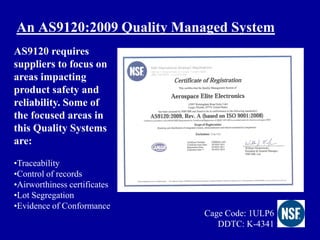

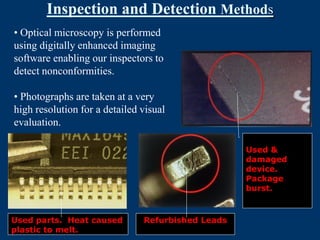

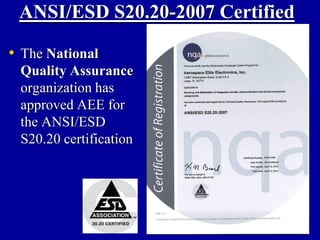

Aerospace Elite Electronics Inc. is an ISO 9001:2008 and AS9120:2002 certified distributor focused on supplying high-quality electronic components to military and defense partners while mitigating the risks associated with substandard products. Founded in 2001, the company emphasizes customer satisfaction and employs strict inspection processes and vendor management to ensure product authenticity and reliability. The organization is known for its commitment to continuous quality improvement and has received accolades for its performance in the industry.