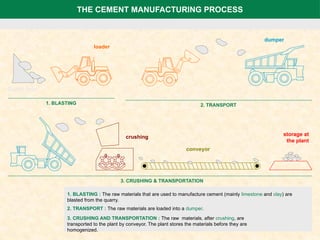

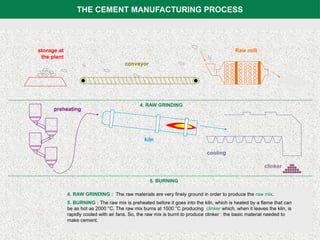

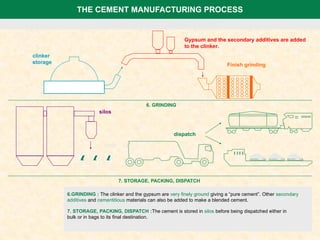

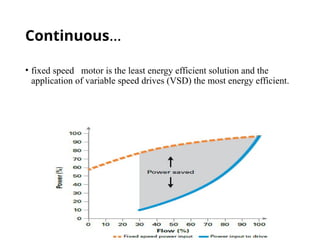

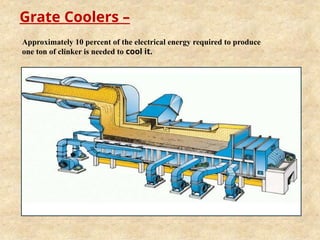

The document presents an industrial training report by Praveen Nuwal at J.K. Cement Ltd, detailing the company's history, types of cement produced, and the manufacturing process. It covers specific stages from raw material handling through to grinding and dispatch, highlighting energy optimization techniques used in production. The conclusion emphasizes the educational experience gained through exposure to various departments in the cement manufacturing process.