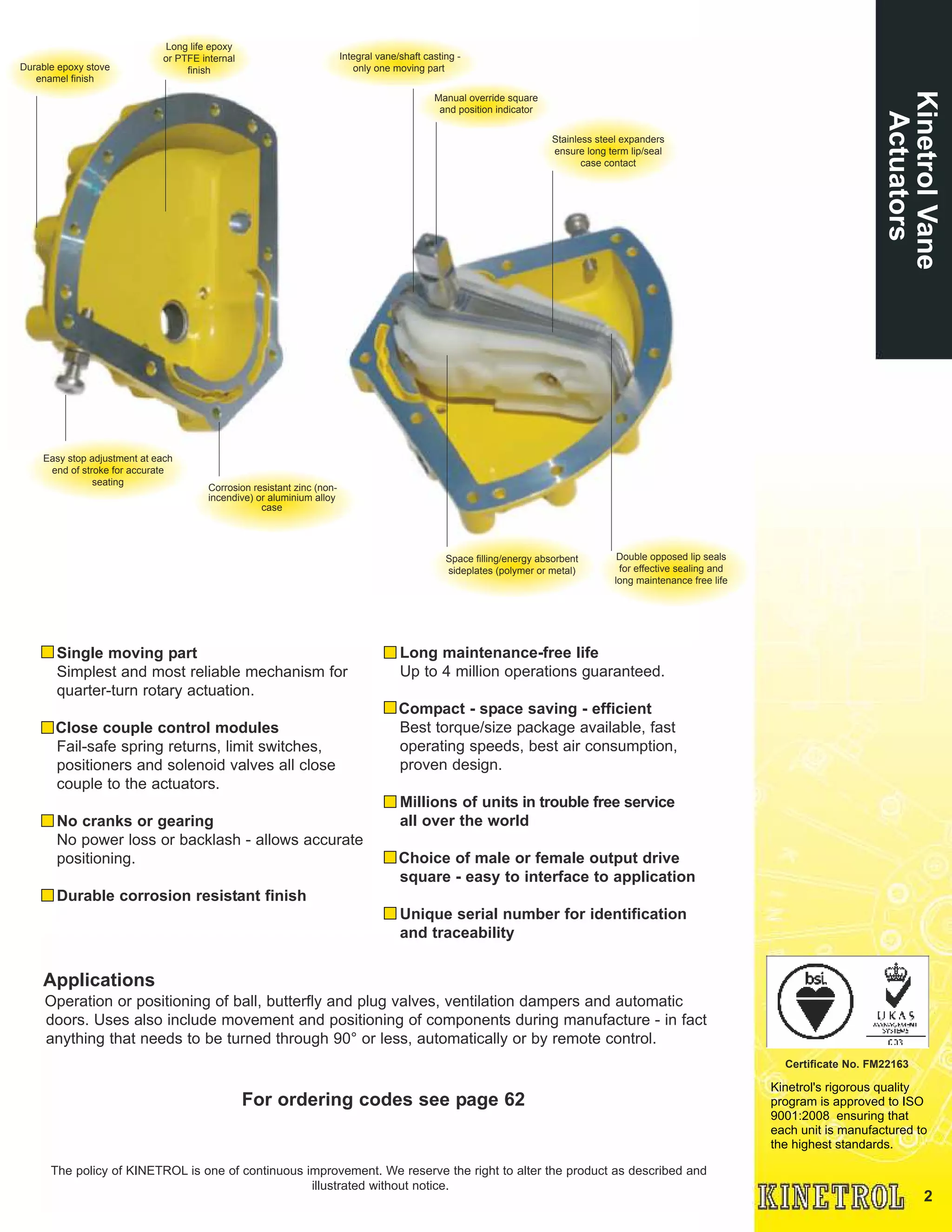

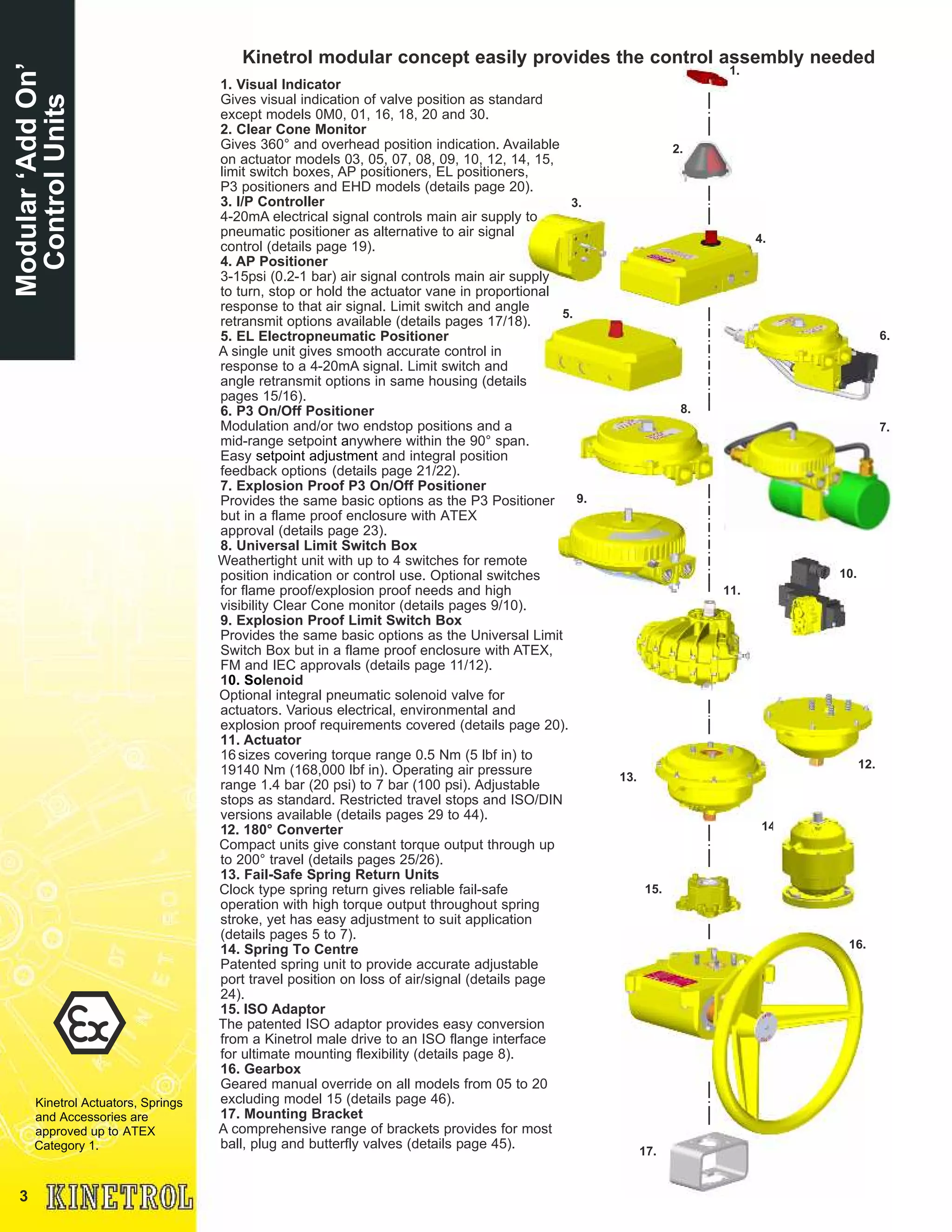

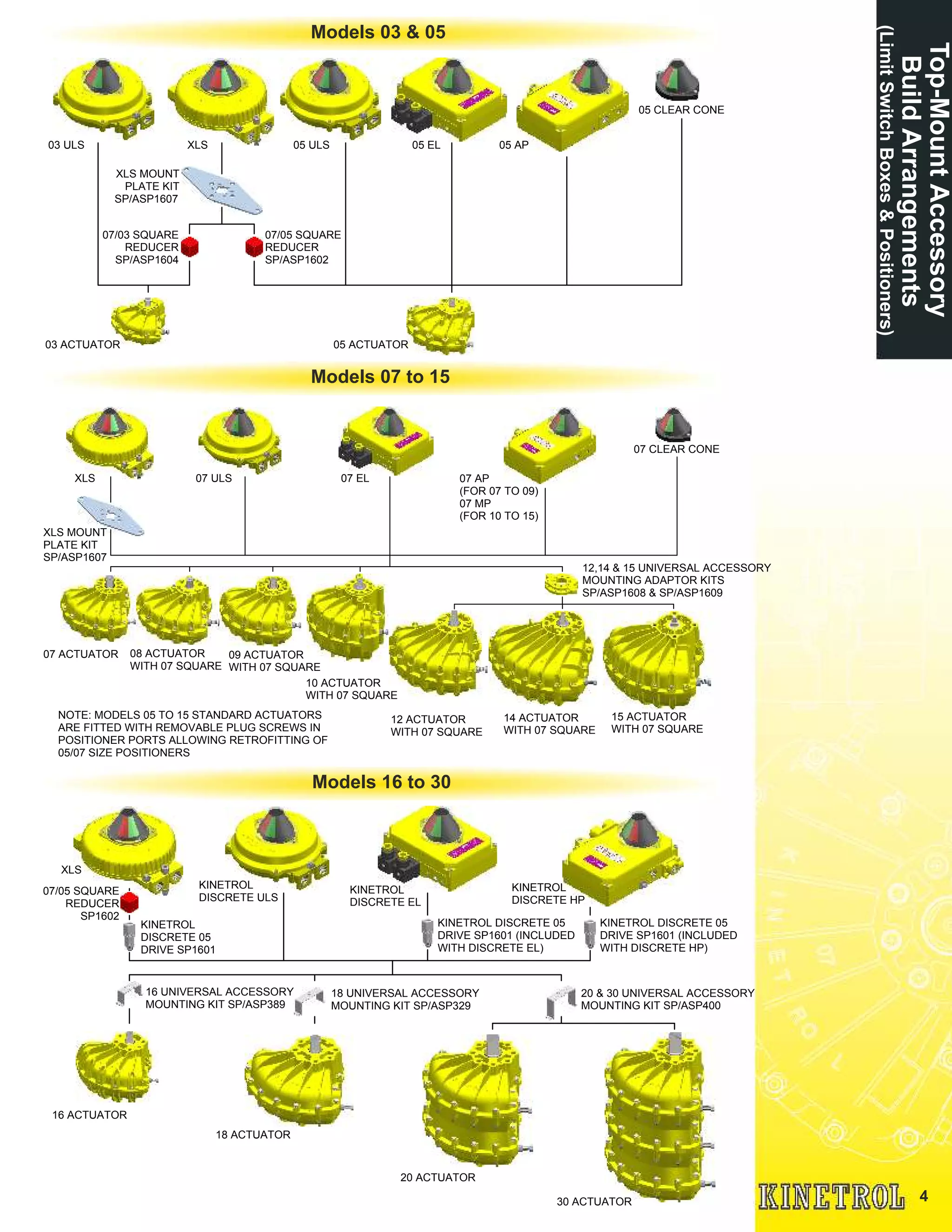

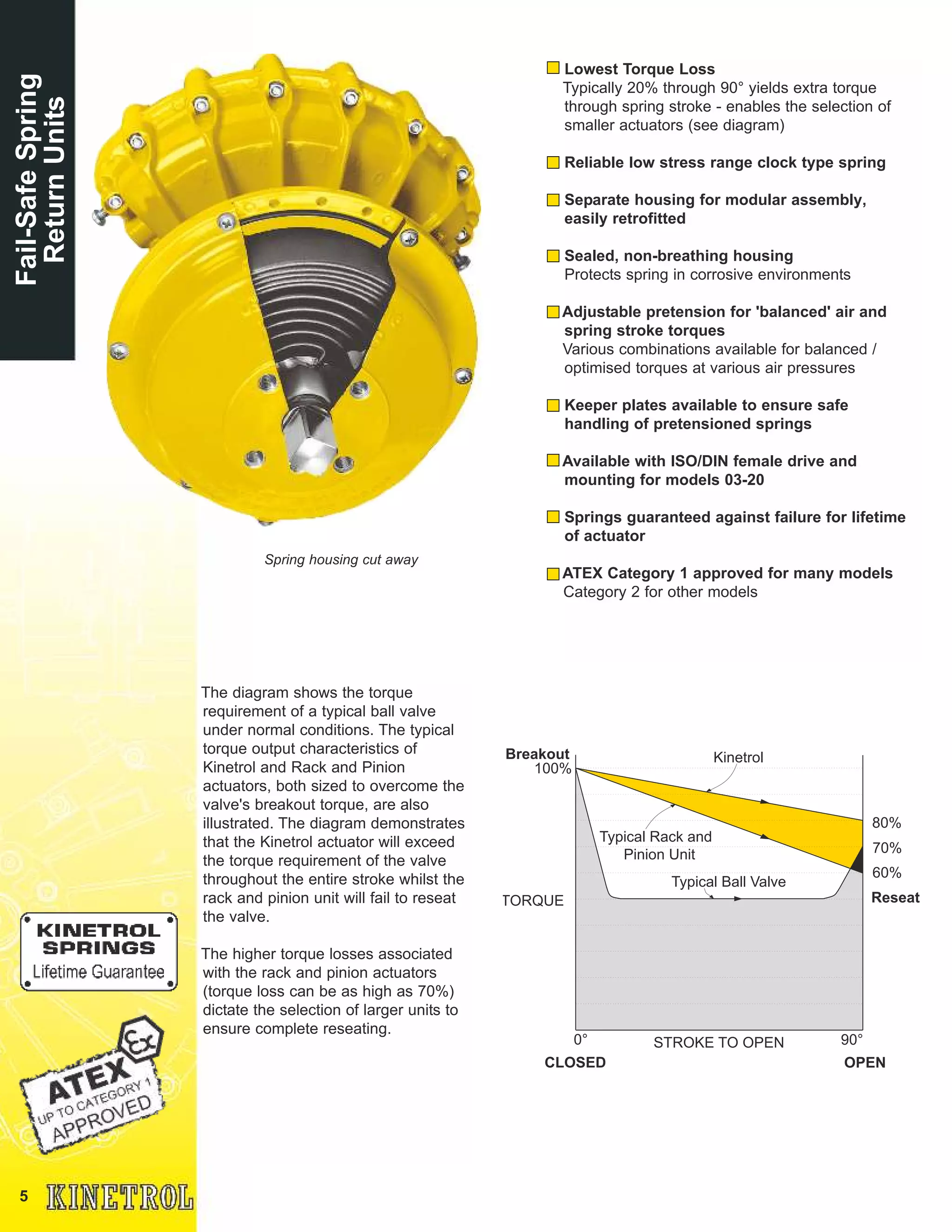

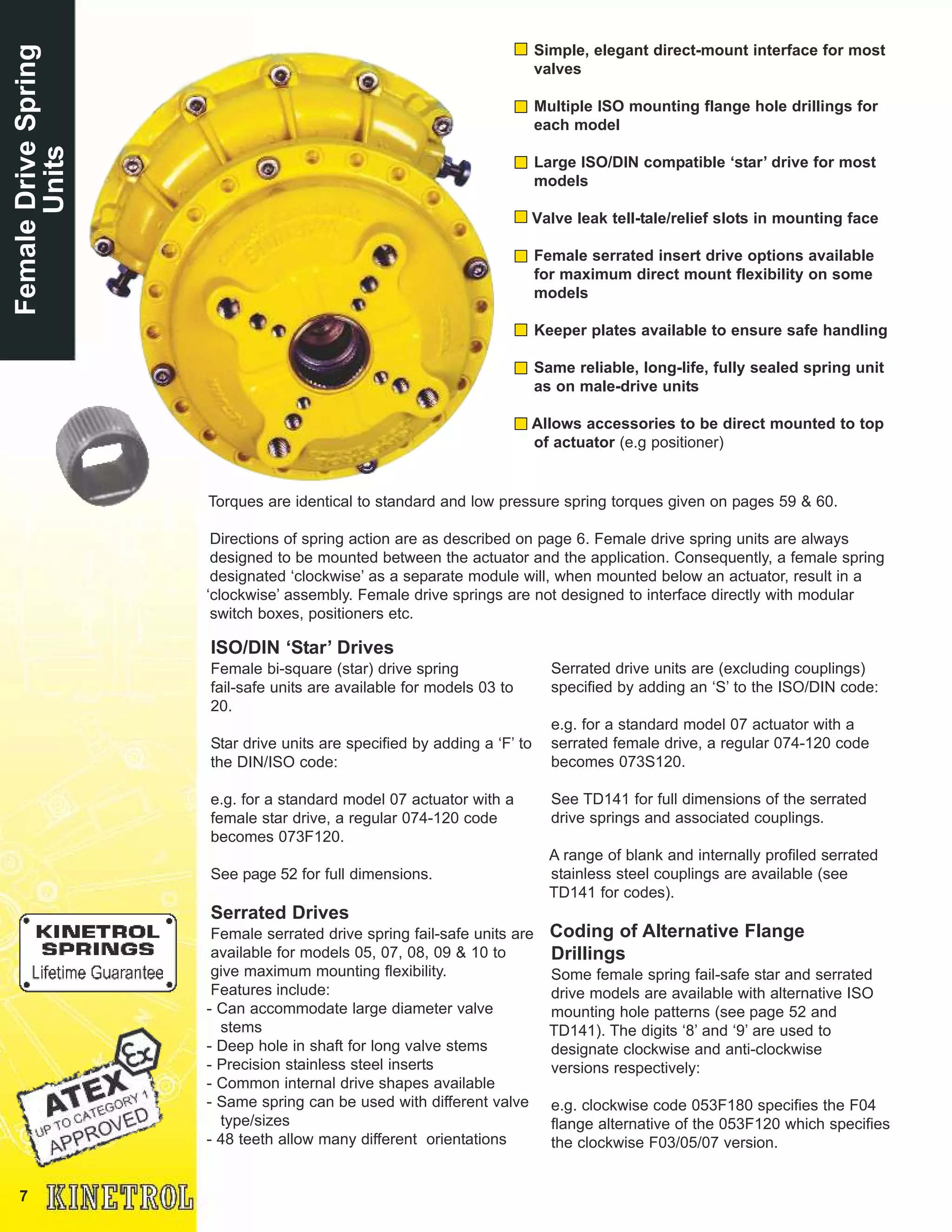

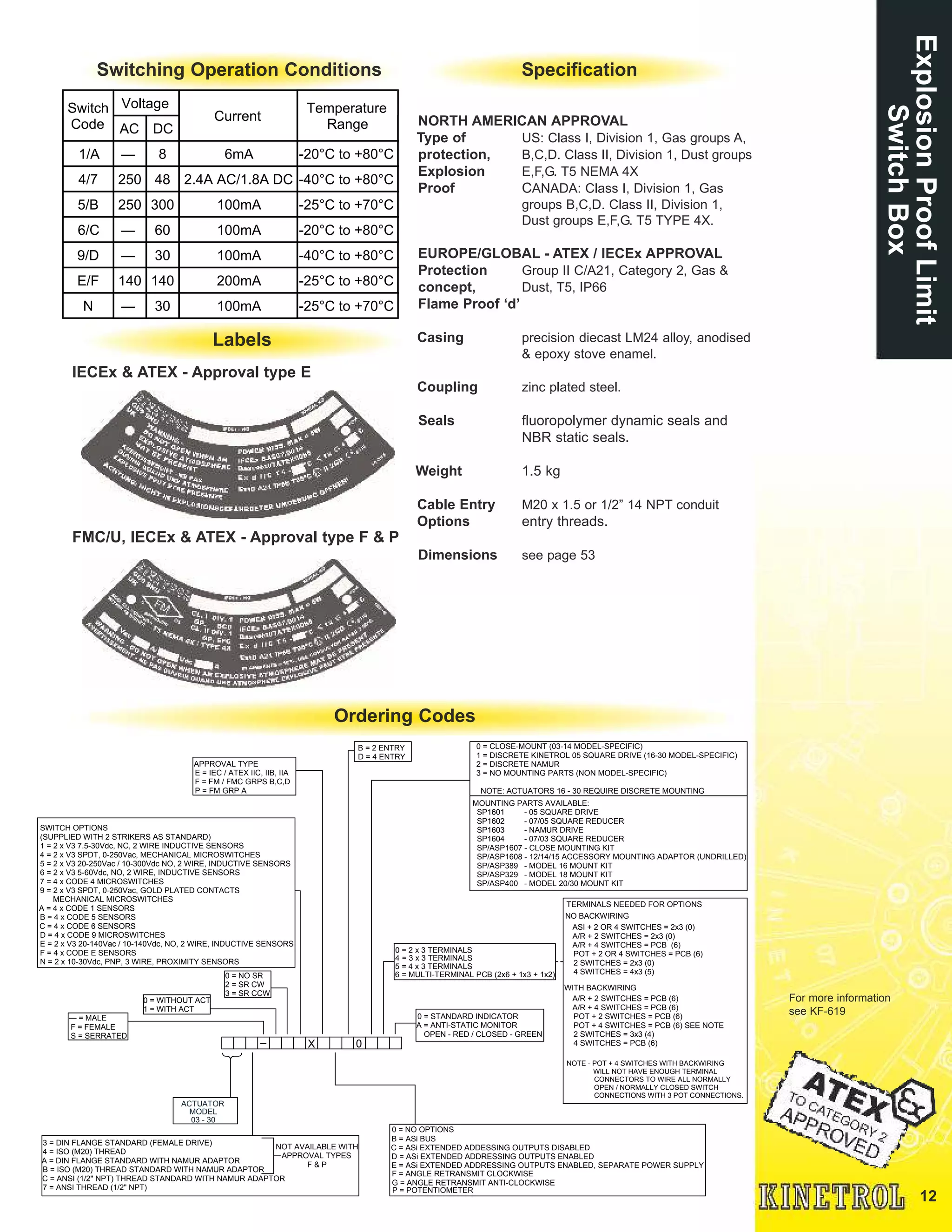

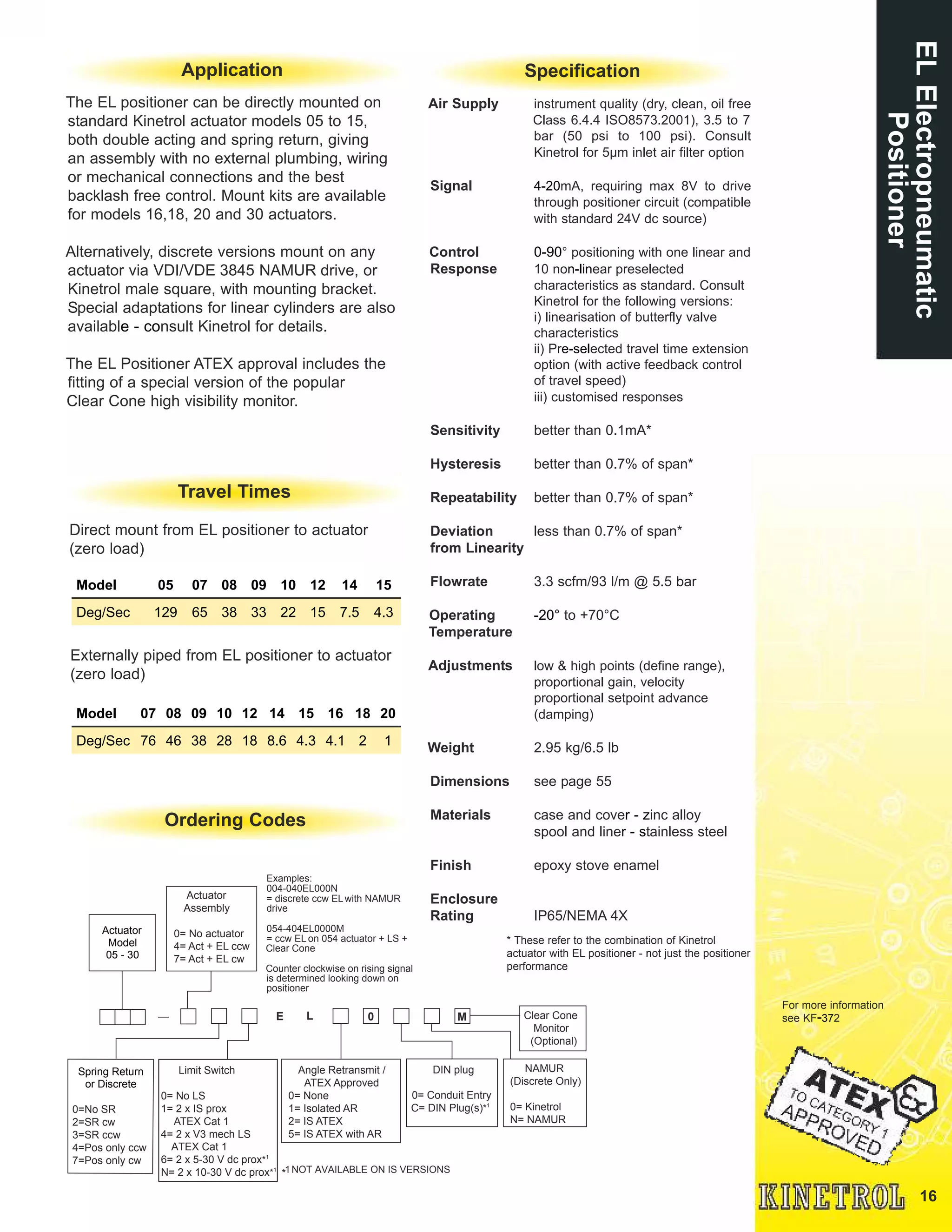

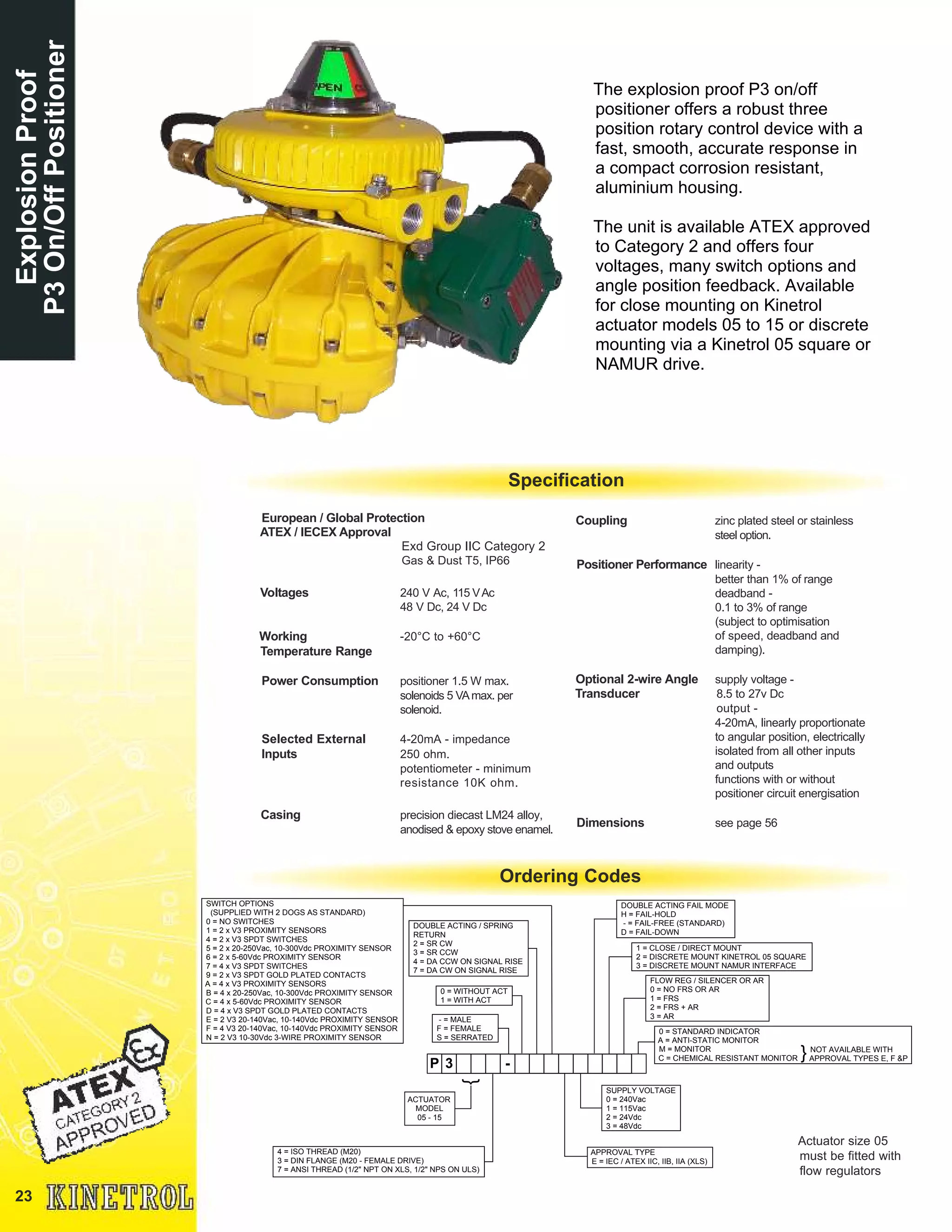

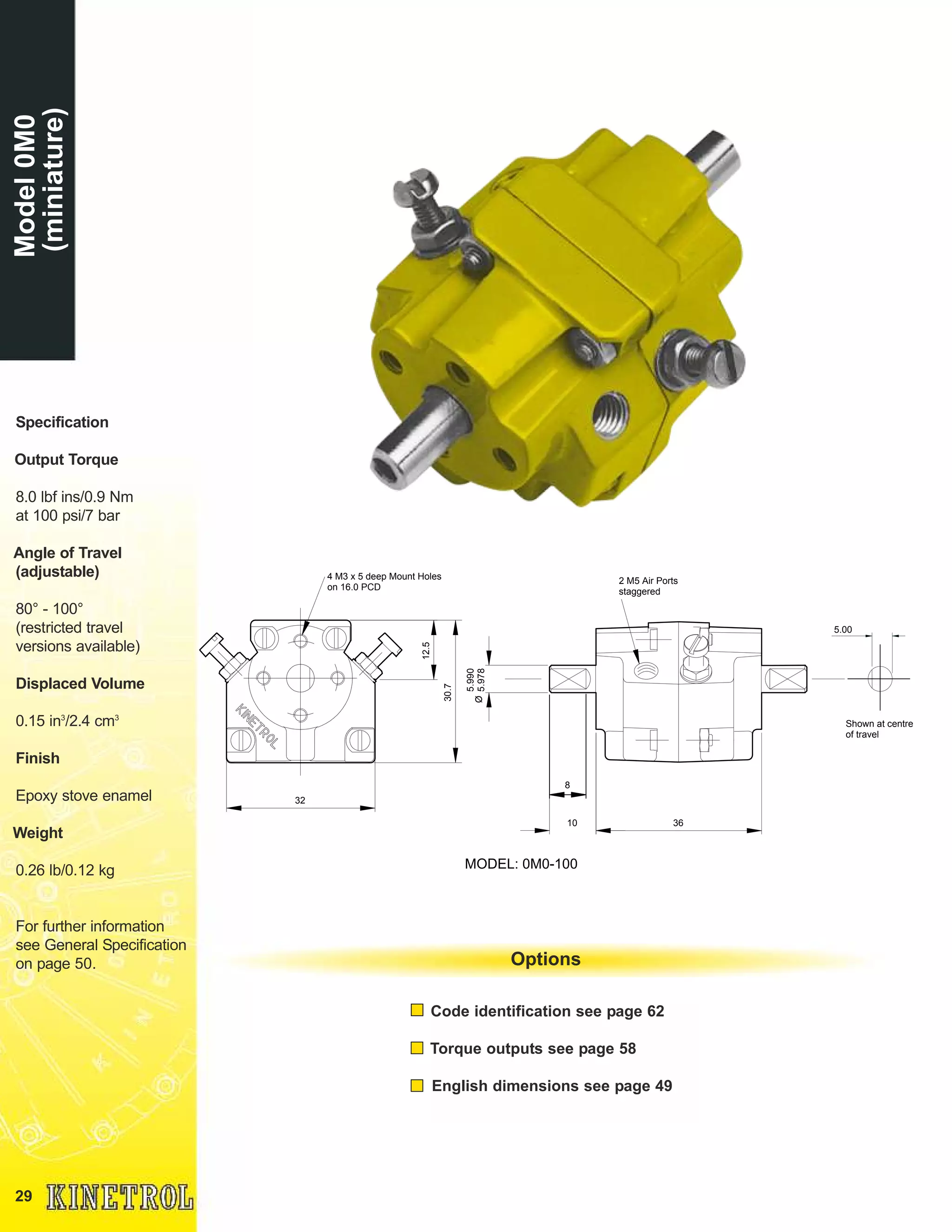

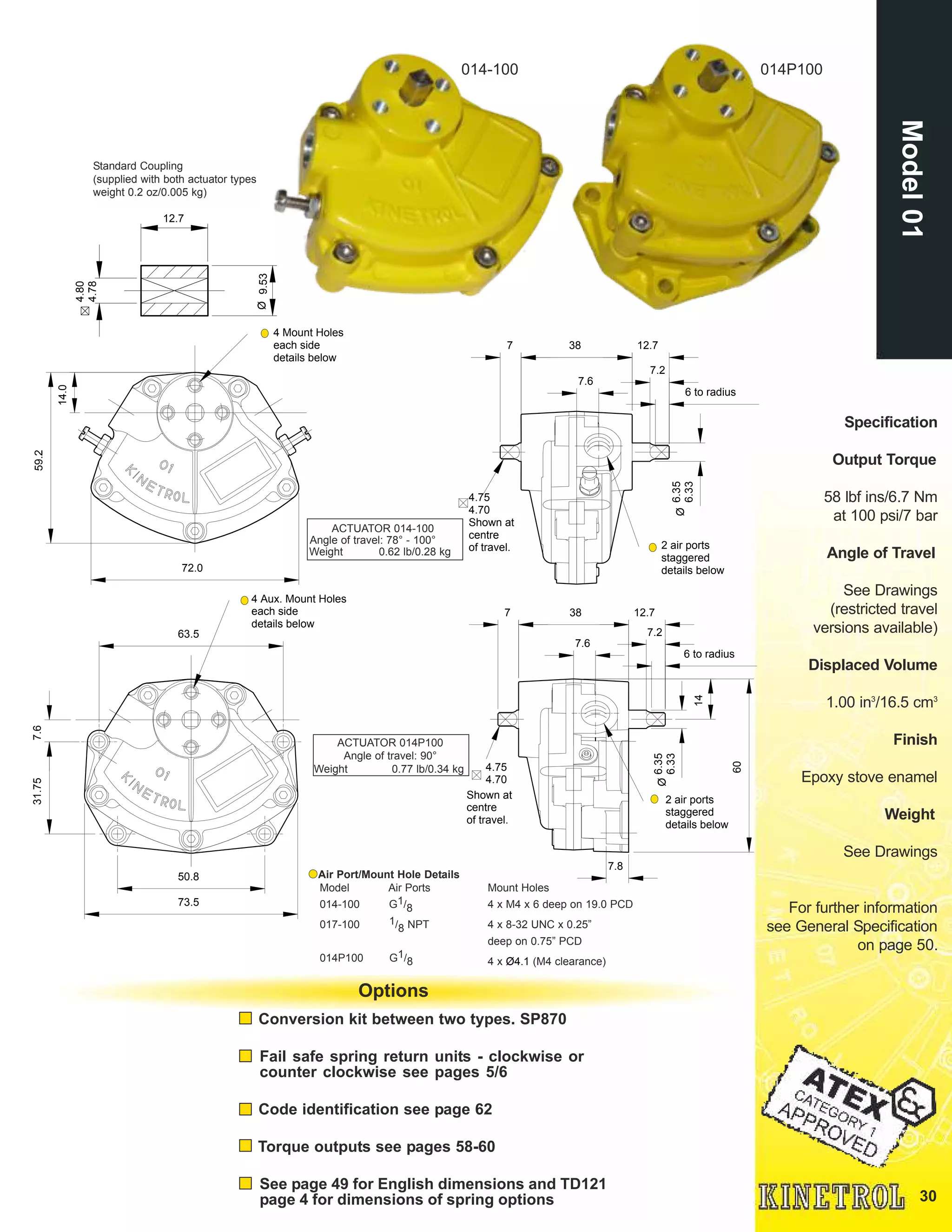

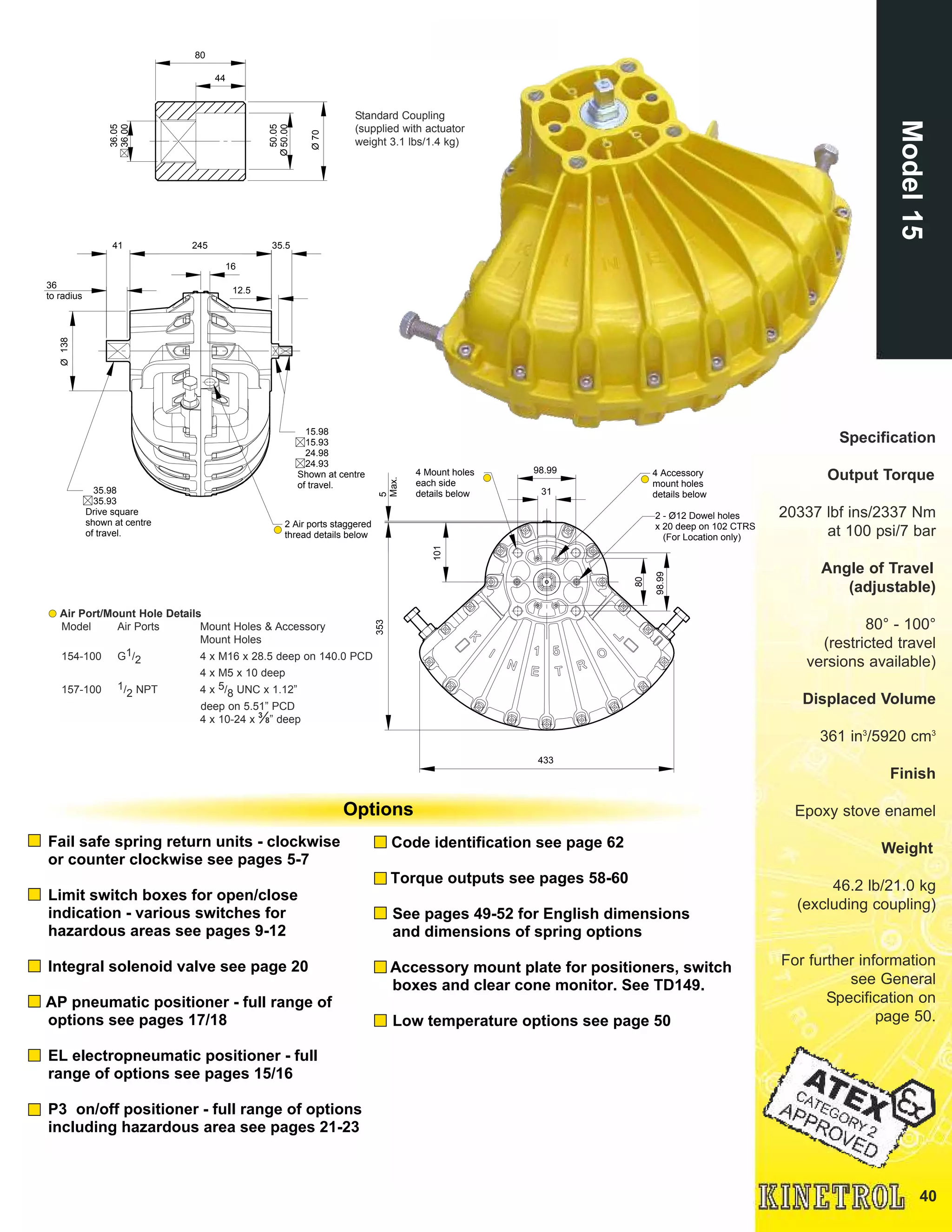

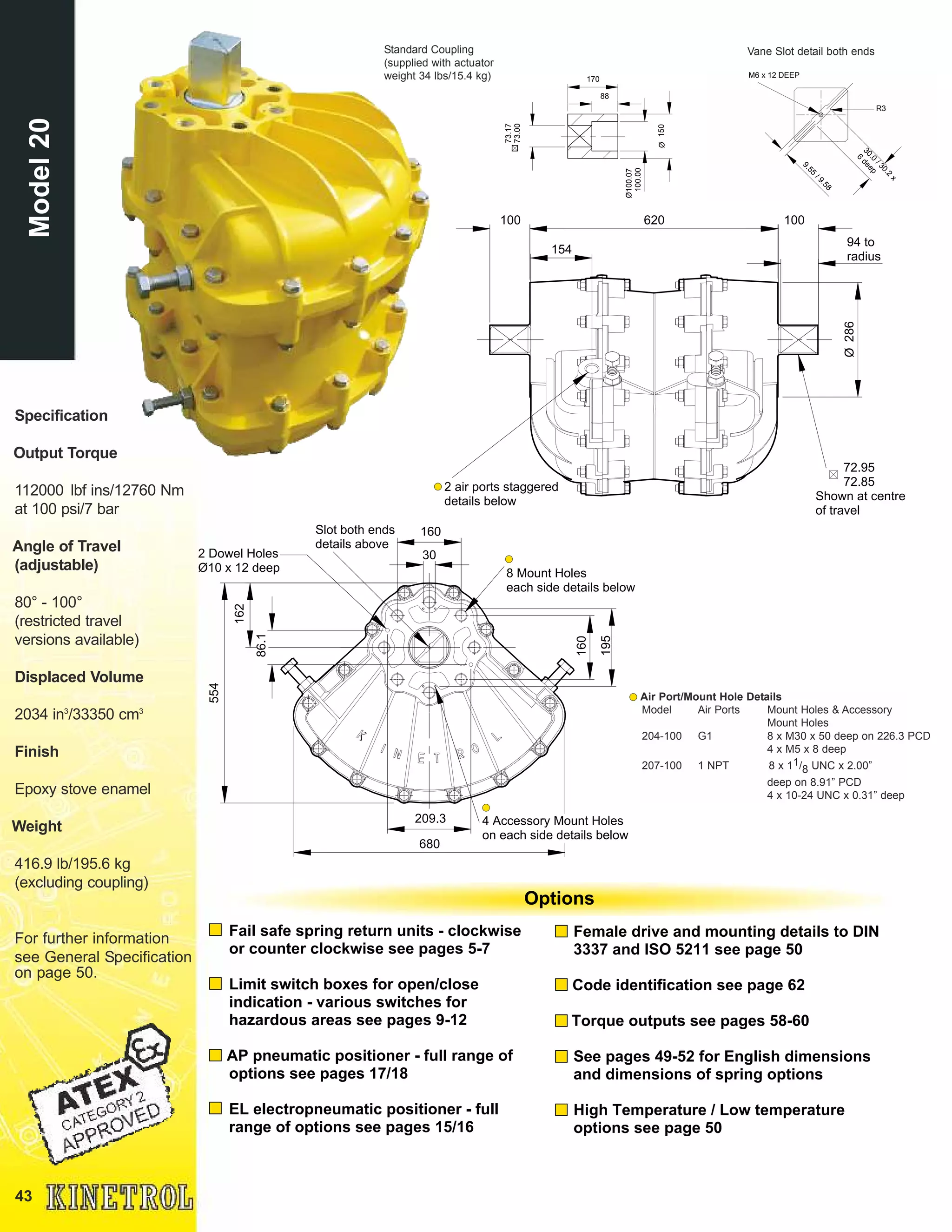

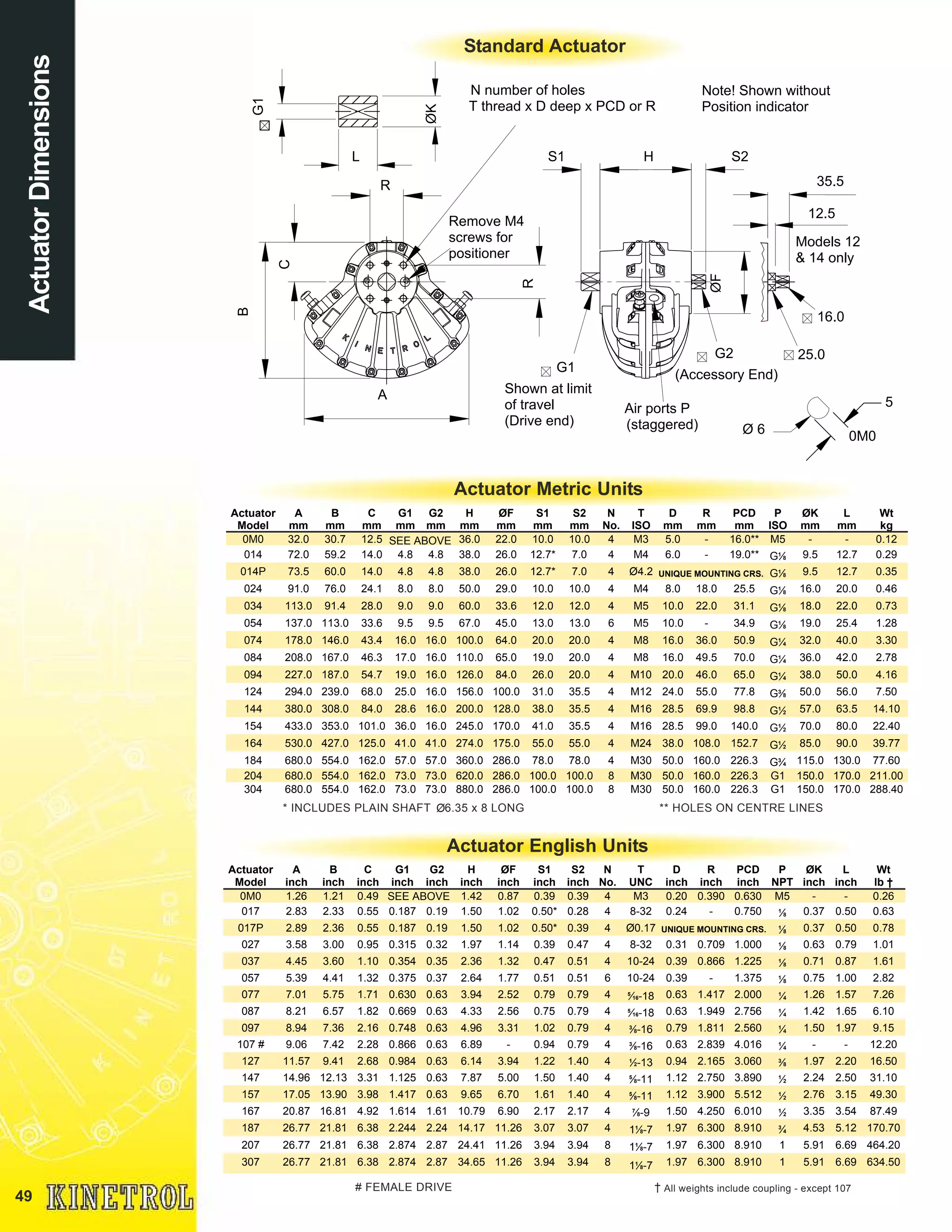

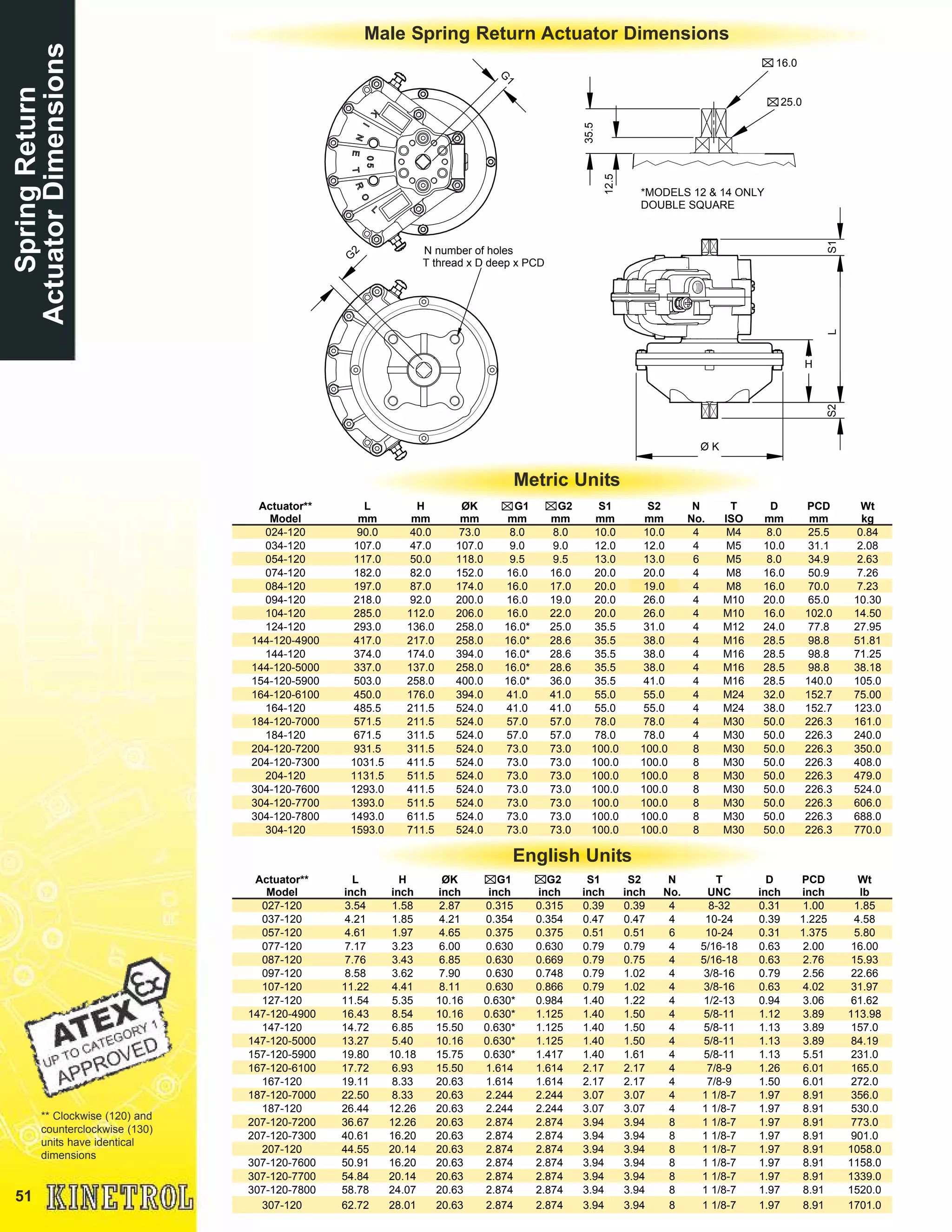

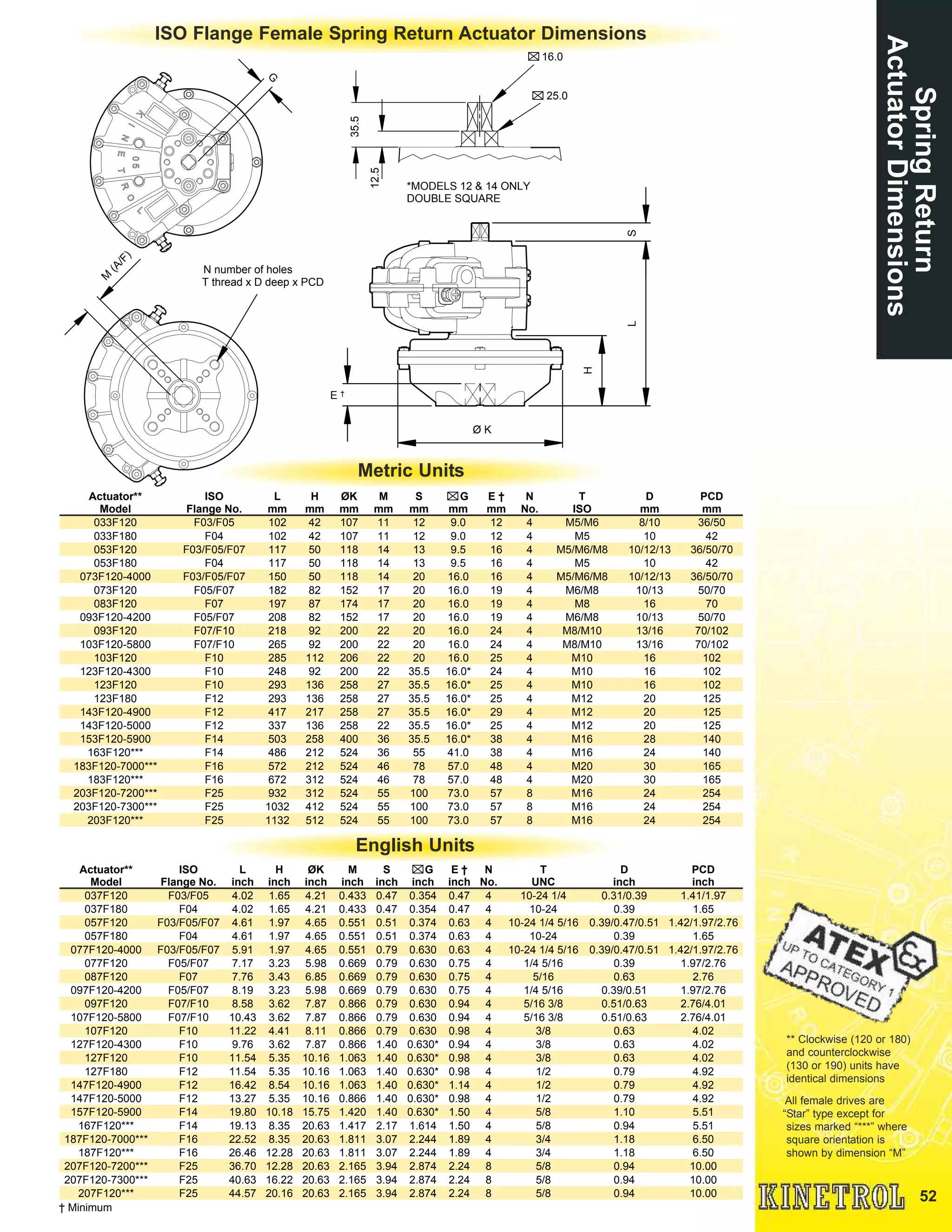

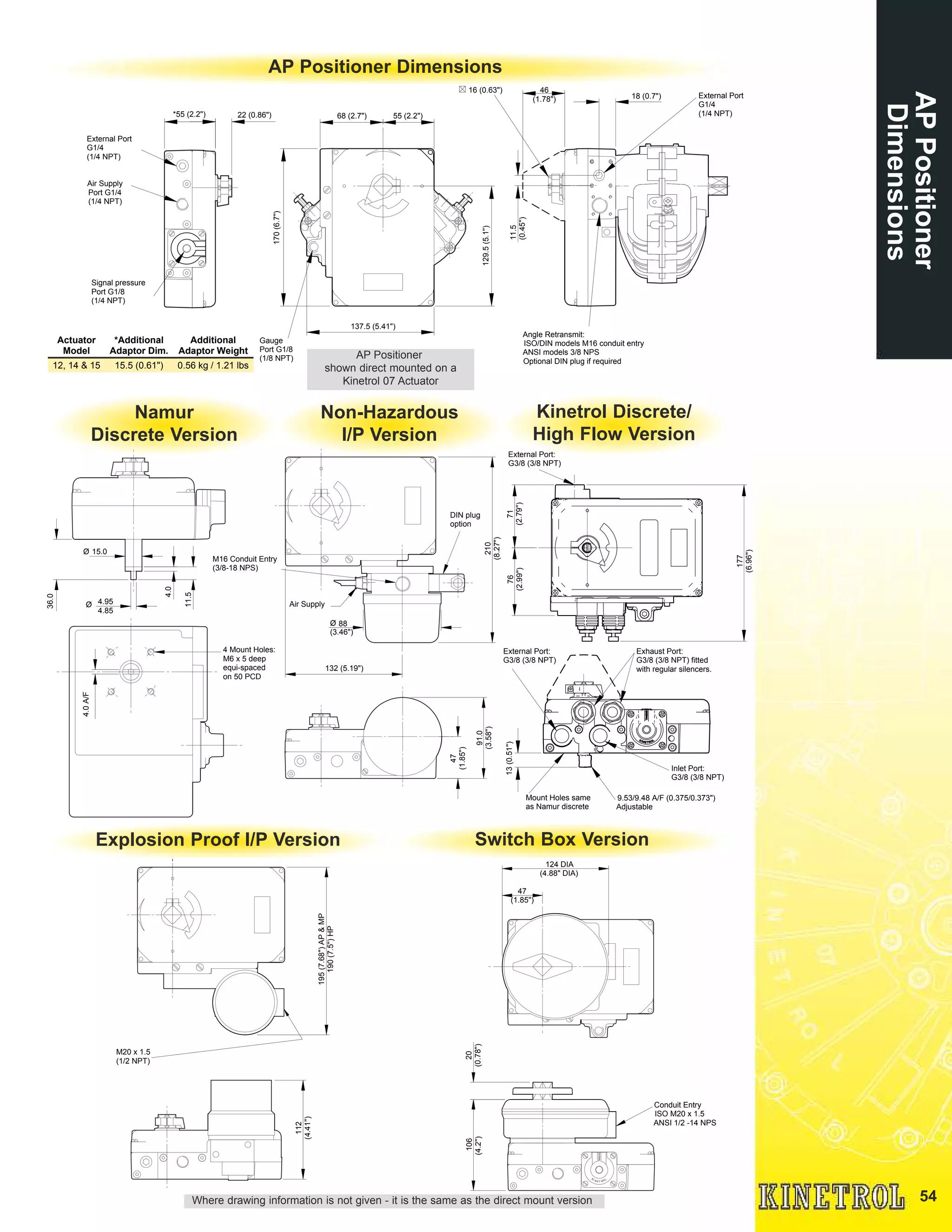

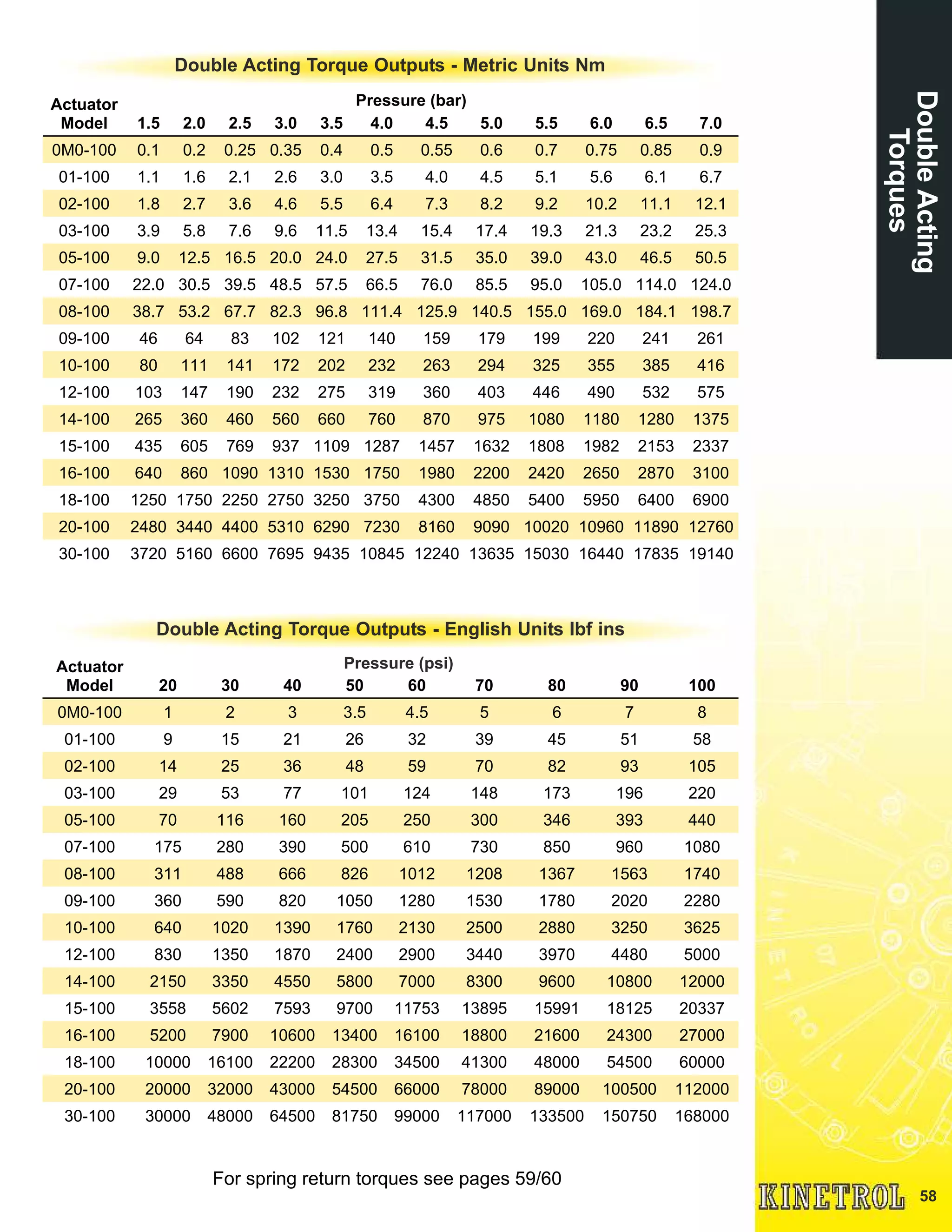

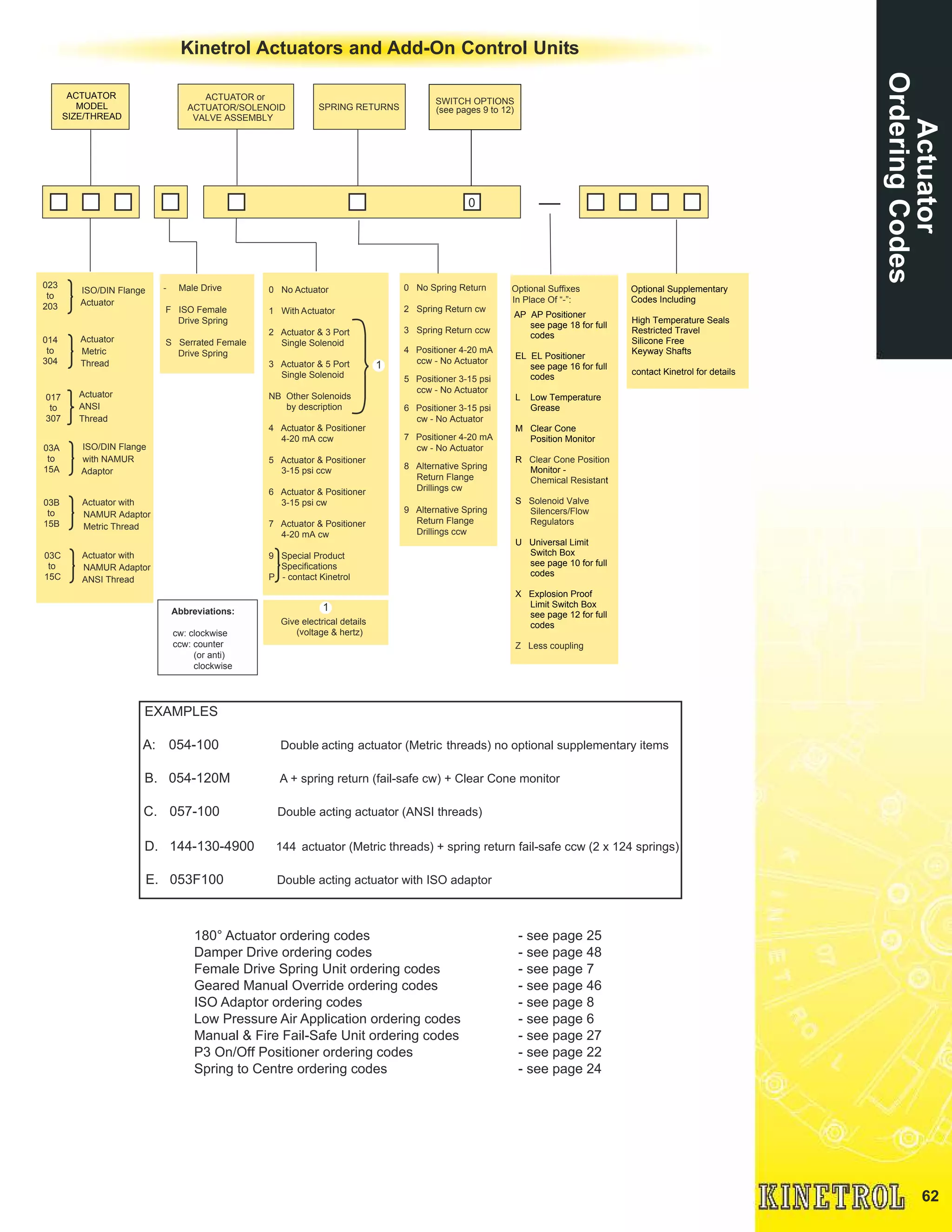

The document is a comprehensive catalogue for Kinetrol rotary actuators, detailing various models and accessories such as control units, springs, limit switches, and positioners. It emphasizes the actuators' reliability, ease of use, and applications for valve and damper automation. The catalogue highlights features like fail-safe operation, durable construction, and the modular design allowing for customization based on specific needs.