Additive manufacturing ppt3

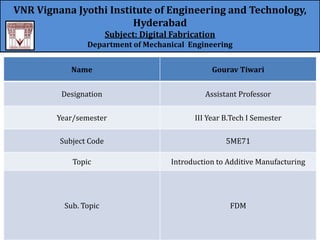

- 1. VNR Vignana Jyothi Institute of Engineering and Technology, Hyderabad Subject: Digital Fabrication Department of Mechanical Engineering Name Gourav Tiwari Designation Assistant Professor Year/semester III Year B.Tech I Semester Subject Code 5ME71 Topic Introduction to Additive Manufacturing Sub. Topic FDM

- 3. Introduction • These technologies can be visualized as similar to cake icing, in that material contained in a reservoir is forced out through a nozzle when pressure is applied • If the pressure remains constant, then the resulting extruded material will flow at a constant rate and will remain a constant cross-sectional diameter. This diameter will remain constant if the travel of the nozzle across a depositing surface is also kept at a constant speed that corresponds to the flow rate. • The material that is being extruded must be in a semi-solid state when it comes out of the nozzle. This material must fully solidify while remaining in that shape. • Furthermore, the material must bond to material that has already been extruded so that a solid structure can result.

- 4. • Once a layer is completed, the machine must index upwards, or move the part downwards, so th • There are two primary approaches when using an extrusion process. The most commonly used approach is to use temperature as a way of controlling the material state.at a further layer can be produced. • An second approach is to use a chemical change to cause solidification. In such cases, a curing agent, residual solvent, reaction with air, or simply drying of a “wet” material permits bonding to occur. Parts may therefore cure or dry out to become fully stable.

- 5. Basic Principles • Loading of material • Liquification of the material • Application of pressure to move the material through the nozzle • Extrusion • Plotting according to a predefined path and in a controlled manner • Bonding of the material to itself or secondary build materials to form a coherent solid structure • Inclusion of support structures to enable complex geometrical features

- 8. FDM Process • The modelling material is in spools — very much like a fishing line. • The filament on the spools is fed into an extrusion head and heated to a semi-liquid state. • The semi-liquid material is extruded through the head and then deposited in ultra thin layers from the FDM head, one layer at a time. • Since the air surrounding the head is maintained at a temperature below the materials’ melting point, the exiting material quickly solidifies. • Moving on the X–Y plane, the head follows the tool path generated • When the layer is completed, the head moves on to create the next layer. • The horizontal width of the extruded material can vary between 0.250 to 0.965 mm depending on model. • This feature, called “road width”, can vary from slice to slice. • Two modeller materials are dispensed through a dual tip mechanism in the FDM machine. • A primary modeller material is used to produce the model geometry and a secondary material, or release material, is used to produce the support structures.

- 9. Materials • The most popular material is the ABSplus material, which can be used on all current Stratasys FDM machines. This is an updated version of the original ABS (acrylonitrile butadiene styrene) material that was developed for earlier FDM technology. • ABSi material, which has similar properties to other materials in the ABS range. • Some machines also have an option for ABS blended with Polycarbonate. • PC-ISO, which is also PC-based. This material, while weaker than the normal PC with a flexural strength of 90 MPa, is certified for use in food and drug packaging and medical device manufacture. • Another material that has been developed to suit industrial standards is the ULTEM 9085 material. This has particularly favourable flame, smoke, and toxicity (FST) ratings that makes it suitable for use in aircraft, marine, and ground vehicles. • FDM works best with polymers that are amorphous in nature rather than the highly crystalline polymers that are more suitable for PBF processes. This is because the polymers that work best are those that are extruded in a viscous paste rather than in a lower viscosity form. • The viscosity at which these amorphous polymers can be extruded under pressure is high enough that their shape will be largely maintained after extrusion, maintaining the extrusion shape and enabling them to solidify quickly and easily.