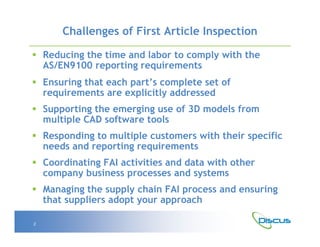

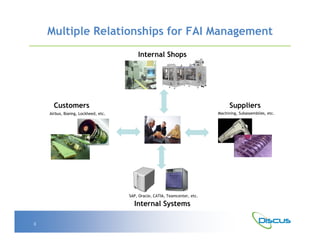

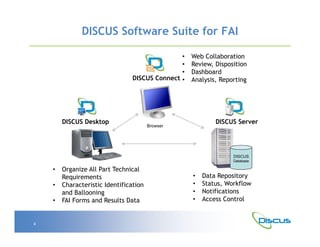

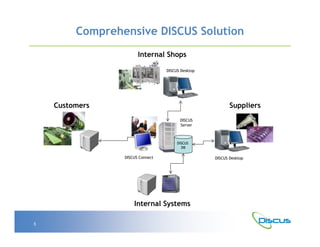

This document discusses challenges with first article inspections and how the DISCUS software suite can help address them. It outlines problems like reducing time/labor for reporting, ensuring all part requirements are addressed, and coordinating activities. The DISCUS solution supports ballooning of 2D/3D models, comprehensive FAI data management, integration with other systems, and benefits like 50% reduced FAI time and avoiding quality issues. It is a flexible software that nearly 1000 aerospace companies already use to lower quality compliance costs.