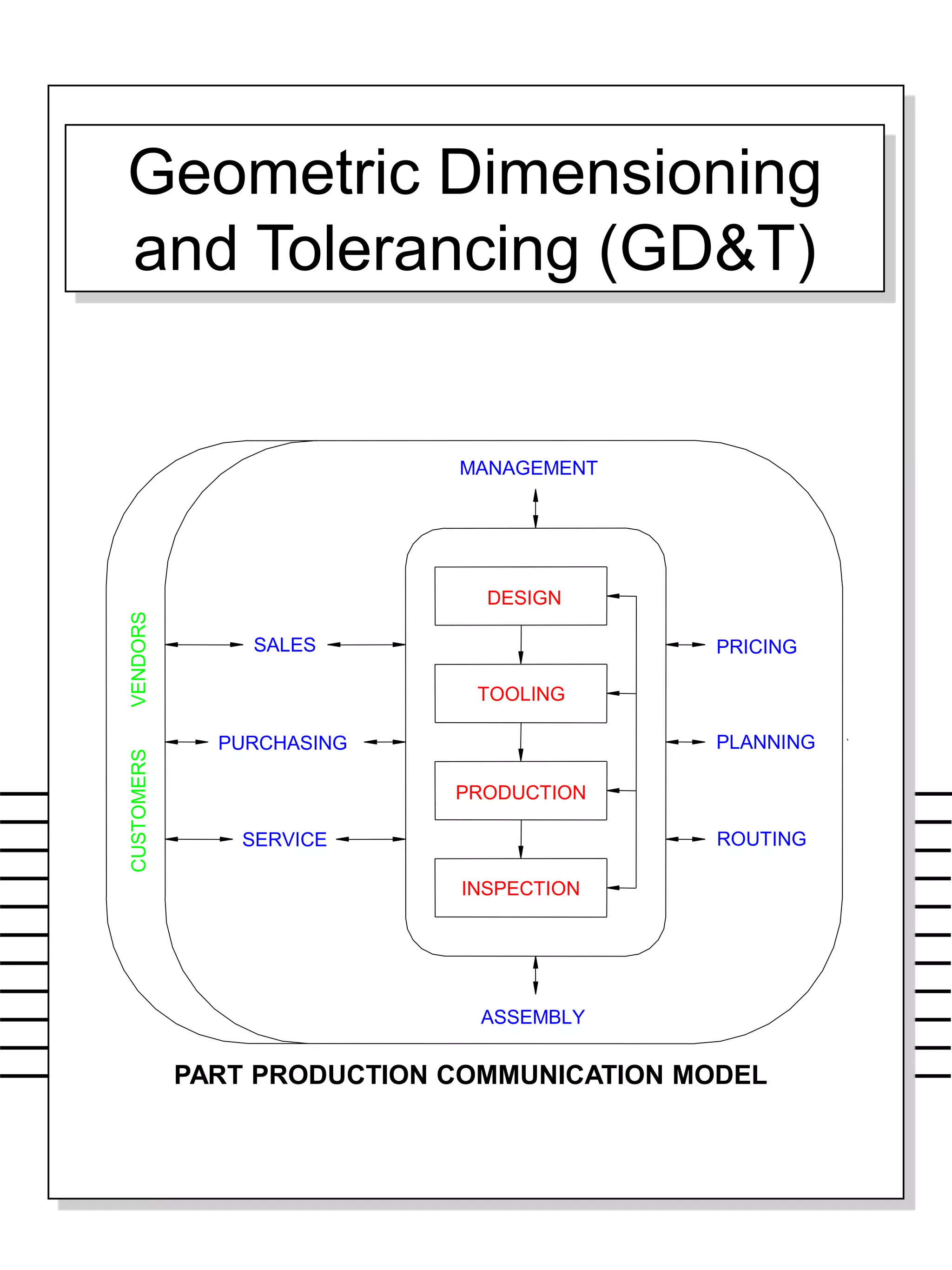

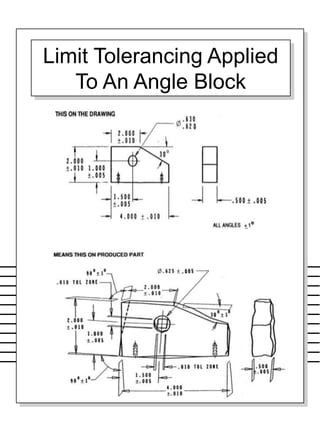

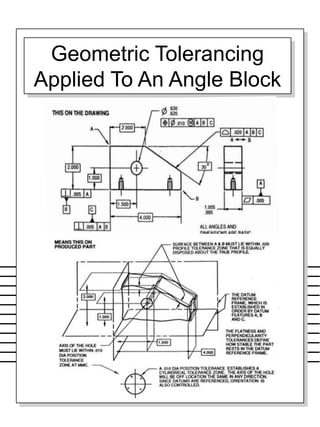

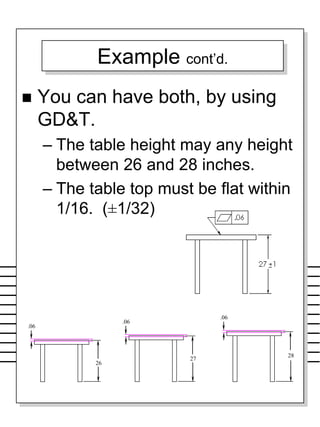

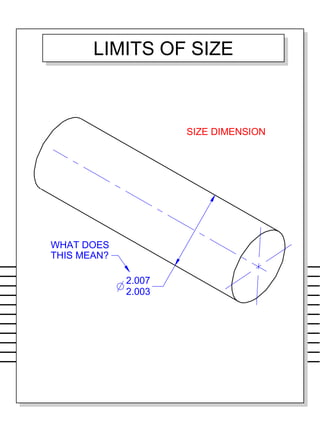

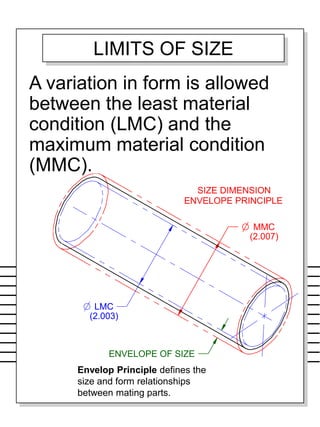

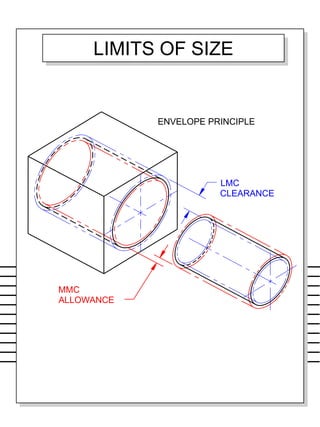

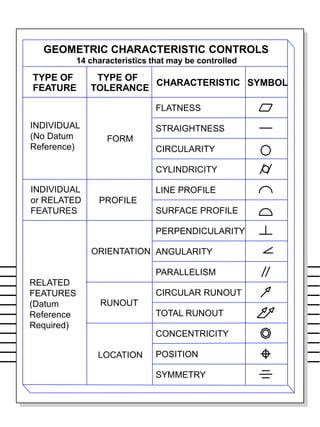

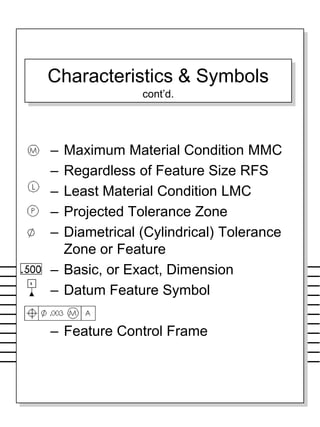

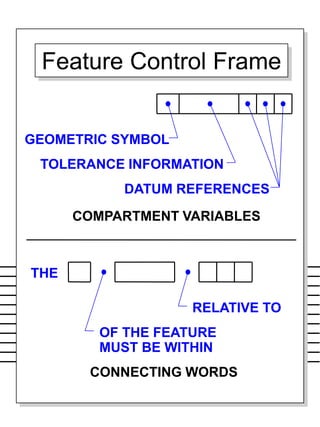

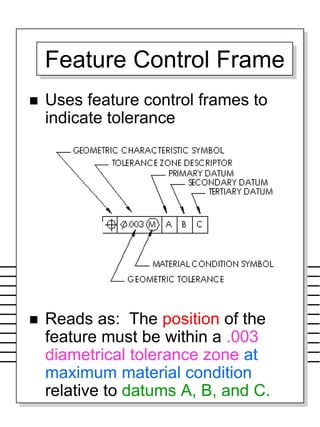

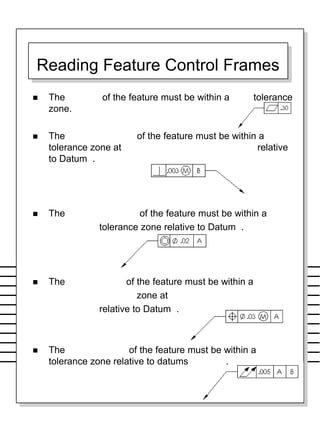

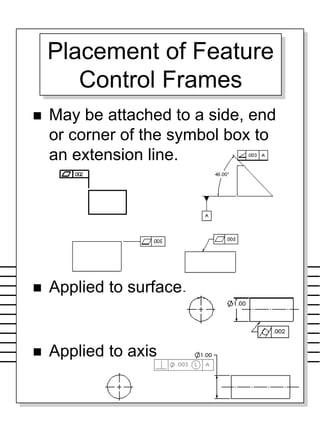

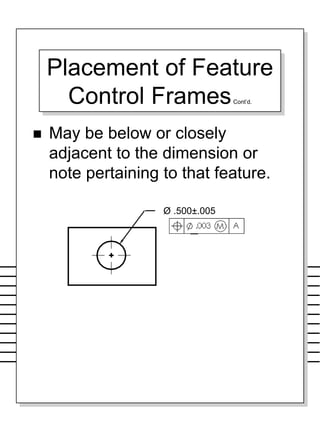

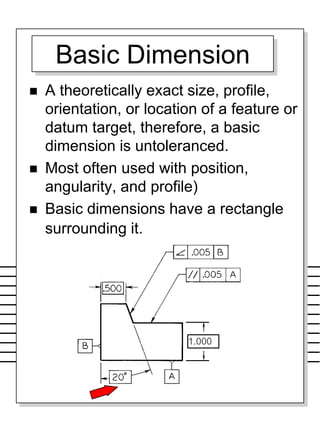

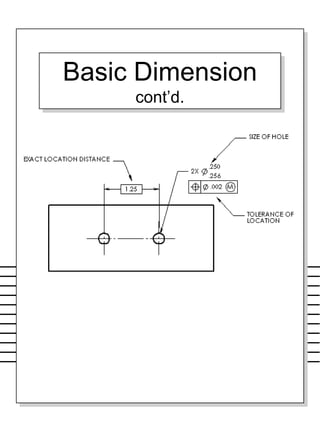

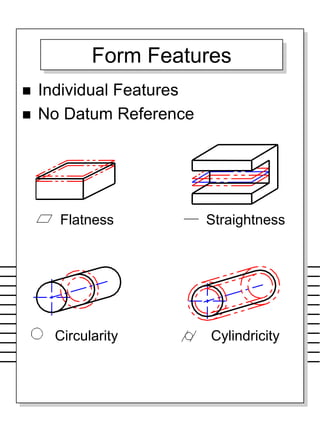

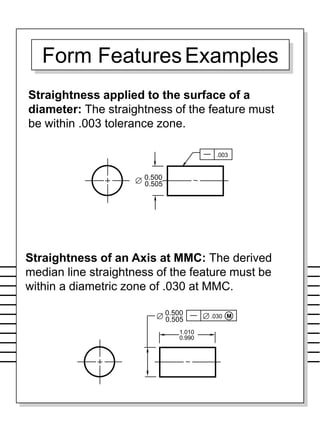

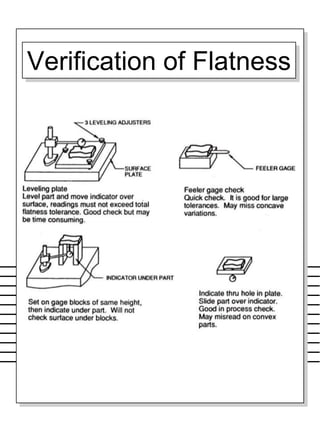

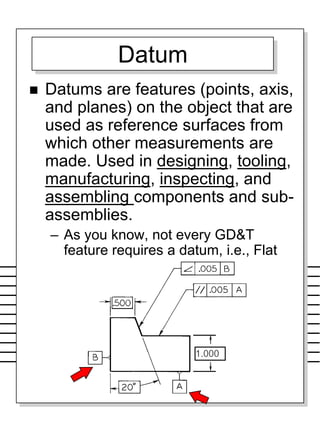

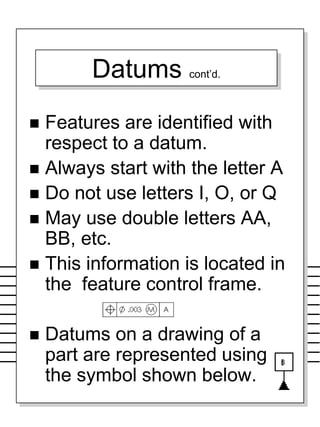

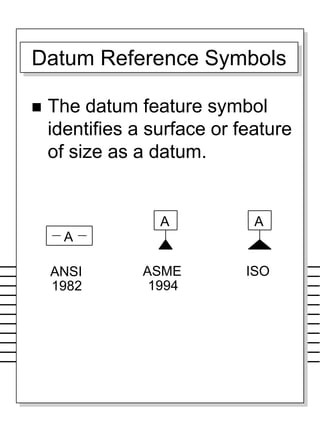

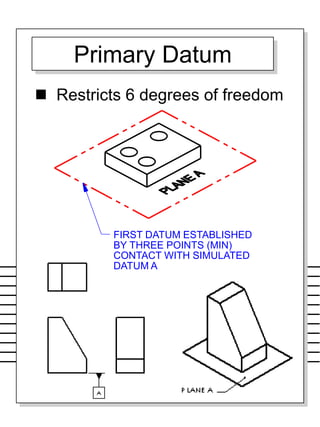

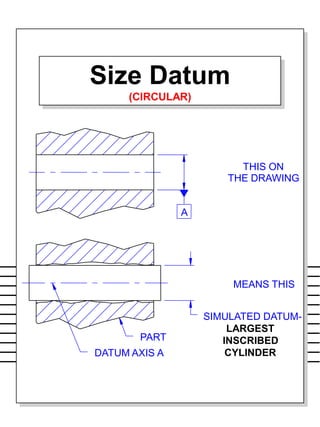

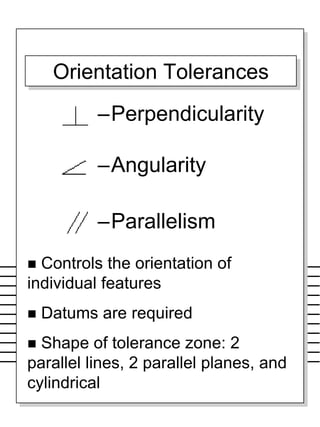

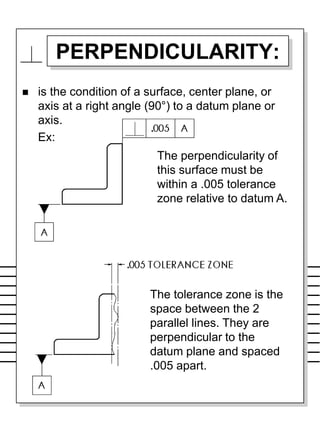

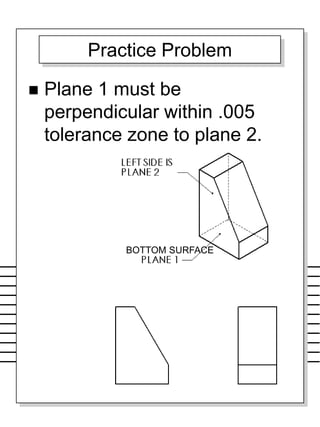

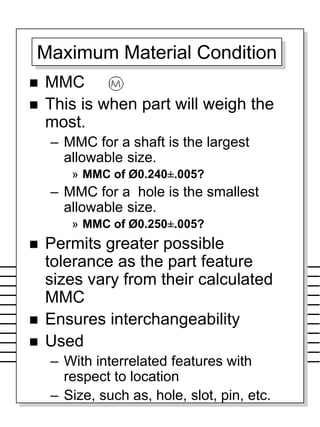

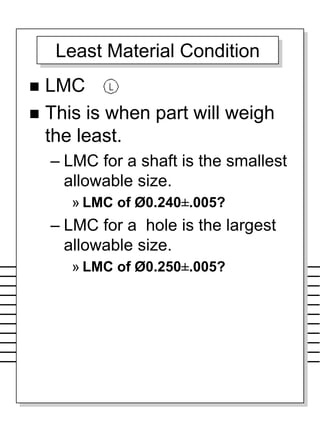

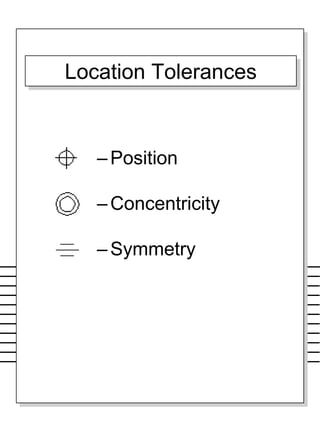

This document provides information about geometric dimensioning and tolerancing (GD&T). It begins by explaining the three categories of dimensioning and then defines GD&T as considering the function of a part and how it interacts with related parts. This allows for more precise dimensioning without increasing tolerances. The document then discusses important GD&T concepts like datums, feature control frames, and how they are used to specify tolerances and dimensions. It also provides examples of how different GD&T features like flatness and straightness are applied.