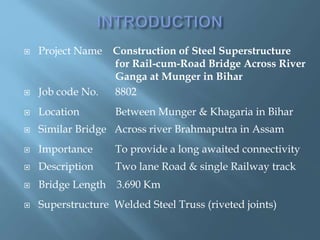

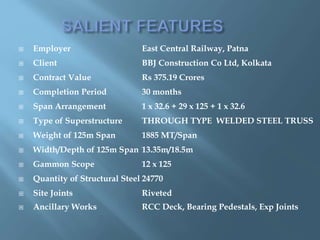

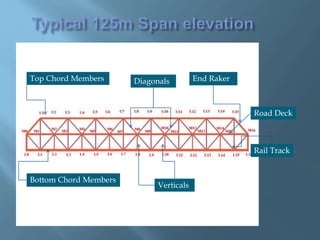

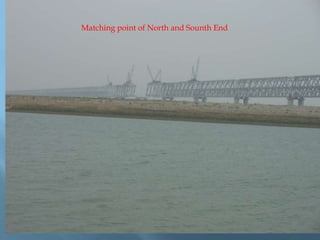

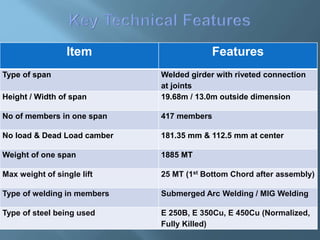

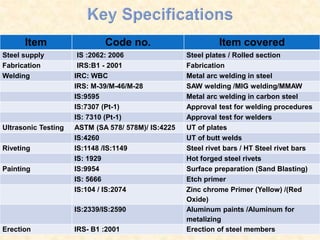

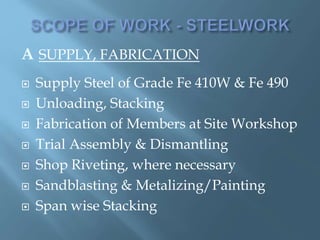

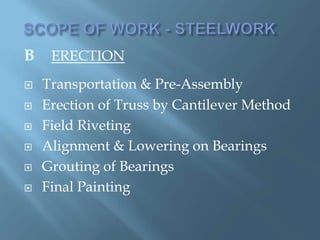

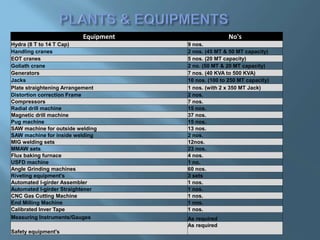

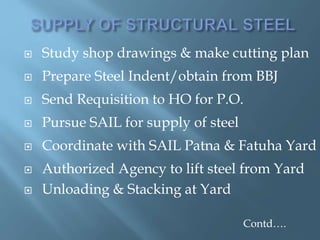

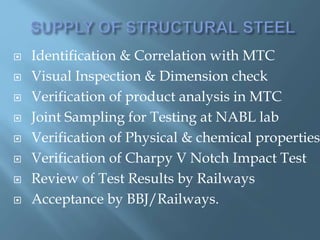

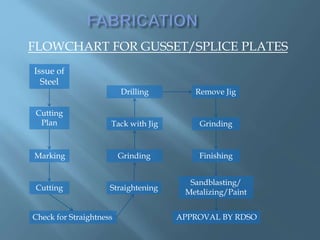

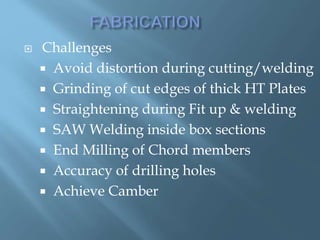

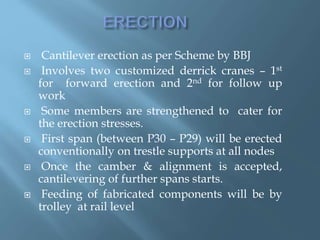

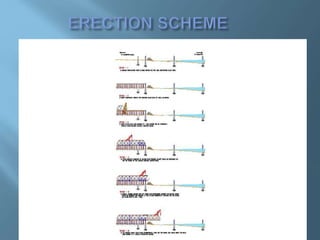

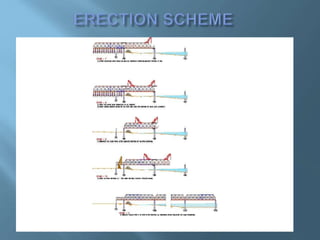

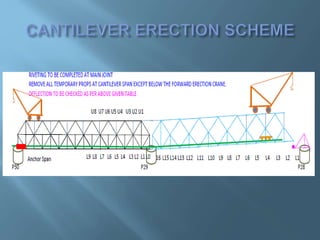

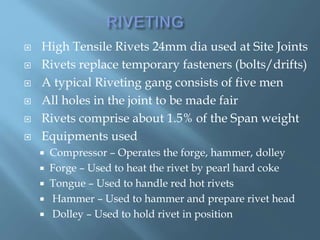

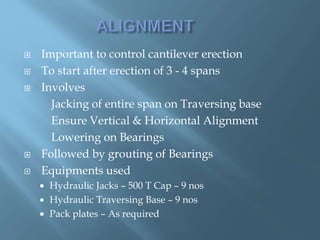

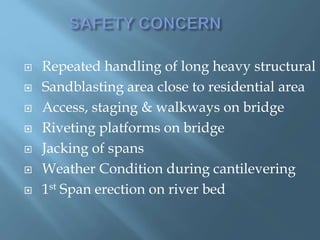

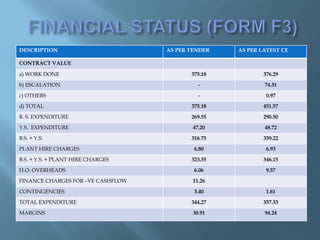

The document discusses the construction of a steel superstructure for a rail-cum-road bridge across the River Ganga in Bihar, India. Key details include a bridge length of 3.690 km using welded steel truss construction. Gammon Infrastructure Projects Ltd has been contracted to fabricate and erect 12 spans of 125m each. The work involves fabricating over 24,000 tons of structural steel at site workshops and erecting the spans by cantilever erection using customized cranes. Challenges include avoiding distortion during fabrication and controlling cantilever erection stresses.