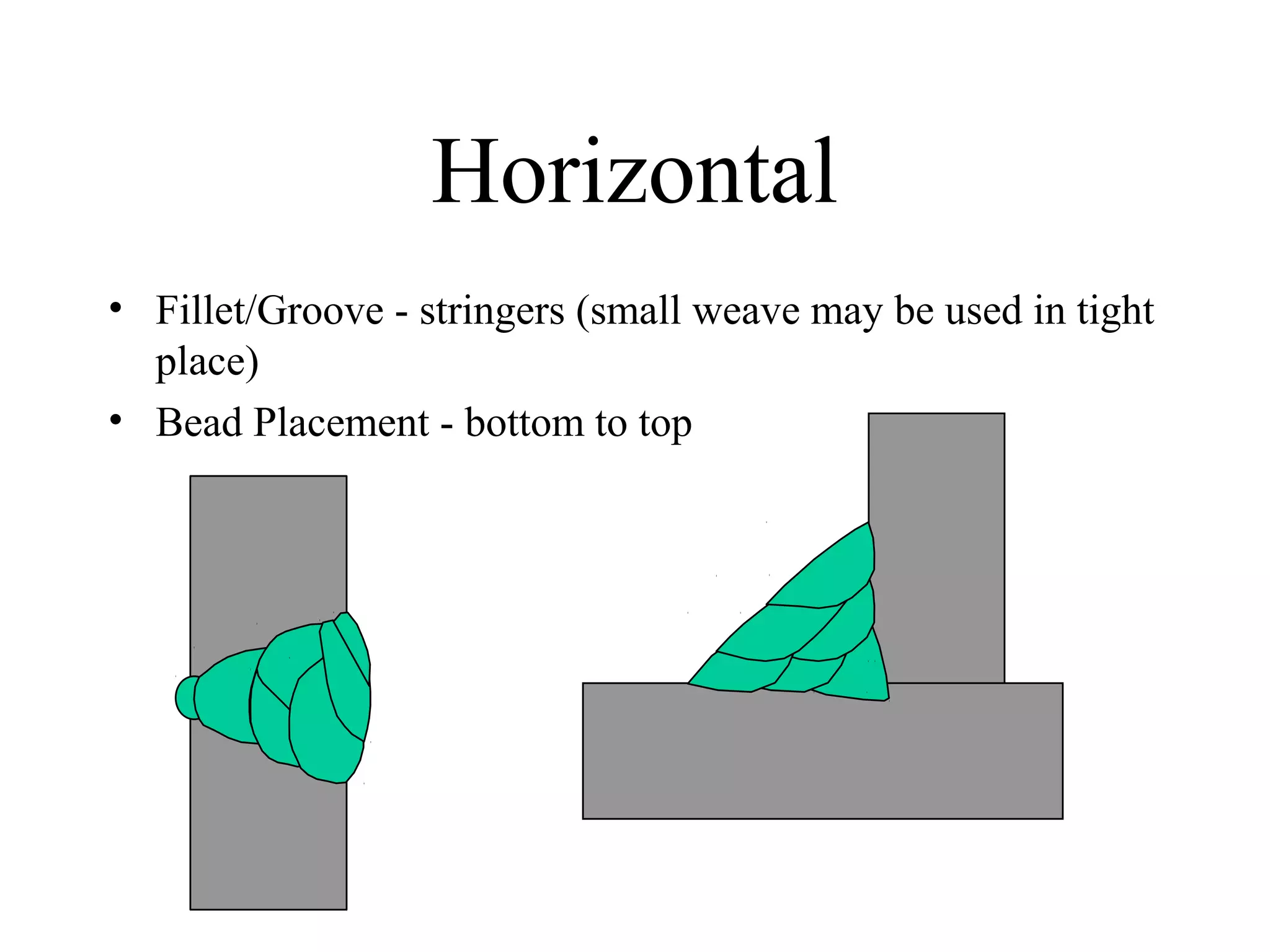

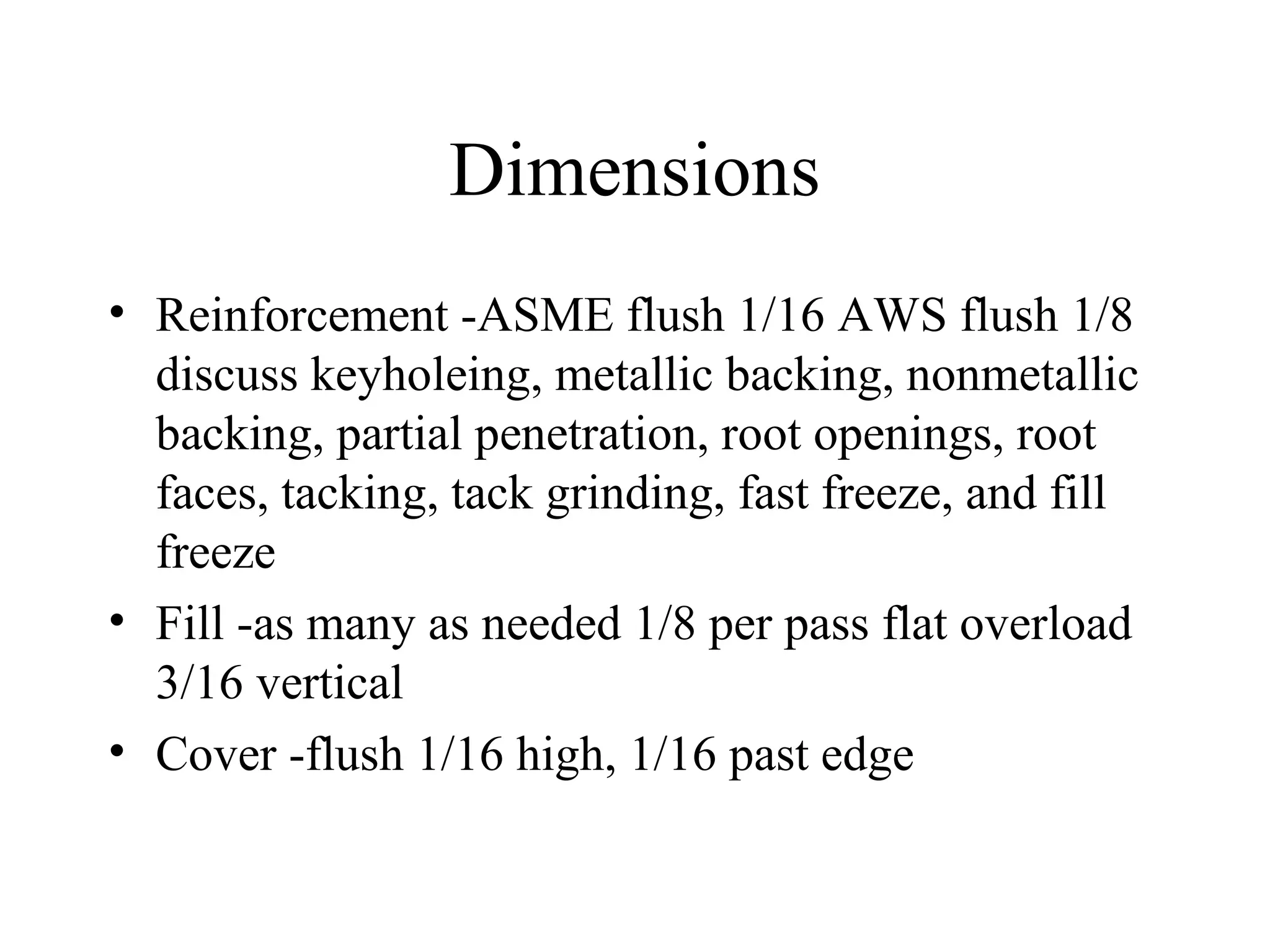

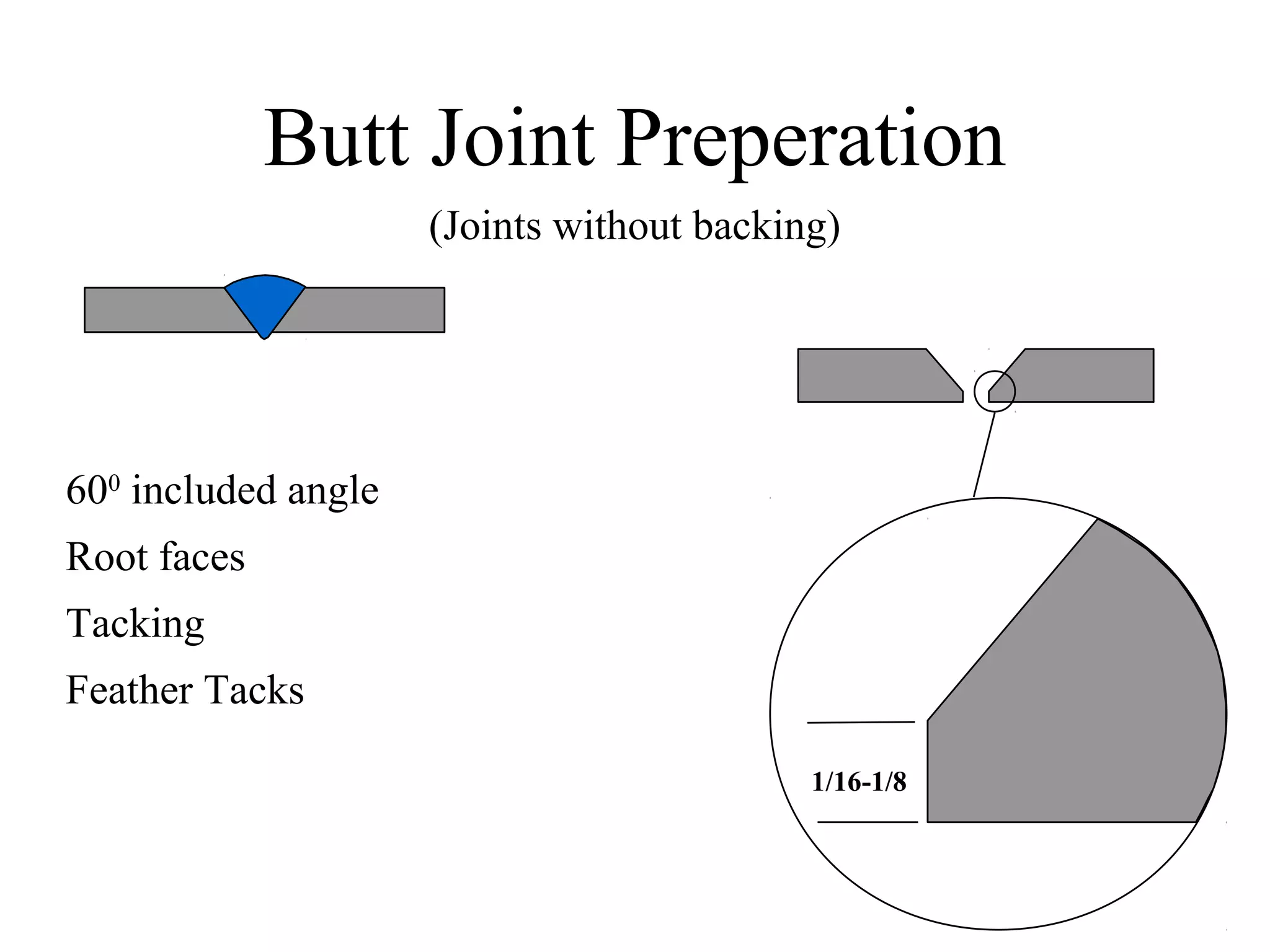

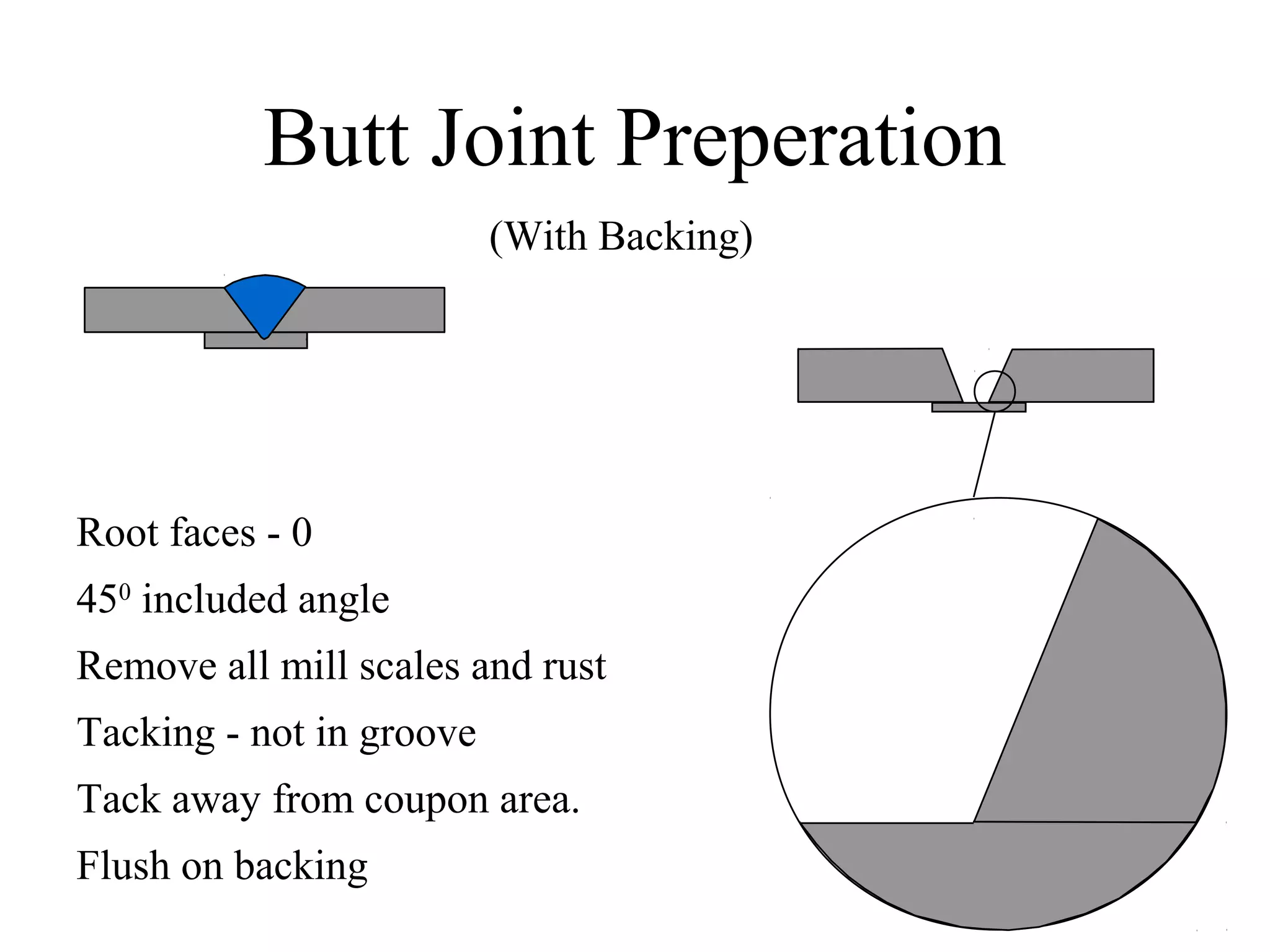

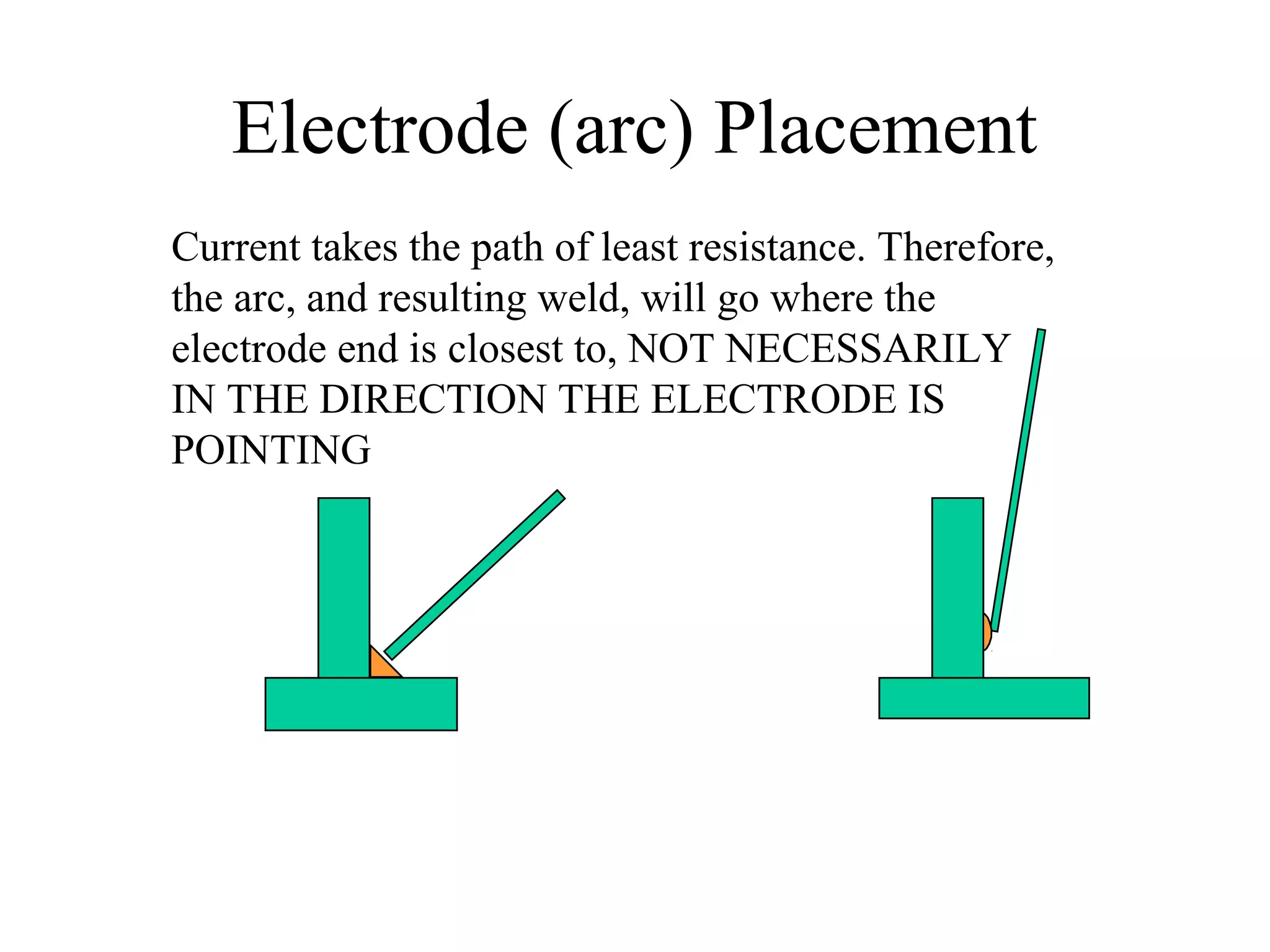

This document summarizes Shielded Metal Arc Welding (SMAW) techniques. It describes different types of weld beads, such as stringer and weave beads, and weld passes like root, fill, and cover passes. It outlines techniques for various weld positions including flat, horizontal, vertical and overhead. It provides guidance on travel speed, electrode placement, arc length and work/drag angles to control weld penetration, dilution and bead shape. It also covers topics like joint preparation, restarts and crater fills.