The cement manufacturing process involves 4 main steps:

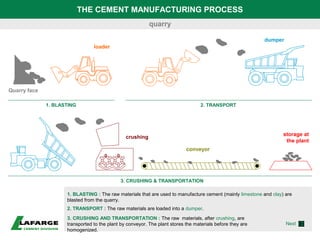

1. Quarrying of raw materials such as limestone and clay, which are then crushed and transported to the cement plant.

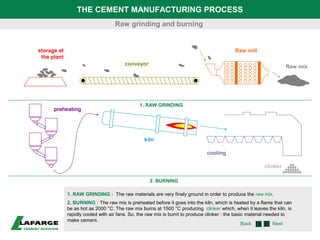

2. Grinding the raw materials into a fine powder and preheating them before burning in a kiln at 1500°C to form clinker.

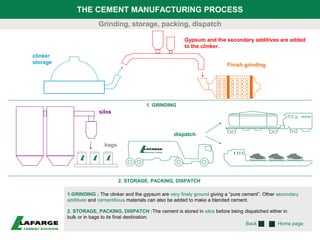

3. Finely grinding the clinker with gypsum and other additives to produce pure cement powder.

4. Storing the cement in silos and packing or dispatching it for distribution.