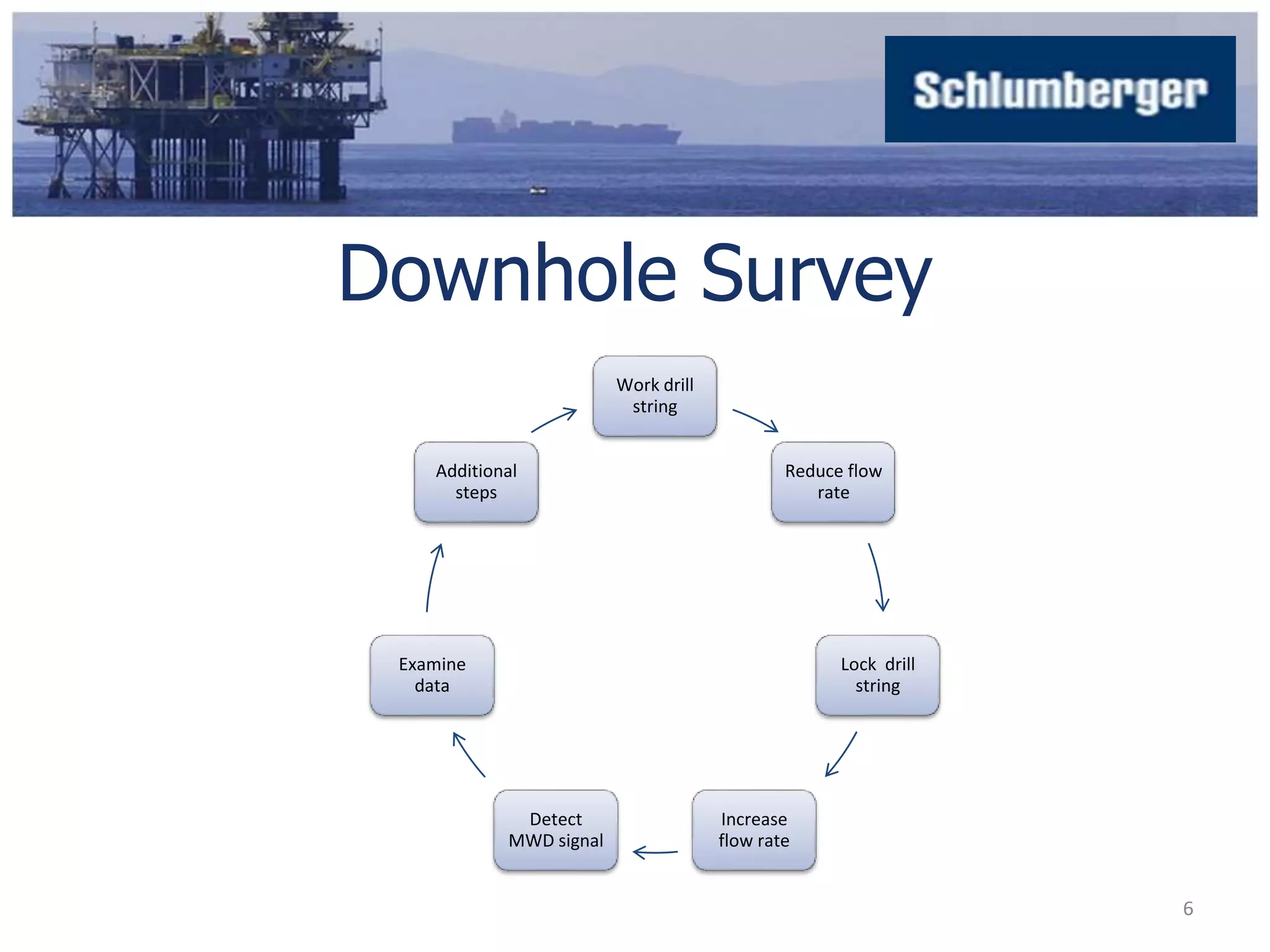

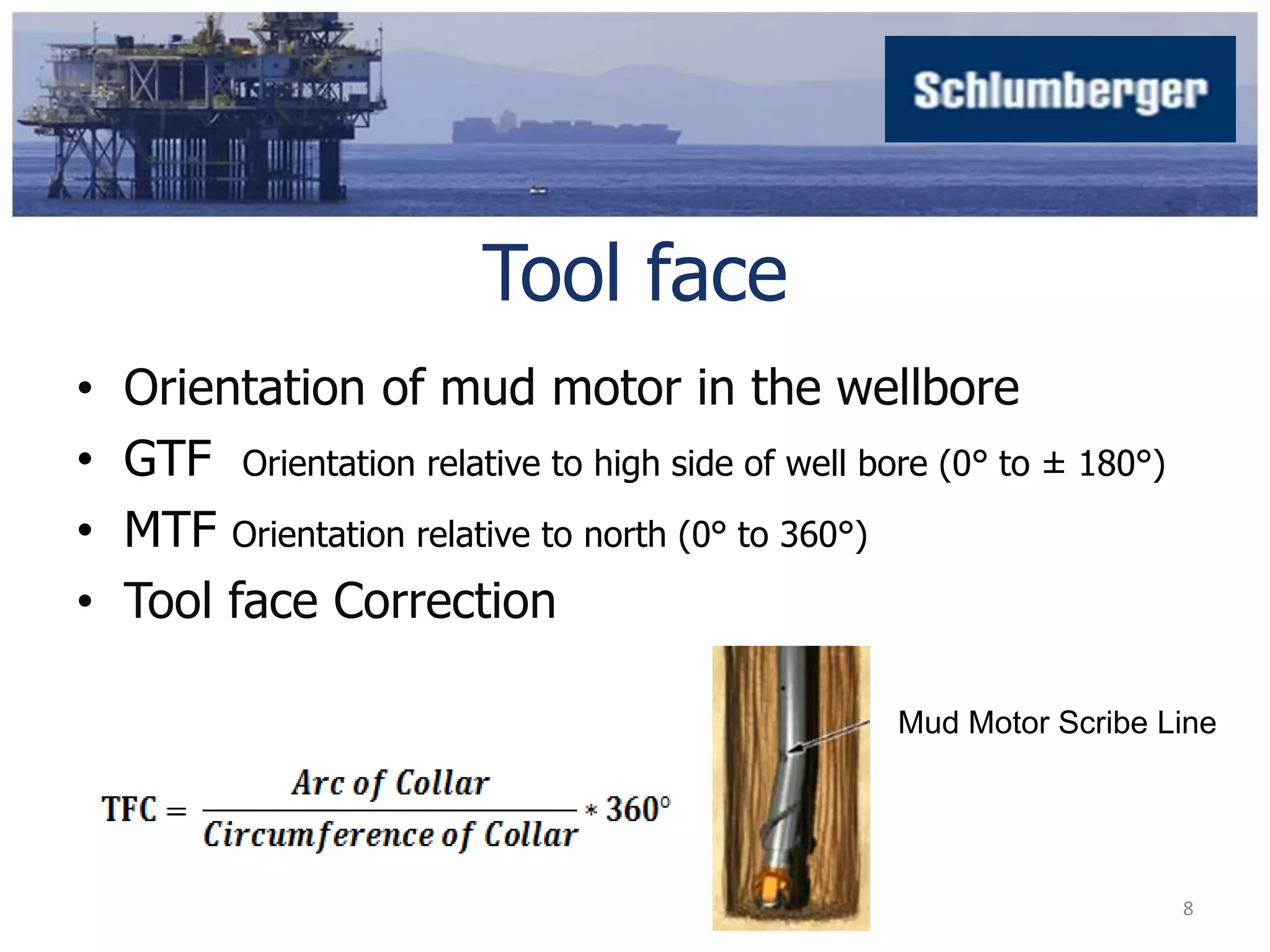

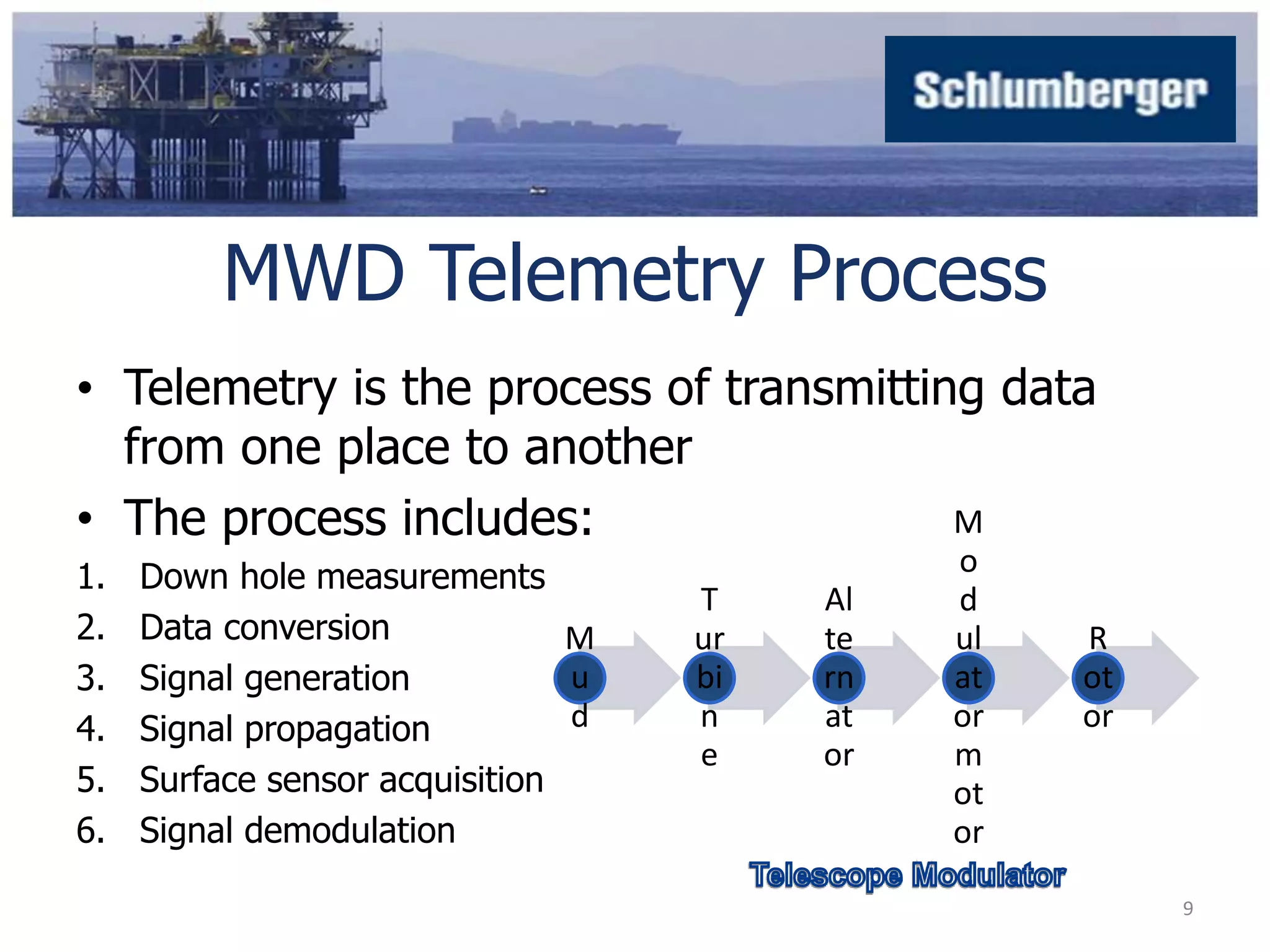

The document presents an overview of the Drilling and Measurement (D&M) operations, detailing key services such as measurements while drilling (MWD) and directional drilling (DD). It outlines essential rig components, telemetry processes, and various terminologies used in drilling operations. The document concludes with a focus on future advancements like sonic logging while drilling and the role of mud logging.