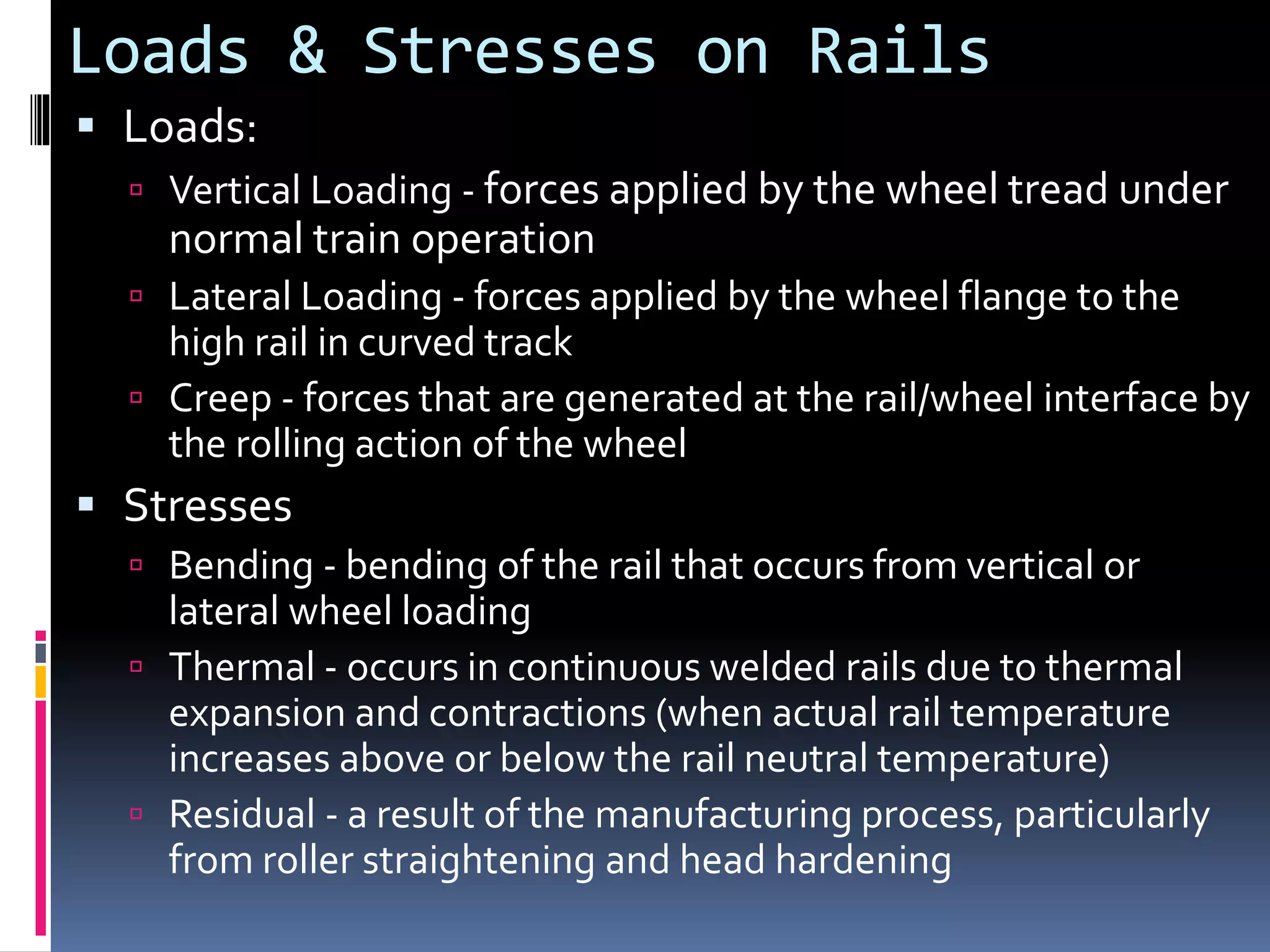

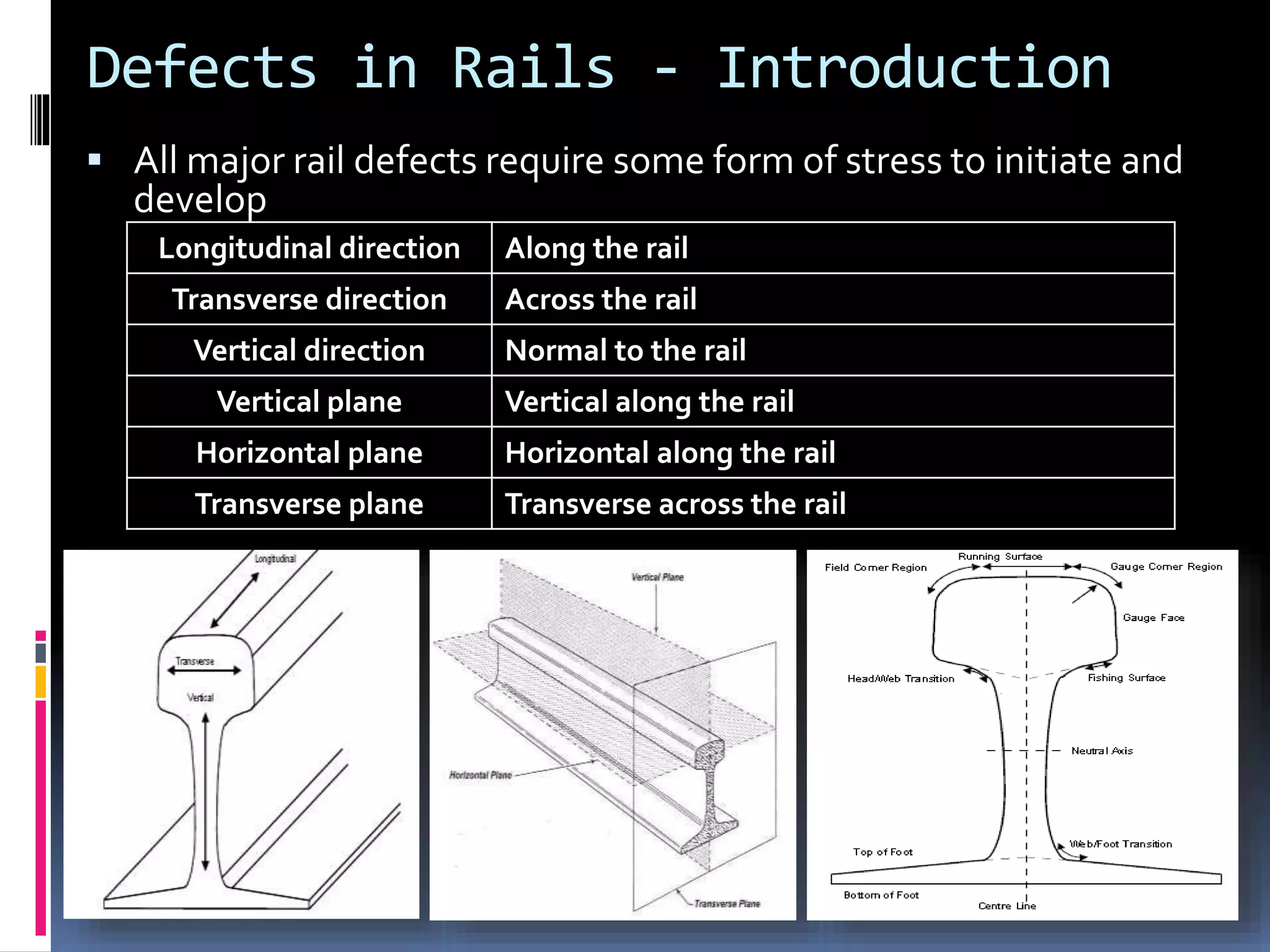

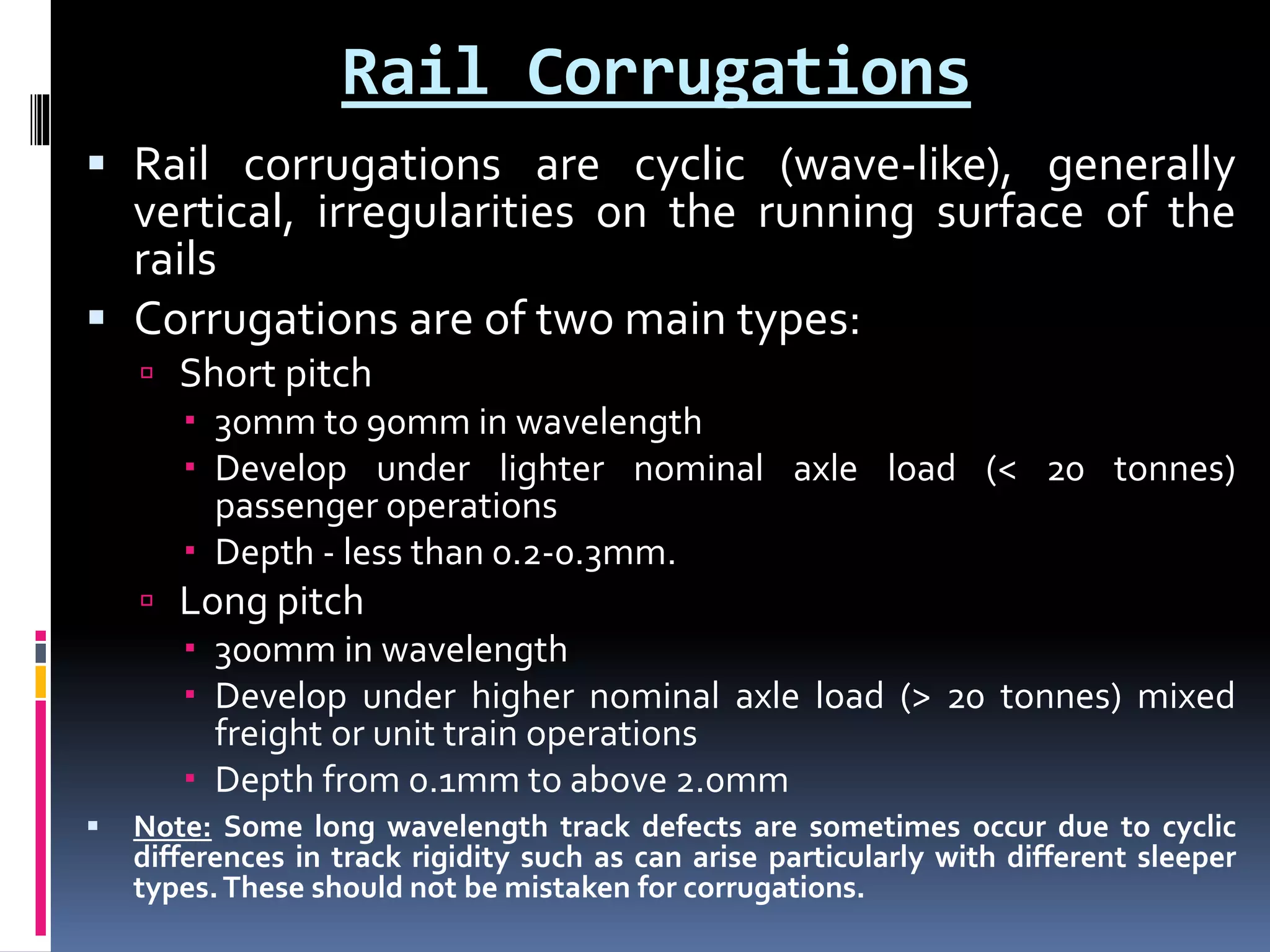

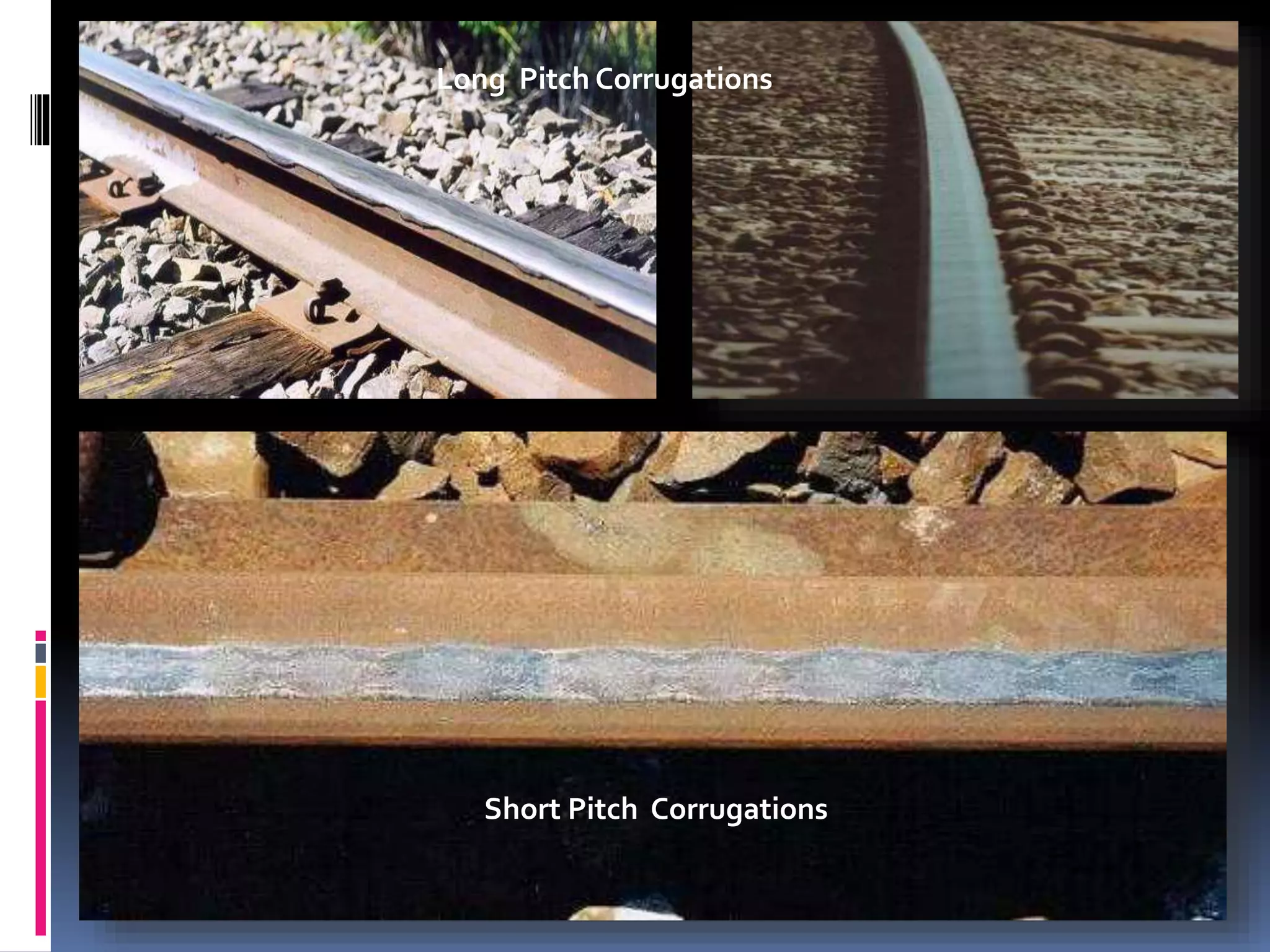

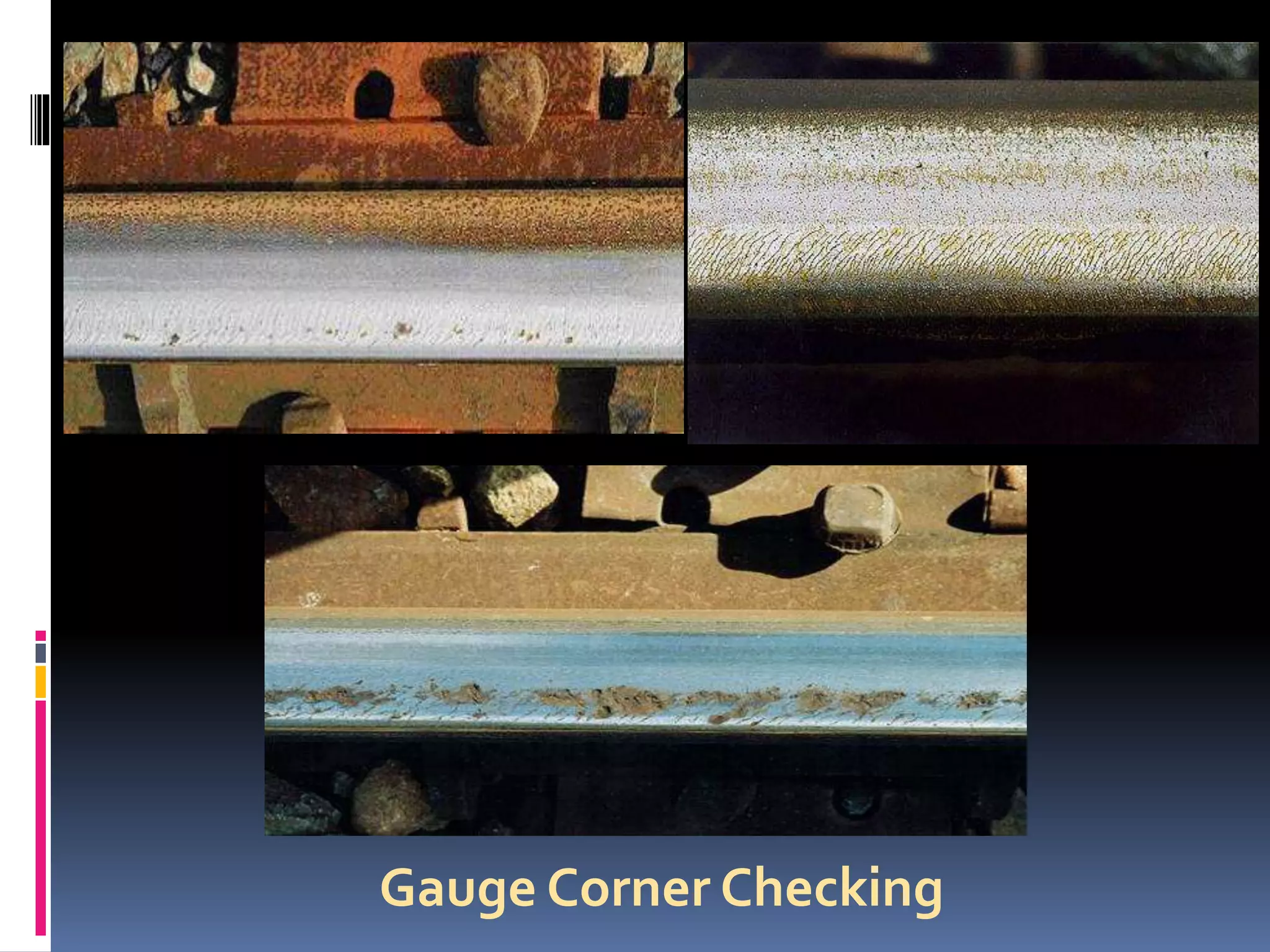

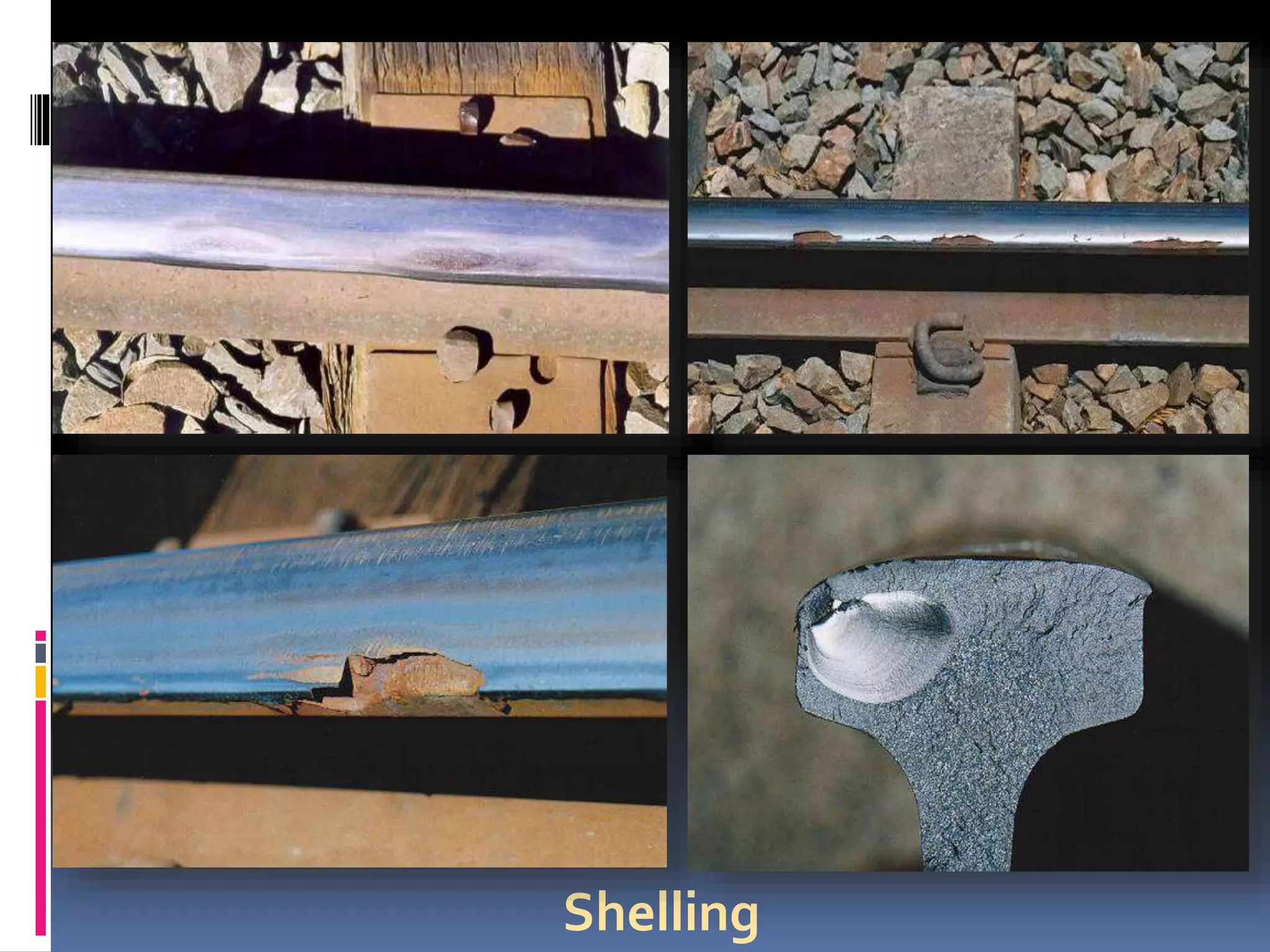

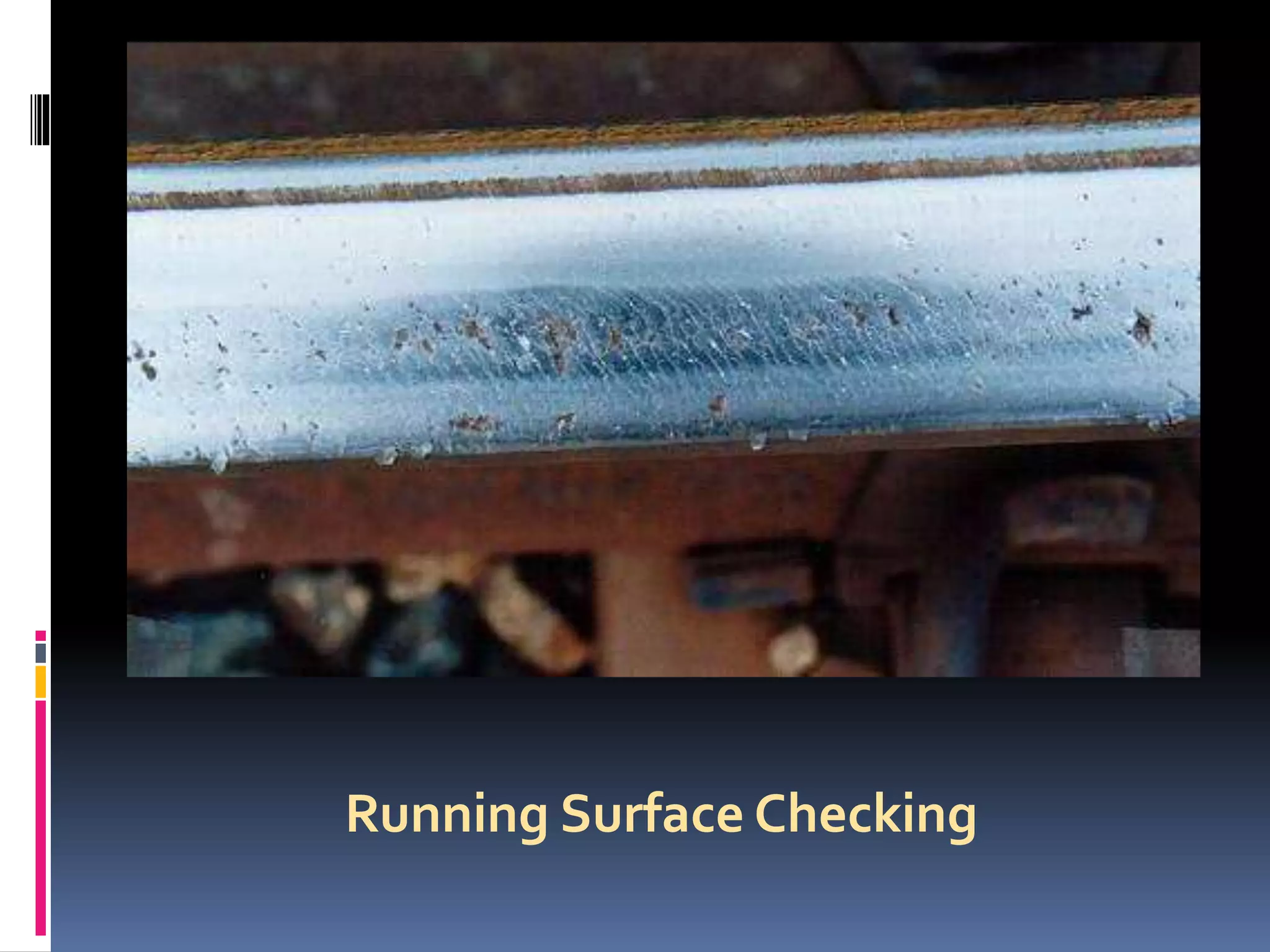

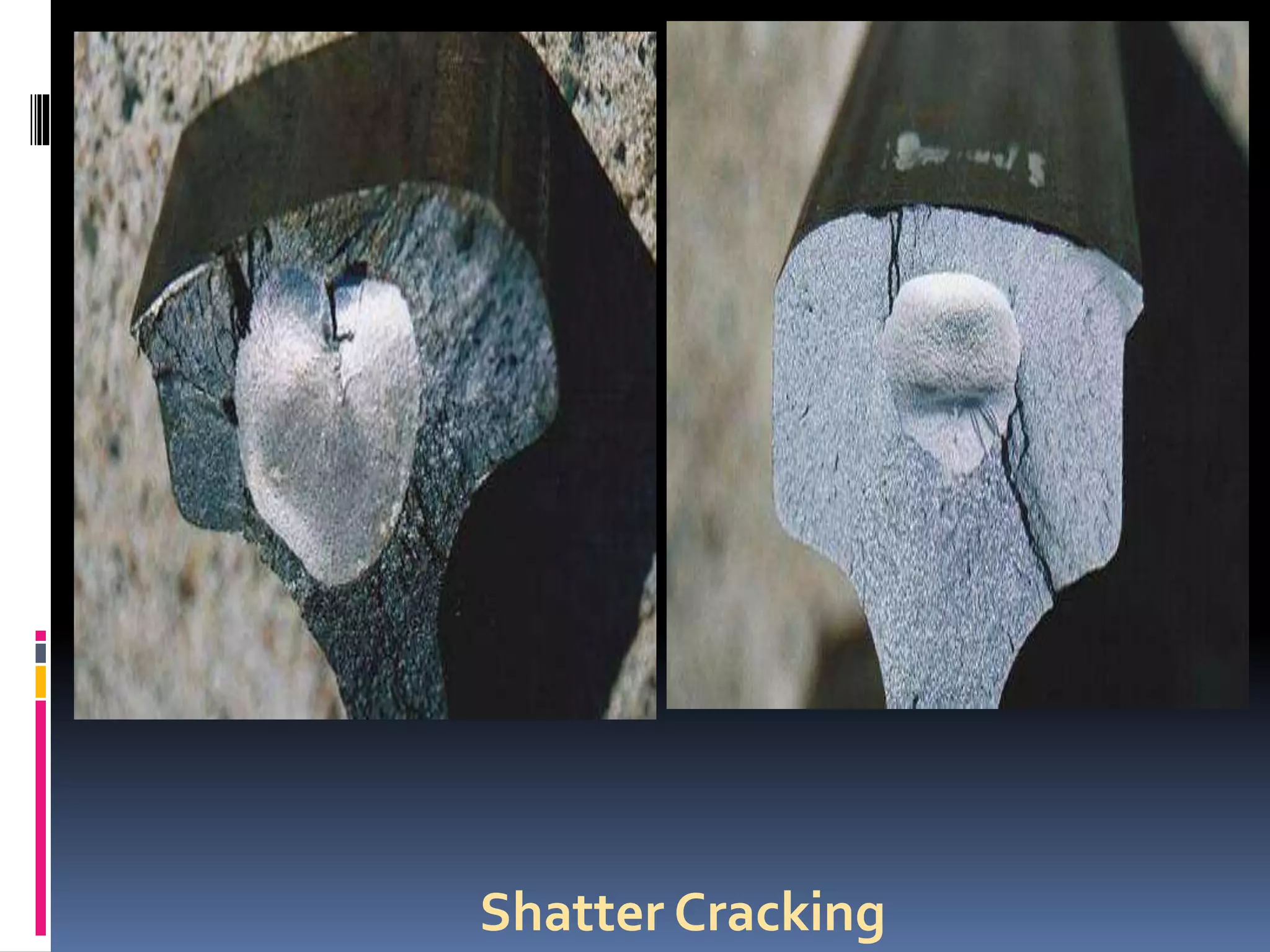

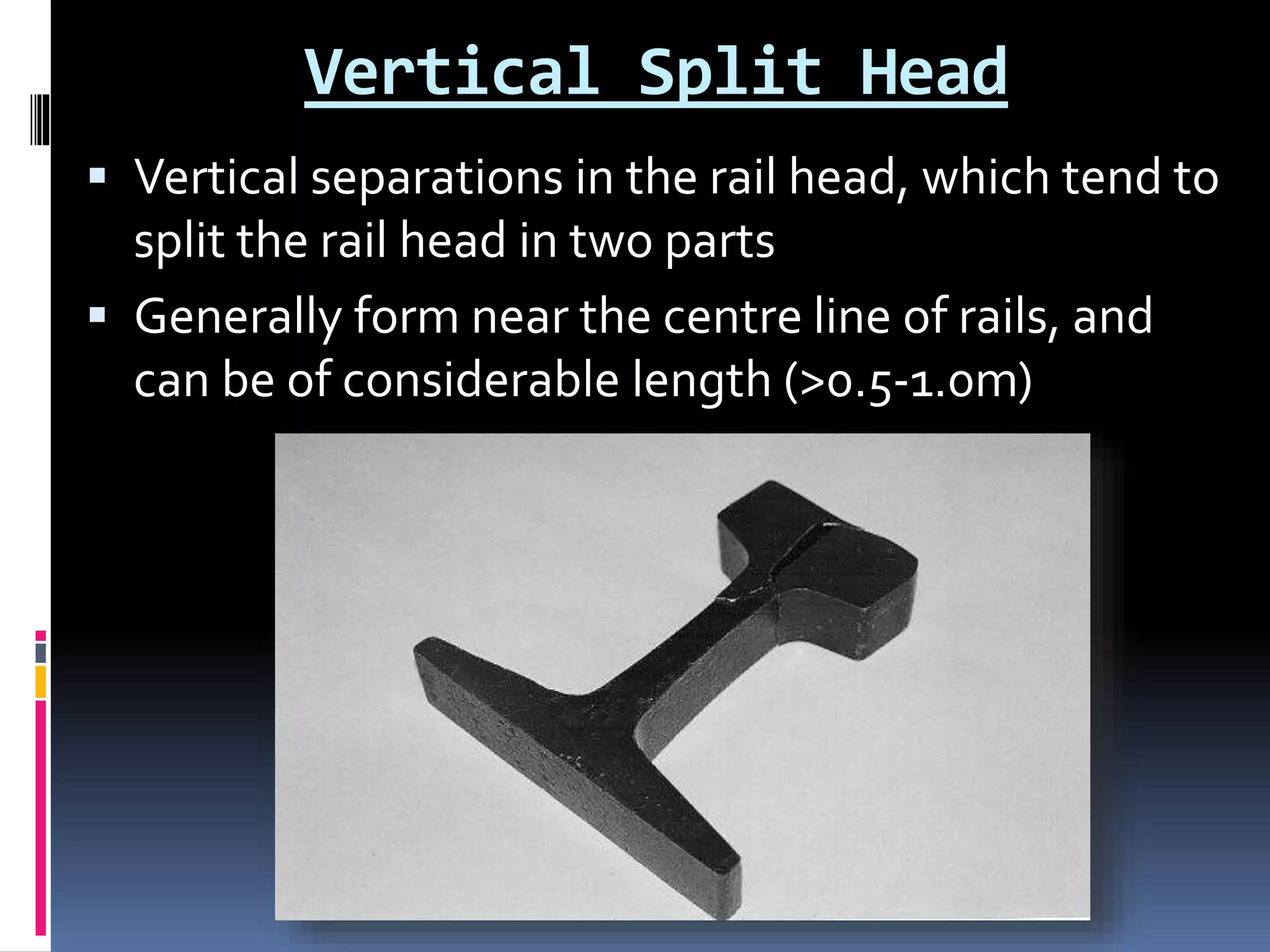

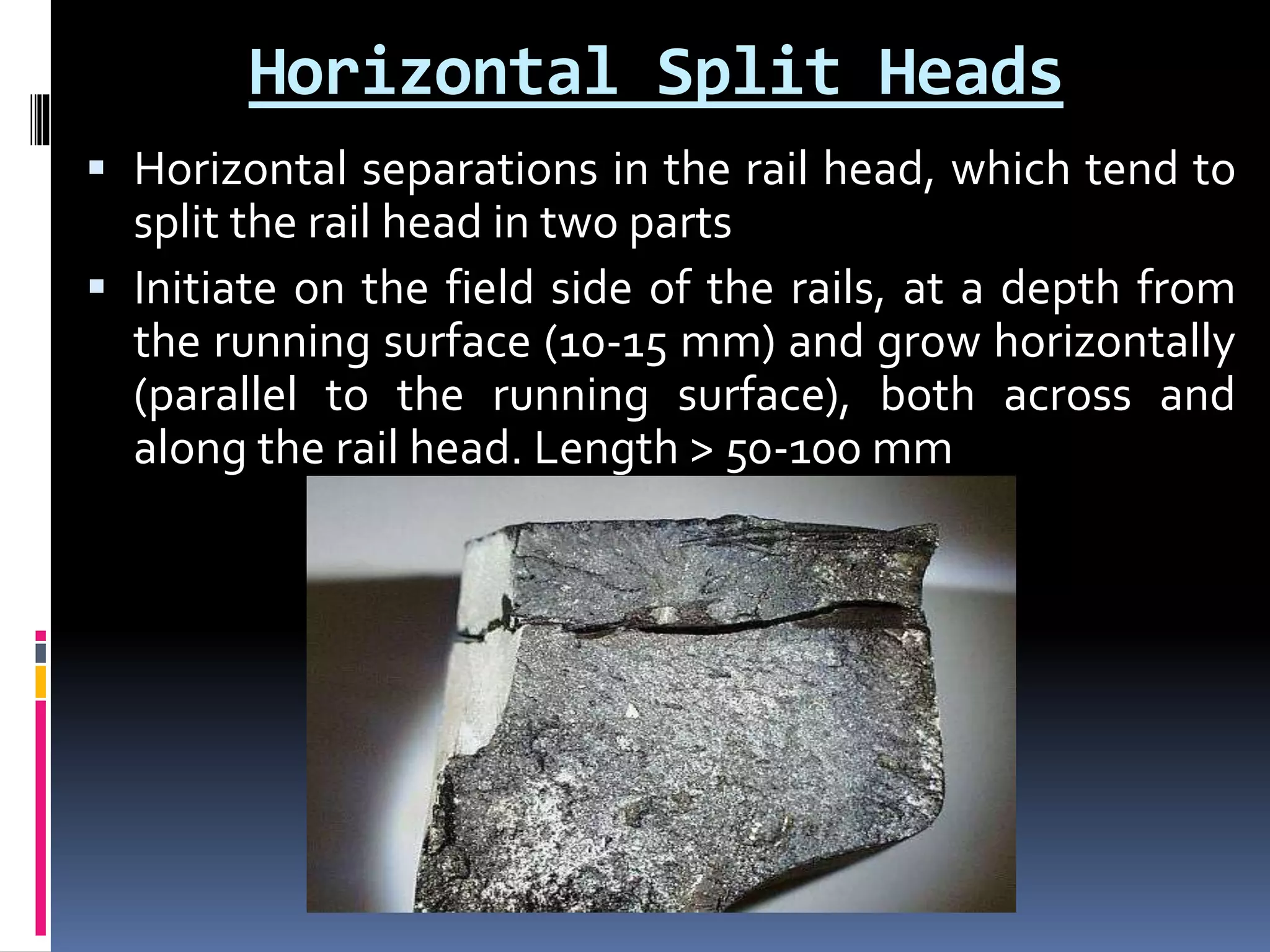

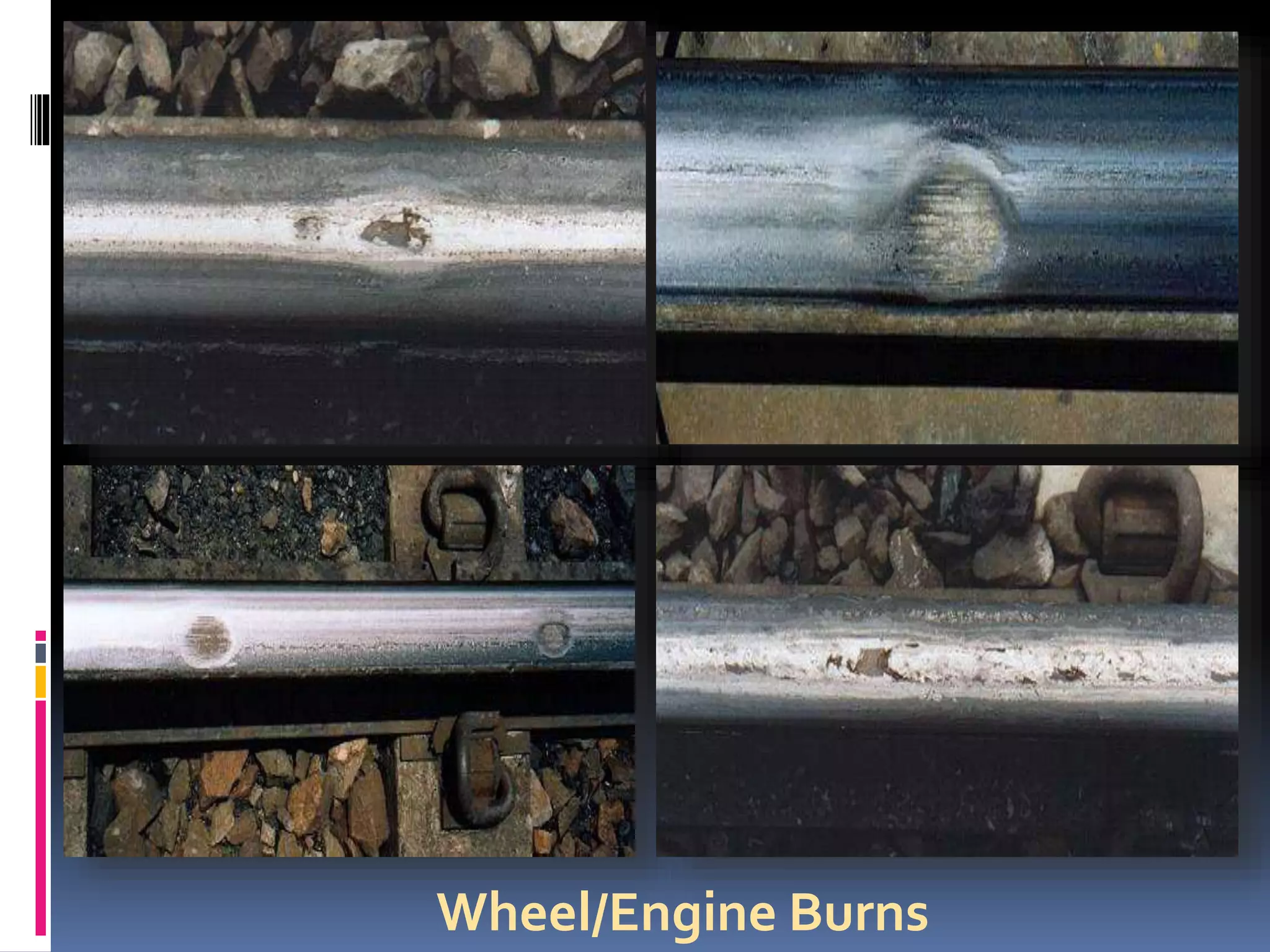

The document discusses various types of defects that can occur in railway tracks, including rail corrugations, rolling contact fatigue defects, squat defects, shatter cracking, split heads, and wheel/engine burns. It provides details on the causes and characteristics of each defect type, as well as their potential effects on track components. The document also outlines treatment methods such as using higher strength rail steels, improved wheel and rail profiles, rail grinding, lubrication practices, and ultrasonic testing to detect and address defects before failure occurs.