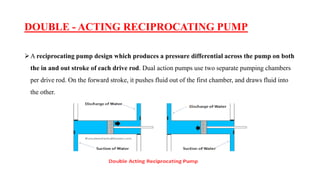

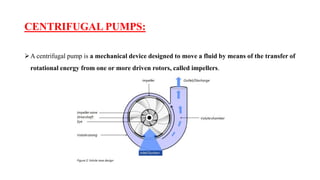

This document discusses different types of pumps. It describes pumps as devices that use rotary or reciprocating mechanisms to lift liquids from one location to another by consuming energy. There are two main categories of pumps: positive displacement pumps and dynamic pumps. Positive displacement pumps are further divided into rotary pumps like vane and gear pumps, and reciprocating pumps like single-acting and double-acting pumps. Dynamic pumps include centrifugal pumps which use a rotating impeller to increase fluid velocity, and axial pumps where flow is parallel to the shaft. Common applications of pumps include water distribution, automotive cooling systems, industrial processes, and more.