1) This document provides guidance for completing First Article Inspection Reports in accordance with the 9102 Standard.

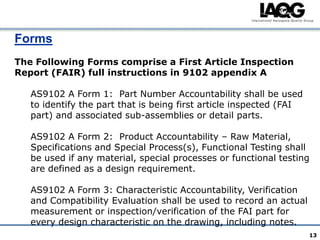

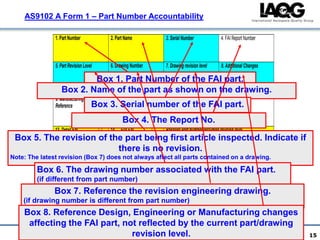

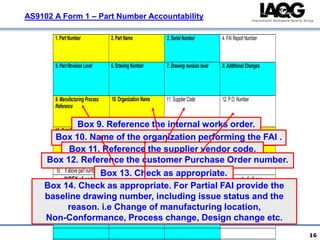

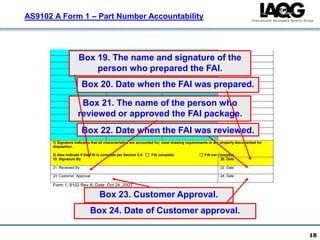

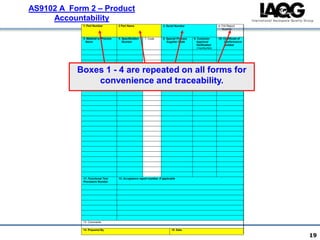

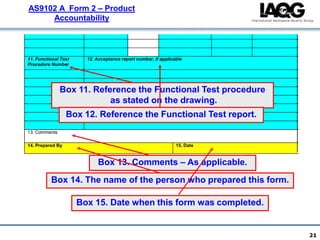

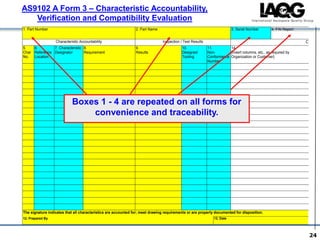

2) Key requirements include recording FAI Reports in English or a specified language, completing the AS9102 forms which include part number accountability, product accountability, and characteristic accountability and verification.

3) An FAI must be performed for new parts, design changes, process changes, and when required by customers. It involves verifying all design characteristics and manufacturing processes.

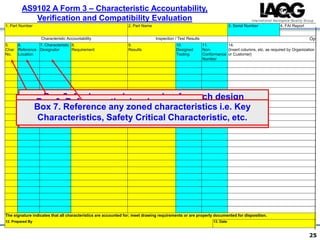

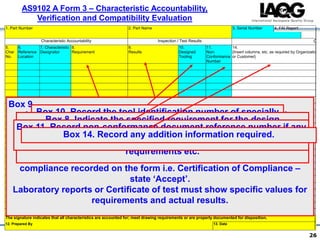

![AS9102 A Form 3 – Characteristic Accountability,

Verification and Compatibility Evaluation

1. Part Number 2. Part Name 3. Serial Number 4. FAI Report

Characteristic Accountability Inspection / Test Results Optio

5. 6. 7. Characteristic 8. 9. 10. 11. 14.

Char Reference Designator Requirement Results Designed Non- [Insert columns, etc., as required by Organization

No. Location Tooling Conformance or Customer]

Number

Box 12. Name of the person who prepared this form.

Box 13. Date when this form was completed.

The signature indicates that all characteristics are accounted for; meet drawing requirements or are properly documented for disposition.

12. Prepared By 13. Date

27](https://image.slidesharecdn.com/faitrainingtutorial011720121-120830022817-phpapp02/85/FIRST-ARTICLE-INSPECTION-27-320.jpg)