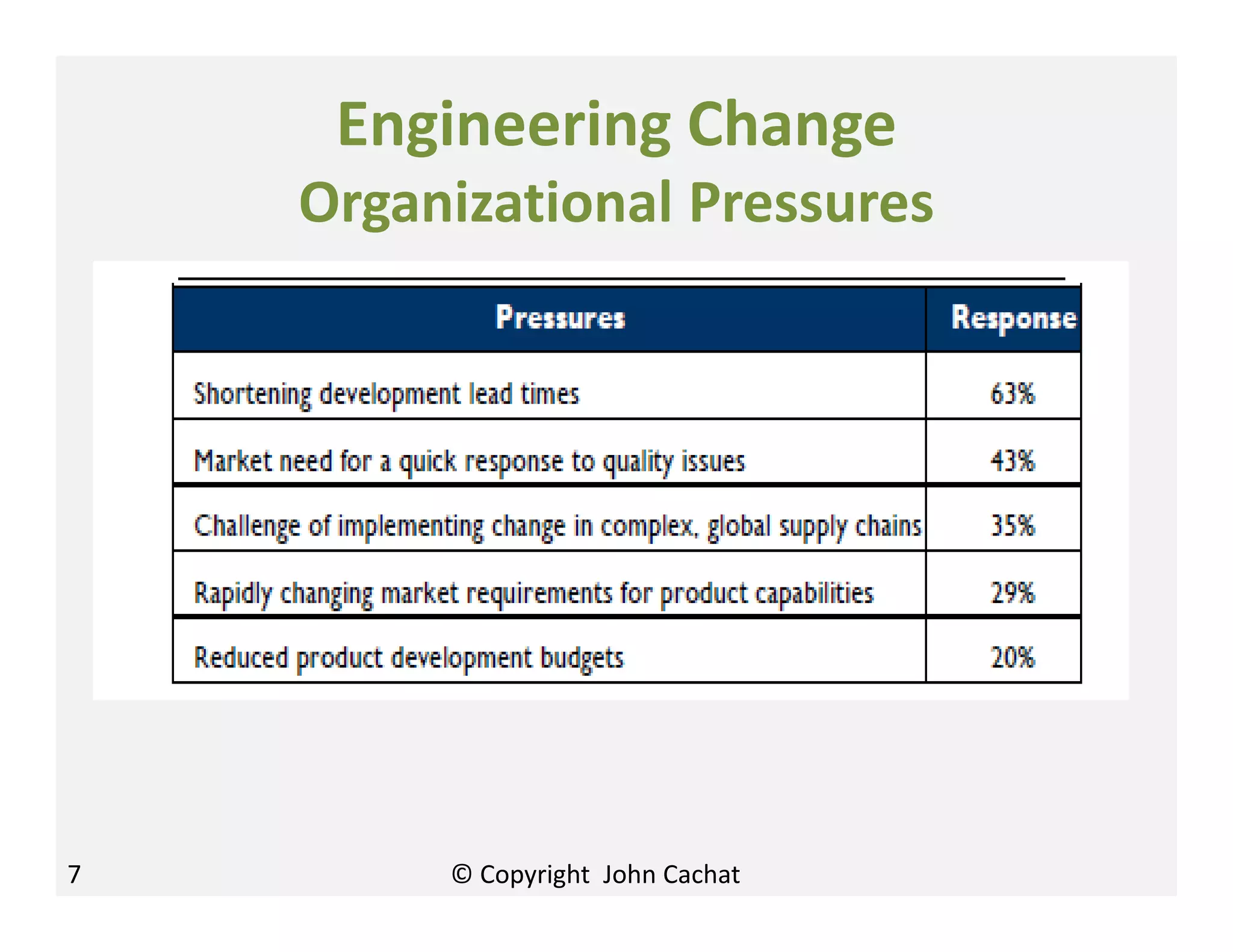

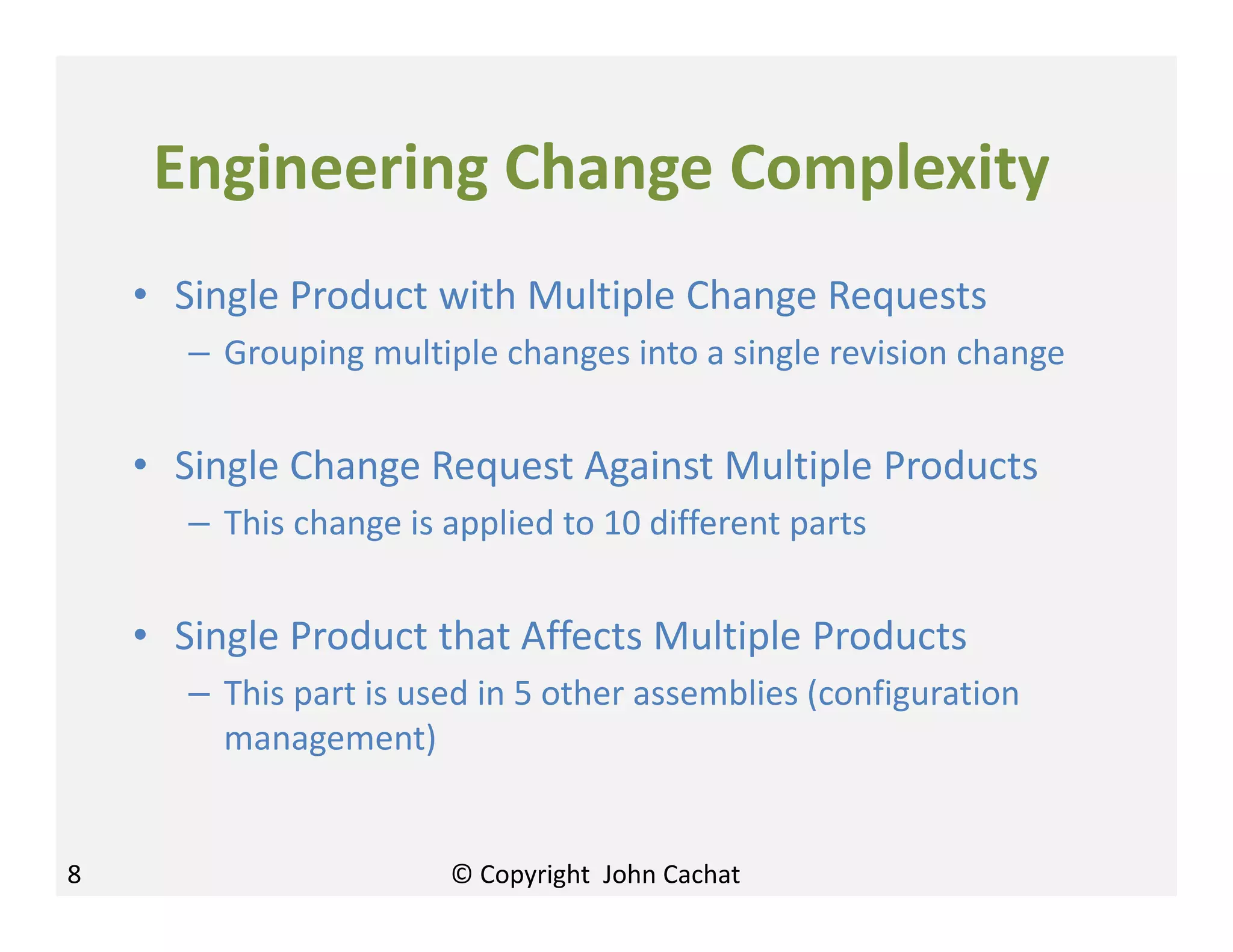

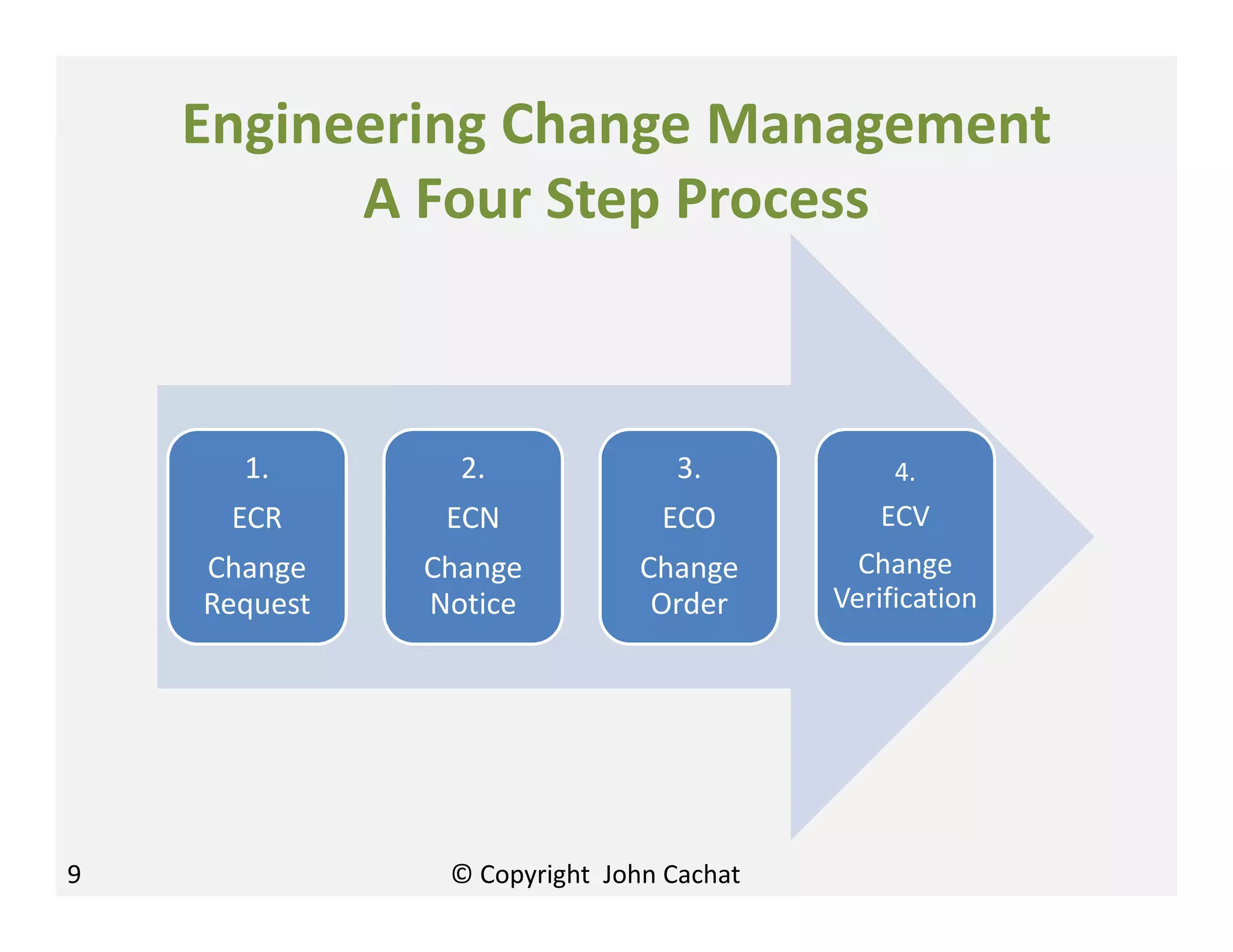

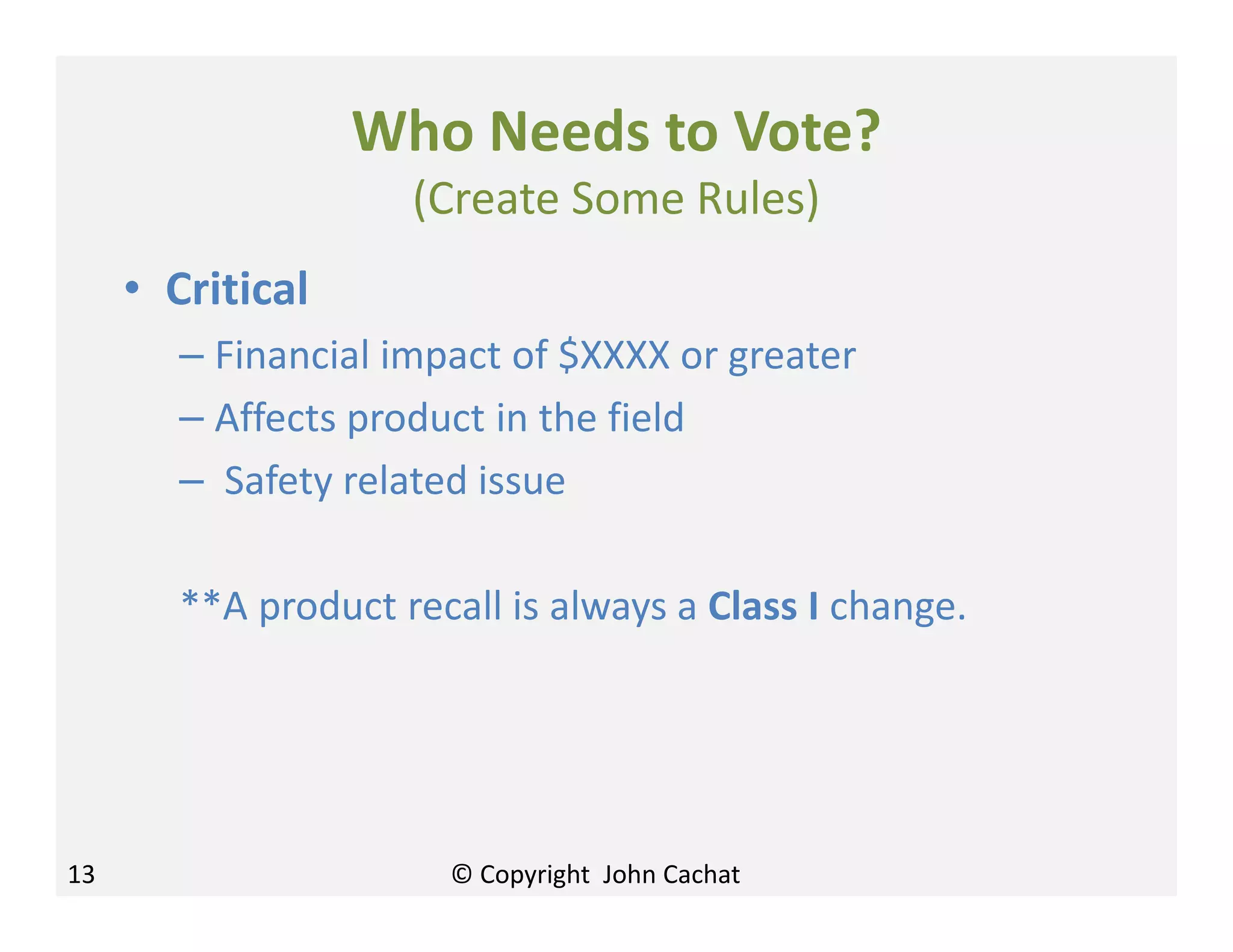

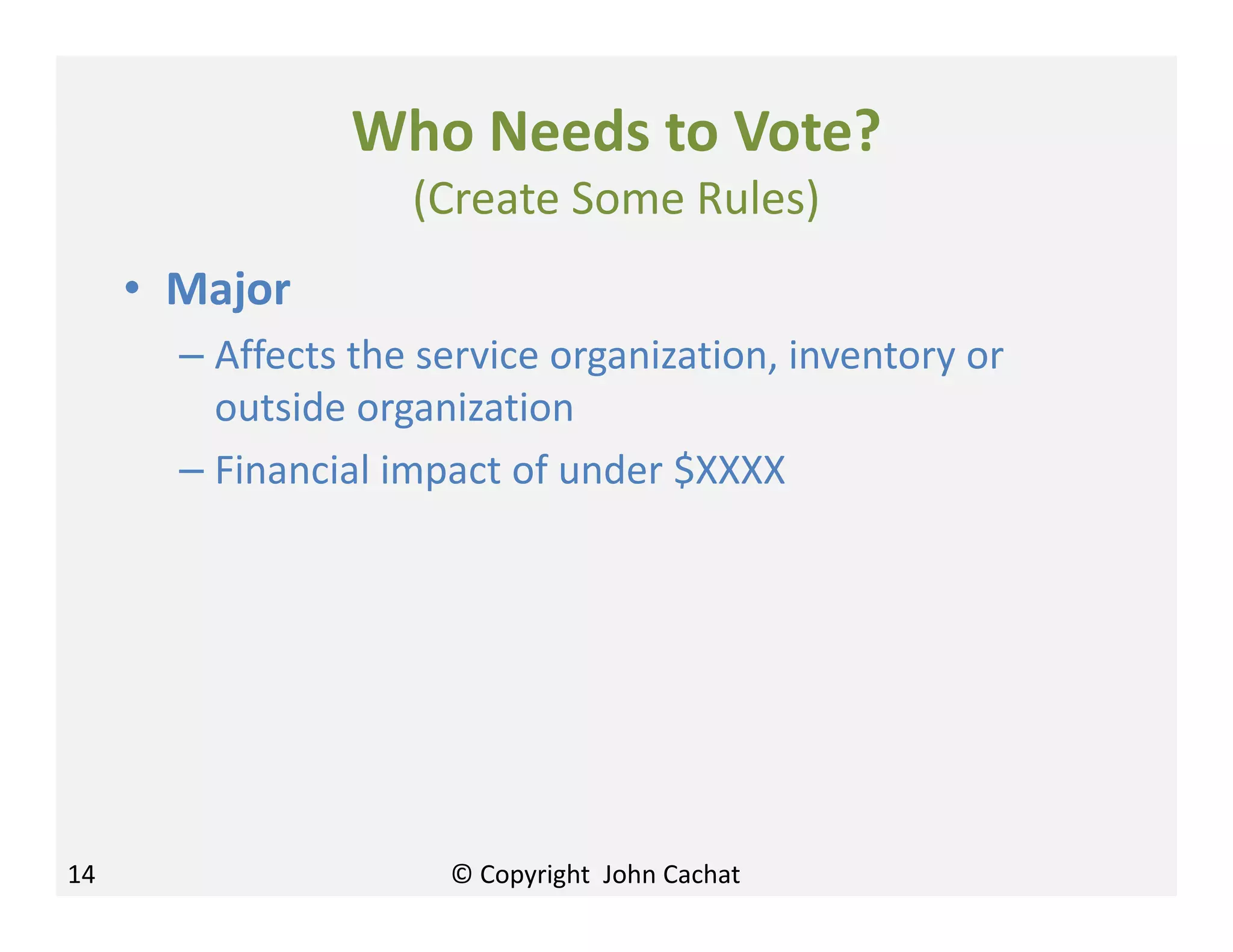

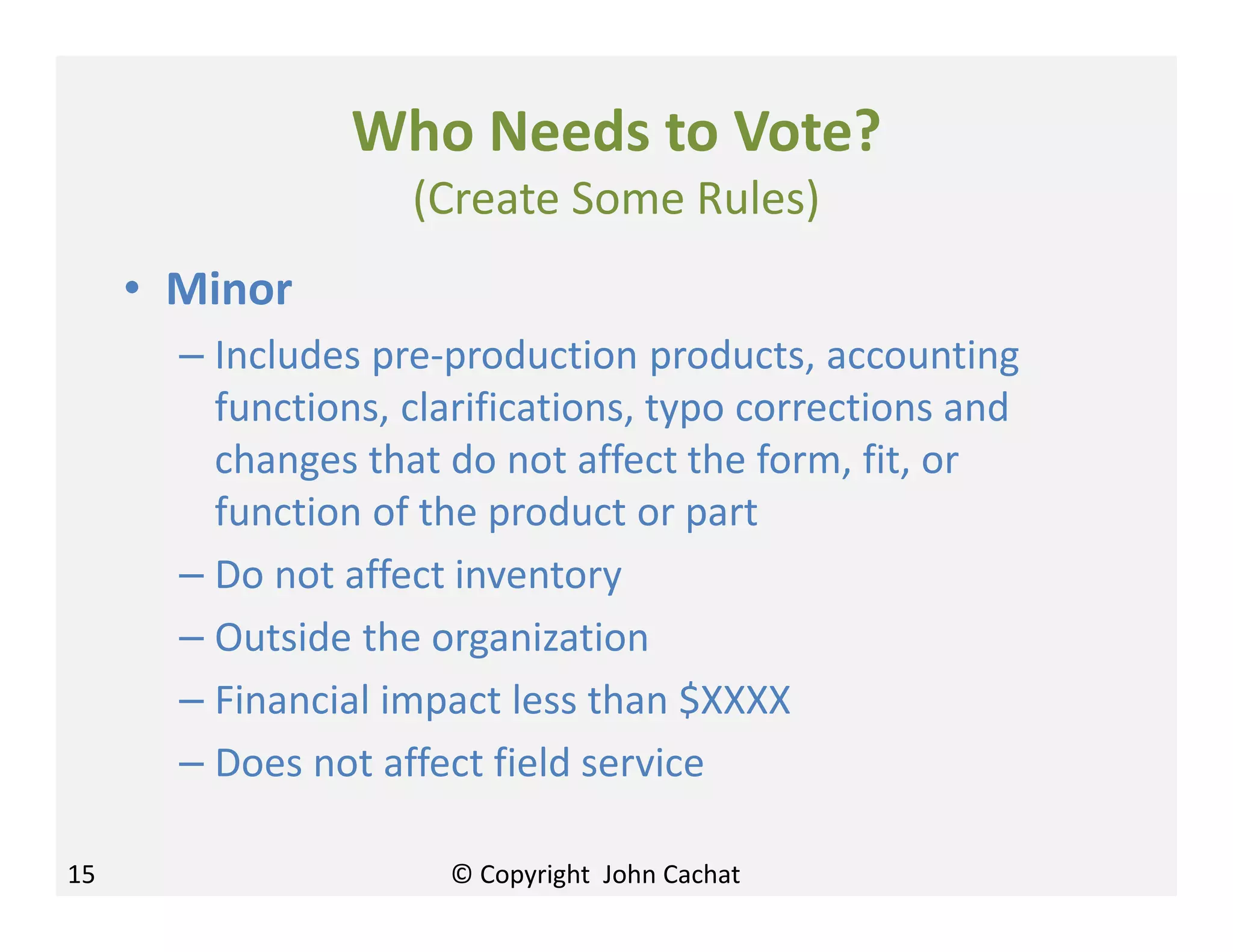

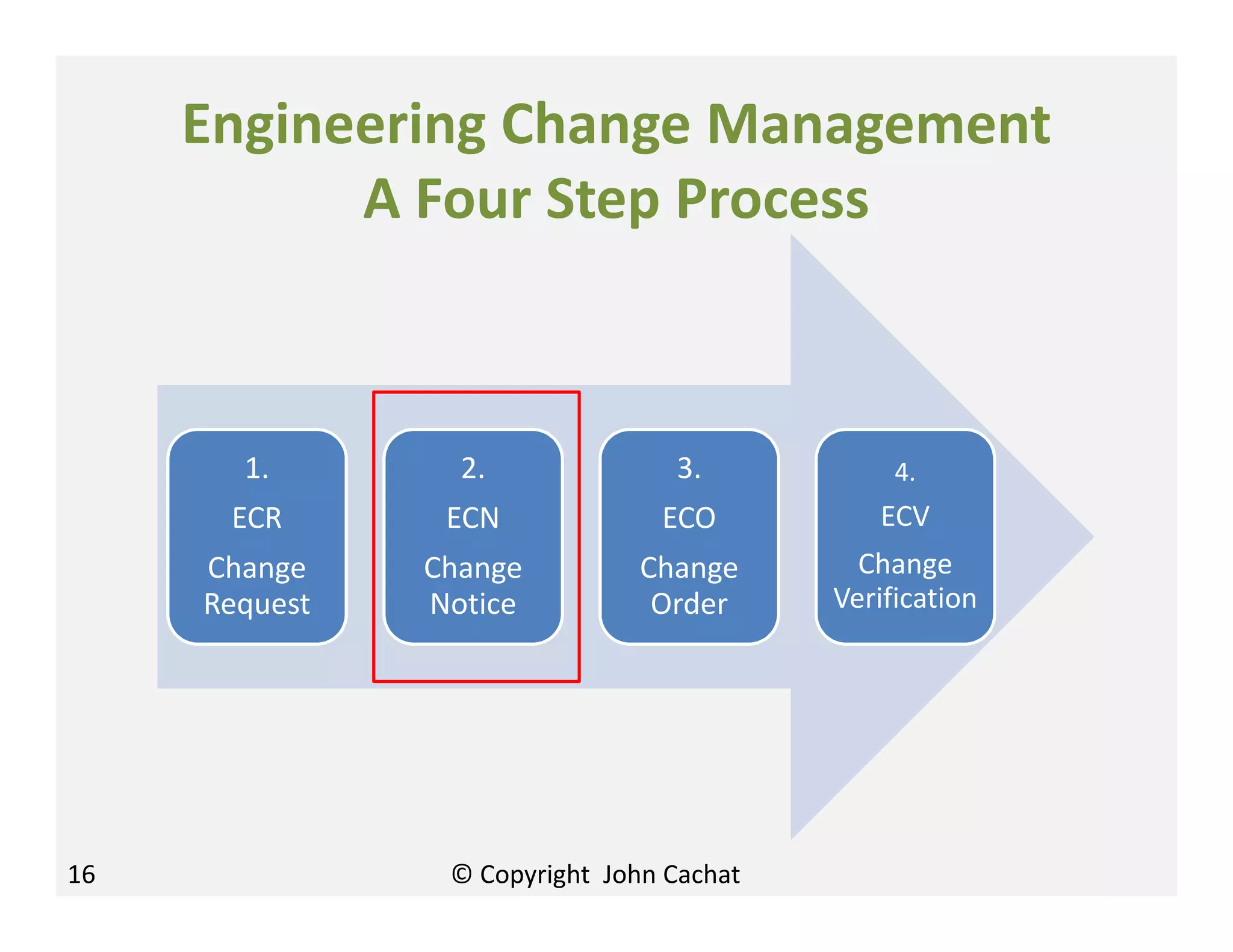

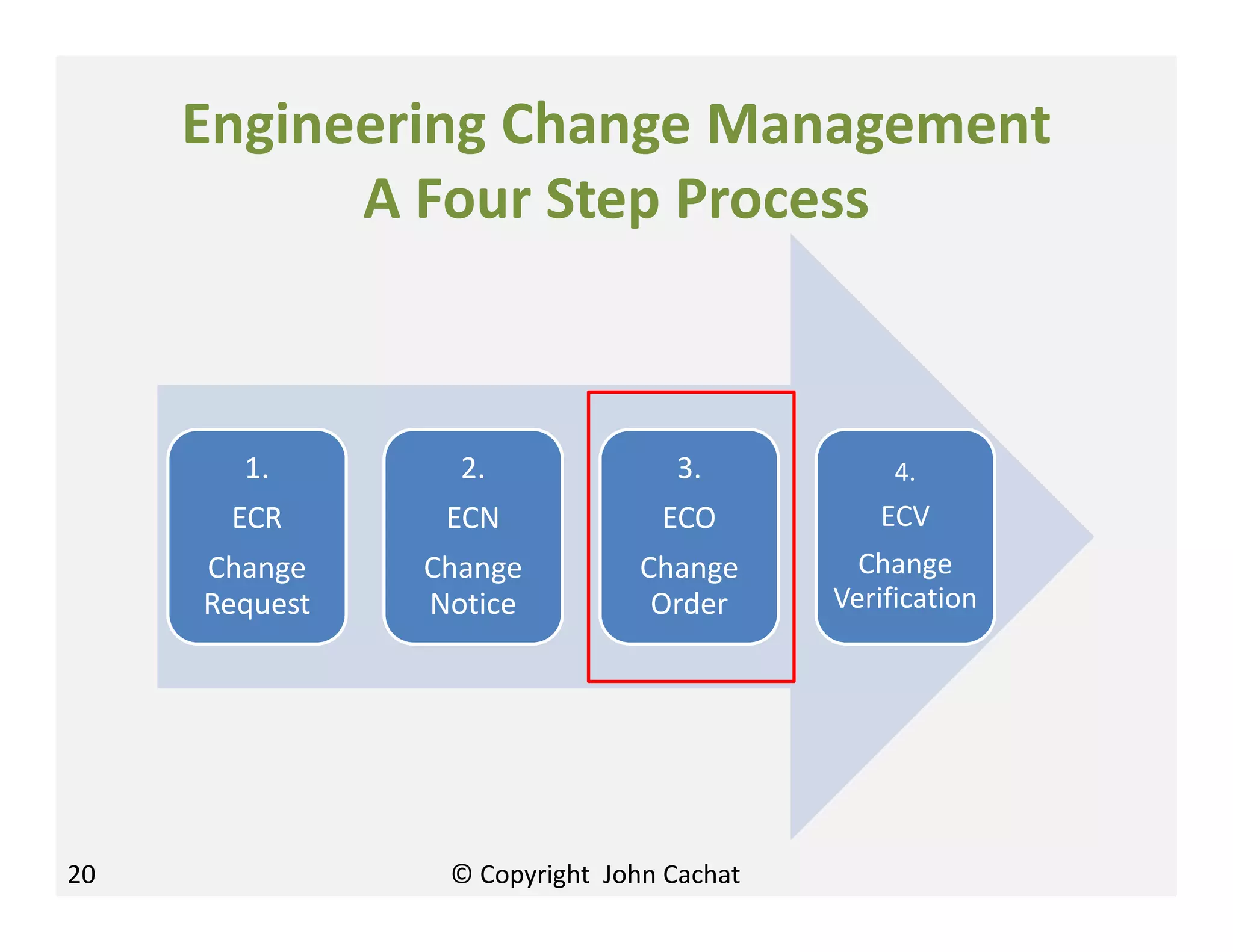

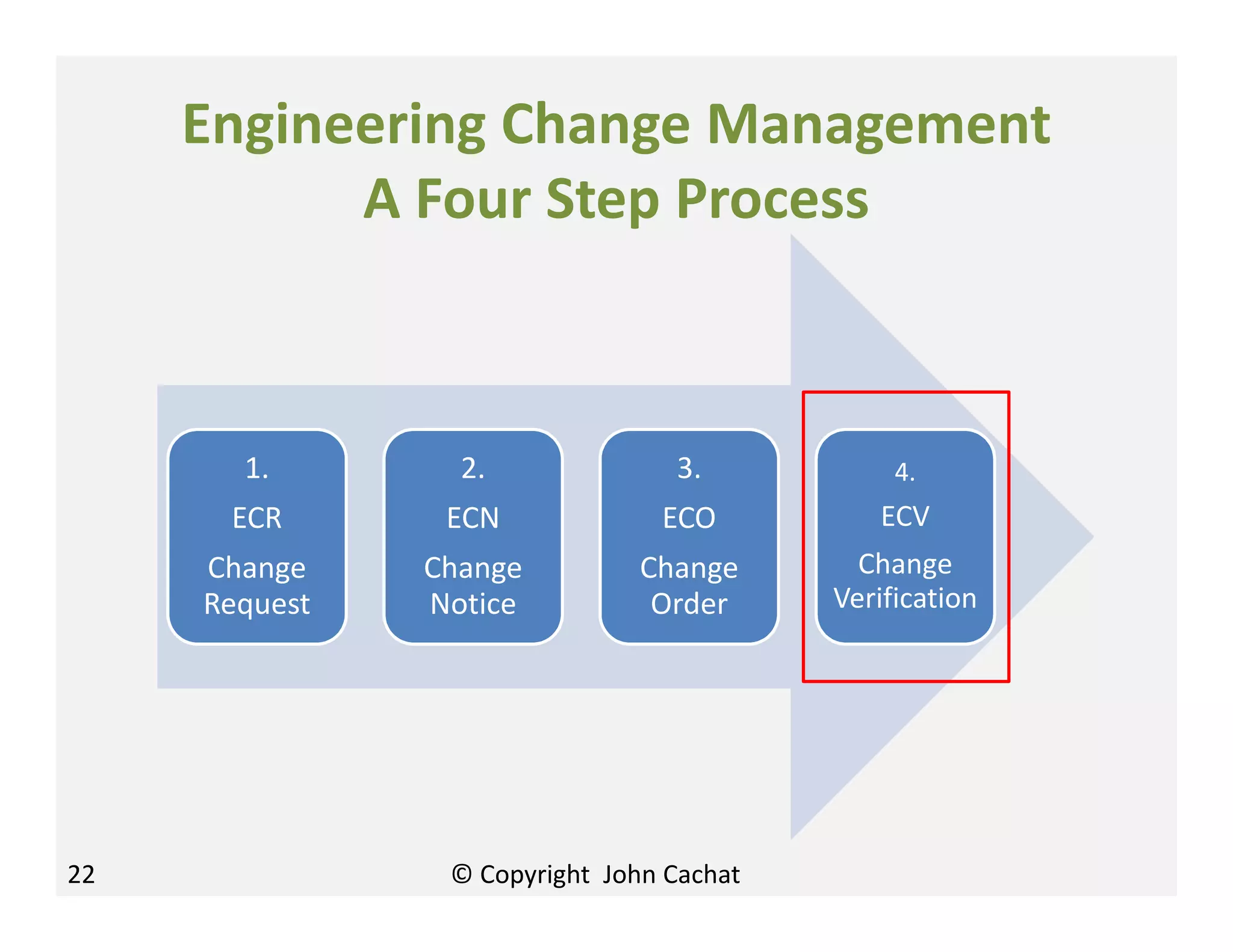

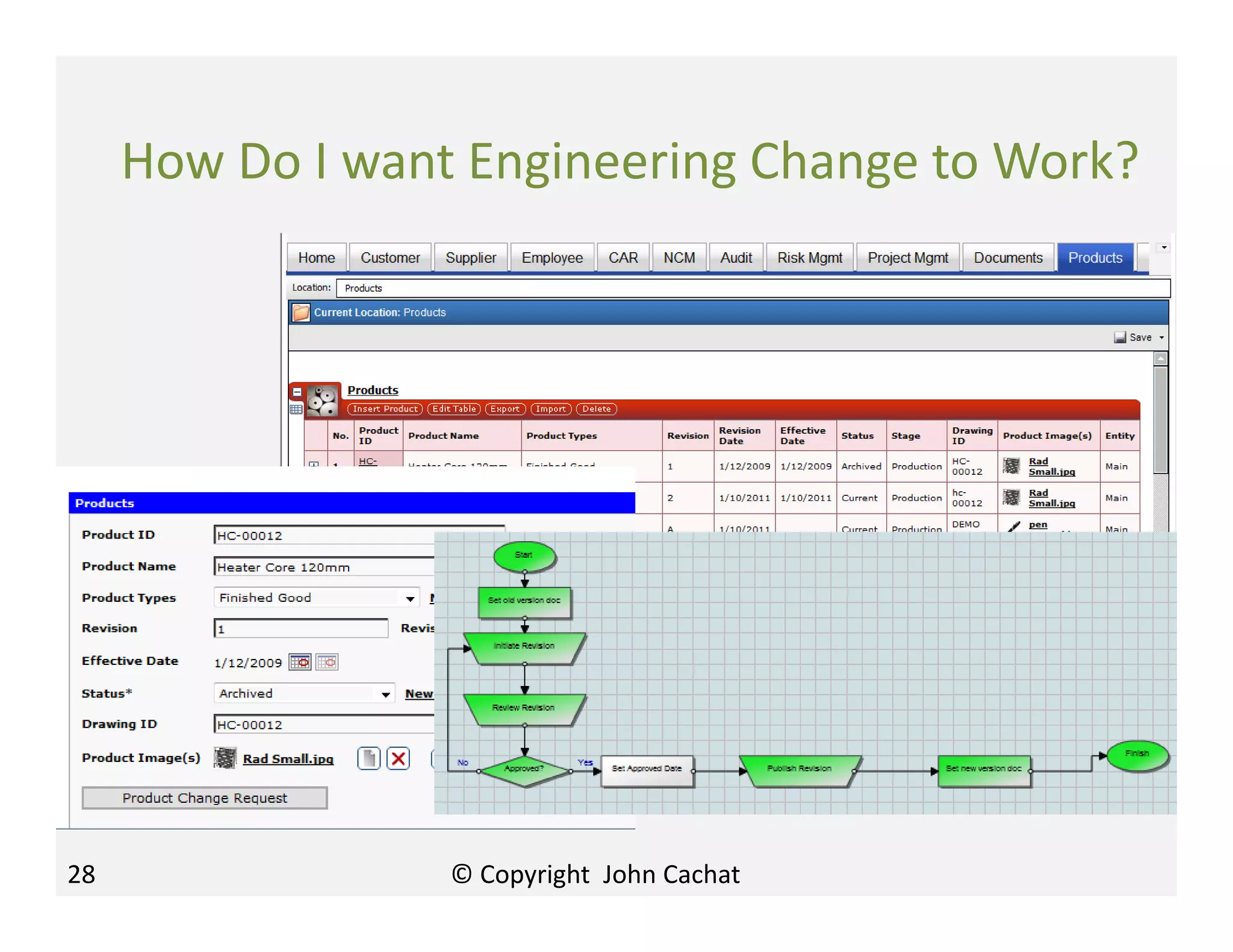

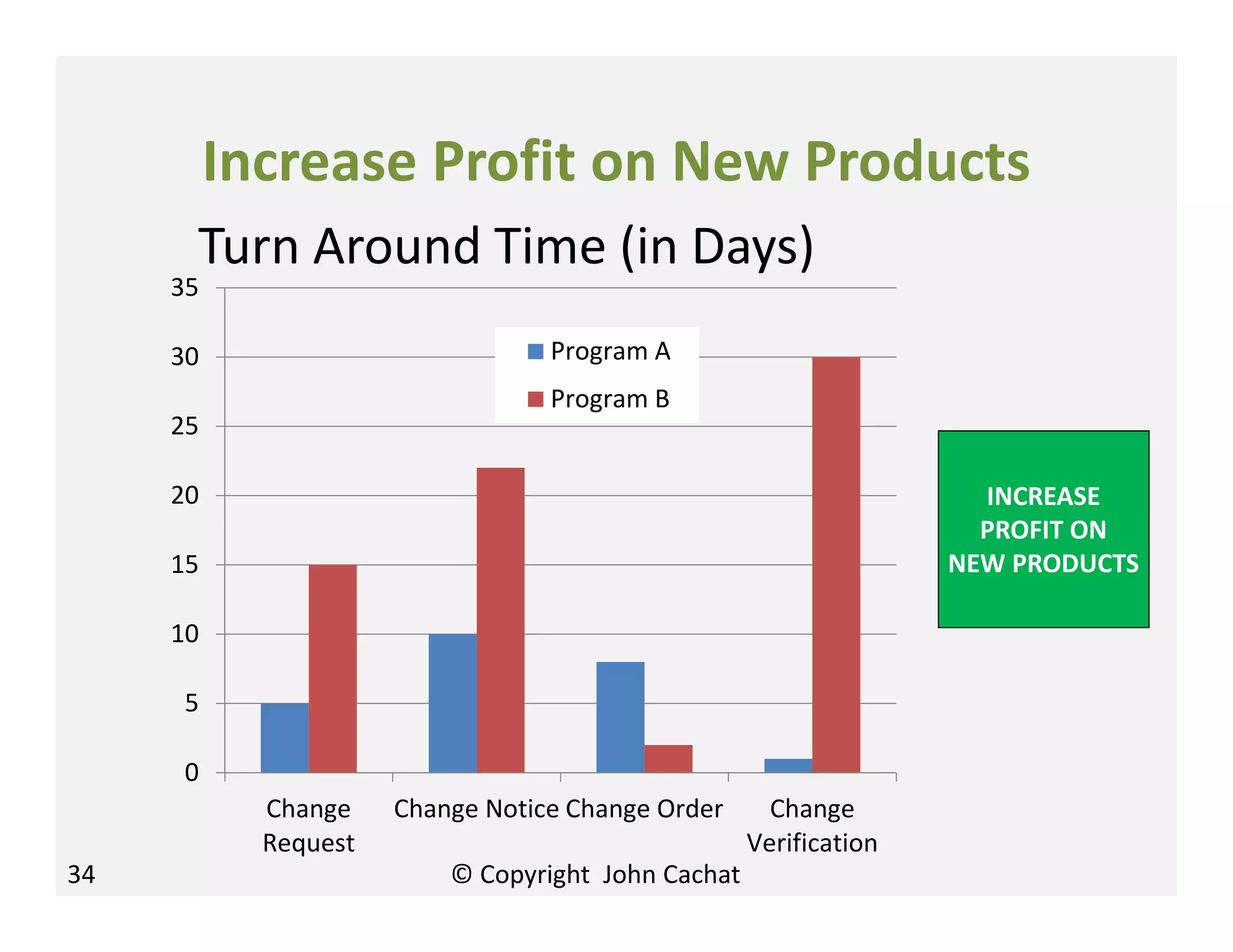

1) Engineering change management is a critical but often poorly defined and executed process for managing changes to products and ensuring compliance. It typically involves four steps - change request, change notice, change order, and change verification.

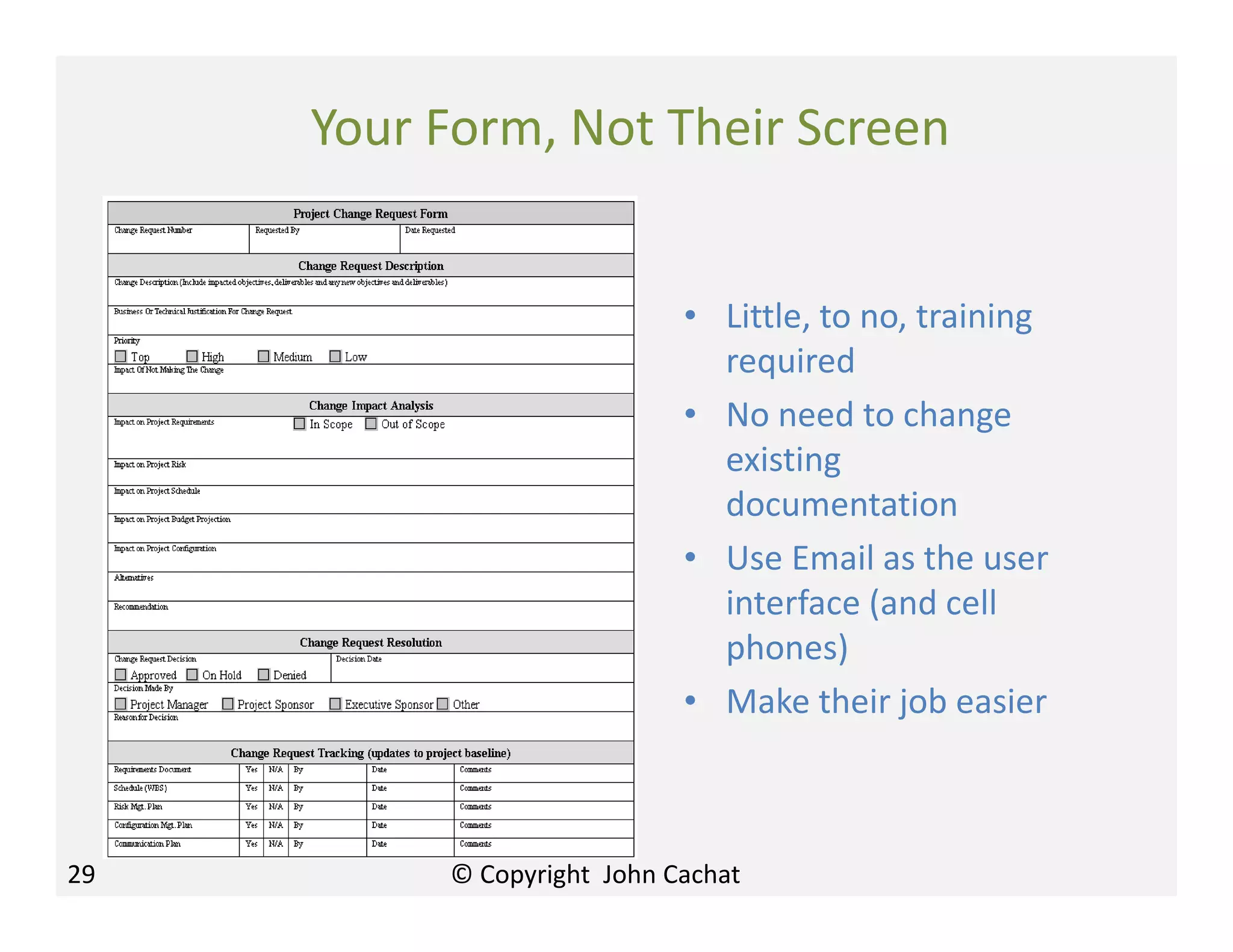

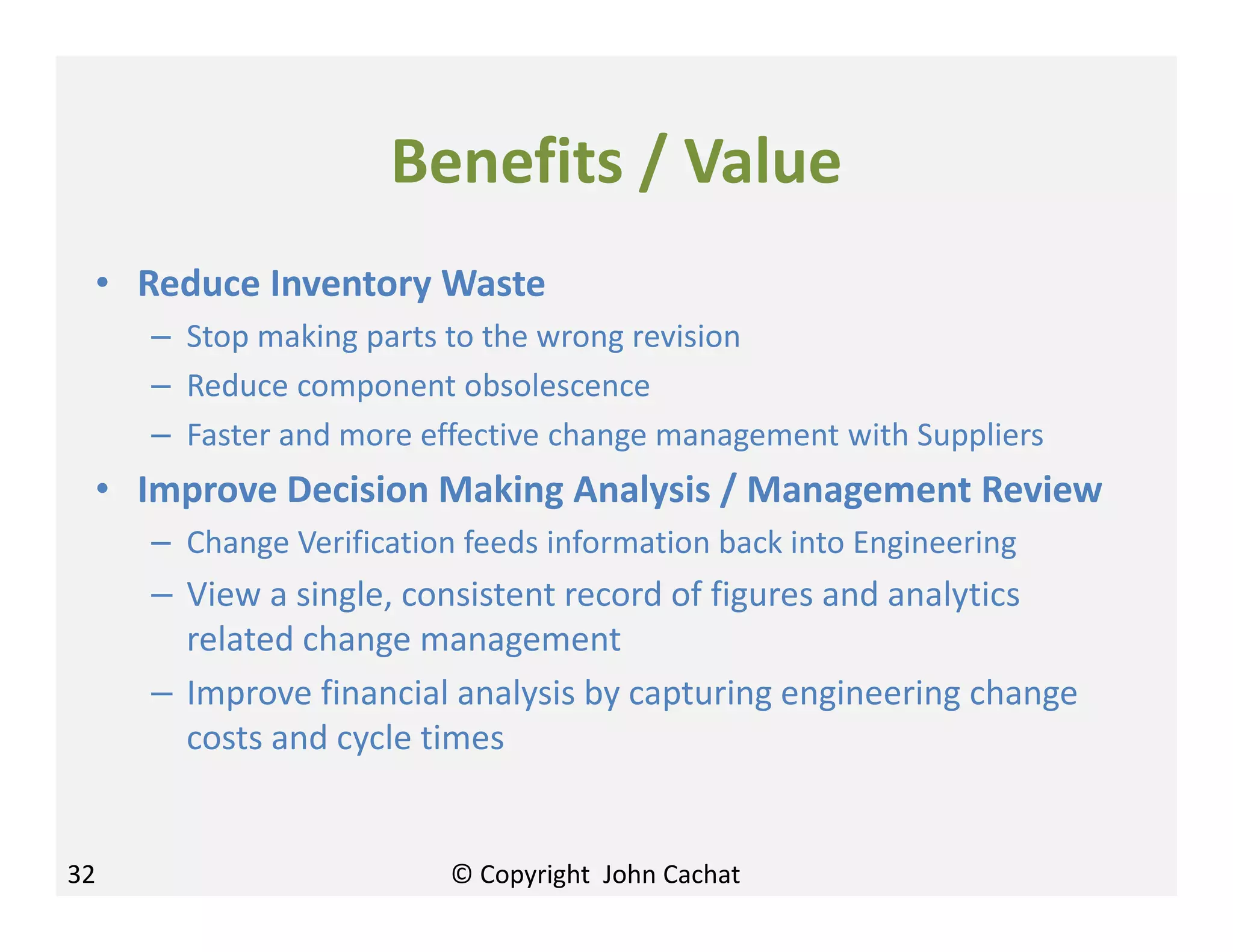

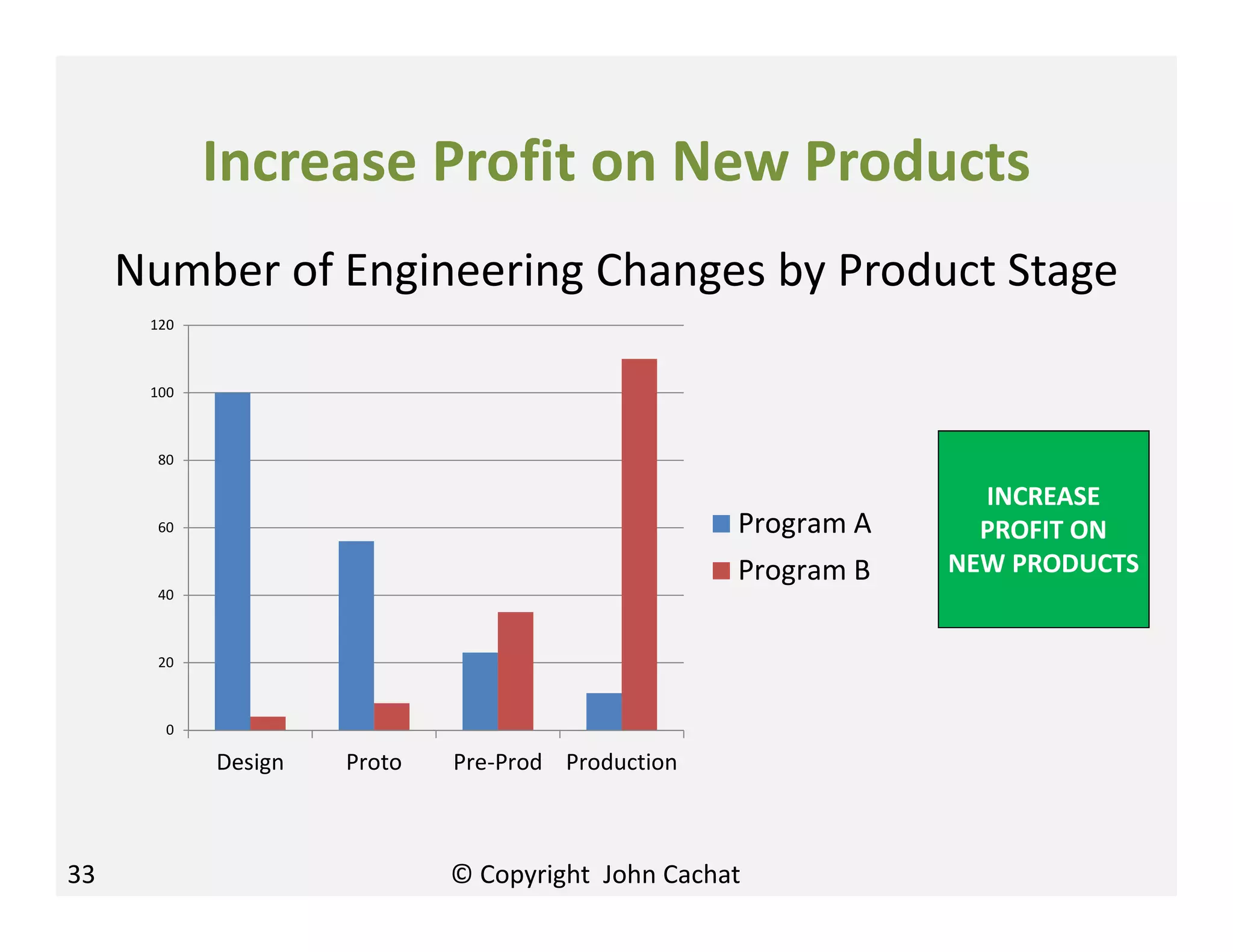

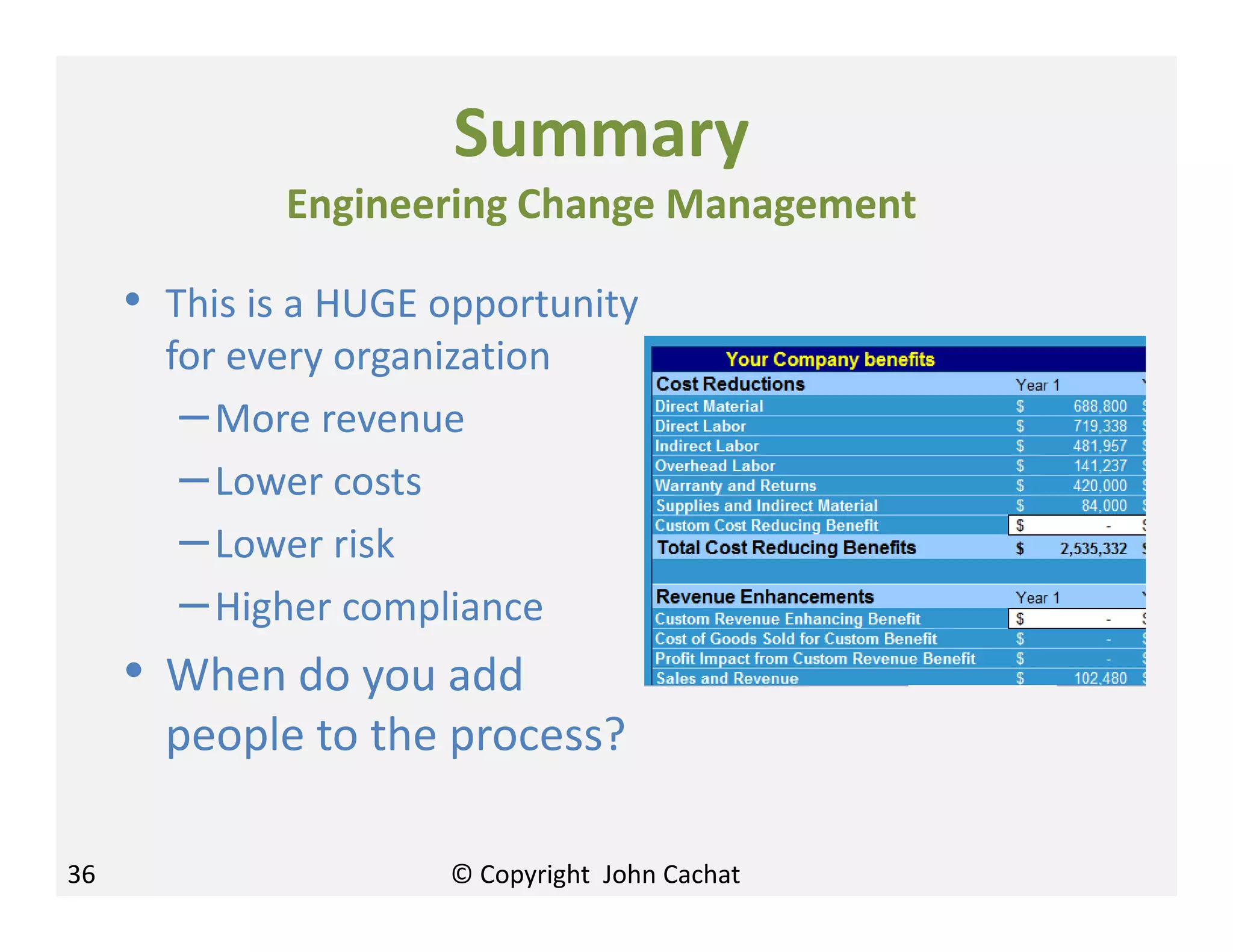

2) Automating the engineering change management process can provide benefits like faster time to market, lower costs, reduced inventory waste, improved decision making, and increased compliance. However, many companies still rely on tools like Excel and lack an integrated process view.

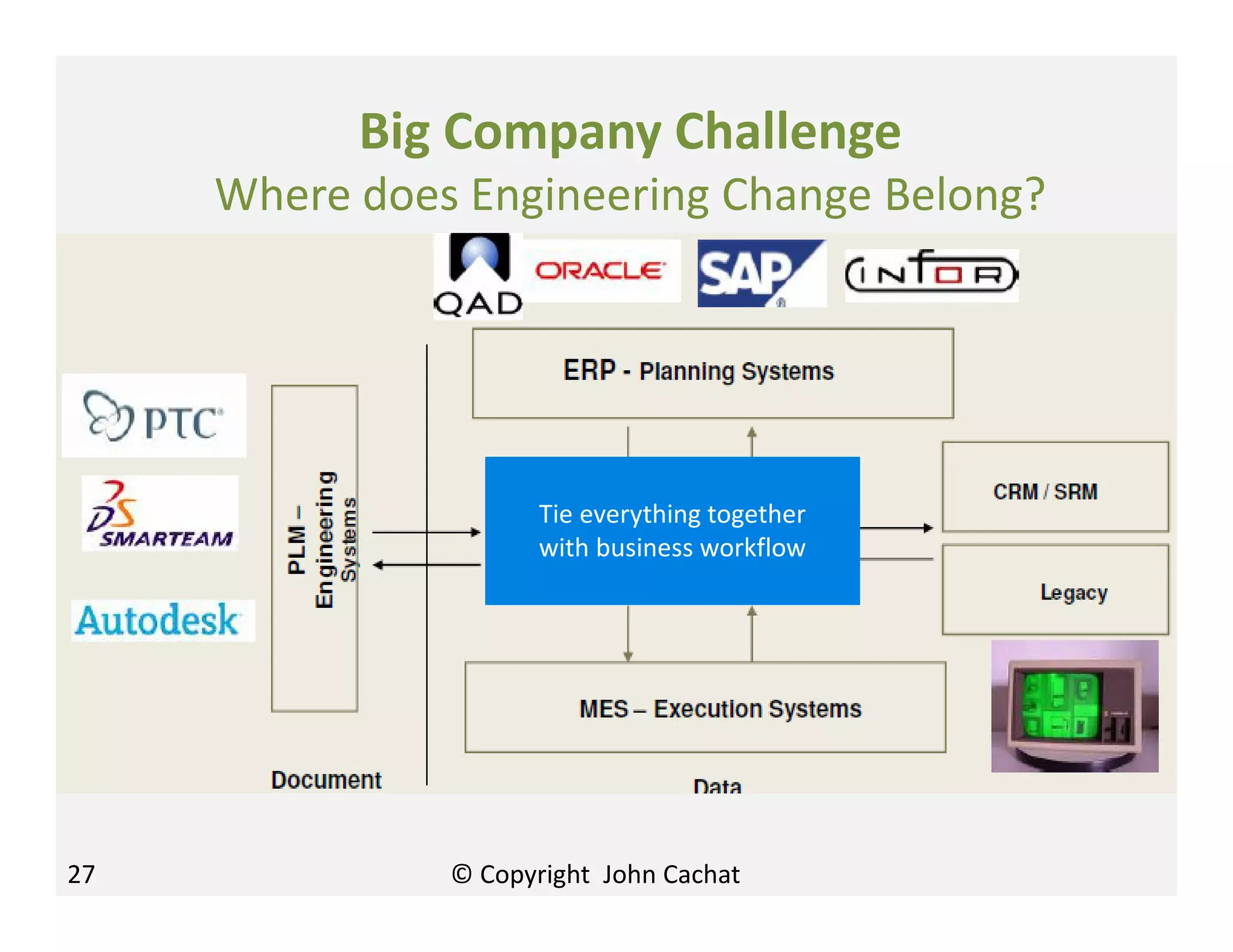

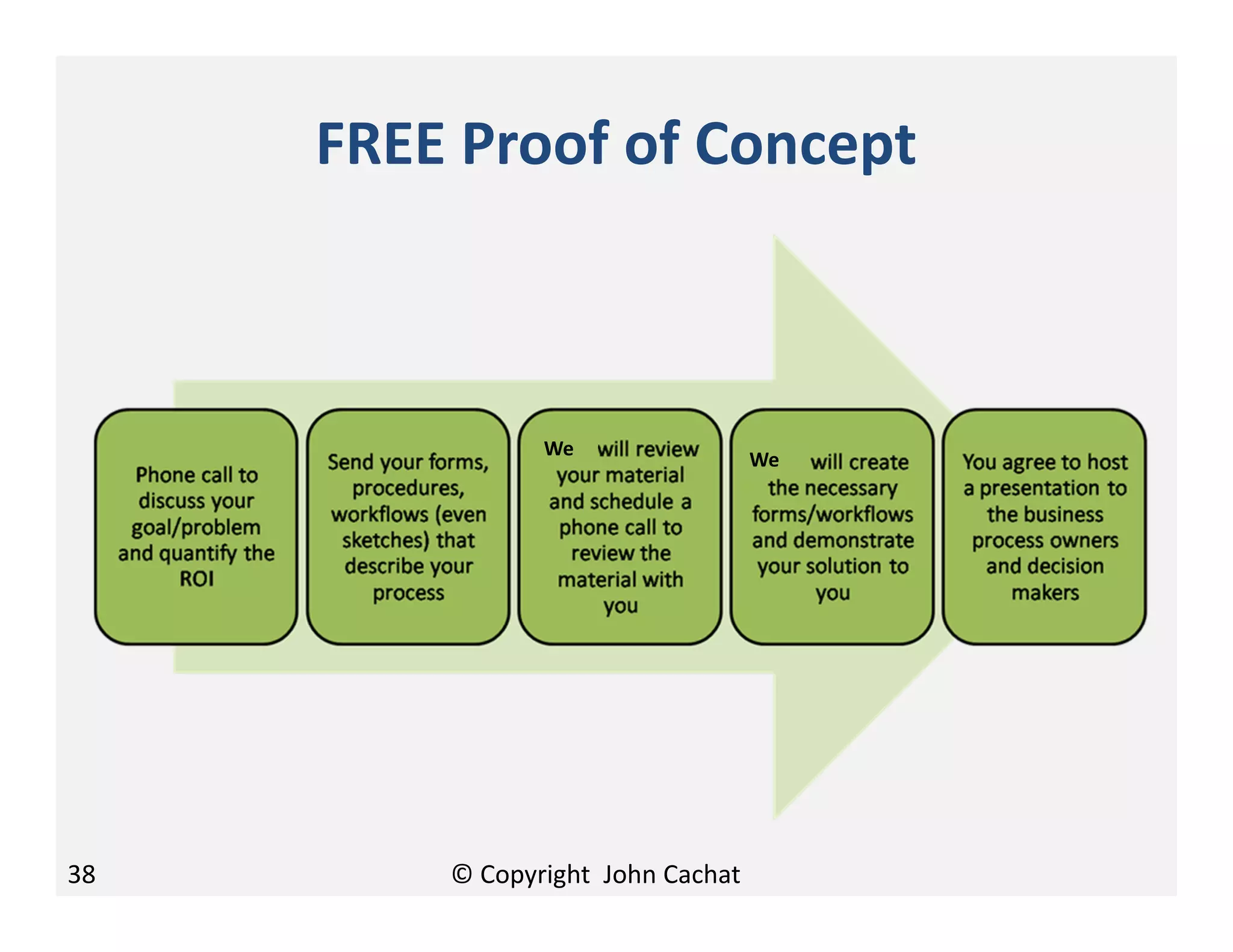

3) The presentation proposes developing a single, integrated engineering change management process supported by enterprise software. This could help organizations more effectively engage stakeholders, reduce variation, eliminate waste, and increase profits on new products.