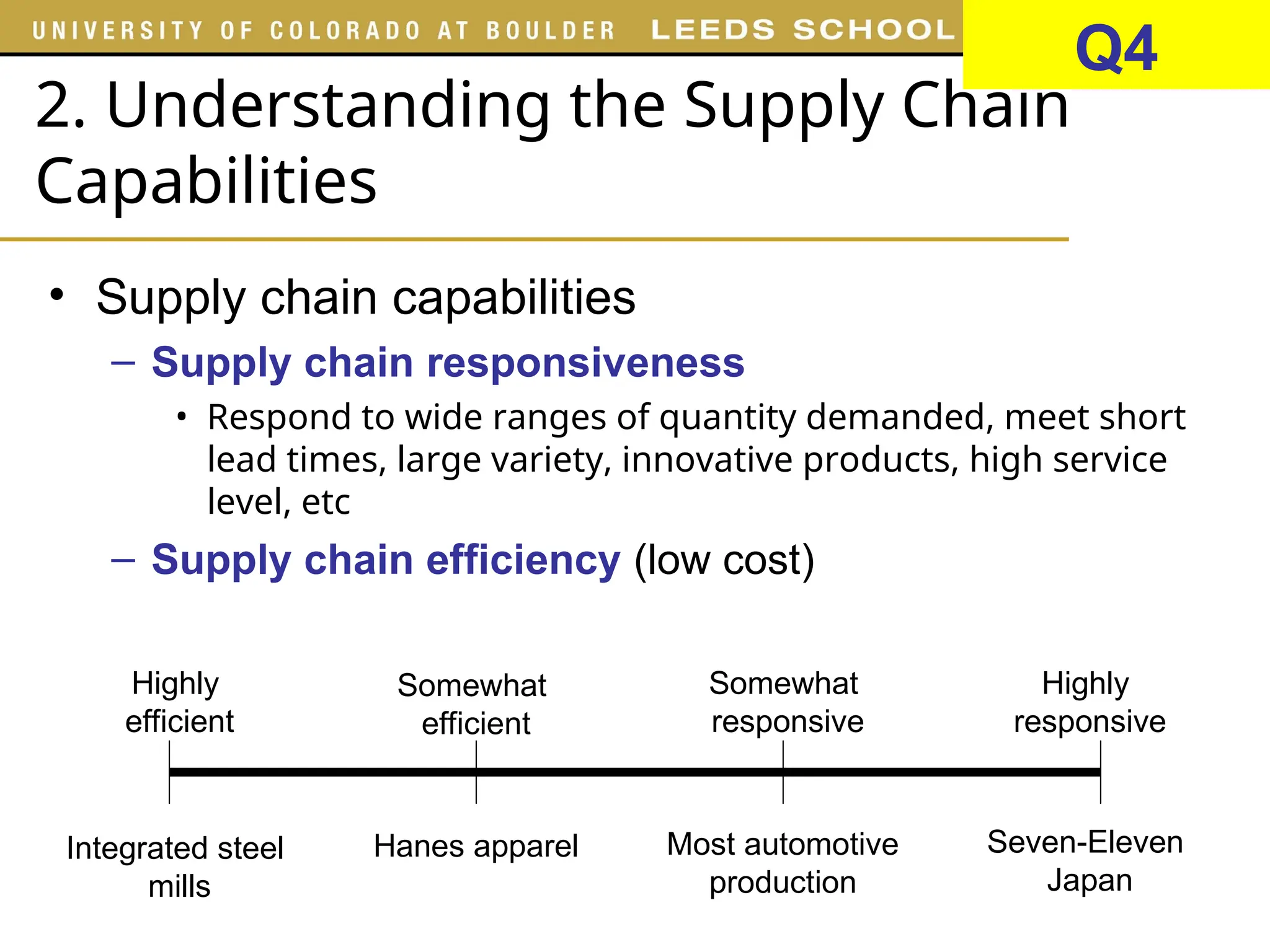

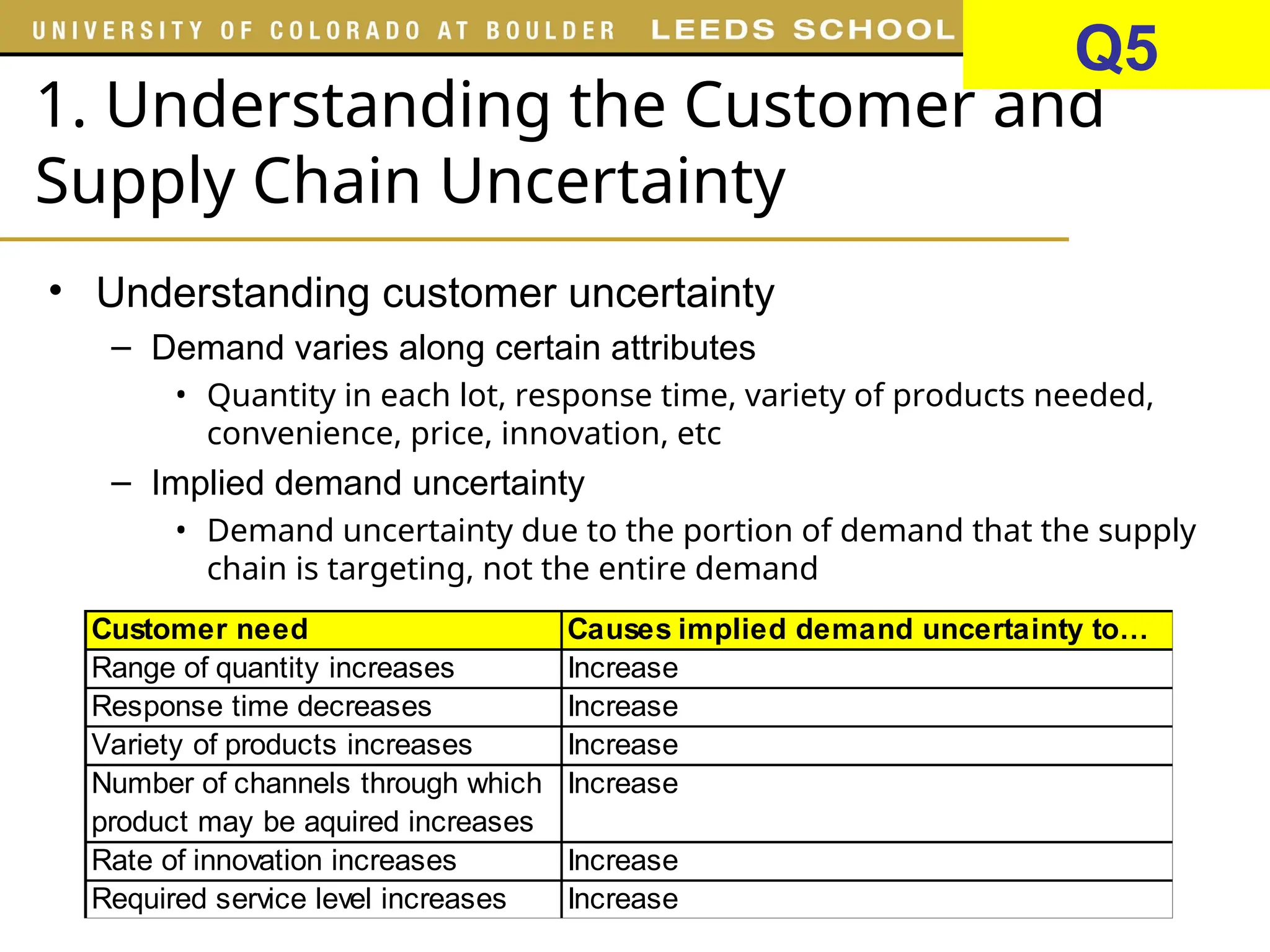

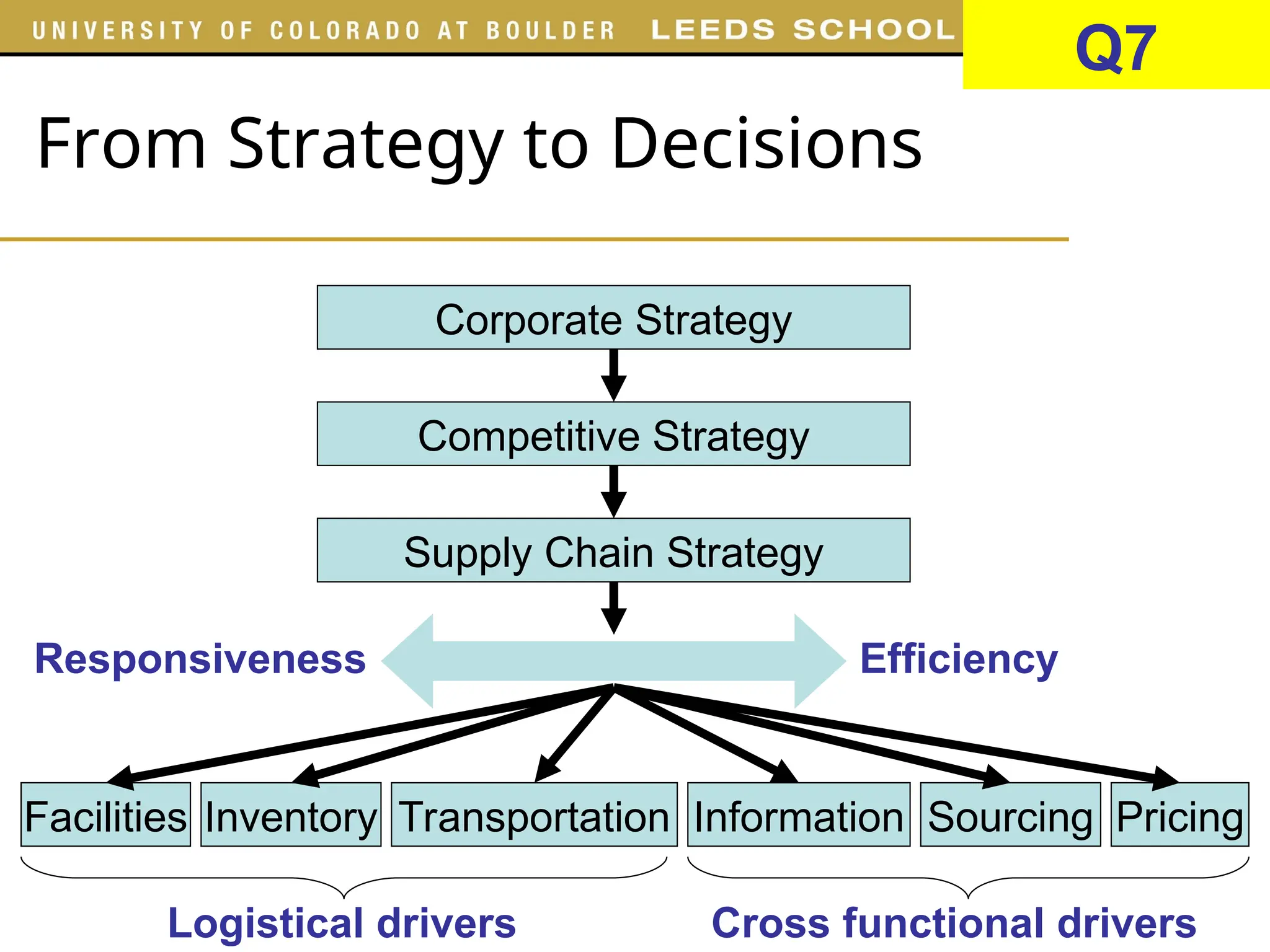

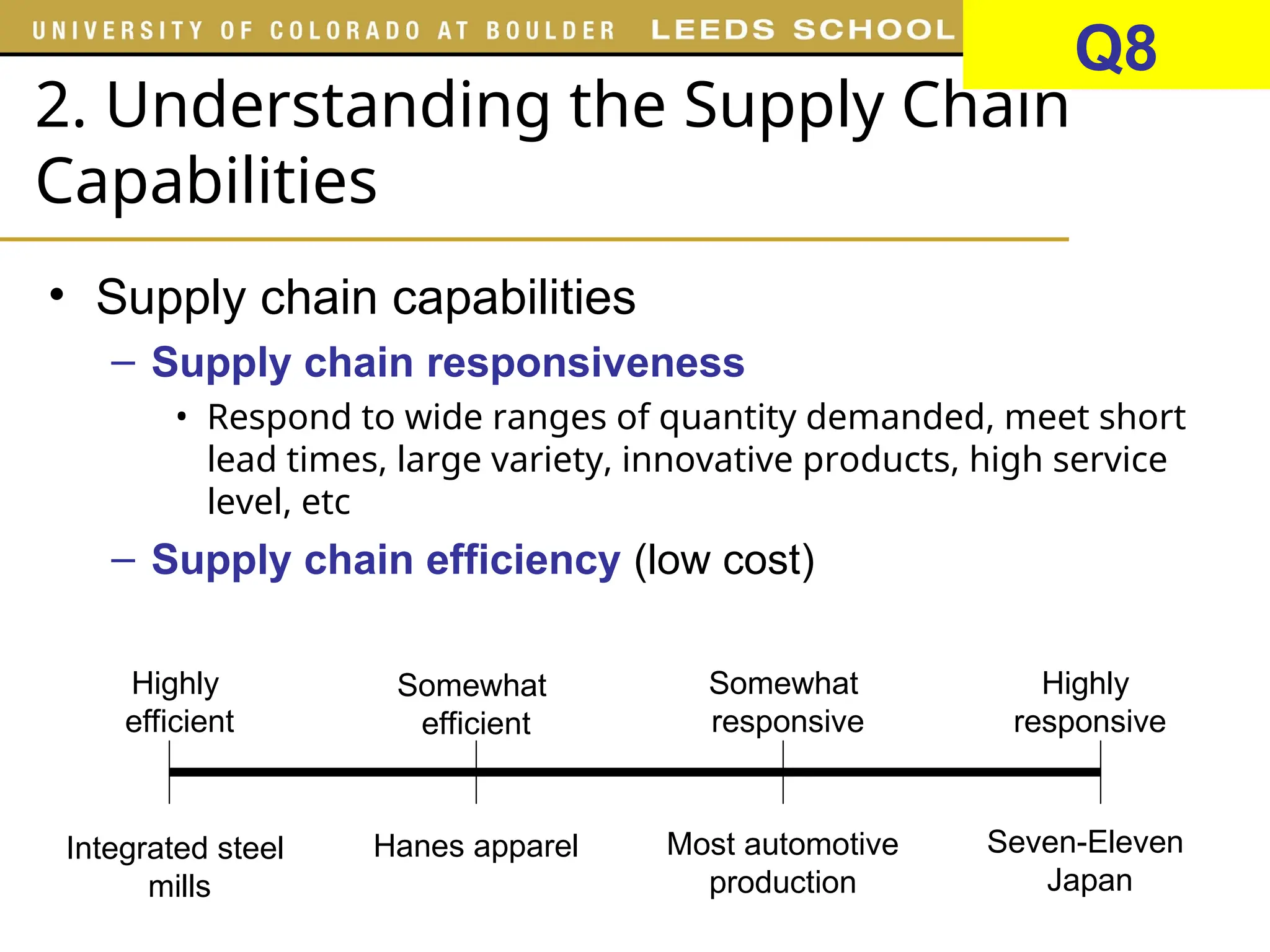

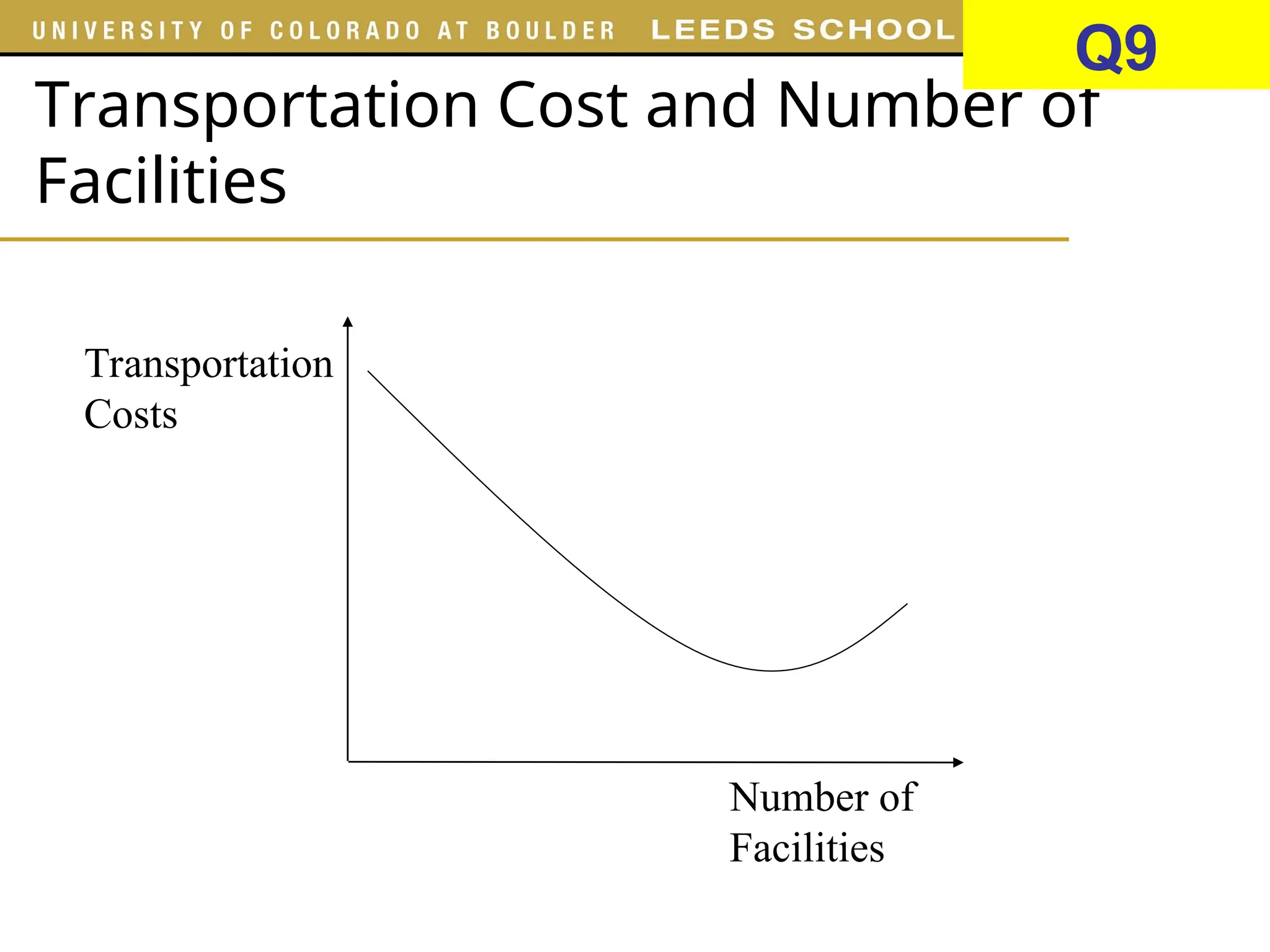

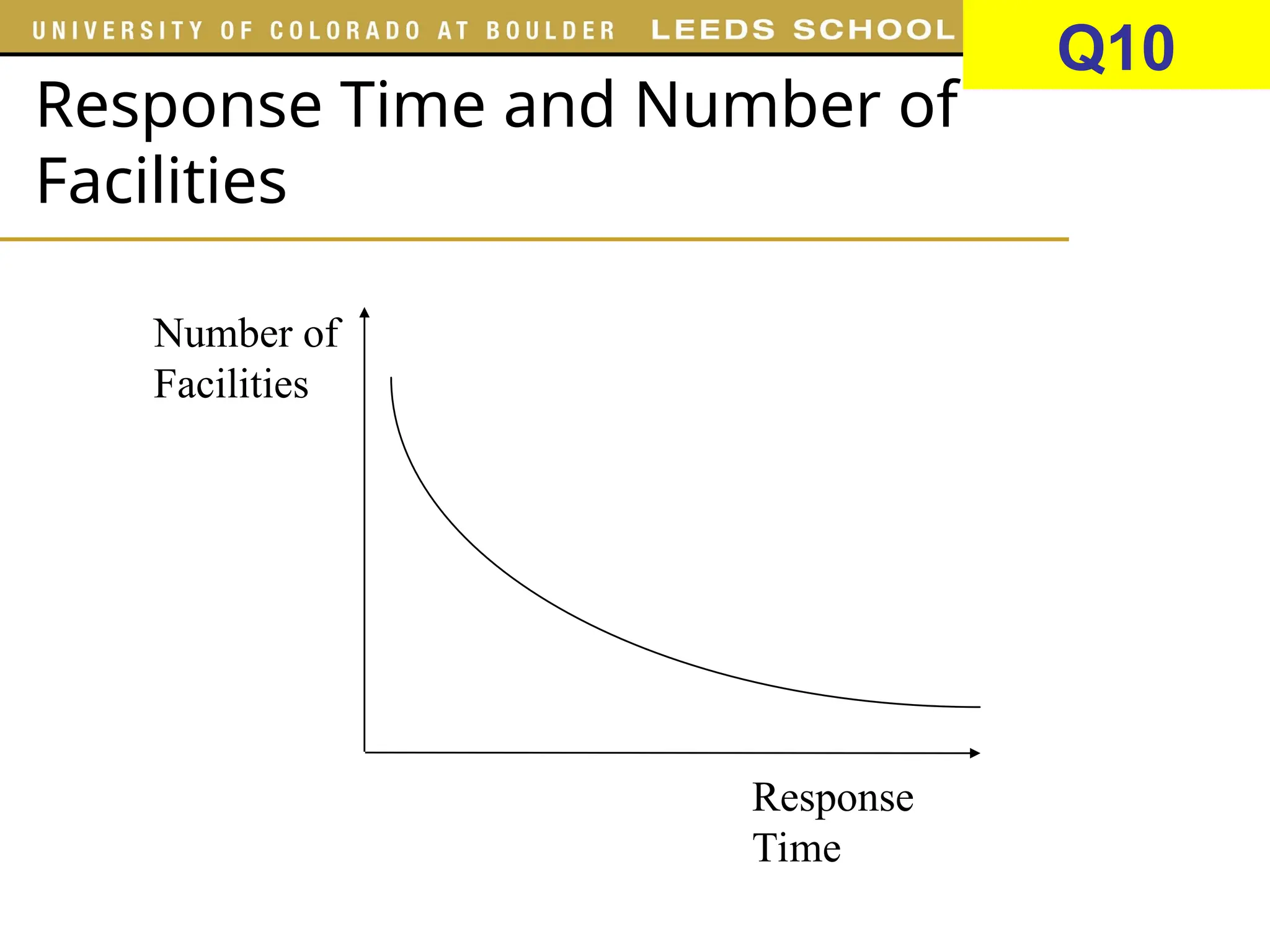

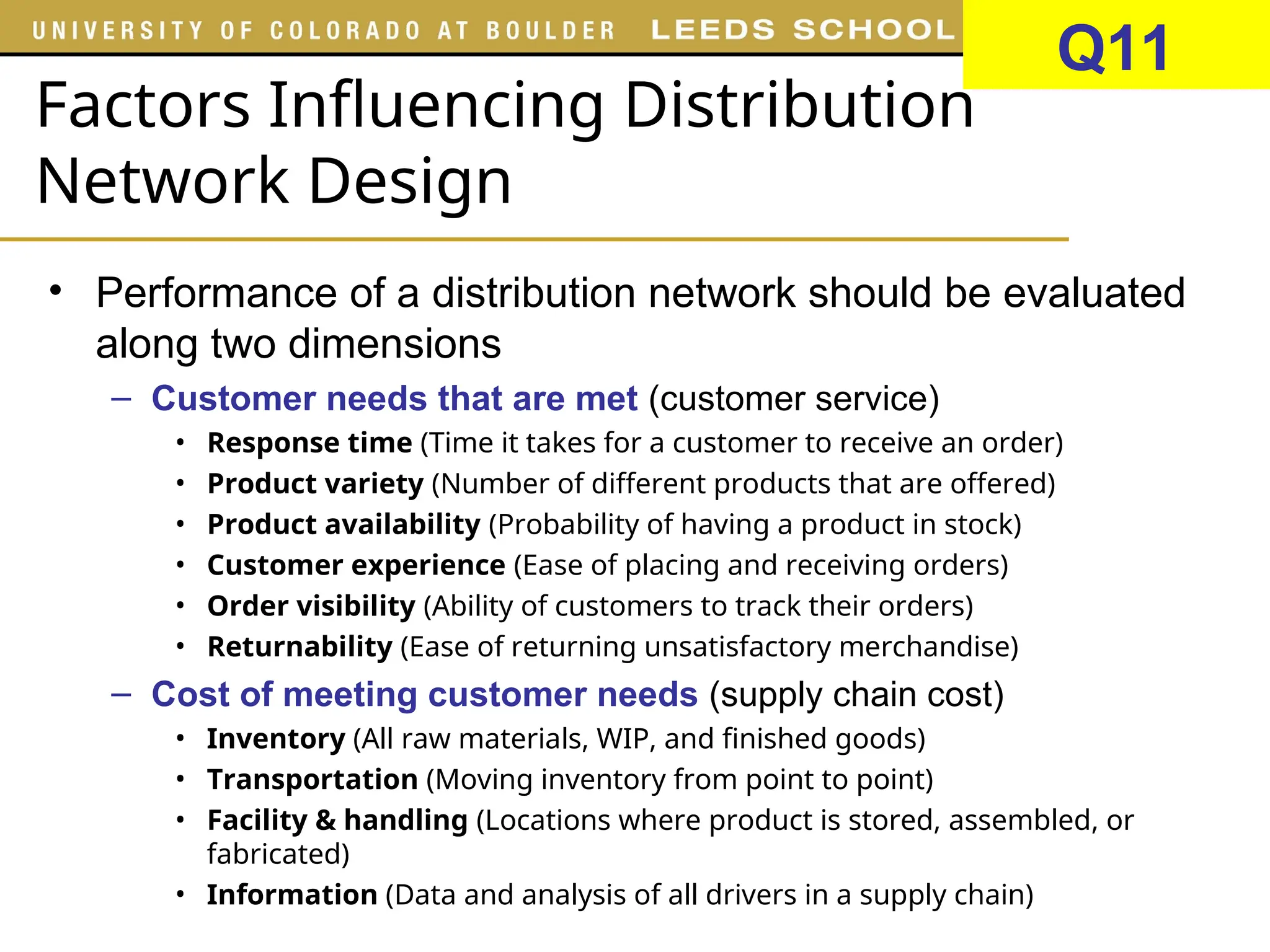

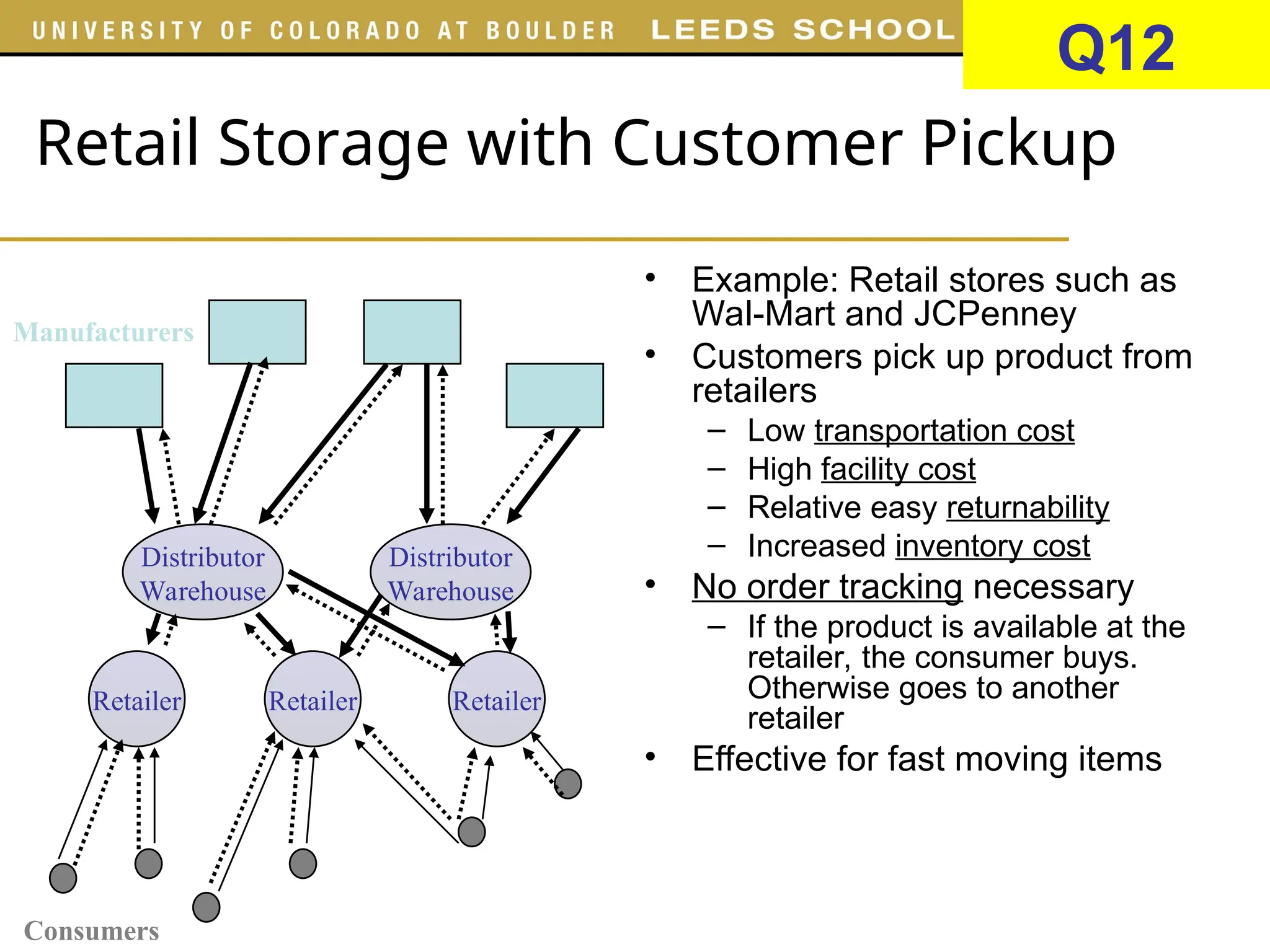

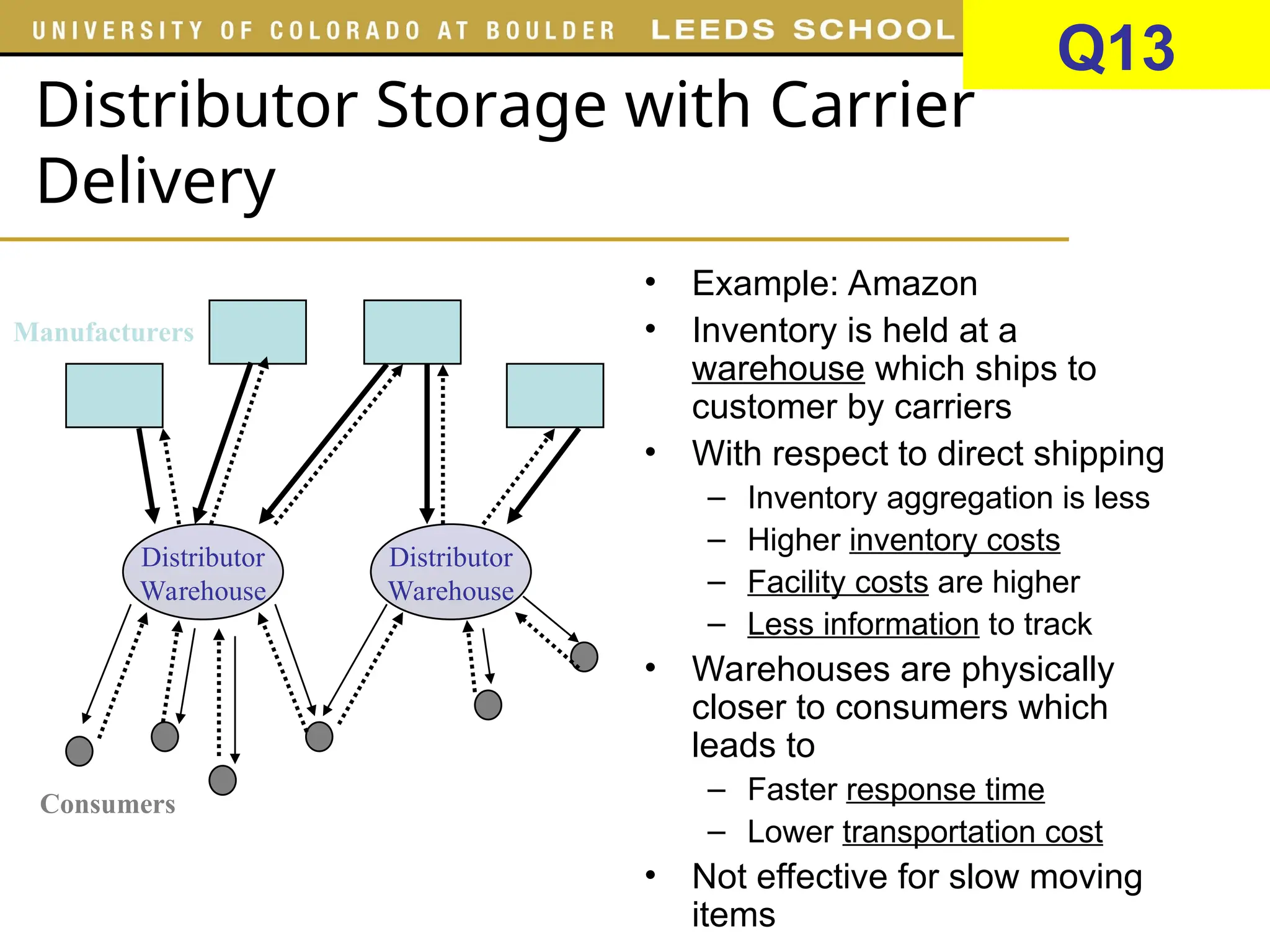

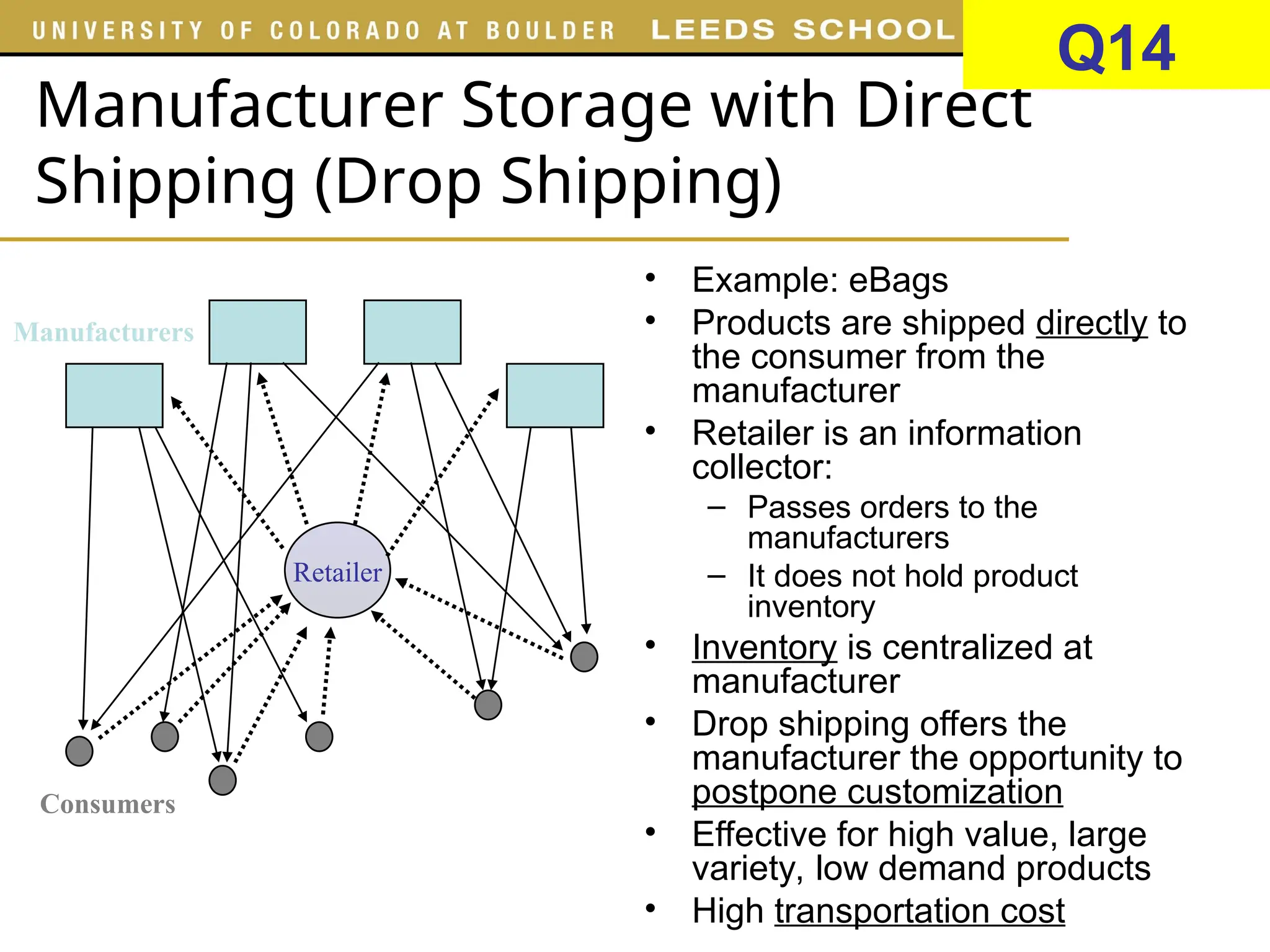

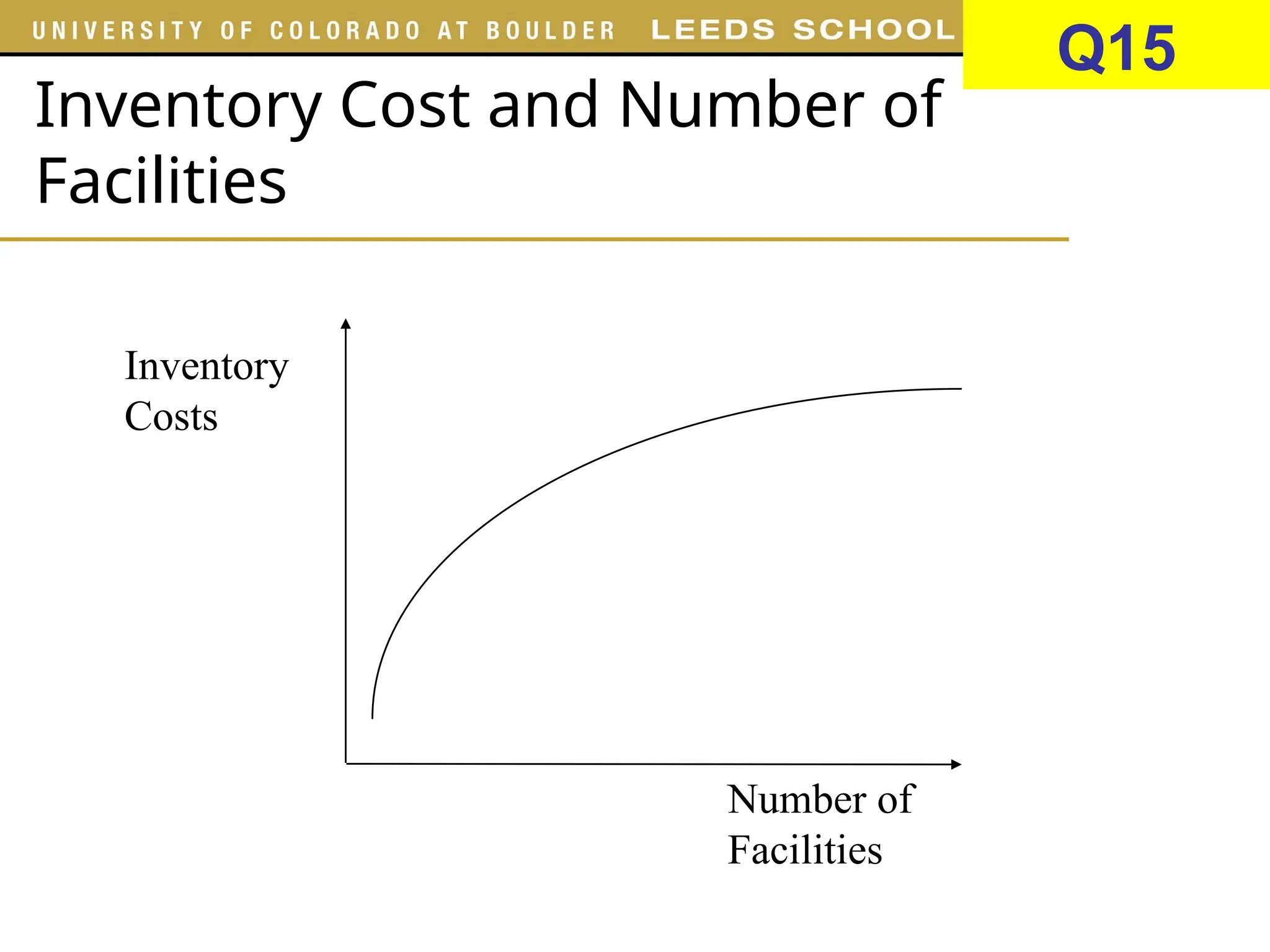

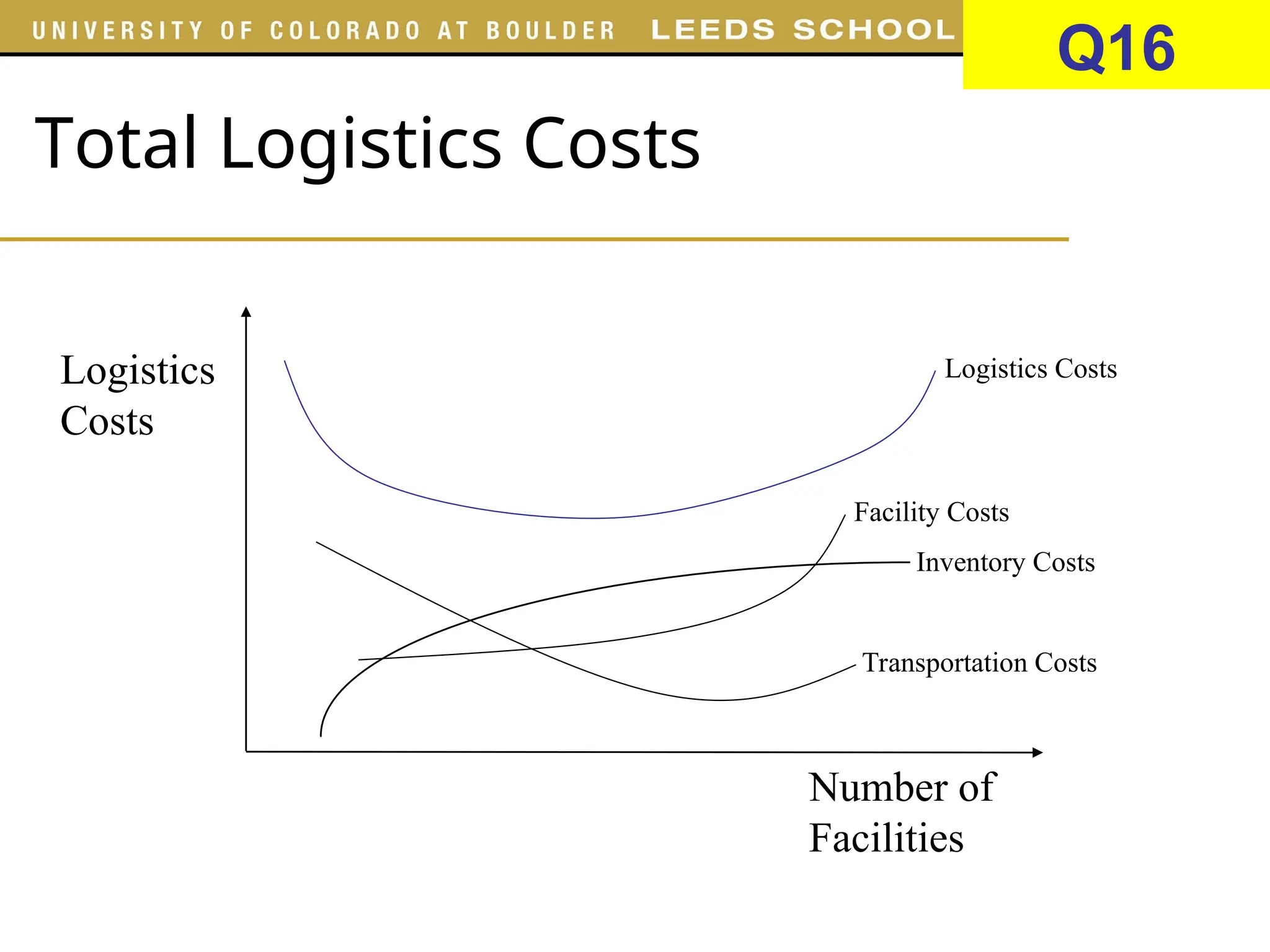

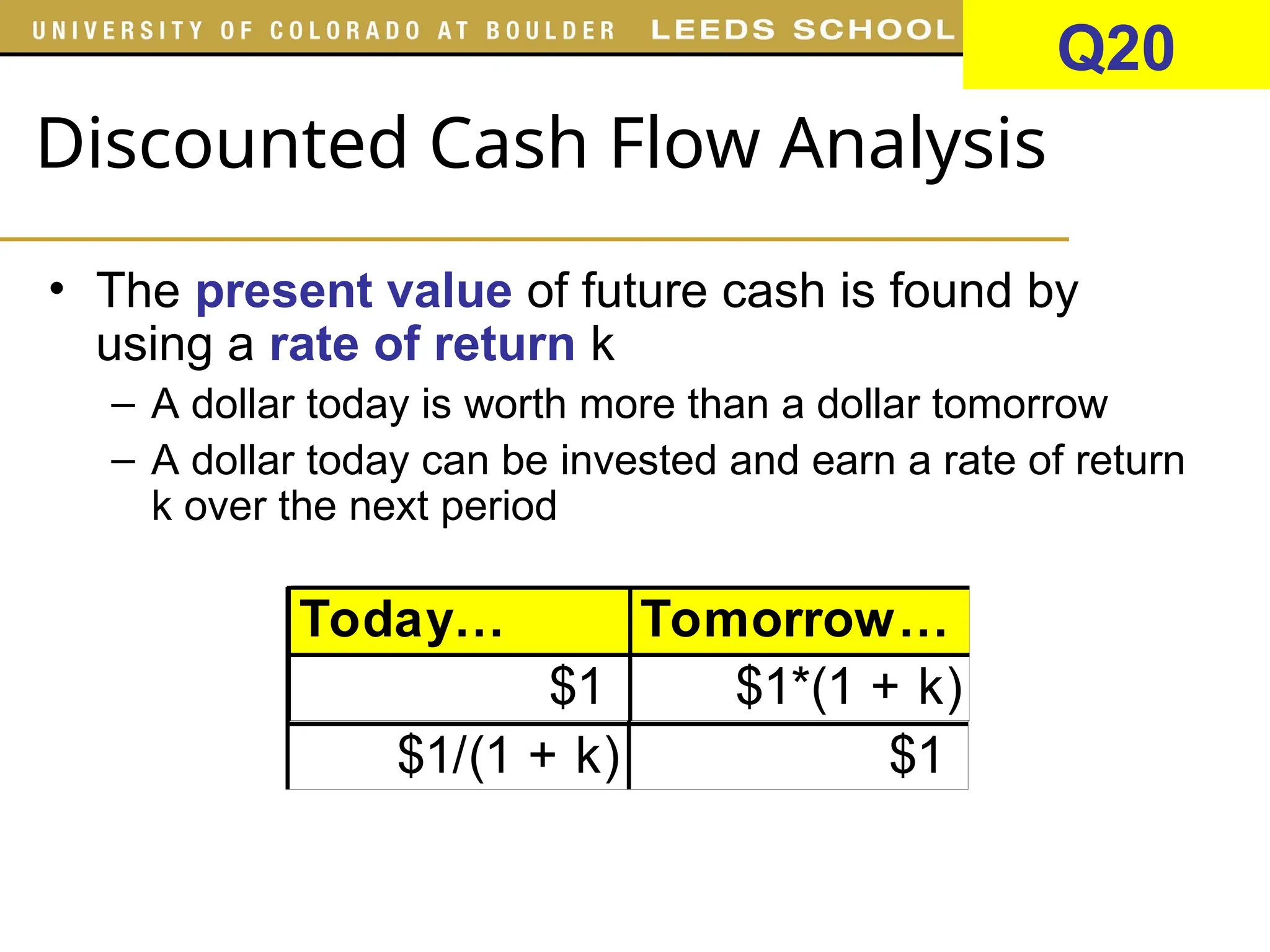

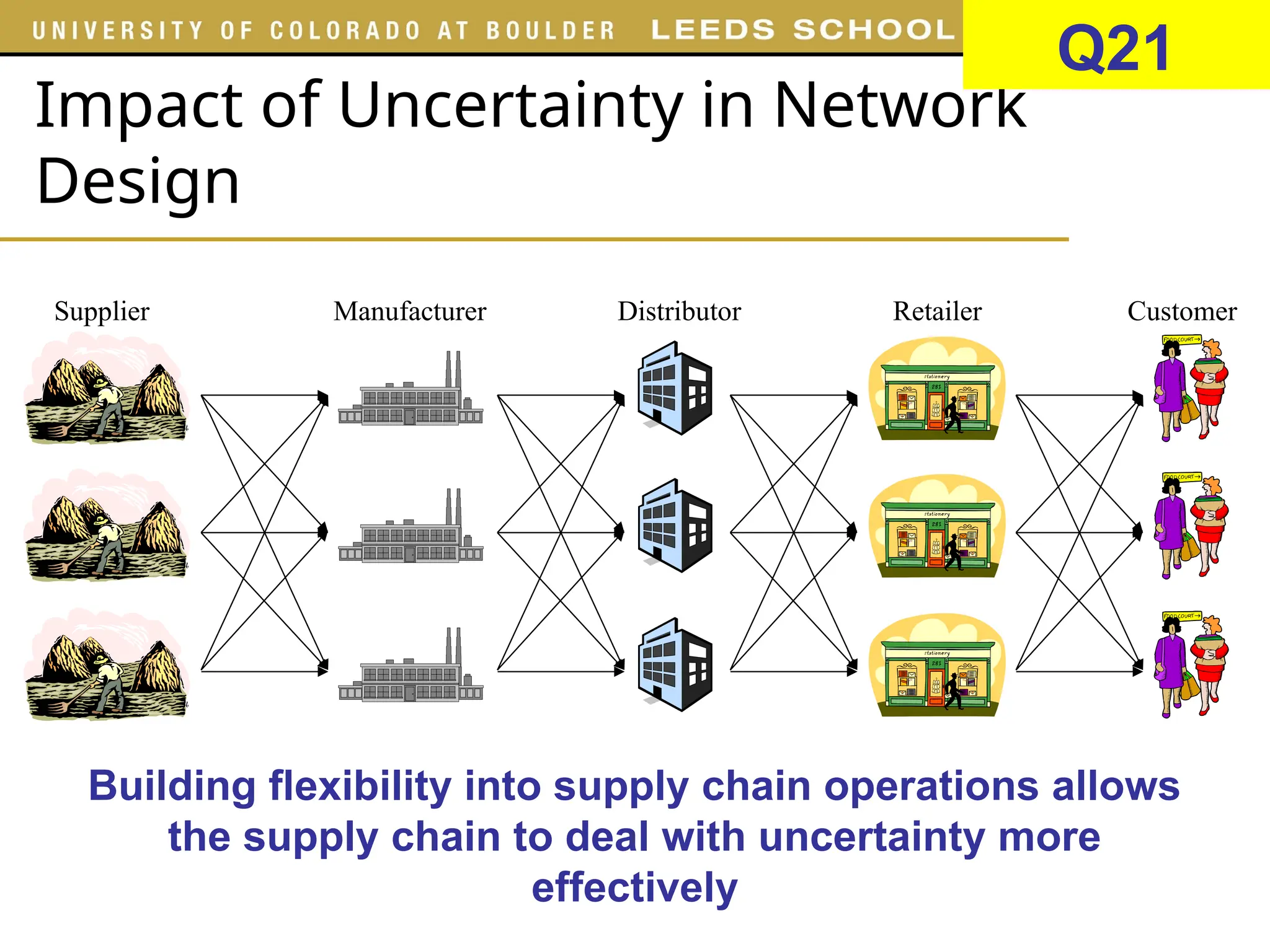

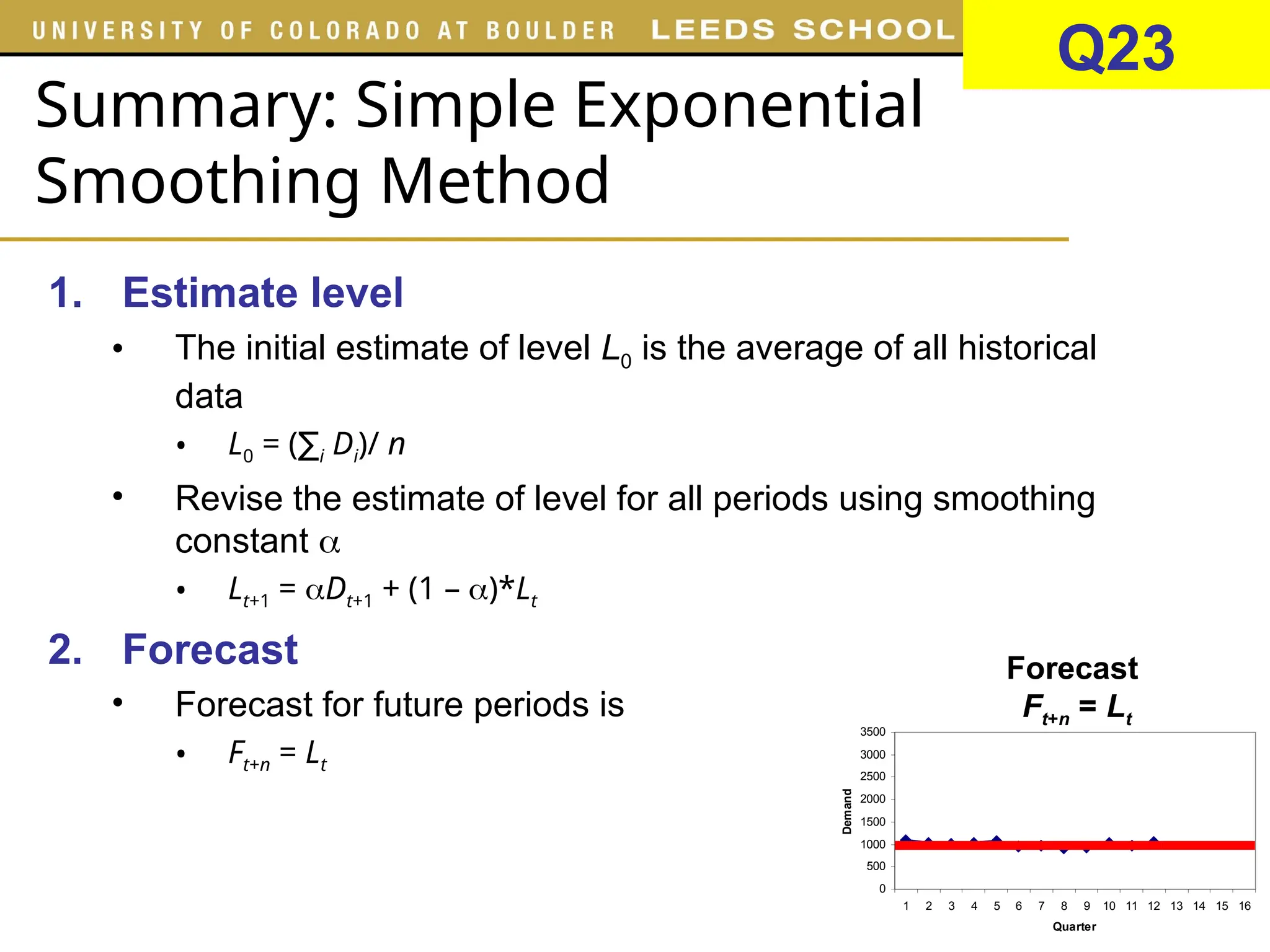

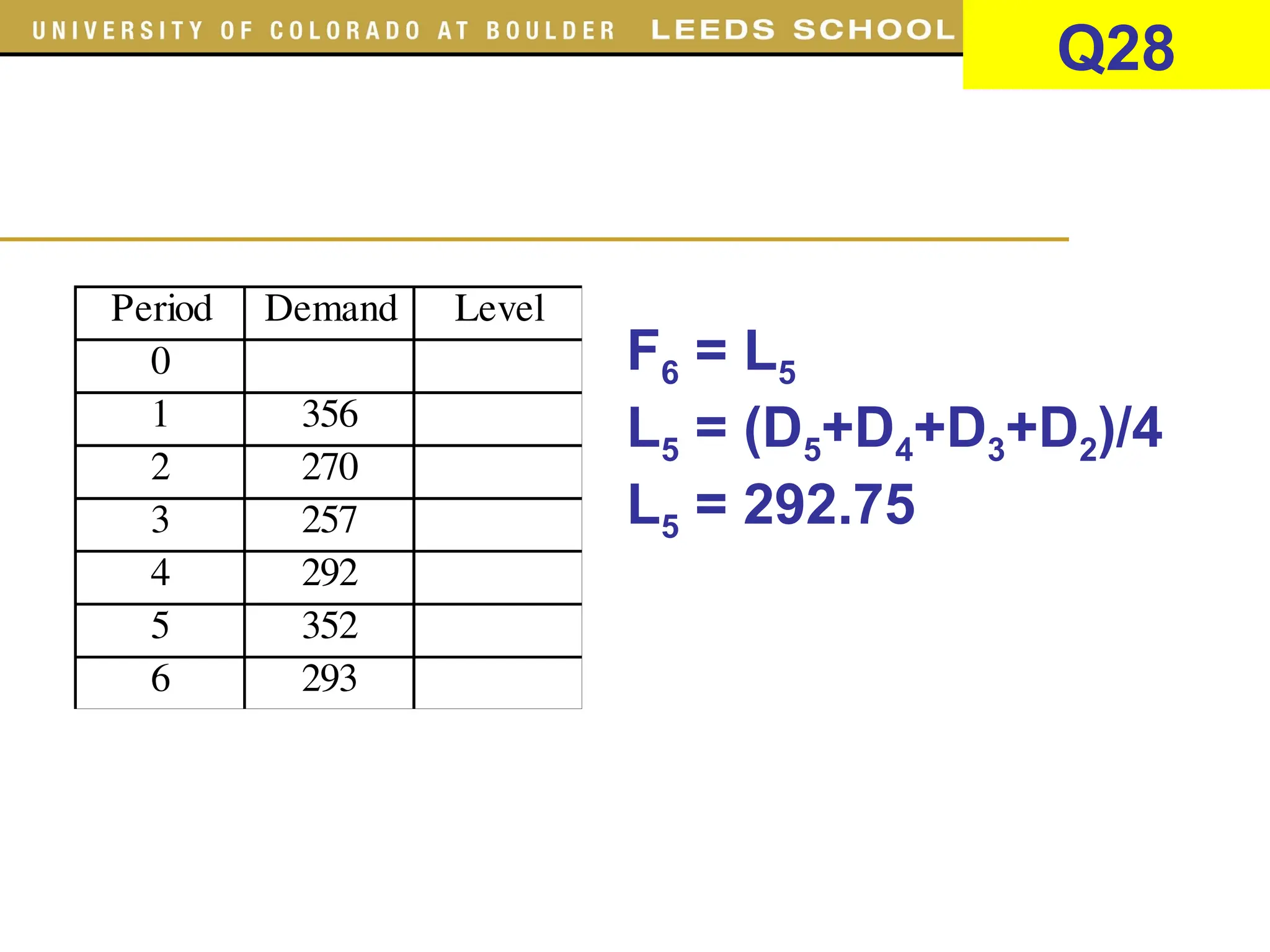

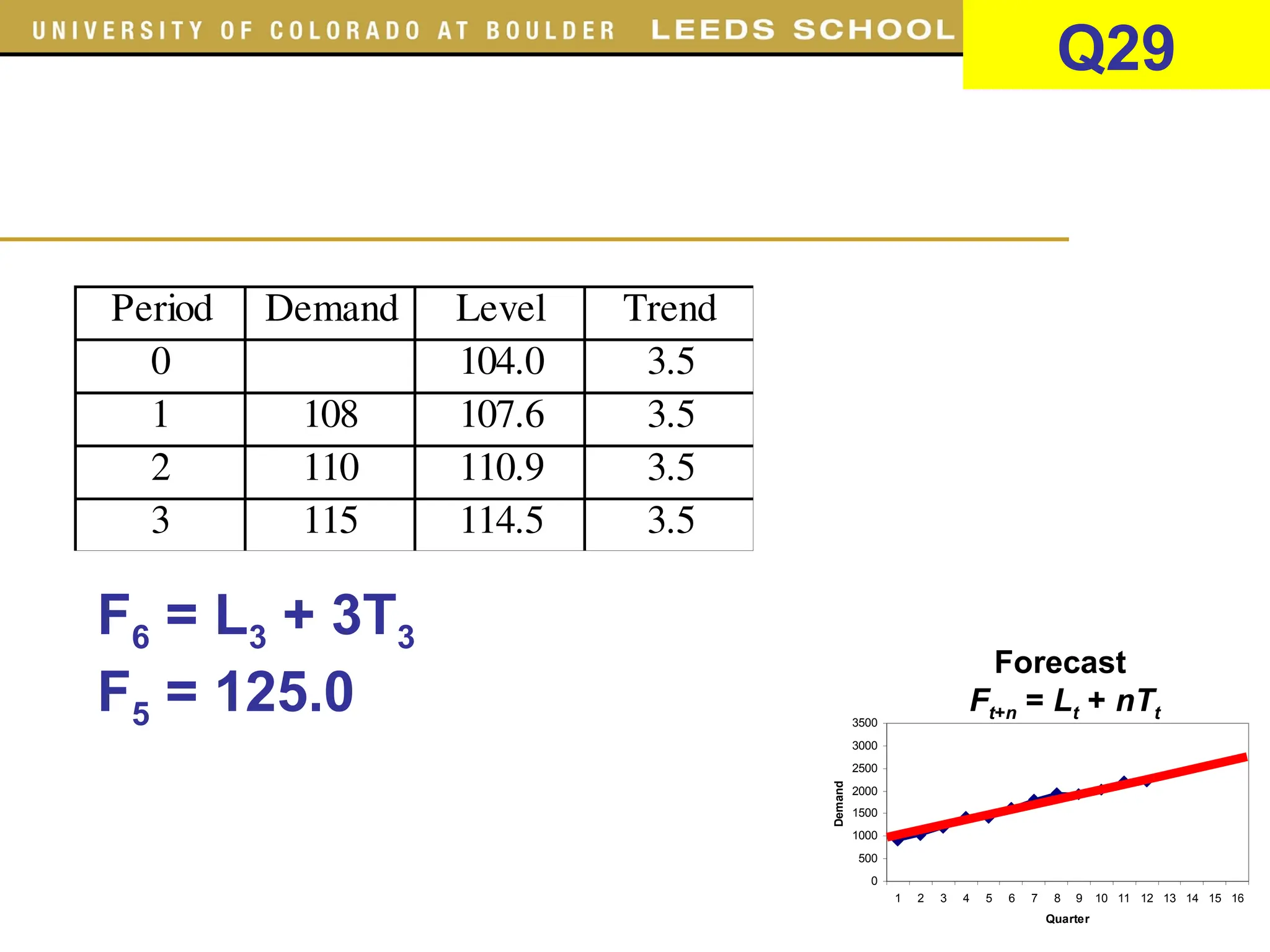

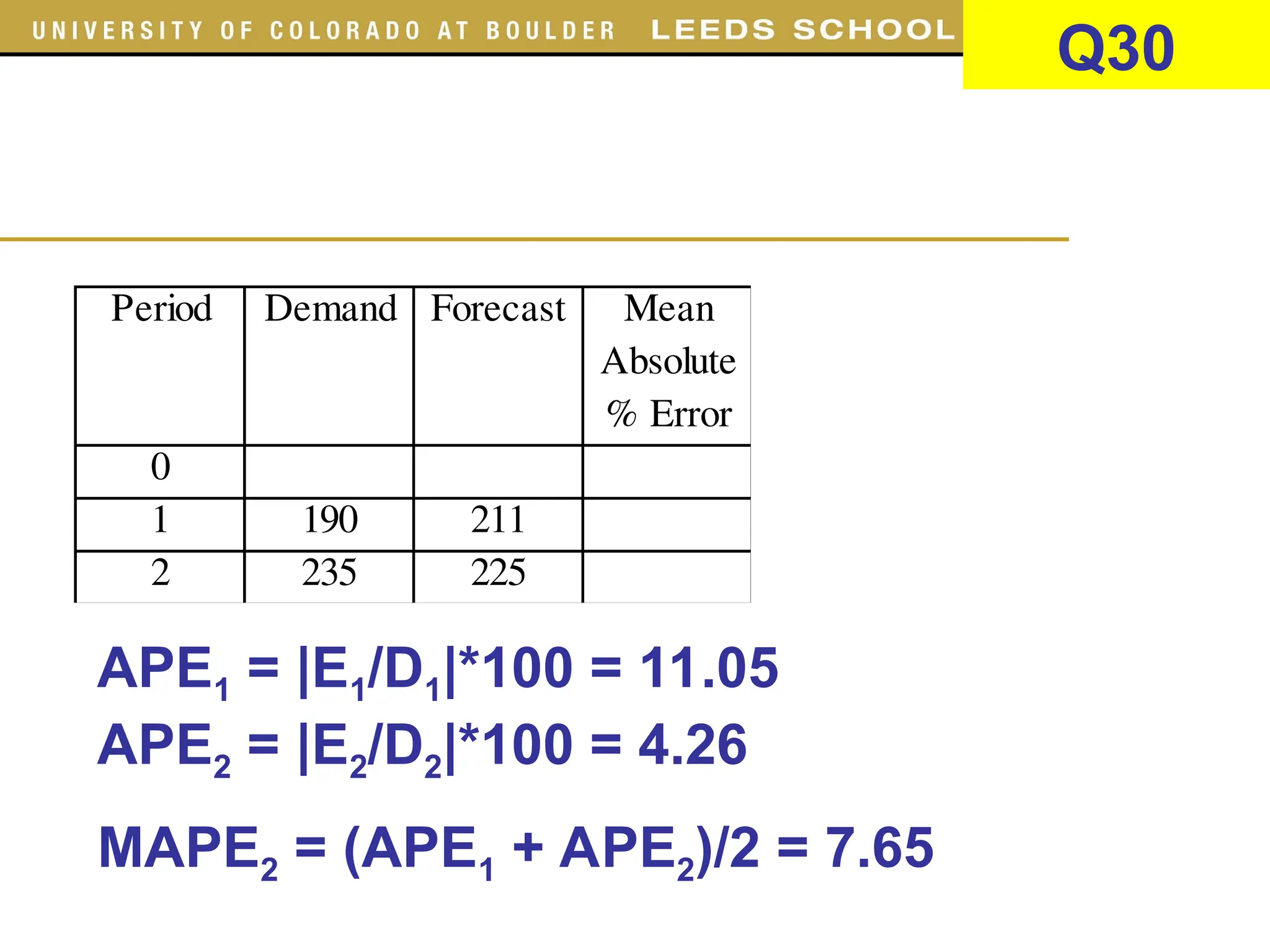

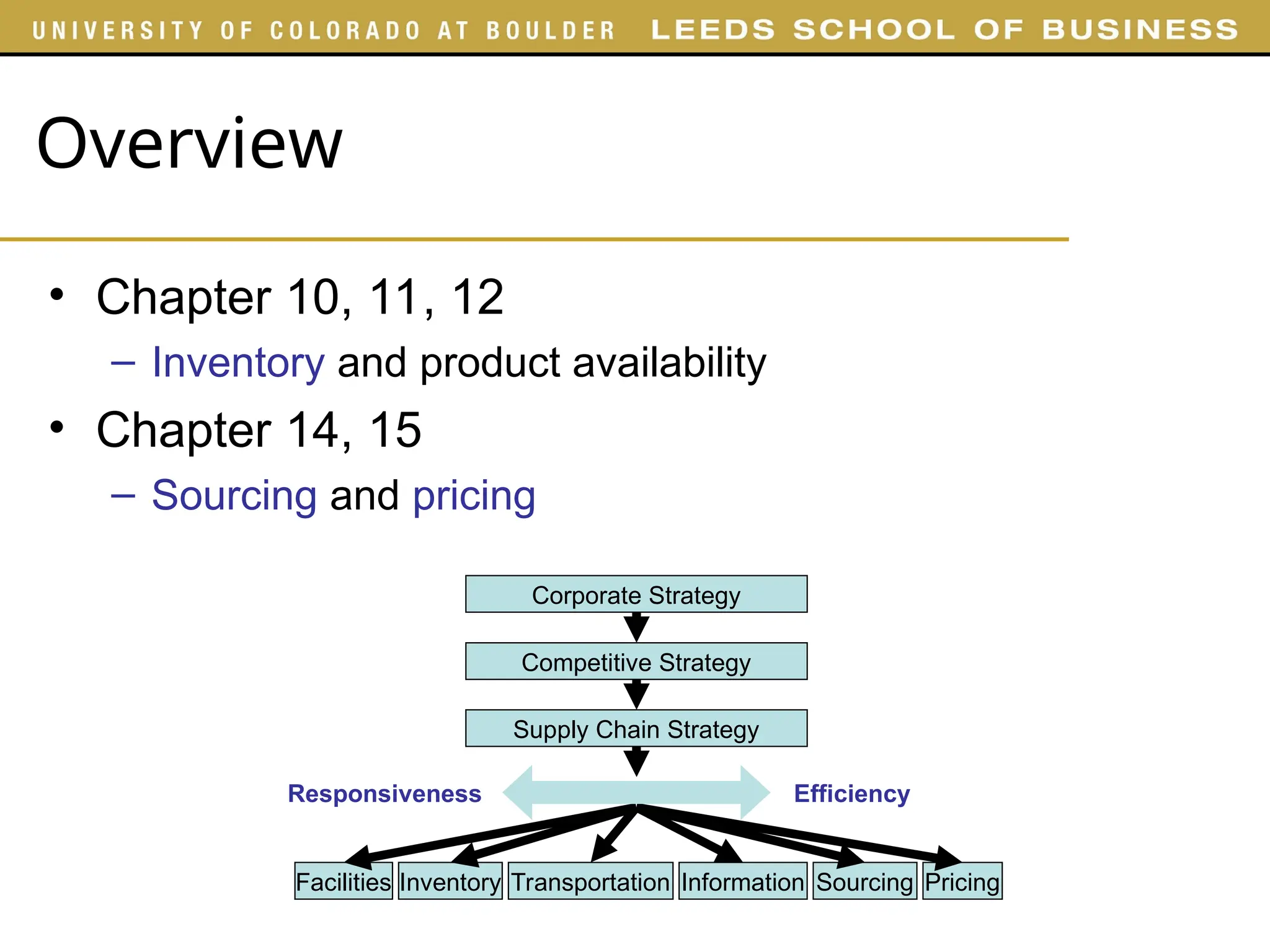

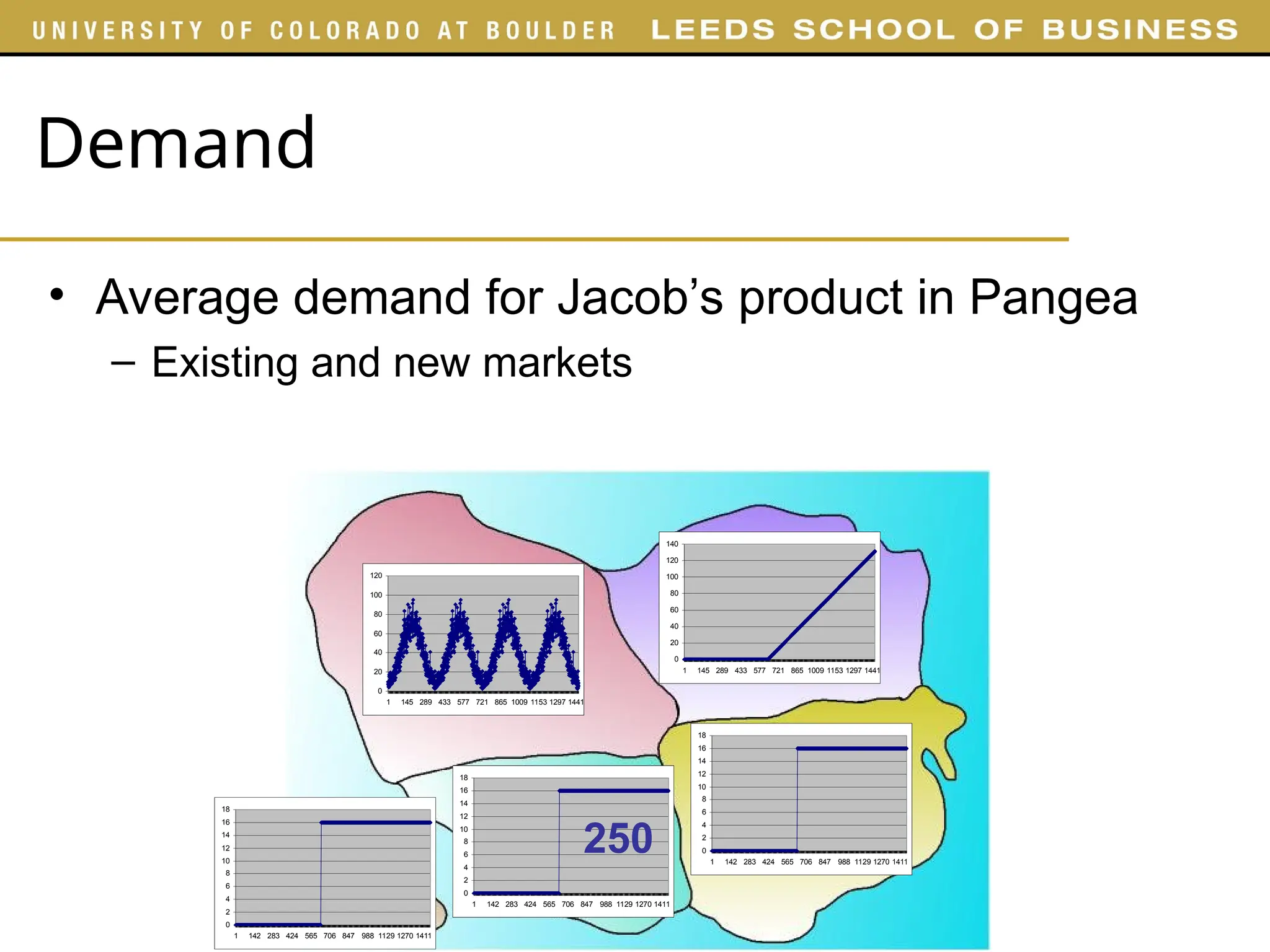

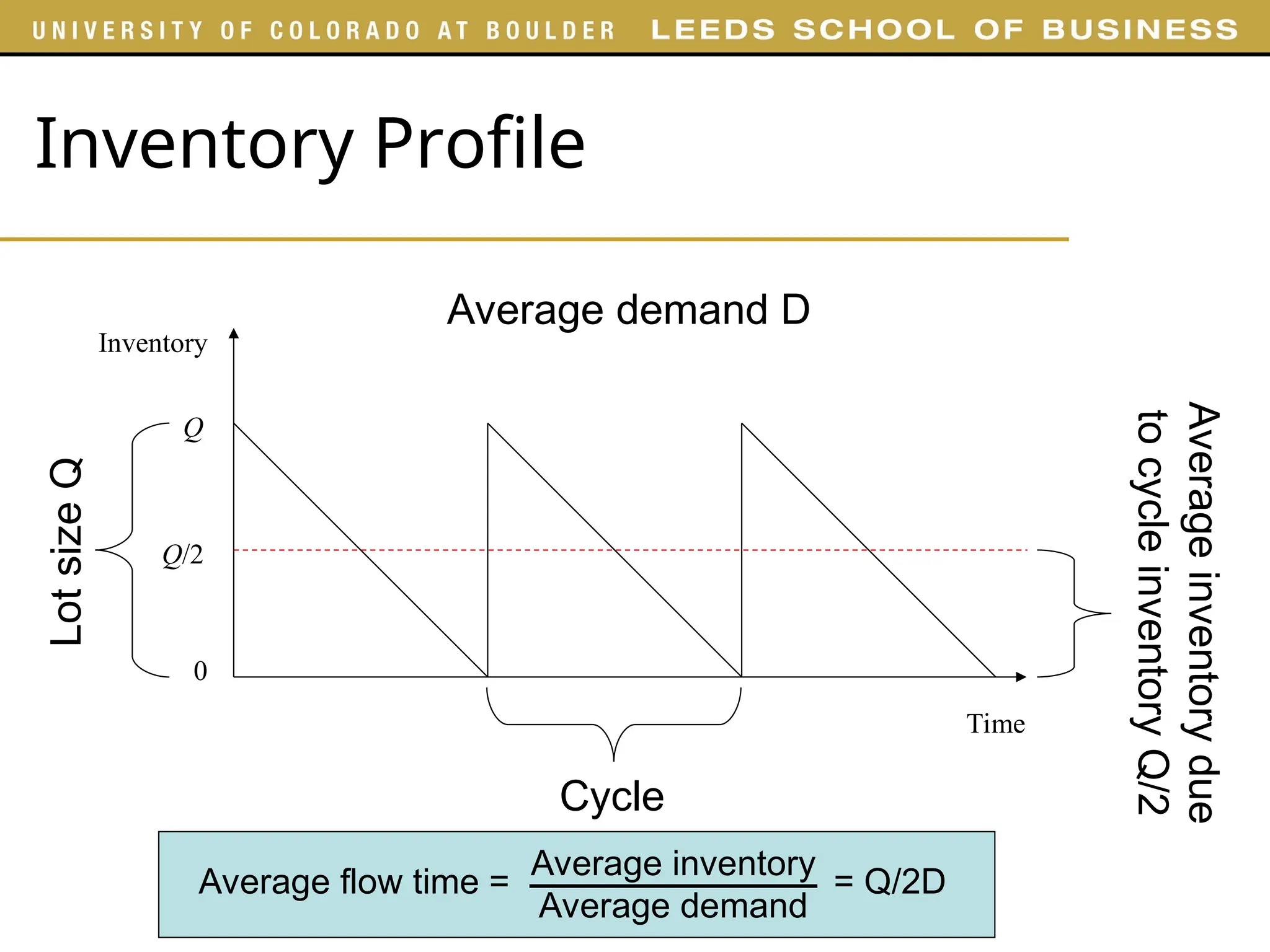

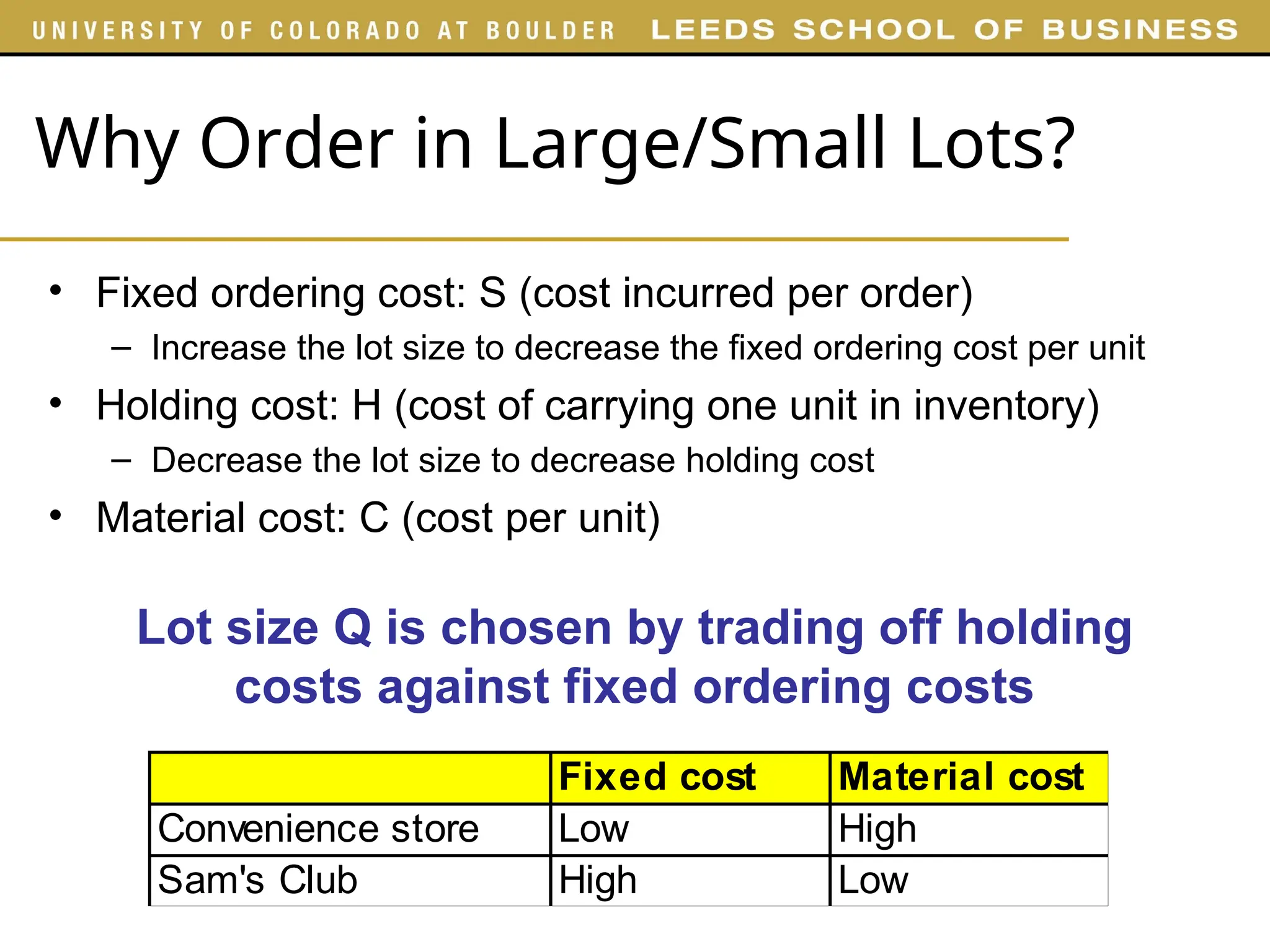

The document outlines a supply chain management lecture that covers various concepts including supply chain stages, capabilities, and strategies for managing uncertainty and inventory. It discusses the push/pull view of processes, the importance of effective network design, and various forecasting methods to predict demand. Additionally, it highlights the balance between inventory investment and customer service as well as strategies for optimizing order quantities and frequency.