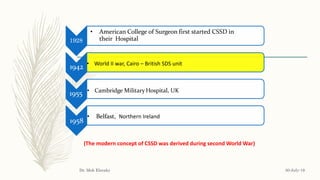

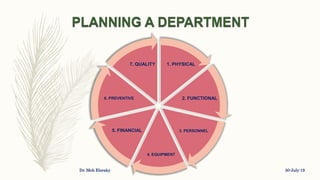

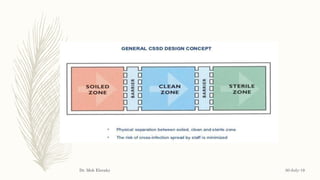

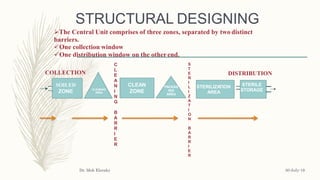

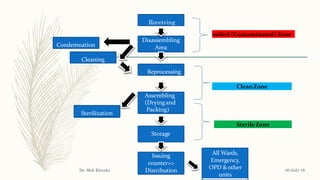

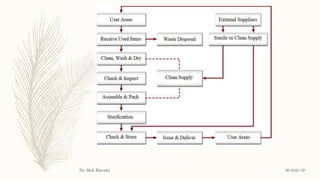

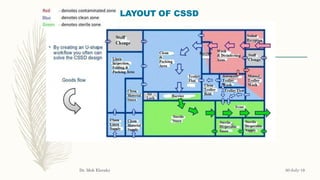

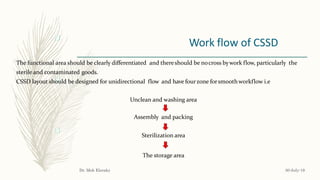

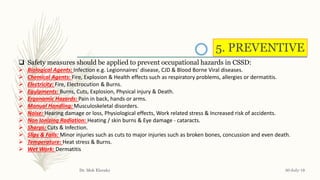

The document provides an introduction to Central Sterile Supply Departments (CSSDs) in hospitals. It discusses the history and development of CSSDs, their aims and objectives, advantages, and key components including physical layout, functions, personnel, finances, preventive measures, equipment, and quality management. CSSDs are responsible for receiving, processing, storing, distributing, and controlling sterile and non-sterile medical supplies and equipment used in patient care. The modern CSSD concept was derived during World War II to help ensure a safe and efficient sterilization and distribution system.