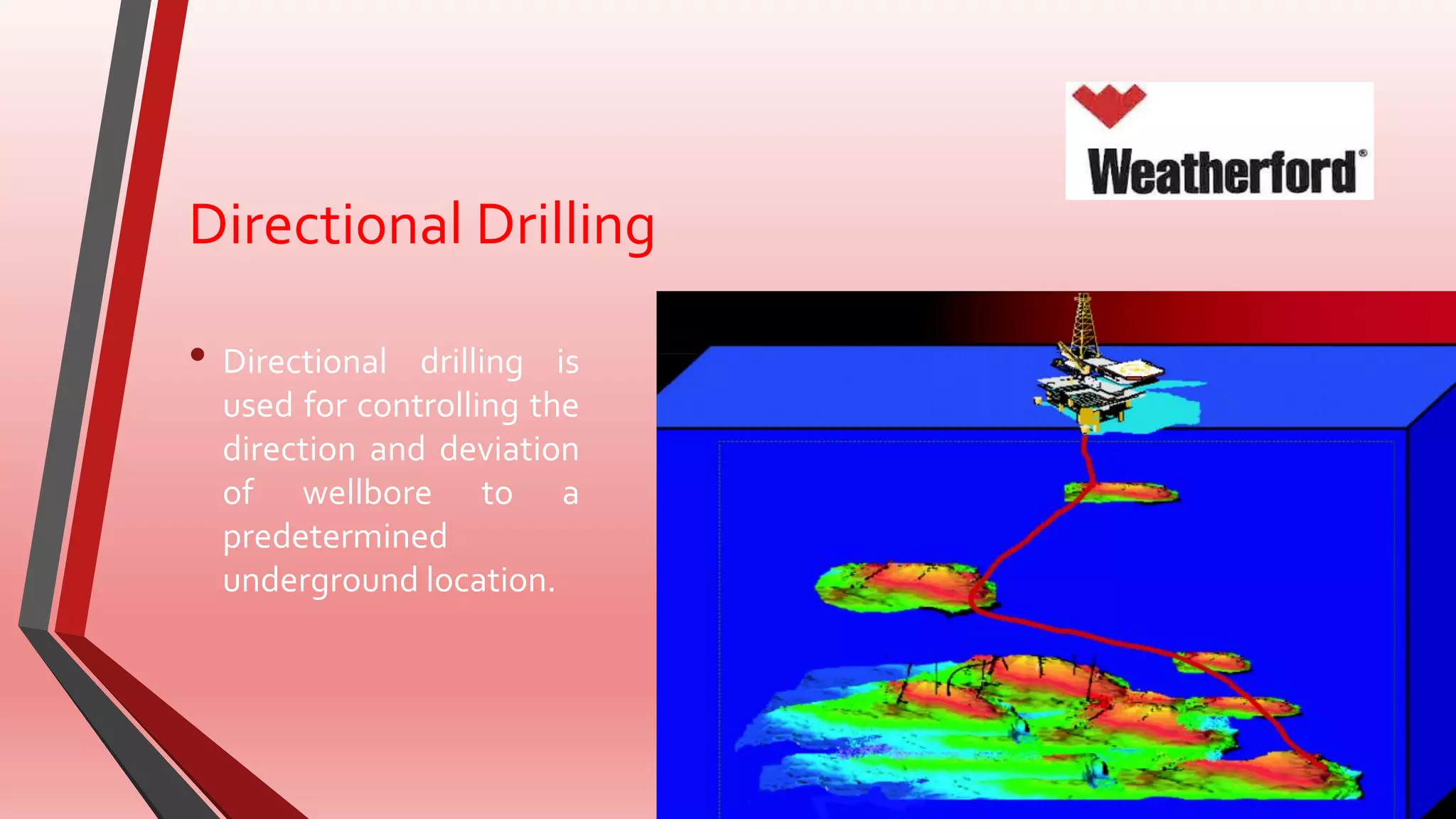

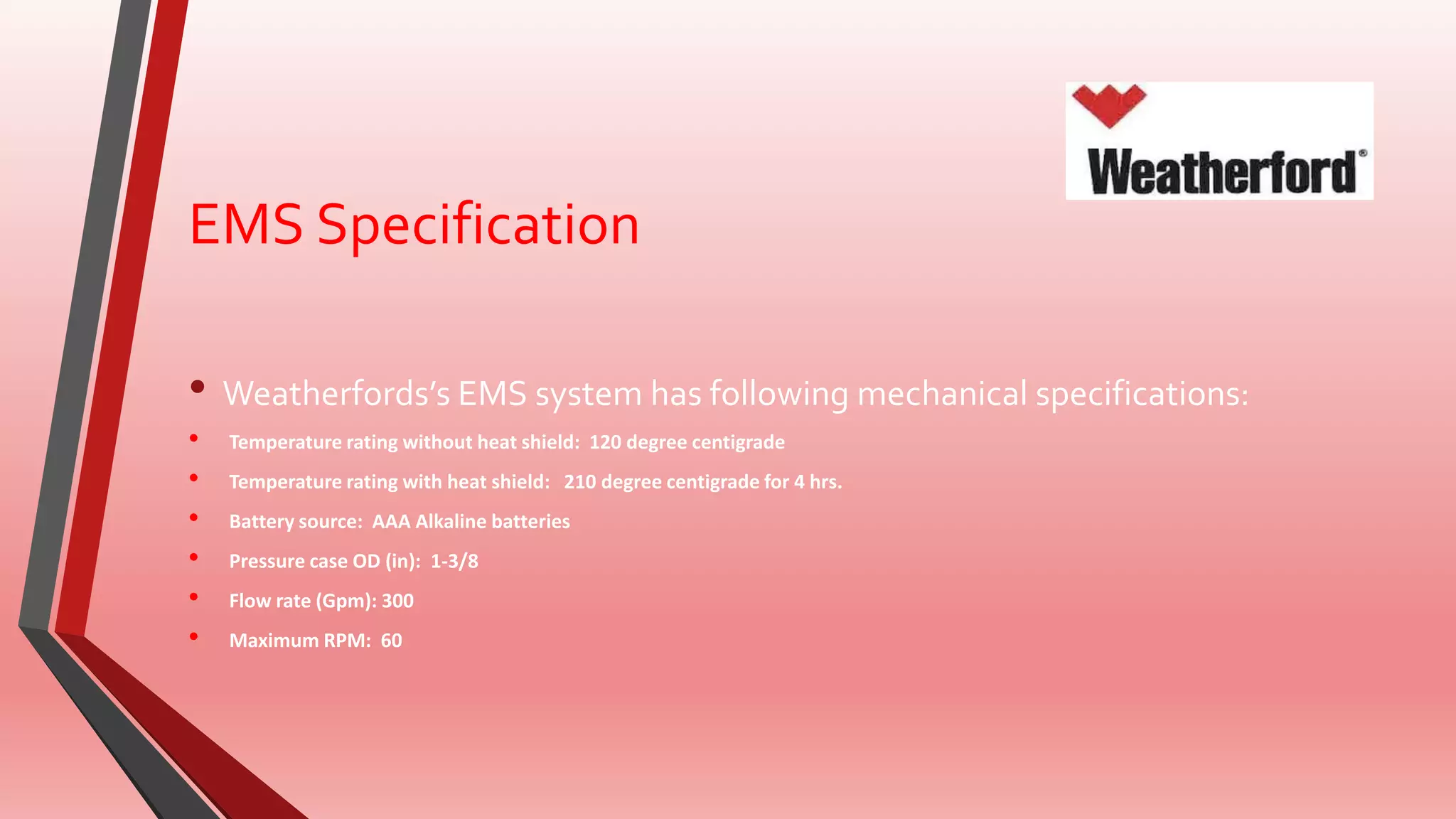

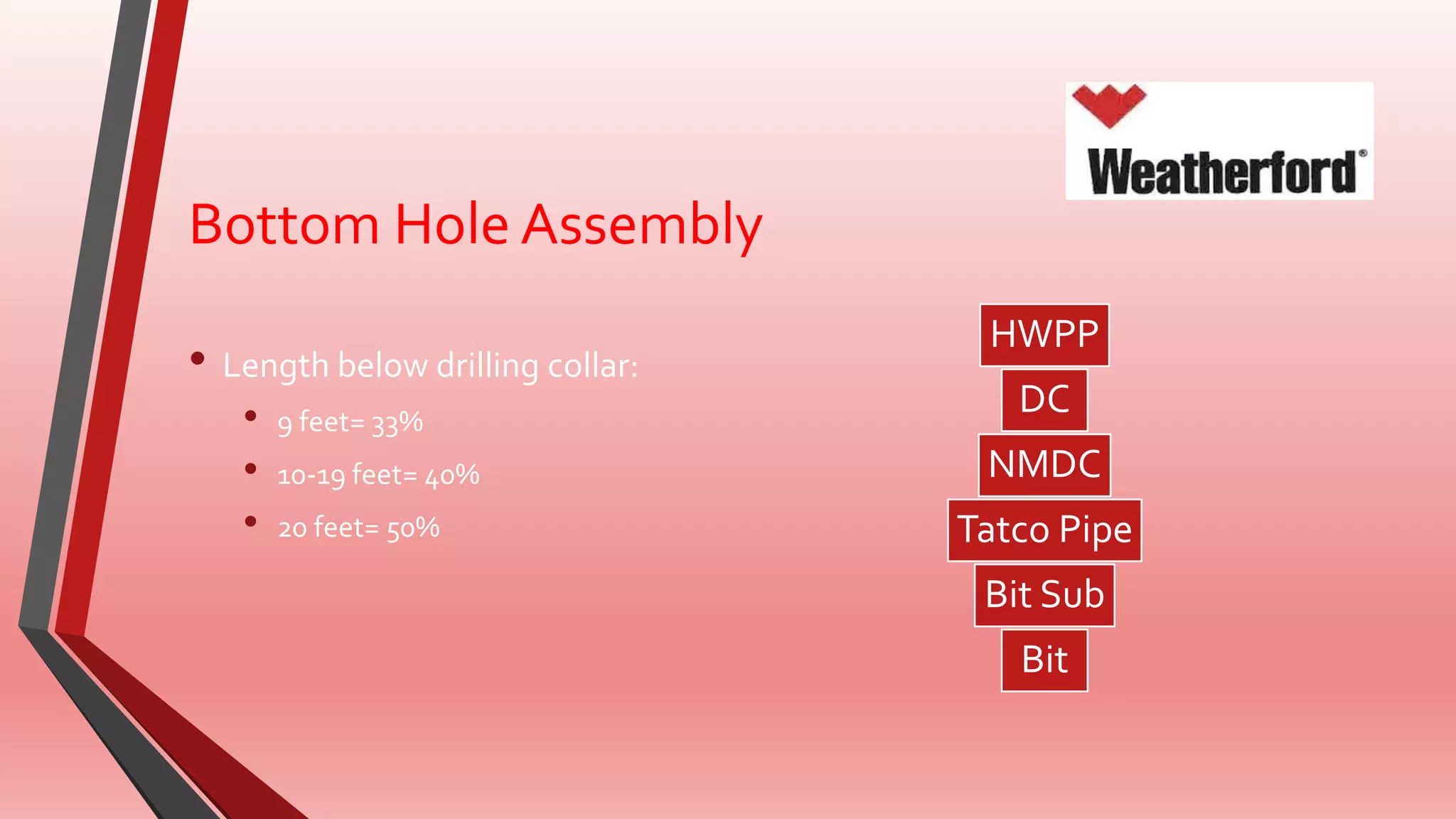

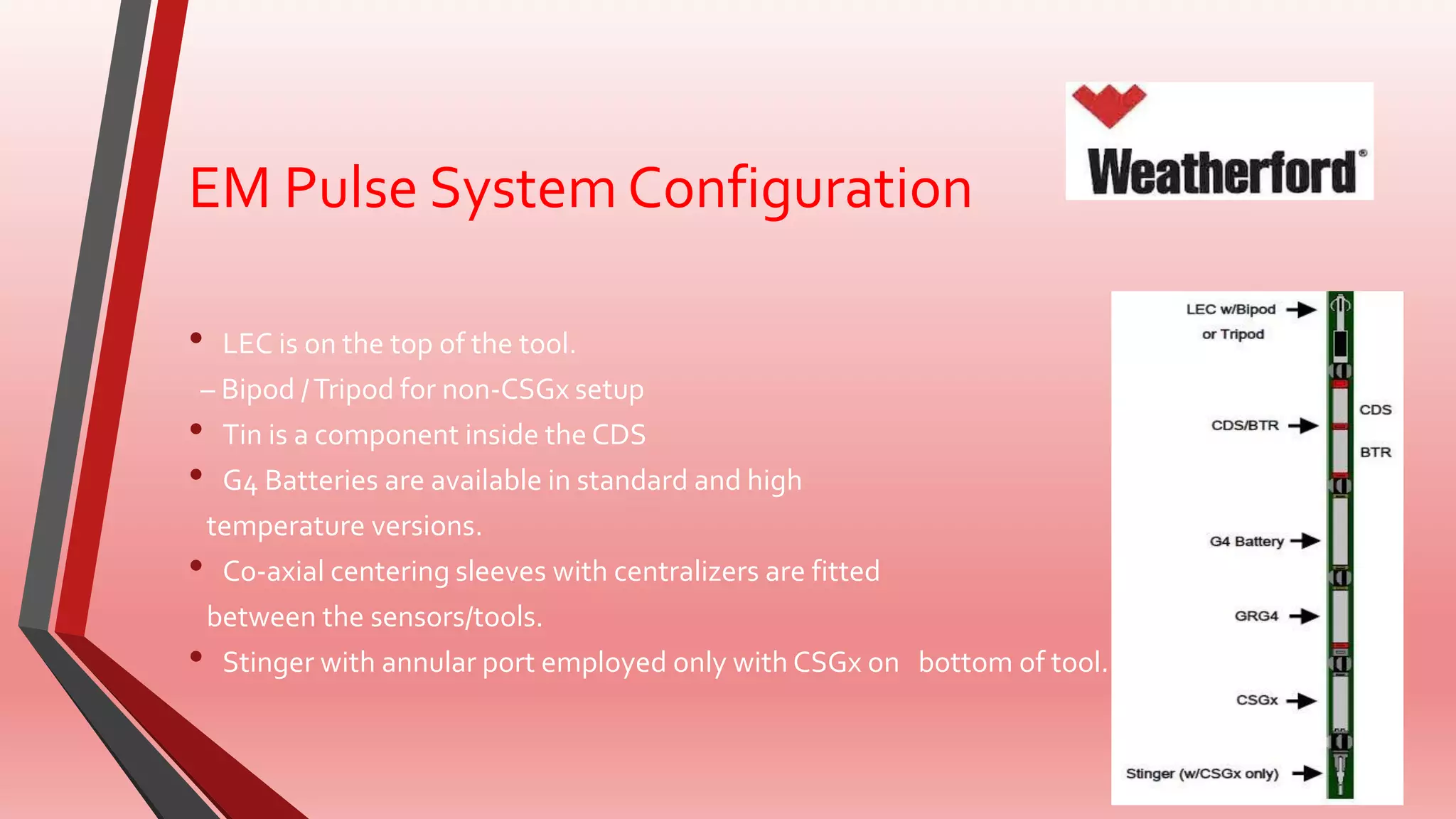

This document provides an overview of Hamza Nasir's internship presentation on drilling services at NUST CEME. The objectives of the internship were to get familiarized with oilfield services, drilling operations, and related tools and equipment. Key topics covered include directional drilling techniques using measurement-while-drilling (MWD) tools to monitor borehole inclination and azimuth in real-time. The presentation discusses Weatherford's electromagnetic MWD and extended range MWD systems, including their specifications, components, benefits, and applications.