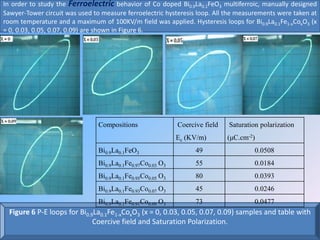

The document discusses the preparation and characterization of doped multiferroic materials, specifically Bi0.9La0.1Fe1-xCoxO3, highlighting their magnetic and electrical properties. It details the experimental methods used, including sol-gel auto-combustion, and presents results related to structural analysis, magnetization, and dielectric properties. The findings indicate that doping significantly enhances the properties of these materials, making them promising for applications in spintronics and microelectronics.

![BiFeO3

1. Distorted Rhombohedral Structure

2. Point Group R3c

3. Perovskite type unit cell with arh =

3.965Å and αrh=89.3°

4. Room temperature Polarization is

along [111]

G. catalan and F. Scot 2009

8](https://image.slidesharecdn.com/multiferroicmaterials-140421192104-phpapp02/85/Multiferroic-materials-8-320.jpg)