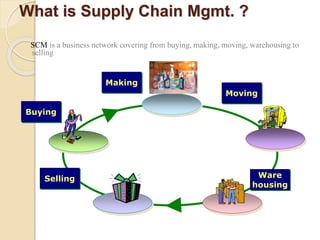

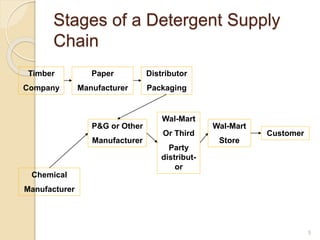

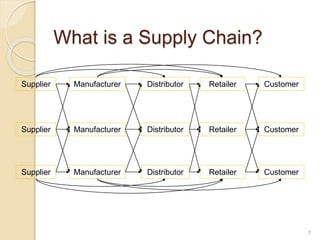

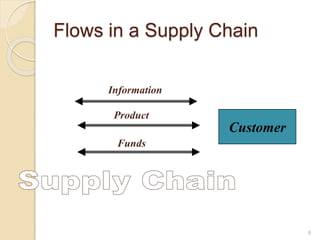

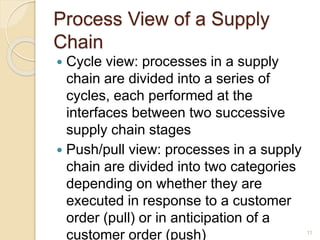

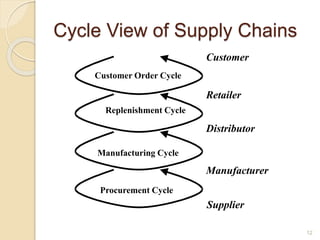

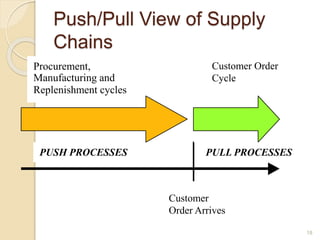

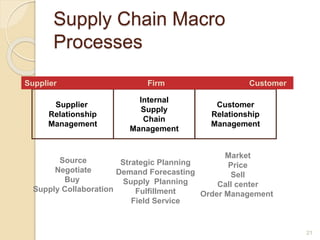

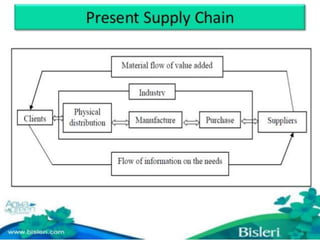

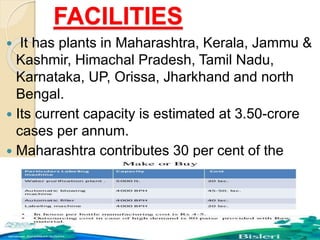

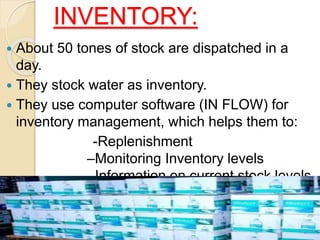

The document provides an overview of supply chain management concepts. It defines a supply chain as including all stages involved in fulfilling a customer request, from suppliers to manufacturers to distributors and retailers. It describes key supply chain flows of information, products, and funds. It also presents different views of viewing supply chains, including the cycle view defining different cycles like procurement, manufacturing, and replenishment, and the push/pull view distinguishing between processes executed in response to customer demand versus in anticipation of demand. Finally it provides examples of supply chains for companies like Toyota, Amazon, and Bisleri mineral water.