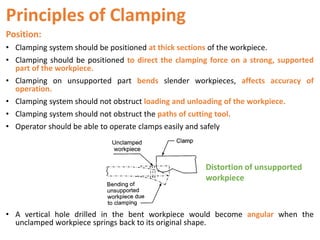

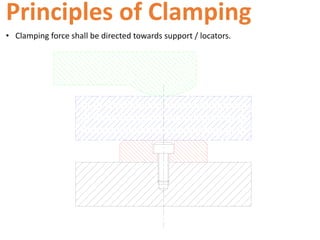

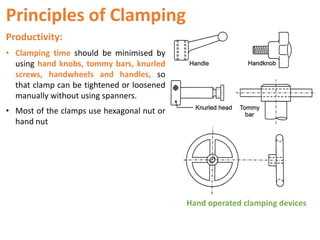

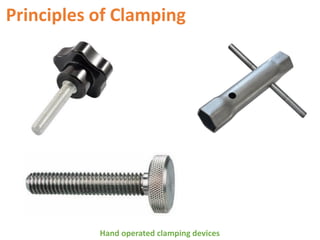

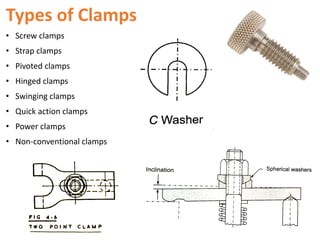

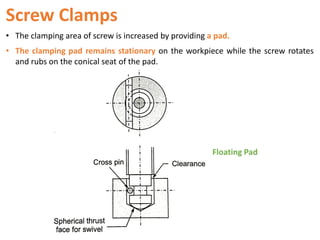

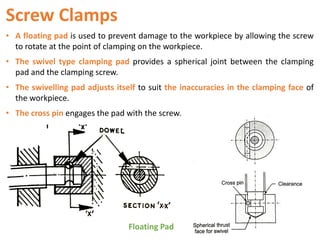

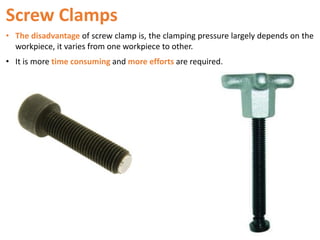

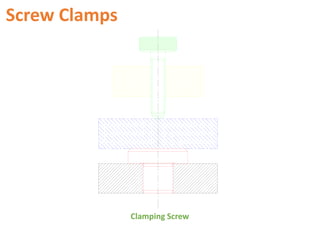

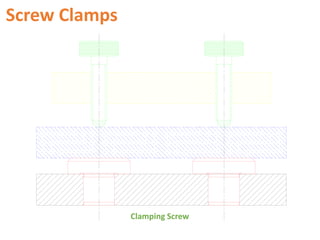

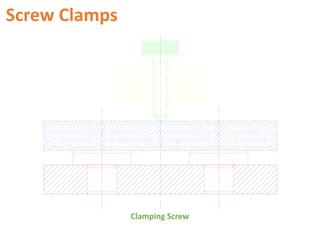

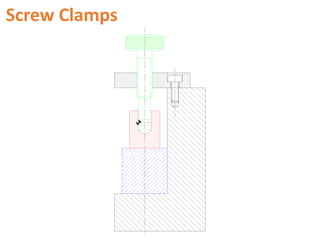

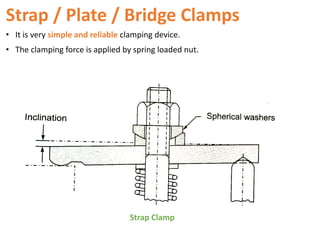

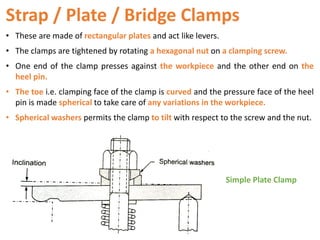

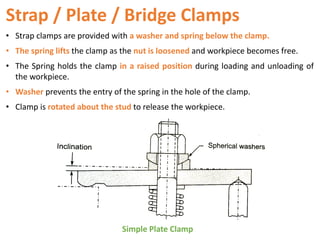

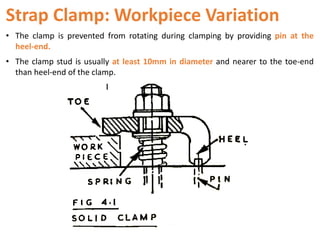

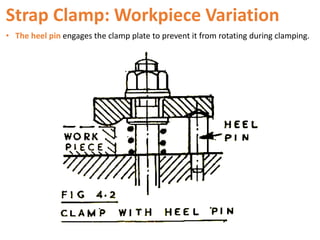

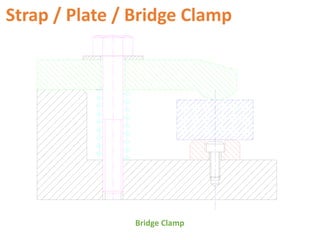

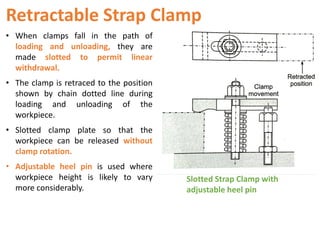

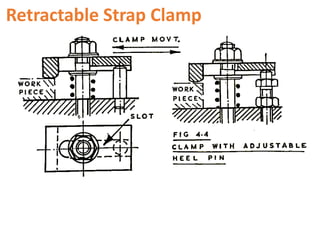

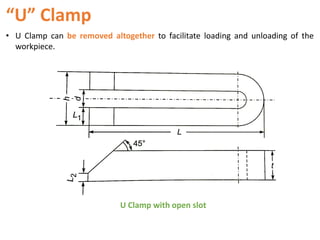

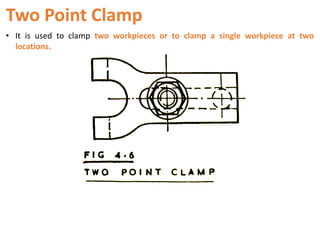

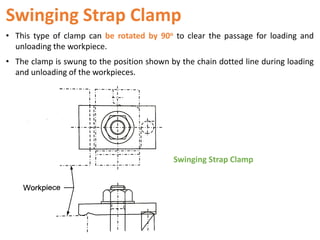

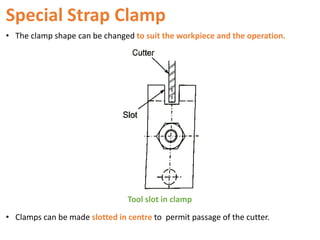

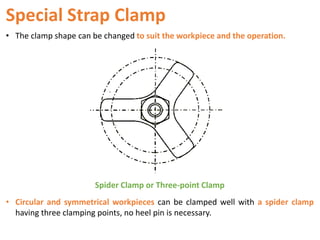

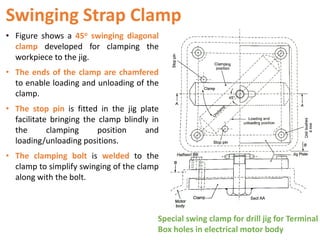

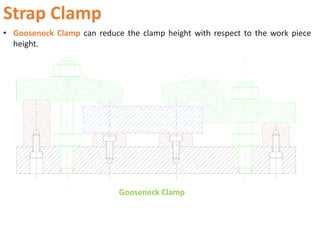

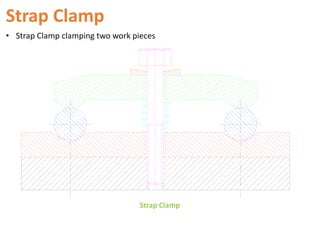

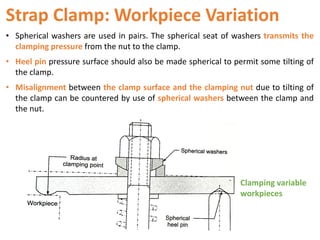

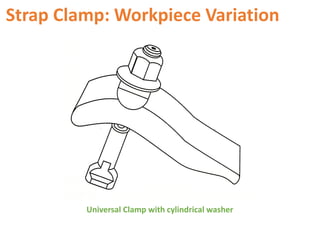

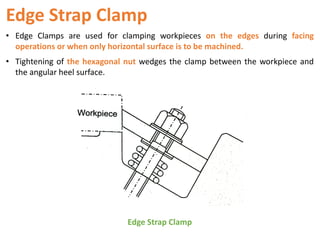

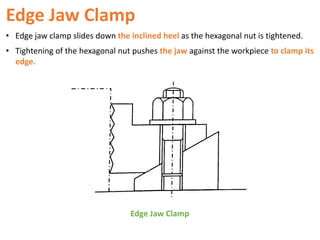

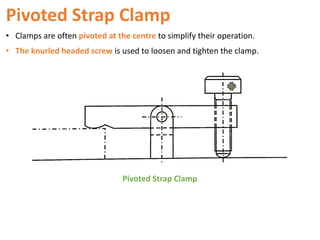

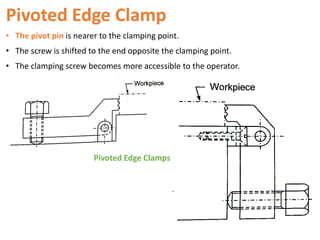

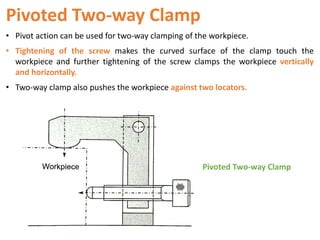

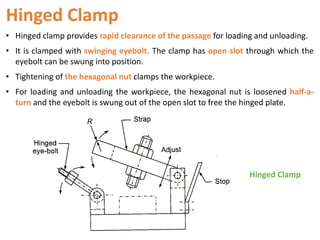

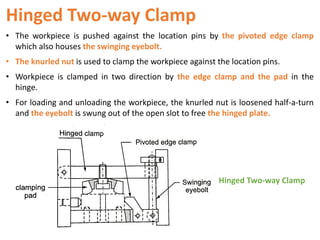

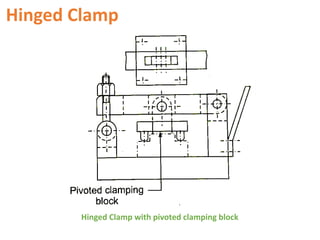

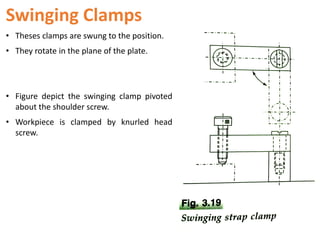

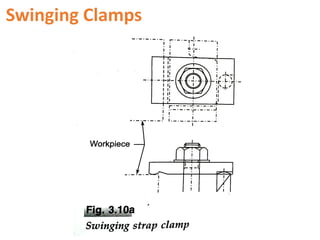

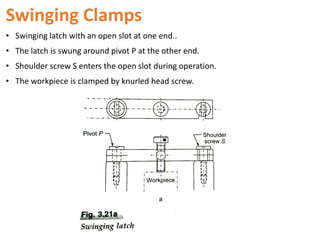

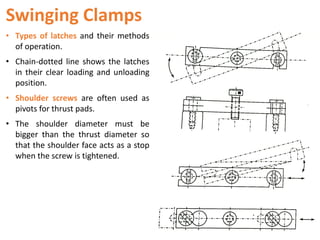

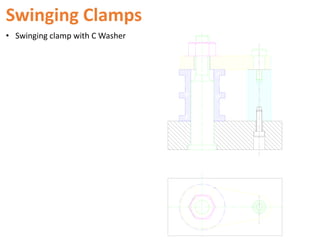

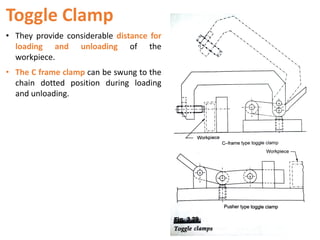

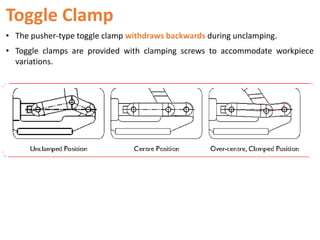

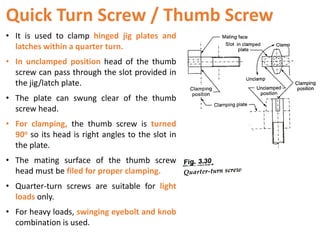

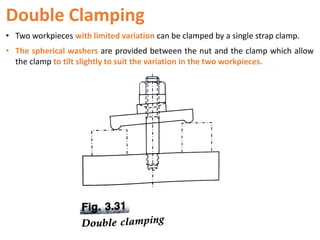

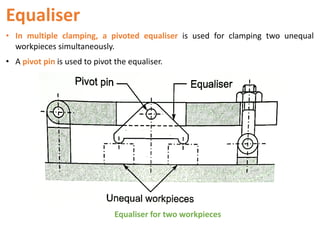

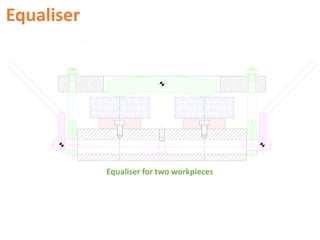

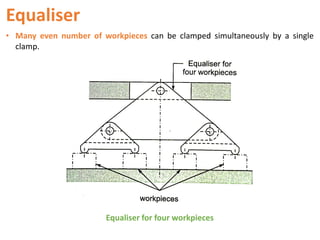

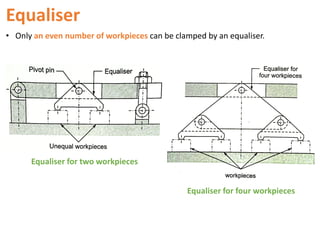

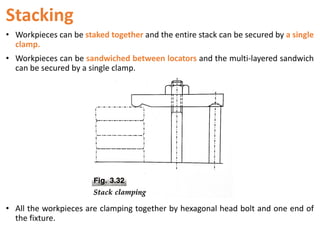

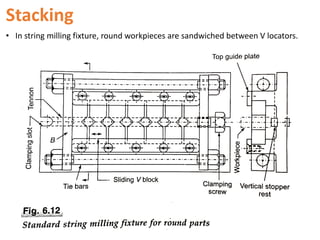

The document discusses the principles, types, and methods of clamping systems used in manufacturing, emphasizing the importance of secure workpiece positioning, adequate clamping strength, and efficient operation. It outlines various clamping devices such as mechanical, pneumatic, and hydraulic clamps, and highlights considerations for operator fatigue and ease of maintenance. Additionally, it details specific clamp designs and their functionalities to accommodate workpiece variations and enhance productivity.