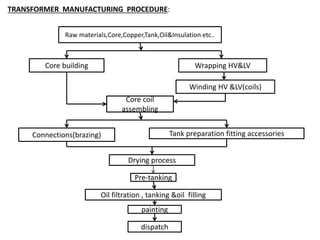

This document summarizes the manufacturing process and maintenance of power transformers. It describes the key components of a transformer like the core, windings, bushings, oil filling, and conservator. The manufacturing process involves preparing the raw materials, winding the coils, assembling the core and coils, connecting accessories, drying, oil filtration and filling. Regular maintenance is needed to monitor the transformer hourly, daily, weekly, monthly, yearly and every 2-5 years to ensure proper functioning. Transformers are important equipment that allow transmitted power to be stepped up or down to usable voltages without changing frequency.