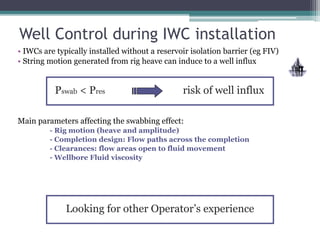

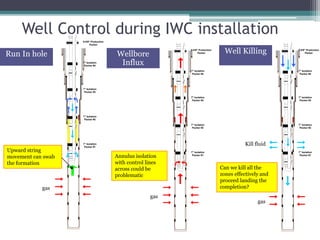

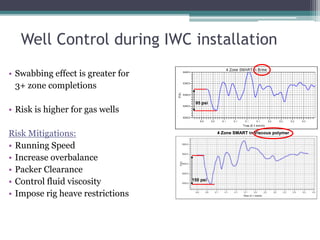

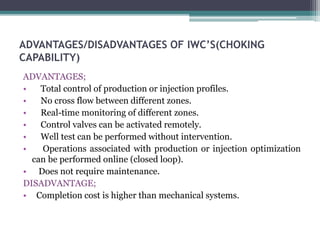

This document discusses intelligent well completions (IWC), which use real-time downhole monitoring and remote control to maximize oil recovery. IWC involves installing gauges and control valves downhole to monitor and adjust production from individual zones. Key benefits include total control of zonal production profiles, ability to test zones without intervention, and optimization of production online. Challenges include higher upfront costs than conventional completions. The document outlines IWC components, applications, installation considerations, case studies and advantages over traditional completions.