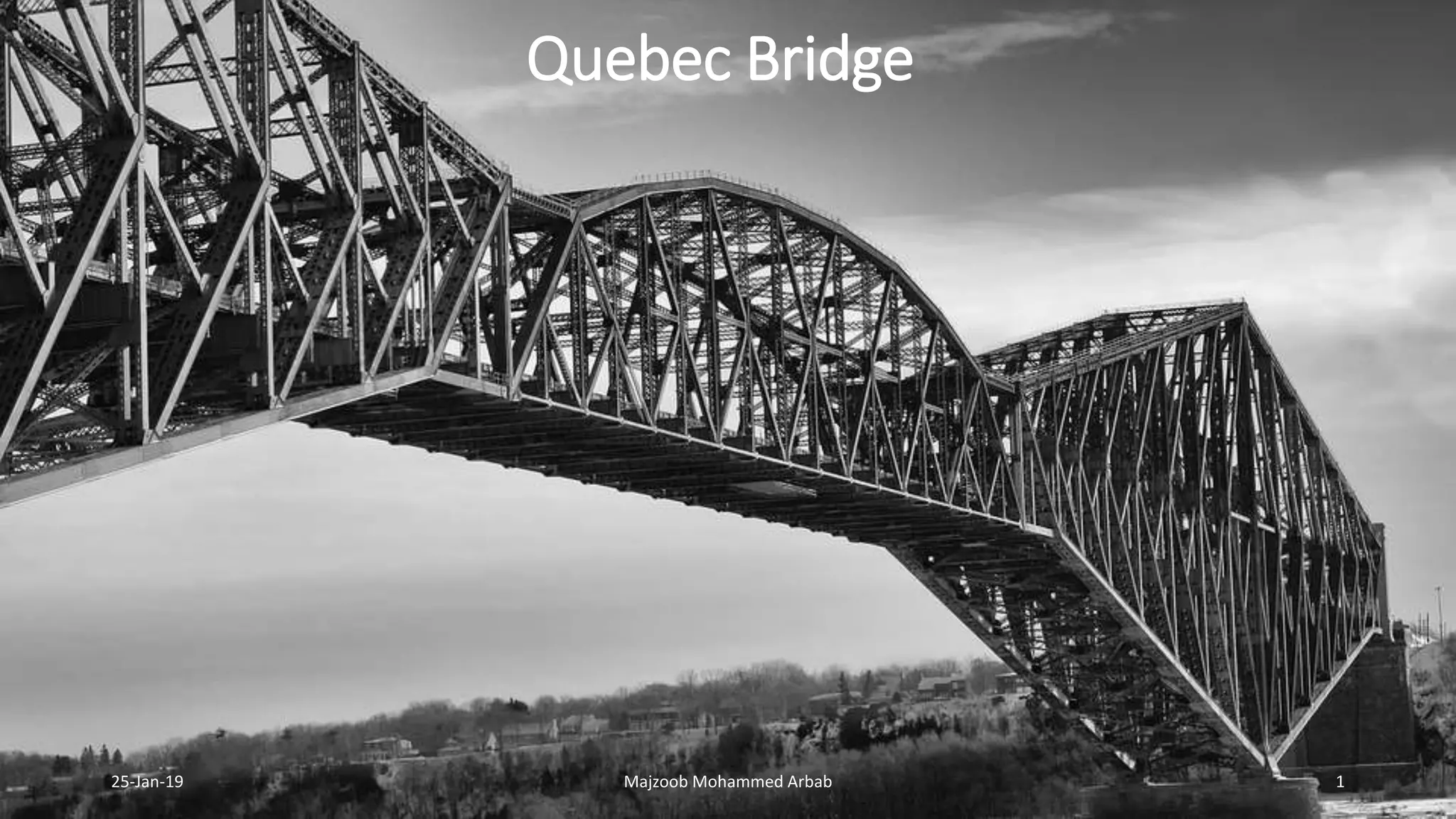

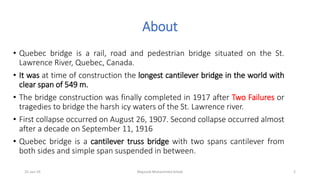

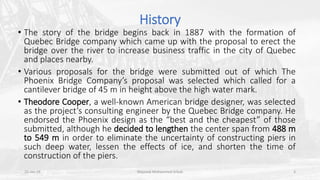

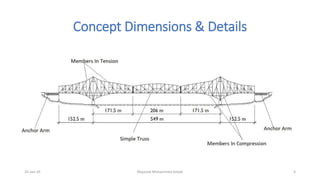

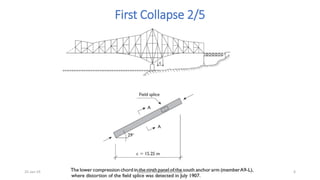

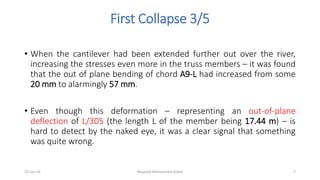

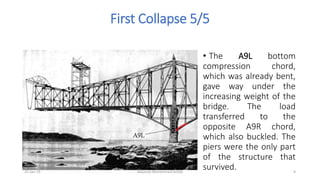

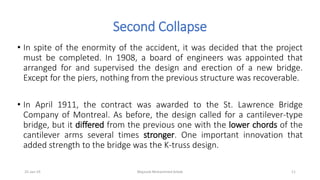

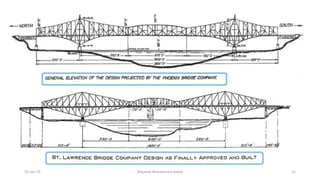

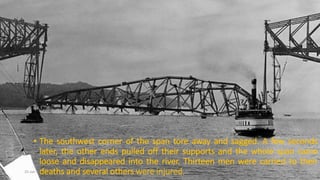

The Quebec Bridge, spanning the St. Lawrence River in Canada, was the longest cantilever bridge during its time and faced two significant collapses during construction in 1907 and 1916 due to structural miscalculations and pressures to proceed. Following these tragedies, a new design was established, utilizing a stronger k-truss design, leading to its completion in 1917. The incidents prompted the creation of Canadian design specifications for bridged engineering and highlighted the need for a collaborative approach in major structural projects.