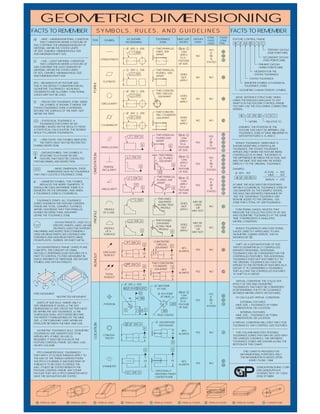

This document defines key terms and rules related to geometric dimensioning and tolerancing. It explains concepts like maximum material condition (MMC), least material condition (LMC), regardless of feature size (RFS), datum features, feature control frames, and how tolerances apply in different conditions. It also defines common tolerance zones and how they are specified in drawings.