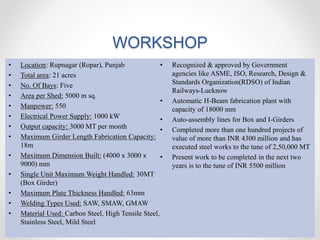

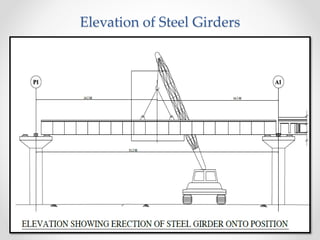

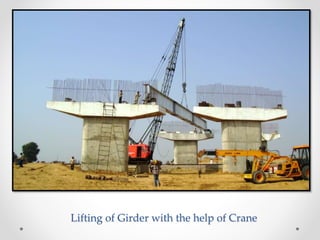

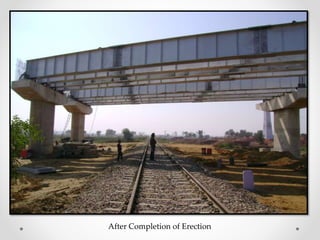

This company was founded in 1986 and specializes in steel structure engineering, thermal plant structures, and civil engineering projects. It has 500 permanent employees and works on various projects sites with 5,000 locally employed staff. The company has received ISO certification and is approved by RDSO for fabrication and supply of steel bridge girders. It is currently ranked 38th among India's fast growing mid-size companies. The document then provides details about a specific project to fabricate and erect steel plate girders for a road over bridge, including the scope of work and specifications of the company's workshop where fabrication will occur.