148937769-Safety-and-Health-Program-for-2011.docx

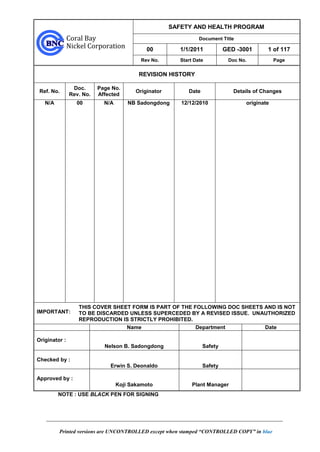

- 1. ________________________________________________________________________________ Printed versions are UNCONTROLLED except when stamped “CONTROLLED COPY” in blue Coral Bay Nickel Corporation SAFETY AND HEALTH PROGRAM Document Title 00 1/1/2011 GED -3001 1 of 117 Rev No. Start Date Doc No. Page REVISION HISTORY Ref. No. Doc. Rev. No. Page No. Affected Originator Date Details of Changes N/A 00 N/A NB Sadongdong 12/12/2010 originate IMPORTANT: THIS COVER SHEET FORM IS PART OF THE FOLLOWING DOC SHEETS AND IS NOT TO BE DISCARDED UNLESS SUPERCEDED BY A REVISED ISSUE. UNAUTHORIZED REPRODUCTION IS STRICTLY PROHIBITED. Name Department Date Originator : Nelson B. Sadongdong Safety Checked by : Erwin S. Deonaldo Safety Approved by : Koji Sakamoto Plant Manager NOTE : USE BLACK PEN FOR SIGNING

- 2. SAFETY AND HEALTH PROGRAM Document Title 00 1/1/2011 GED - 3001 2 of 117 Rev. No. Start Date Document No. Page ________________________________________________________________________________ Printed versions are UNCONTROLLED except when stamped “CONTROLLED COPY” in blue Coral Bay Nickel Corporation TABLE OF CONTENTS LETTER TO MGB REVISION/APPROVAL SHEET ……………… 1 TABLE OF CONTENTS ……………… 2 APPENDICES ……………… 4 LIST OF FIGURES ……………… 4 LIST OF TABLES ……………… 5 1 INTRODUCTION ………………. 6 1.1 GENERAL INFORMATION …………………. 6 1.2 ORGANIZATIONAL STRUCTURES …………………. 7 1.3 NATURE OF THE PROJECT …………………. 9 2 GENERAL PROCESS DESCRIPTION …………………. 9 2.1 PROCESS OPERATION …………………. 9 2.1.1 ORE PREPARATION 2.1.2 HIGH PRESSURE ACID LEACH 2.1.3 PRE NEUTRALIZATION AND COUNTER CURRENT DECANTATION (CCD) 2.1.4 NEUTRALIZATION 2.1.5 DE ZINC 2.1.6 SULFURIZATION 2.1.7 FINAL NEUTRALIZATION 2.2 SERVICE FACILITIES …………………. 12 2.2.1 HYDROGEN SULFIDE PLANT 2.2.2 CHEMICAL PREPARATION 2.2.3 POWER SUPPLY 2.2.4 WATER SUPPLY 2.3 TAILINGS DISPOSAL …………………. 15 2.3.1 TAILINGS DAM 2.3.2 SUPERNATANT 2.3.3 CAUSEWAY AND TRESTLE 2008 SAFETY & HEALTH PROGRAM 3 LEADERSHIP AND ADMINISTRATION …………………. 17 3.1. CBNC SAFETY POLICY STATEMENT …………………. 17 3.2 SAFETY AND HEALTH STANDARDS …………………. 18 3.3 SAFETY PERSONNEL …………………. 18 3.3.1 SAFETY SECTION ORGANIZATION 3.4 SAFETY BOARDS AND SIGNS …………………. 19 3.4.1 SAFETY POLICY 3.4.2 SAFETY STATISTICS 4 ORGANIZATIONAL RULES AND PROCEDURES …………………. 22 4.1 ESTABLISHMENT OF SAFETY AND HEALTH RULES …………………. 22 4.2 SAFETY AND HEALTH MANUAL …………………. 22 4.3 SAFETY SIGNS …………………. 23 4.4 RESTRICTED AREAS …………………. 24 4.5 SAFETY CARDS PRACTICES …………………. 25 4.5.1 KY CARD 4.5.2 HHK CARD 4.5.3 4RKY 4.5.3 Unusual Work KY

- 3. SAFETY AND HEALTH PROGRAM Document Title 00 1/1/2011 GED - 3001 3 of 117 Rev. No. Start Date Document No. Page ________________________________________________________________________________ Printed versions are UNCONTROLLED except when stamped “CONTROLLED COPY” in blue Coral Bay Nickel Corporation 5 MEETINGS …………………. 31 5.1 CENTRAL SAFETY AND HEALTH COMMITTEE (CSHC) MEETING …………………. 32 5.2 CONTRACTORS SAFETY COMMITTEE MEETING …………………. 33 5.3 SAFETY AUDIT COMMITTEE MEETING …………………. 34 5.4 SECRETARIAT MEETING …………………. 34 5.5 DEPARTMENTAL MEETING …………………. 35 5.6 PEP TALK/TURN OVER MEETING …………………. 35 5.7 SEMI ANNUAL SAFETY REVIEW …………………. 35 5.8 SAFETY COORDINATION MEETING …………………. 35 6 PLANNED INSPECTIONS …………………. 36 6.1 WALK THRU INSPECTION …………………. 36 6.1.1 CONTRACTORS SAFETY COMMITTEE 6.1.2 SAFETY AUDIT COMMITTEE 6.2 RADIATION MONITORING …………………. 38 6.3 SAFETY INSPECTION TEAM MONITORING …………………. 38 6.3.1 FIRE EXTINGUISHER INSPECTION 6.3.2 FIRE HYDRANT 6.3.3 HOIST AND CRANE SLING AND WIRE ROPE 6.3.4 CONVEYOR PULL CORDS FUNCTION TEST 6.3.5 MOTOR CENTRAL CONTROL (MCC) INSPECTION 6.3.6 SCABA INSPECTION 6.3.7 AIRLINE MASK INSPECTION 6.3.8 FIRST AID KIT INSPECTION 6.3.9 PIER SITE INSPECTION 6.3.10 TAILINGS DAM INSPECTION 6.3.11 INTAKE DAM 6.3.12 FIRE TRUCK INSPECTION 6.3.13 EMERGENCY VEHICLE INSPECTION 6.3.14 WEEKLY INSPECTION 6.3.15 DAILY INSPECTION 7 SAFETY TRAINING ………………….. 45 7.1 SAFETY ORIENTATION ………………….. 45 7.1.1 FOR NEWLY HIRED CBNC EMPLOYEES 7.1.2 FOR CONTRACTORS 7.1.3 FOR VISITORS 7.2 SAFETY CARDS ………………….. 46 8 PERSONNEL SAFETY DEVELOPMENT ………………….. 47 8.1 SAFETY TRAININGS ………………….. 47 8.1.1 SAFETY CONVENTIONS 8.1.2 FIRST AID TRAINING COURSES 8.1.3 RADIATION SAFETY 8.1.4 FIRE FIGHTING TRAINING 8.1.5 DEFENSIVE DRIVING 8.1.6 SAFETY PROFIENCY TEST/ KNOWLEDGE TEST 8.1.7 MOBILE AND LIFTING EQUIPMENT SAFETY TRAINING 9 ACCIDENT/INCIDENT ANALYSIS ………………….. 49 9.1 ACCIDENT REPORTING ………………….. 49 9.1.1 PRODUCTION

- 4. SAFETY AND HEALTH PROGRAM Document Title 00 1/1/2011 GED - 3001 4 of 117 Rev. No. Start Date Document No. Page ________________________________________________________________________________ Printed versions are UNCONTROLLED except when stamped “CONTROLLED COPY” in blue Coral Bay Nickel Corporation 9.1.2 UTILITY 9.1.3 MAINTENANCE 9.1.4 LABORATORY 9.1.5 MANNJ/DCR-PRODUCTION 9.1.6 MANNJ/DCR-UTILITY 9.1.7 RTNMC-ORE PREPARATION 9.1.8 JGC-MAINTENANCE 9.1.9 INDIGENOUS PEOPLE (AT GEN. AFFAIRS 9.1.10 LOGISTICS (AT PIER SITE) 9.1.11 RTNMC – PIER 9.1.12 INDIGENOUS PEOPLE –TAGDALONGON (AT PIER SITE) 9.2 INVESTIGATING BODY ………………….. 55 9.2.1 DIRECT SUPERIOR/DEPARTMENT 9.2.2 SAFETY SECTION 9.2.3 POLICE 9.2.4 MGB 9.3 REPORT FORMAT ………………….. 56 9.3.1 SUPERVISOR’S REPORT 9.3.2 MGB REPORT 9.4 ACCIDENT DISCUSSION ………………….. 57 9.5 REMEDIAL ACTIONS ………………….. 58 10 HEALTH CONTROL AND SERVICES ………………….. 58 10.1 PRE EMPLOYMENT PHYSICAL EXAMINATION………………. 59 10.2 ANNUAL MEDICAL EXAMINATION ………………….. 59 10.3 RETURN TO WORK MEDICAL EXAMINATION………………… 59 10.4 DRUG-FREE WORKPLACE PROGRAM ………………….. 60 10.5 MONITORING OF WORKING ENVIRONMENT………………….. 60 10.6 MALARIA ERADICATION ………………….. 60 11 EMERGENCY PREPAREDNESS PROGRAM ………………….. 60 12 PERSONAL PROTECTIVE EQUIPMENT ………………….. 60 13 SAFETY AND HEALTH INCENTIVES ………………….. 61 14 SAFETY PROMOTIONS ………………….. 61 14.1 SAFETY CIRCULAR ………………….. 61 14.2 4RKY COMPETITION ………………….. 62 14.3 POSTER AND SIGN BOARDS ………………….. 62 14.4 SAFETY SLOGAN MAKING CONTEST ………………….. 62 15 COMMUNITY CONSULTATION ………………….. 63 16 TARGETS AND BUDGETS ………………….. 63 APPROVALS ………………….. 64 APPENDICES ………………….. 65 APPENDICES APPENDIX 1 SAFETY ENGINEERS’/INSPECTORS’ MGB PERMIT……………. 66 APPENDIX 2 SAFETY POLICY STATEMENT ………………….. 72 APPENDIX 3 SAFETY STATISTICS BOARD ………………….. 73 APPENDIX 4 PLANT SITE RESTRICTED AREAS LAYOUT ………………….. 74 APPENDIX 5 COMMON SAFETY SIGNS ………………….. 75 APPENDIX 6 SAFETY CARDS ………………….. 79 APPENDIX 7 4RKY SHEET ………………….. 86 APPENDIX 8 4RKY MAKING PROCEDURE ………………….. 87 APPENDIX 9 4RKY EXAMPLE ………………….. 88 APPENDIX 10 4RKY PRESENTATION PROCEDURE ………………….. 90 APPENDIX 11 4RKY COMPETITION GUIDELINES ………………….. 90

- 5. SAFETY AND HEALTH PROGRAM Document Title 00 1/1/2011 GED - 3001 5 of 117 Rev. No. Start Date Document No. Page ________________________________________________________________________________ Printed versions are UNCONTROLLED except when stamped “CONTROLLED COPY” in blue Coral Bay Nickel Corporation APPENDIX 12 SAFETY MANAGEMENT TARGET AND ACCOMPLISHMENT REPORTING FORMAT (CSHC) ………………….. 91 APPENDIX 13 CONTRACTORS’ SAFETY MANAGEMENT REPORT FORMAT ………………….. 92 APPENDIX 14 RADIATION MONITORING SHEET ………………….. 93 APPENDIX 15 FIRE EXTINGUISHER MONITORING SHEET ………………….. 94 APPENDIX 16 FIRE HYDRANT INSPECTION CHECKLIST ………………….. 95 APPENDIX 17 SLINGS AND WIRE ROPES INSPECTION SHEET ………… 97 APPENDIX 18 PULL CORD FUNCTION TEST SHEET ………………….. 98 APPENDIX 19 MCC INSPECTION CHECKLIST ………………….. 99 APPENDIX 20 SCABA MONITORING SHEET ………………….. 100 APPENDIX 21 FIRST AID KIT CHECKLIST ………………….. 101 APPENDIX 22 EMERGENCY VEHICLE INSPECTION CHECKLIST…………………. 102 APPENDIX 23 SPINE BOARD INSPECTION CHECKLIST ………………….. 103 APPENDIX 24 SUBSTANDARD CONDITION REPORT ………………….. 102 APPENDIX 25 ACCIDENT REPORTING ………………….. 104 APPENDIX 26 REPORTING FORMAT ………………….. 112 APPENDIX 27 ACCIDENT INVESTIGATION FORMAT ………………….. 113 APPENDIX 28 MGB ACCIDENT REPORT FORMAT ………………….. 114 APPENDIX 29 SAFETY AND HEALTH TARGETS AND BUDGETS…..……………... 117 LIST OF FIGURES FIGURE 1 ORGANIZATIONAL CHART ………………….. 8 FIGURE 2 FLOW SHEET ………………….. 10 FIGURE 3 SAFETY SECTION ORGANIZATION ………………….. 18 FIGURE 4 SAFETY POLICY BOARD ………………….. 20 FIGURE 5 SAFETY STATISTICS BOARD ………………….. 21 FIGURE 6 SAFETY SIGNS ………………….. 23 FIGURE 7 RESTRICTED AREA SAFETY SIGN ………………….. 24 FIGURE 8 KY CARD ………………….. 26 FIGURE 9 HHK EXAMPLE ………………….. 28 FIGURE 10 FIRE EXTINGUISHER TAG. ………………….. 38 FIGURE 11 KY CARD FORM ………………….. 74 FIGURE 12 KY CARD: THE PROPER WAY OF EXPRESSING THE POTENTIAL HAZARDS ………………….. 75 FIGURE 13 KY CARD: THE USUAL PRACTICE ………………….. 75 FIGURE 14 HHK FORM ………………….. 76 FIGURE 15 HHK EXAMPLE 1 ………………….. 77 FIGURE 16 HHK EXAMPLE 2 ………………….. 77 FIGURE 17 UNUSUAL WORK KY SHEET ………………….. 79 FIGURE 18 EXAMPLE OF UNUSUAL KY SHEET ………………….. 80 LIST OF TABLES TABLE 1 SLING AND WIRE ROPE INSPECTION COLOR CODE………………… 39

- 6. SAFETY AND HEALTH PROGRAM Document Title 00 1/1/2011 GED - 3001 6 of 117 Rev. No. Start Date Document No. Page ________________________________________________________________________________ Printed versions are UNCONTROLLED except when stamped “CONTROLLED COPY” in blue Coral Bay Nickel Corporation 1 INTRODUCTION Coral Bay Nickel Corporation takes seriously its commitment to protect its workforce. It has undergone a significant transformation that continues at an astounding pace. New technologies and methods have reduced worker’s exposure to harmful conditions, and the industry continues to adopt new technologies that advance the complimentary goals of safety and productivity. CBNC Safety and health programs have been made to organize the plans and to initiate the implementation of this program. Employer commitment and meaningful employee participation and involvement in safety and health are a key ingredient in effective programs. 1.1 GENERAL INFORMATION Project Hydrometallurgical Processing Plant Proponent Coral Bay Nickel Corporation Principal Office Rio Tuba Export Processing Zone Brgy. Rio Tuba, Bataraza 5306 Palawan, Philippines Tel.: (632) 750-2289 to 90 Fax: (632) 750-2291 Manila Office 24th Floor, Pacific Star Building Makati Avenue corner Gil Puyat Avenue 1200 Makati City, Philippines Tel.: (632) 750-1536 to 39 Fax: (632) 750-1530

- 7. SAFETY AND HEALTH PROGRAM Document Title 00 1/1/2011 GED - 3001 7 of 117 Rev. No. Start Date Document No. Page ________________________________________________________________________________ Printed versions are UNCONTROLLED except when stamped “CONTROLLED COPY” in blue Coral Bay Nickel Corporation Company Officials Mr. Takanori Fujimura, President Mr. Arturo Manto, V-President for External Affairs Mr. Masahiro Kamiya, Treasurer Mine site Officials Mr. Koji Sakamoto, Plant Manager Mr. Isao Nishikawa, Production Manager Mr. Hidehiko Harada, General Affairs Manager Mr. Yuji Tange, Utilities Manager Mr. Shigeru Onozaki, Maintenance Manager Mr. Takao Niiyama, PLD Manager 1.2 ORGANIZATIONAL STRUCTURE Coral Bay Nickel plant site organization consists of seven departments namely: General Affairs, Maintenance, Production, Utilities, Procurement and Logistics, and Safety and Technical. Each department and section is headed by a Department Manager and a Section Head respectively. Production Department consists of about 240 staffs; followed by the General Affairs Department which has 64 staffs; and then Maintenance, Utilities, Purchasing and Logistics, and Safety and Technical each has 79, 38, 57, and 53 respectively. This comprises a total of 561 as of November 2010 to include 22 Japanese Staff.

- 8. SAFETY AND HEALTH PROGRAM Document Title 00 1/1/2011 GED - 3001 8 of 117 Rev. No. Start Date Document No. Page _____________________________________________________________________________________________________________________________ Printed versions are UNCONTROLLED except when stamped “CONTROLLED COPY” in blue Coral Bay Nickel Corporation Figure 1 Organizational Chart

- 9. SAFETY AND HEALTH PROGRAM Document Title 00 1/1/2011 GED - 3001 9 of 117 Rev. No. Start Date Document No. Page ________________________________________________________________________________ Printed versions are UNCONTROLLED except when stamped “CONTROLLED COPY” in blue Coral Bay Nickel Corporation 1.3 NATURE OF THE PROJECT CBNC enhances the resource utilization capability of Rio Tuba Nickel Mining Corporation (RTNMC) through the processing of the existing low-grade nickel ore stockpiled at the mining area. This project does not involve mining operation except for the limestone quarrying which is under the management of RTNMC. CBNC is a mineral processing plant, which processes low-grade nickel ores adopting the high-pressure acid leach (HPAL) technology producing Nickel/Cobalt mixed sulfides. 2 GENERAL PROCESS DESCRIPTION The raw material that we process is a low-grade limonite ore averaging 1.26% nickel and 0.09% cobalt, enough to maintain production at the nameplate capacity for 20 years. The intermediate product is shipped to Niihama Nickel Refinery of SMM in Japan and is further refined to electrolytic nickel and cobalt, respectively by the proven Sumitomo technology. The plant consists of seven (7) stages and three (3) service facilities. Service facilities include 11 MW Power Plant, Hydrogen Sulfide Plant, and Chemical Preparation, serving separately line 1 and line 2 with several tie-in points. 2.1 PROCESS OPERATION 2.1.1 ORE PREPARATION The objective of the ore preparation process is to prepare the ore feed slurry for acid leaching. The ore is washed and screened to come up a particle size of <1.4mm and then thickened to achieve at about 40% solid slurry, necessary for the leaching stage. 2.1.2 HIGH PRESSURE ACID LEACH The purpose of HPAL is to leach the nickel and cobalt from the ore selectively. Nickel and cobalt, which are present in the ore, are leached with concentrated

- 10. SAFETY AND HEALTH PROGRAM Document Title 00 1/1/2011 GED - 3001 10 of 117 Rev. No. Start Date Document No. Page ________________________________________________________________________________ Printed versions are UNCONTROLLED except when stamped “CONTROLLED COPY” in blue Coral Bay Nickel Corporation sulfuric acid (98%) in the Autoclave. The reaction is carried out under high temperature (2450C) and high pressure (4MPa). In this manner, at 70 minutes retention time about 95% of the nickel and cobalt is leached. Figure 2 Flow Sheet Nickel Ore Screening H2SO4 H2S Mixed Sulfide Final Neutralization To Niihama Nickel Refinery Oversize Ore Effluent Gypsum Tailings Dam Leach Residue Limestone CCD Impurity Neutralization Pressure Leach Zinc Removal Sulfurization Limestone Lime Pre- Neutralization

- 11. SAFETY AND HEALTH PROGRAM Document Title 00 1/1/2011 GED - 3001 11 of 117 Rev. No. Start Date Document No. Page ________________________________________________________________________________ Printed versions are UNCONTROLLED except when stamped “CONTROLLED COPY” in blue Coral Bay Nickel Corporation 2.1.3 PRE NEUTRALIZATION AND COUNTER CURRENT DECANTATION (CCD) Pre-Neutralization circuit neutralizes excess free acid of HPAL discharge slurry, which is yielded by hydrolysis. This minimizes neutralized residue treated in the neutralization circuit. Excess free acid is neutralized with limestone slurry. The reaction is carried out for 45 minutes at about 100º C with a pH of 0.7. The neutralized slurry is sent to the CCD circuit for residue washing and solid- liquid separation. The operation proceeds in a series of seven (7) identical thickeners. Flocculant at 0.3 wt% concentration is used to enhance the solid-liquid separation. The underflow slurry from the last thickener is discharged to the final neutralization circuit at high solid density while the overflow of the first thickener called pregnant solution is sent to the next refining stage, the neutralization circuit. 2.1.4 NEUTRALIZATION Pregnant liquor from the CCD circuit is neutralized with limestone to hydrolyze and precipitate the dissolved metals such as iron, aluminum, and chromium as hydrated oxides and basic sulfates. The resulting mixture of gypsum (CaSO4) and metal hydroxides, which is referred to as “sludge”, is separated from the nickel- rich liquor in the thickener with the aid of flocculant. Thickener underflow which contains the impurities and some adhered nickel and cobalt is recycled back to the CCD circuit for nickel and cobalt recovery while the overflow proceeds to the next refining stage, the zinc removal circuit. 2.1.5 DE ZINC The objective of zinc removal circuit is to remove the zinc from the solution. The pregnant solution is reacted with hydrogen sulfide (H2S) with the pH range of 3.0 to 3.5. The reaction is carried out for 60 minutes at 600ºC under a pressure of less than 0.01MPa. Zinc is precipitated selectively, as well as copper, as sulfides. Precipitates are removed via polishing filters and to final neutralization circuit for disposal. Filtrate, nickel-rich liquor, proceeds to Sulfurization circuit.

- 12. SAFETY AND HEALTH PROGRAM Document Title 00 1/1/2011 GED - 3001 12 of 117 Rev. No. Start Date Document No. Page ________________________________________________________________________________ Printed versions are UNCONTROLLED except when stamped “CONTROLLED COPY” in blue Coral Bay Nickel Corporation 2.1.6 SULFURIZATION Zinc free liquor is sent to a series of four reaction tanks. The solution is heated up to 80º C by steam and is reacted with hydrogen sulfide (H2S) in the range of pH 1.6 and 2.0. The pressure is controlled at the range of 200 to 300kPa. In this manner, more than 99 percent of nickel and cobalt is precipitated as mixed sulfide. Impurities such as manganese and magnesium remain in the solution. The sulfurized slurry is sent to the thickener to increase the solid concentration to about 40% in preparation for the filtration stage. Mixed Sulfides is recovered via pressure filters. The filtrate is recycled back to the CCD circuit as the washing solution or sent to the final neutralization circuit. 2.1.7 FINAL NEUTRALIZATION Waste liquids and slurries are treated in this circuit before sending them to the tailings dam. CCD residue, excess barren liquor from Sulfurization circuit, and waste water from neutralization pond of Utilities Area are the main wastes that are treated in final neutralization circuit. This circuit aims to precipitate the heavy metals such as manganese, iron and chromium. The reaction is carried out in the series of four reaction tanks by the addition of limestone and slaked lime slurries to maintain the final pH of 8.0. The neutralized and final slurry is sent to tailings dam via Geho pumps. 2.2 SERVICE FACILITIES 2.2.1 HYDROGEN SULFIDE PLANT Hydrogen sulfide gases are produced by the reaction of hydrogen and sulfur both in the gaseous states. Hydrogen gas is generated from the vaporized methanol which is reacted with water with the aid of a catalyst. Hydrogen gas is purified through Pressure Swing Absorption (PSA) unit. Hydrogen sulfide is synthesized by a catalytic reaction with hydrogen and sulfur gases. Hydrogen sulfide is purified by cooling and washing with water to remove

- 13. SAFETY AND HEALTH PROGRAM Document Title 00 1/1/2011 GED - 3001 13 of 117 Rev. No. Start Date Document No. Page ________________________________________________________________________________ Printed versions are UNCONTROLLED except when stamped “CONTROLLED COPY” in blue Coral Bay Nickel Corporation the un-reacted sulfur. This is then compressed and delivered to the end users: Sulfurization and De Zinc stages. Safety Features o All facilities are closed system for gas leakage prevention. o Hydrogen sulfide facilities are automatically operated through Distributed Control System (DCS) to eliminate human errors. o Gas detection network is installed within the area to constantly monitor the gas leakages. Detectors undergo regular preventive maintenance to ensure its operability. o Fire hydrants stations and fire extinguishers are installed in various locations. 2.2.2 CHEMICAL PREPARATION In the Chemical Preparation section, there are four reagents that are being made namely: limestone slurry, slaked lime slurry, flocculant solution, and caustic soda solution. Limestone slurry is prepared from pre-crushed raw Gotok and Bohol limestone. Limestone is crushed to 10mm and ground by Vertical Mill to 98% passing 200 mesh. The concentration is controlled to about 25% solids. Limestone is used as alkaline reagent for Pre- NTRL to neutralize excess free acid which is yielded by hydrolysis and present in the Autoclave slurry discharge and for Neutralization to complete the hydrolysis and precipitation of Ferric iron, Aluminum and chromic chromium as hydroxides and other basic sulfates. Slaked slurry is prepared from a refined slaked lime powder. The operation is just simply the mixing of slaked lime powder and water and is controlled at a concentration of 25% solids. Slaked lime is used to precipitate the heavy metals such as manganese and magnesium in the Final Neutralization circuit.

- 14. SAFETY AND HEALTH PROGRAM Document Title 00 1/1/2011 GED - 3001 14 of 117 Rev. No. Start Date Document No. Page ________________________________________________________________________________ Printed versions are UNCONTROLLED except when stamped “CONTROLLED COPY” in blue Coral Bay Nickel Corporation Flocculant is prepared via hopper and is driven by a screw feeder to draw the flocculant powder at a constant rate. The powder enters the Jet Wet dispenser/ mixing head where it passes through a spray pattern produced by a series of water spray nozzles so that every particle is wetted by the sprays to avoid the formation of fish eyes. The sprayed powder is agitated at a certain amount of time enough to homogenize the solution and not to break the polymer chains. The flocculant is made of 0.3 wt% concentration. Flocculant is used to improve the solid-liquid separation and settling characteristics of some colloidal particles in the thickening operation. Caustic Soda solution is prepared at 25% concentration strength. 2.2.3 POWER SUPPLY Each plant is operated with a coal-fired boiler and turbine generator with a capacity of 11MW. The power is distributed through substations to the load facilities. Cable racks and conduit pipes are installed for power transmissions. A 3 MW emergency diesel power is also available in case of outages. 2.2.4 WATER SUPPLY The main source of fresh water supply is the East Ibelnan River, located 3.8 km west of the plant. Other sources include siltation ponds and return water pond of supernatant. A 300 cubic meters of storage structure was constructed as an intake point for water supply. The water is stored in a 3000 cubic meter water pond. 2.3 TAILINGS DISPOSAL 2.3.1 TAILINGS DAM Tailings dam is constructed to safely and adequately hold the waste materials generated from the process. The ground condition of the dam site is composed of

- 15. SAFETY AND HEALTH PROGRAM Document Title 00 1/1/2011 GED - 3001 15 of 117 Rev. No. Start Date Document No. Page ________________________________________________________________________________ Printed versions are UNCONTROLLED except when stamped “CONTROLLED COPY” in blue Coral Bay Nickel Corporation a laterite layer and weathered ultramafic rock. The bearing force of the ground of the dam is adequately capacitated for earth dam wall construction. Tailings Dam 1 is now in undergoing rehabilitation. Tailings Dam 2 which commenced its operation in June 2010 is situated at the northwest side of the previous facility, with an estimated capacity of 35 million cubic meters. 2.3.2 SUPERNATANT LINE The supernatant liquid from the tailings dam is pumped to the sea through a partially buried pipeline along the existing access road of RTNMC. Portion of which is being recycled back for re-use. Offshore, the pipeline is laid on a causeway and trestle. The effluent complies with all applicable DENR standards as contained in DENR Administrative Order No. 35. 2.3.3 CAUSEWAY & TRESTLE A 380-meter long causeway is constructed southwest of Nagoya Beach. This is designed with culvert pipes at 30-meter intervals to allow the cross flow of tidal currents. The causeway is connected to a 900-meter long southwest trending trestle, mounted on the steel piles. The trestle supports the 250mm diameter stainless pipeline for sulfuric acid, 200mm diameter carbon steel pipeline for methanol, and 250mm diameter carbon steel pipeline for effluent discharge. The trestle is 4.5 meters high from the sea level and is 2.7 meters wide.

- 16. SAFETY AND HEALTH PROGRAM Document Title 00 1/1/2011 GED - 3001 16 of 117 Rev. No. Start Date Document No. Page ________________________________________________________________________________ Printed versions are UNCONTROLLED except when stamped “CONTROLLED COPY” in blue Coral Bay Nickel Corporation 2011 SAFETY & HEALTH PROGRAM

- 17. SAFETY AND HEALTH PROGRAM Document Title 00 1/1/2010 GED - 3001 17 of 119 Rev. No. Start Date Document No. Page ________________________________________________________________________________ Printed versions are UNCONTROLLED except when stamped “CONTROLLED COPY” in blue Coral Bay Nickel Corporation 3 LEADERSHIP AND ADMINISTRATION 3.1 CBNC’S ENVIRONMENTAL AND SAFETY POLICY STATEMENT

- 18. SAFETY AND HEALTH PROGRAM Document Title 00 1/1/2010 GED - 3001 18 of 119 Rev. No. Start Date Document No. Page ________________________________________________________________________________ Printed versions are UNCONTROLLED except when stamped “CONTROLLED COPY” in blue Coral Bay Nickel Corporation 3.2 SAFETY AND HEALTH STANDARD The company’s basis for establishing safety and health standards are DAO 2000-98 (Mine Safety and Health Standards) and RA 7942 (Philippine Mining Act of 1995). The safety rules and regulations and standard operating procedures of the company are based mainly from this standard. 3.3 SAFETY PERSONNEL 3.3.1 SAFETY SECTION ORGANIZATION Safety Section is headed by a Section Head reporting directly to the Plant Manager. Figure 3. Safety Section Organization PLANT MANAGER SECTION HEAD Safety Coordinator Safety Supervisor Safety Inspectors

- 19. SAFETY AND HEALTH PROGRAM Document Title 00 1/1/2010 GED - 3001 19 of 119 Rev. No. Start Date Document No. Page ________________________________________________________________________________ Printed versions are UNCONTROLLED except when stamped “CONTROLLED COPY” in blue Coral Bay Nickel Corporation 3.3.1.1 Safety Inspection Group Safety Inspection Team composes of a Safety Supervisor (reports to Safety Head) and Safety Inspectors reporting on three shifts. Safety Supervisor and Inspectors are duly registered to the Mines and Geosciences Bureau – RIVB and passed with the bureau qualifications and standards as safety inspectors. MGB Permits for the existing Safety Engineer and Safety Inspectors can be seen in Appendix 1. 3.3.1.2 Safety Secretariat Safety Secretariat consists of a Safety Head (also supervises Safety Inspection Group) and Safety Coordinator. The group is responsible for safety documentations and preparations. 3.4 SAFETY BOARDS AND SIGNS 3.4.1 ENVIRONMENTAL AND SAFETY POLICY The company environmental and safety and quality policy statements has been posted in the steel board of 5 meter wide and 4 meter high. The policy board is situated at Main Avenue Southside of the General Building so that everyone has to read it when passing by. Each building in the plant had been provided also with a copy of the policy to ensure awareness of all employees (see Figure 4).

- 20. SAFETY AND HEALTH PROGRAM Document Title 00 1/1/2010 GED - 3001 20 of 119 Rev. No. Start Date Document No. Page ________________________________________________________________________________ Printed versions are UNCONTROLLED except when stamped “CONTROLLED COPY” in blue Coral Bay Nickel Corporation Figure 4 Environmental and Safety Policy Further, the posting of this policy is intended to all workers and visitors to remind everyone that safety to our works and us has been practiced at its maximum level. 3.4.2 SAFETY STATISTICS Safety statistics board is constructed with dimensions the same as the safety policy board. It is located beside policy board at Main Avenue Southside of the General Office Building.

- 21. SAFETY AND HEALTH PROGRAM Document Title 00 1/1/2010 GED - 3001 21 of 119 Rev. No. Start Date Document No. Page ________________________________________________________________________________ Printed versions are UNCONTROLLED except when stamped “CONTROLLED COPY” in blue Coral Bay Nickel Corporation Safety statistics board is designed in a plain white background to enhance the statistics data as seen in Figure 5 below. Please see the detailed safety statistics data reflected in the board in Appendix 3. Figure 5 Safety Statistics Board Updated safety statistics is posted publicly to remind everyone the present safety status and the frequency of accidents occurring in a specific month. This is also to encourage everyone, if there are accidents occurring in a specified month or even a year, to think and to practice the effective, practical and applicable countermeasures.

- 22. SAFETY AND HEALTH PROGRAM Document Title 00 1/1/2010 GED - 3001 22 of 119 Rev. No. Start Date Document No. Page ________________________________________________________________________________ Printed versions are UNCONTROLLED except when stamped “CONTROLLED COPY” in blue Coral Bay Nickel Corporation 4 ORGANIZATIONAL RULES AND PROCEDURES 4.1 ESTABLISHMENT OF SAFETY AND HEALTH RULES In order to make the safety program consistent, Safety Department and the respective departments’ supervisors and foremen have developed the Safety and Health Manual. This manual composed of rules and regulations, and standard procedures relating to the daily activities and practices. Safety and Health Manual was established in the late half of 2004. It was a collaboration of all rules and procedures established in all areas. Rules and procedures were drafted by the supervisors and foremen from the respective departments. These were submitted to the Central Health and Safety Committee for the discussion. Upon the approval of the committee, these rules and procedures were finalized and came up with a handbook, the Safety and Health Manual. Since the working areas and conditions change, this manual is subjected for revision. Annually, the rules are reviewed and necessary changes done. 4.2 SAFETY AND HEALTH MANUAL Safety and Health Manual covers the subjects of the plant operations, electrical and mechanical rules, traffic safety rules, plant site visitors, canteen rules and regulation, workshop and warehouse safety, laboratory safety, tagging and isolation procedure, gate control policy among others. Please see the details to Safety and Health Manual. 4.3 SAFETY SIGNS In all critical areas, safety signs are legibly displayed in most pertinent locations. Safety signs are designed in a standards size of 18 x 30 inches dimension. They are made in both English and Filipino versions, examples are shown in Figure 6 below.

- 23. SAFETY AND HEALTH PROGRAM Document Title 00 1/1/2010 GED - 3001 23 of 119 Rev. No. Start Date Document No. Page ________________________________________________________________________________ Printed versions are UNCONTROLLED except when stamped “CONTROLLED COPY” in blue Coral Bay Nickel Corporation Figure 6 Safety Signs Common safety signs installed in strategic locations within plant site as well as in tailings dam and pier site are shown in Appendix 5. Safety signs are usually posted to remind the workers in their respective areas the hazards that can possibly harm them. These can also set the minds of the workers to be ready in for appropriate actions in case a potential accident will happen, where the safety signs are addressed to. 4.4 RESTRICTED AREAS

- 24. SAFETY AND HEALTH PROGRAM Document Title 00 1/1/2010 GED - 3001 24 of 119 Rev. No. Start Date Document No. Page ________________________________________________________________________________ Printed versions are UNCONTROLLED except when stamped “CONTROLLED COPY” in blue Coral Bay Nickel Corporation The plant site has various restricted areas. Delineating restricted areas are meant to prohibit the entry of the unauthorized personnel in a specified area. Restricted areas are usually indicated with a safety sign at the entrance of the area. Restricted area safety sign is designed with a standard size of 49 x 32 inches. It is mounted in a steel pipe stand with lockable wheels at its base as shown in the Figure 7 below. Figure 7 Restricted Area Safety Sign If you are an unauthorized person, necessary permit or permission from the area- in-charge is required before entering the said area. Detailed rules and procedures for acquiring restricted area permits in all the restricted areas within the plant site are discussed in the Safety and Health under the Restricted Area Entry Permit System. There are three major areas in the plant site that are considered restricted areas namely: HPAL (02 and 202 areas), MS (05, 205,06 and 206 areas), and H2S Plants. Aside from these areas, areas where radioactive devices and instruments

- 25. SAFETY AND HEALTH PROGRAM Document Title 00 1/1/2010 GED - 3001 25 of 119 Rev. No. Start Date Document No. Page ________________________________________________________________________________ Printed versions are UNCONTROLLED except when stamped “CONTROLLED COPY” in blue Coral Bay Nickel Corporation are installed are also considered restricted areas. See Appendix 4 for restricted areas layout. The restricted area permit has been practiced to regulate the entry and to monitor the whereabouts of the personnel working on the said area. 4.5 SAFETY CARDS PRACTICES One of the safety practices in CBNC is the use of the safety cards. In Chemical Industries, safety card summarizes essential health and safety information on chemicals for their use at the "shop floor" level by workers and employers in factories, agriculture, construction and other work places. In CBNC, however, it serves as the record for the potential accident, potential hazard identification, countermeasures for the identified potential risk, record for the encountered near miss accident, and analysis for possible hazards in a particular working place. There are three kinds of safety cards the company is using namely KY Card, Unusual KY Card, HHK (Nearmiss Incidents), and 4RKY. 4.5.1 KY CARD KY Card is derived from the Japanese words Kiken Yotchi, which means hazard prediction. Generally it is called as Hazard Prediction Card. This card aims to help predict potential hazard in the job so as to enable us to carry out our job safely. KY Card is made before going to working places or before starting to work. By doing this card, potential hazards in the work places are studied carefully and countermeasures are also geared up. Example of this card is showed in Figure 8 below.

- 26. SAFETY AND HEALTH PROGRAM Document Title 00 1/1/2010 GED - 3001 26 of 119 Rev. No. Start Date Document No. Page ________________________________________________________________________________ Printed versions are UNCONTROLLED except when stamped “CONTROLLED COPY” in blue Coral Bay Nickel Corporation Figure 8 KY Card All employees are required to make this card before the start of the shift activities. The making of this card will take only about 5 to 10 minutes within the first hour of the shift. The card will be collected and reviewed by the Department Manager or the supervisors. The most critical KY Cards will be discussed among crews led by the supervisor. By doing this, employees’ ability in identifying potential hazards and setting countermeasures will keep on developing. The detailed procedure on making KY Cards as well as the form and examples can be seen in Appendix 6. 4.5.2HHK Card HHK Card is derived from the Japanese words Hiyari Hatto Kigakari, which means a Near miss Accident Report Card. This card is intended for reporting incidents

- 27. SAFETY AND HEALTH PROGRAM Document Title 00 1/1/2010 GED - 3001 27 of 119 Rev. No. Start Date Document No. Page ________________________________________________________________________________ Printed versions are UNCONTROLLED except when stamped “CONTROLLED COPY” in blue Coral Bay Nickel Corporation encountered on the job and activities that will help improve those facilities, or call other workers’ operating at the same level attention to those incidents thus assuring occupational safety. If anyone encounters a near miss accident, he or she is required to report immediately, by using this card, for the awareness of the next person who will work in the same assignment/working place. Basically, Example of this card is shown in Figure 9 below. The most critical HHK is discussed during turnover meetings so that everyone must be aware of the near misses and effective countermeasures must be applied immediately to avoid recurrence. Detailed procedure in making this card and other examples can be seen in Appendix 6. Figure 9 HHK Example Date Febr u a r y 18, 2005 Section Ou tsi d e Pla n tsi te Name Nei l Tem per a tu r a Date & Time Place Type of Incident Incident in Detail Account for the Incident RTN Gym Fa lli n g Object RTN M anagem ent - for not fitting the bolt w ell and checking. Hiyari Hatto Kigakari Card Feb 18, 2005 6:00a m I w as going to shoot the basketball ball in the r ing, and so m y head w as up to see the ball's dir ection. A t the m om ent of shooting, ther e w as an object fr om abov e falling dow n m y head and face. It w as a r ing bolt. A nd luckily the r ing bolt hit m y head and not m y ey es. If it hit m y ey es, I m ight be blind now .

- 28. SAFETY AND HEALTH PROGRAM Document Title 00 1/1/2010 GED - 3001 28 of 119 Rev. No. Start Date Document No. Page ________________________________________________________________________________ Printed versions are UNCONTROLLED except when stamped “CONTROLLED COPY” in blue Coral Bay Nickel Corporation 4.5.3 4RKY 4RKY is a KY or hazard prediction with four rounds. 4RKY aims to setting a limit to a job and implementing hazard prediction in order to help highlight potential hazards in relevant jobs and produce countermeasures. It has four rounds with understanding the current state of affairs is the first, investigation into the true nature of the incident is the second, setting up countermeasures and setting up objectives are the third and fourth rounds respectively. Before this activity will start, a picture of the unsafe practices must be taken for thorough investigation. This activity will be done in a group consisting of five to seven members. The group will have to nominate themselves the leader, presenter, and scribe, and the rest will be the members. The activity runs from studying the picture, identifying the potential hazards, narrowing the potential hazard by identifying the important and especially important potential hazards, setting up practical and effective countermeasures, making of a team objective, and finally the drawing out of a one-point objective. The analysis of the unsafe practice will be filled up in the form found in Appendix 7. After the form is completed, the group will have to present their work according to the 4RKY Presentation Procedure found in Appendix 10. Please see Appendix 8 for the detailed 4RKY Making Procedure and example of filled up form. This potential hazard analysis is made when a production or maintenance activity is believed to have the most critical identified potential hazard or an activity generates a near miss accident. The activity will not be pursued upon the evaluation of the supervisor that the activity must be at its

- 29. SAFETY AND HEALTH PROGRAM Document Title 00 1/1/2010 GED - 3001 29 of 119 Rev. No. Start Date Document No. Page ________________________________________________________________________________ Printed versions are UNCONTROLLED except when stamped “CONTROLLED COPY” in blue Coral Bay Nickel Corporation maximum safety, thus, 4RKY must be made. This is also done periodically of at least once in a month per department. 4RKY competition will also be made during the scheduled major shutdown. Normally, the competition will be made on April and November every year. It will be participated by all departments that involve in the direct operation such as Production, Maintenance, Utility, Laboratory/EMO, Logistics, General Affairs Departments. Number of participating teams in every department will depend on the size of manpower. Prices for the three winning teams will be included in the Safety and Health Budget. See Appendix 11 for the competition guidelines. 4.5.4 UNUSUAL KY CARD Unusual KY card is an improvised KY card also for hazard prediction. As the name suggests, it is intended for unusual activities, being done at low frequencies especially activities done not on daily basis like shutdown activities and others. Unlike KY card, this is performed by the group of employees with a leader assigned to do the activity. Before the activity proceeds, the form is filled up taking into account the sequence of work, risky factors and object for action, and the necessary safety precautions and materials needed. The filled up form is reviewed by the shift foreman or the leader in case of foreman’s unavailability. Once approved, the team proceeds to the actual work area for further evaluation of the situation. After the activity, filling up of unusual KY is continued with problems identified during the activity and putting up countermeasures for each problem. Then, department manager approves the completed form. This document will serve as the basis of doing the same activity again. Please see Appendix XX for the detailed Unusual KY Procedure and example of filled up form.

- 30. SAFETY AND HEALTH PROGRAM Document Title 00 1/1/2010 GED - 3001 30 of 119 Rev. No. Start Date Document No. Page ________________________________________________________________________________ Printed versions are UNCONTROLLED except when stamped “CONTROLLED COPY” in blue Coral Bay Nickel Corporation 5 MEETINGS Meeting is a formally arranged gathering with a common purpose. Meeting with respect to the plant operation is usually made to carry out the operation smoothly and systematically aiming maximum safety within workforce and workplaces. Safety meetings have been practiced regularly for the following major purposes: (1) to present the identified potential hazards of the workplaces; (2) to collect ideas and opinion from the group in making remedial actions both engineering and administrative approaches to the identified potential risks; (3) to let everyone know the safety targets and achievements of the different departments and institutions; (4) to discuss both minor and major accidents encountered; and (5) To make decisions whether to approve or not approve the presented suggestions, recommendations, new rules and procedures, and safety programs and plans. In CBNC, there are seven regular safety meetings that have been practiced in either monthly, weekly, daily or in every change of shifts. These are the Central Safety and Health Committee Meeting (CSHC), Contractors Safety Committee Meeting, Safety Audit Committee, Secretariat Meeting, Departmental Safety Meeting, Turnover Meeting, and Toolbox Meeting. 5.1 CENTRAL SAFETY AND HEALTH COMMITTEE (CSHC) MEETING CSHC Meeting is a regular monthly meeting participated in by all department managers, section heads, foremen and supervisors, and union representatives. Members of the safety team are also required to participate in this meeting.

- 31. SAFETY AND HEALTH PROGRAM Document Title 00 1/1/2010 GED - 3001 31 of 119 Rev. No. Start Date Document No. Page ________________________________________________________________________________ Printed versions are UNCONTROLLED except when stamped “CONTROLLED COPY” in blue Coral Bay Nickel Corporation The Plant Manager is the chairman of this committee. However, the Safety Section Head will preside the meeting. Preparations and organizing the minutes will be made by Safety Section. This meeting is normally scheduled on the third Friday of the month at 1:30 in the afternoon. The schedule will be changed in case the third Friday of the month falls on a holiday. The standard flow of this meeting begins by the words from the chairman. It follows the presentation and approval of the previous meeting minutes. Once the minutes have been approved, presentation of safety management targets and accomplishments will follow. Department Managers/ Section Heads or his representative will report according to the standard presentation format (see Appendix 12). The following departments will present their respective targets and accomplishment in this order: Production, Maintenance, Utilities, Laboratory, General Affairs, Procurement and Logistics, Environmental Management and Quality Control (EMQC) and Laboratory. The coverage of the target and accomplishment report will be from a day after the previous month meeting up to the day of the meeting. After the presentation of the different departments, discussion of the accident cases of the previous month will follow; next is the presentation of safety statistics for the previous month; and then the presentation of new safety suggestions from the result of the Safety Inspectors’ inspection; Medical Report from the Medical Director and finally, the updates of the result of Safety Audit Inspection. Minutes of this meeting will be submitted to the Mines and Geosciences Bureau – RIVB (MGB) and to the Department of Labor and Employment. 5.2 CONTRACTORS SAFETY COMMITTEE MEETING Contractors’ Meeting is a regular safety meeting with all the contractors and affiliates of CBNC. These include RTNMC, JGC-Maintenance, SMCC, MANNJ, DCR, RTNFI Hospital, PSSI, PCBSI, and all other contractors with existing project

- 32. SAFETY AND HEALTH PROGRAM Document Title 00 1/1/2010 GED - 3001 32 of 119 Rev. No. Start Date Document No. Page ________________________________________________________________________________ Printed versions are UNCONTROLLED except when stamped “CONTROLLED COPY” in blue Coral Bay Nickel Corporation with CBNC at the time of the meeting. The participants of the meeting will be the managers and/or the Safety Officer of the respective contractors, CBNC Plant Manager, CBNC Department Managers and CBNC Safety Team. The CBNC Plant Manager is the chairman of this committee however, CBNC Safety Section Head presides the meeting. Preparations and organizing the minutes will be made by Safety Section. This meeting is normally scheduled on the third Saturday of the month after the safety walk through (see Inspection Section) at 1:00 in the afternoon. The schedule will be changed in case the third Saturday of the month falls on a holiday. The meeting begins by the words of the CBNC Plant Manager, followed by the discussion of the result of the walk through inspection, and then the presentation of the previous meeting minutes. If the minutes are approved by the body, the meeting proceeds to the contractors report on safety and health (see Appendix 13 for the reporting format) and then the presentation of the safety statistics. RTNFI Hospital health updates will be presented by the Hospital Director. The report includes the top rate diseases frequency of admissions as well as the causes of how the diseases incurred by the patients. Security report will be presented by the CBNC/RTNMC Security Consultant. After the hospital and security reports, the new safety suggestions from the result of the inspection of the CBNC Safety Inspection Team will follow. Minutes of this meeting will be submitted to the Mines and Geosciences Bureau – RIVB (MGB) and to the Department of Labor and Employment.

- 33. SAFETY AND HEALTH PROGRAM Document Title 00 1/1/2010 GED - 3001 33 of 119 Rev. No. Start Date Document No. Page ________________________________________________________________________________ Printed versions are UNCONTROLLED except when stamped “CONTROLLED COPY” in blue Coral Bay Nickel Corporation 5.3 SAFETY AUDIT COMMITTEE MEETING Safety Audit Committee Meeting is a regular monthly safety meeting conducted right after the safety audit walk through inspection (see inspection section) every first working day of the month. Participants of this meeting will be the Plant Manager, all department managers, section heads, foremen and supervisors, and representatives from Union. Safety Section Head will be presiding the meeting. This meeting discusses only the result of the safety audit walk through inspection. Suggestions and recommendations are also presented here. Updates of the suggestions and recommendations for the remedial actions will be presented during the Central Safety and Health Committee meeting. PM’s monthly safety audit is a presentation of a specific activity in the area being audited through a 4RKY format. An open discussion follows for concerns of the personnel and a walk through to the area depicted in the presentation comes next to come up with countermeasures. 5.4 SECRETARIAT MEETING Secretariat Meeting is a regular safety meeting conducted at least twice a month by the Safety Section Head and participated by all department managers, foremen and supervisors. The meeting focuses on the result of the weekly inspection report by the Safety Inspection Team, updates of the safety suggestions and recommendations, discussions of establishment and revisions of safety documents such as Safety and Health Manual, Emergency Response Plan, Emergency Management Plan, and Safety and Health Program.

- 34. SAFETY AND HEALTH PROGRAM Document Title 00 1/1/2010 GED - 3001 34 of 119 Rev. No. Start Date Document No. Page ________________________________________________________________________________ Printed versions are UNCONTROLLED except when stamped “CONTROLLED COPY” in blue Coral Bay Nickel Corporation 5.5 DEPARTMENTAL MEETING Departmental meeting is a regular meeting conducted once a month by the respective departments one week prior to the holding of the Central Safety Committee meeting to ensure that safety and health issues are properly address. 5.6 PEP TALK/TURNOVER MEETING Turnover Meeting is a regular meeting conducted during shifting of personnel. This is usually the turnover of assignments of the outgoing shift to the incoming shift. Aside from the turnover activities, accident, near miss accident, and potential hazards encountered by the outgoing shift are also discussed during this meeting so that everyone should be aware and immediate countermeasures will be initiated. 5.7 SEMI ANNUAL SAFETY PERFORMANCE REVIEW The semi-annual safety review is a discussion of accidents and incidents that took place within the first and second halves of the year. The discussion also focuses on the effective countermeasures done to prevent recurrence of the problem. Also, this meeting announces safety strategies of every department in line with Plant manager’s safety targets. Every department manager represents his own department. This review is set every January, for the second half of the previous year and July, for the first half of the present year. 5.8 SAFETY COORDINATION MEETING Safety coordination meeting was established to be known to each safety inspectors of each contractor. Discussions include problems encountered and its relevant countermeasures. More specifically, this meeting is a learning venue to all and be one with the set standard of the occupational safety and health and other government regulations.

- 35. SAFETY AND HEALTH PROGRAM Document Title 00 1/1/2010 GED - 3001 35 of 119 Rev. No. Start Date Document No. Page ________________________________________________________________________________ Printed versions are UNCONTROLLED except when stamped “CONTROLLED COPY” in blue Coral Bay Nickel Corporation 6 PLANNED INSPECTIONS CBNC adopted safety inspection as a means of regulating improved safety of the operation. Safety inspections consist of a series of safety-related checks for various systems, equipment and work areas. Safety inspections represent a good opportunity to have minor problem corrected before they become major problems or hazards. Safety inspection can also detect problems that could cause major breakdown headaches in the near future. Planning the inspection ahead gives us time to make better choices about different repairs or services that may be needed as determined during the inspection. CBNC has programs that require inspections on a monthly basis, but there are also some areas that require inspections on a weekly or even daily basis. 6.1 WALK THRU INSPECTION 6.1.1 CONTRACTORS SAFETY COMMITTE The Contractors’ Safety Committee walk through inspection is a regular monthly safety inspection. This is a 30-minute inspection before the start of the Contractors Safety Committee Meeting. Attendees for the mentioned meeting will be the participants for this inspection. CBNC Safety Section will decide the area to be inspected. Only one area will be inspected per month. Area of inspection will not be repeated unless all areas in the Plant Site have already been inspected by this committee. The result of the inspection will be discussed during the Contractors’ Safety Committee Meeting. Safety suggestions and recommendations are also presented in this meeting.

- 36. SAFETY AND HEALTH PROGRAM Document Title 00 1/1/2010 GED - 3001 36 of 119 Rev. No. Start Date Document No. Page ________________________________________________________________________________ Printed versions are UNCONTROLLED except when stamped “CONTROLLED COPY” in blue Coral Bay Nickel Corporation 6.1.2 SAFETY AUDIT COMMITTEE Safety Audit Committee walk through inspection is a regular monthly safety inspection conducted during the first working day of the month or the following day in case the first day falls on a holiday. Participants of this inspection will be the Plant Manager, all department managers, section heads, foremen and supervisors, and union representatives. The team is divided into two (2) groups to facilitate inspection of more areas. The Safety Audit Committee has established the system of inspection. All at once, the committee proceeds to the area for inspection usually determined by the Safety Team. The Safety Team will facilitate the inspection. The duration of this inspection will be 30 minutes to 1 hour. The teams are required to bring a digital camera so that all unsafe conditions, work practices, and work places will be properly documented with pictures. The picture taken will be used for the presentation of unsafe acts and conditions. Every unsafe condition will be analyzed carefully and all of the attendees are encouraged to submit their ideas, suggestions, and recommendations for the immediate remedial actions. After all the unsafe acts and conditions have been discussed, Safety Department will have to compile the identified hazards and will be submitted to the respective departments. Unsafe acts and conditions that are not resolved during the meeting will be given a specific date and time for the countermeasures to be completed. All of the tasks will be given to a specific person, usually the head or supervisor of the area, so that updates or status of the unsafe conditions will be properly monitored. After approximately three weeks from the inspection, updates and status of the finished and unfinished tasks will be presented to the Central Safety and Health Committee.

- 37. SAFETY AND HEALTH PROGRAM Document Title 00 1/1/2010 GED - 3001 37 of 119 Rev. No. Start Date Document No. Page ________________________________________________________________________________ Printed versions are UNCONTROLLED except when stamped “CONTROLLED COPY” in blue Coral Bay Nickel Corporation 6.2 RADIATION MONITORING The entire plant has a total of 72 radioactive devices. Since these devices contained gamma emitter radioactive material namely Co-60 and Cs-137, absorbed and exposure doses of radiation are constantly monitored especially to the workers who are directly involved with these devices. Employees associated with these radioactive instruments are required to wear the film badge type dosimeter always. Film badge dosimeter is used to monitor the radiation doses of the worker. The film badge will be submitted to PNRI quarterly to evaluate the readings. Anyone who will reach to the maximum limit of radiation exposure will be subjected for investigation. Radioactive instruments are also inspected quarterly (see Radiation Monitoring Sheet in Appendix 14). This is to ensure that these instruments remain intact and safe, and radiation leakages can be detected before unwanted accident will happen. Only the designated Radiation Officer will conduct the radiation monitoring as well as to open and close the shutters of the radioactive material. 6.3 SAFETY INSPECTION TEAM MONITORING Safety Inspection Team has established a program of inspections. The frequency of inspections is based on the degree of area with respect to possibility of hazards. Inspection is either on monthly, weekly or daily basis. By doing this, inspection sheets and checklists have been established. 6.3.1 FIRE EXTINGUISHER INSPECTION

- 38. SAFETY AND HEALTH PROGRAM Document Title 00 1/1/2010 GED - 3001 38 of 119 Rev. No. Start Date Document No. Page ________________________________________________________________________________ Printed versions are UNCONTROLLED except when stamped “CONTROLLED COPY” in blue Coral Bay Nickel Corporation Fire extinguishers are inspected regularly on a monthly basis. The inspection is normally done every second week of the month. All of the fire extinguishers are identified with a plastic laminated tag as shown in Figure 10 below. Figure 10 Fire Extinguisher Tag. (A) For Carbon Dioxide Type (B) For ABC Dry Chemical Type When a fire extinguisher is found defective on the basis that: FIRE EXTINGUISHER INSPECTION TAG Month Inspection Date Inspected by Remarks Jan Feb Mar Apr May Jun Jul Aug Sep Oct Nov Dec FIRE EXTINGUISHER INSPECTION TAG Month Inspection Date Inspected by Remarks Jan Feb Mar Apr May Jun Jul Aug Sep Oct Nov Dec

- 39. SAFETY AND HEALTH PROGRAM Document Title 00 1/1/2010 GED - 3001 39 of 119 Rev. No. Start Date Document No. Page ________________________________________________________________________________ Printed versions are UNCONTROLLED except when stamped “CONTROLLED COPY” in blue Coral Bay Nickel Corporation a) Pressure in the cylinder indicates “recharge” range or b) any part of the fire extinguisher assembly is damaged, said fire extinguisher will be replaced immediately. Fire extinguisher has a unique codename which reflects in the tag. It identifies the specific location of the fire extinguisher. Codenames and fire extinguisher’s specifications are written in the fire extinguisher monitoring sheet (see Appendix 15). 6.3.2 FIRE HYDRANT Fire Hydrant tools are inspected on a monthly basis. There are 17 fire hydrant stations distributed in strategic locations within the plant site. Each station has 4 spanners, 2 rubber gaskets, 2 hoses, 2 portable spray nozzles, and an axe. Any of these tools found missing or damage will be replaced immediately after the inspection, and it will be noted in the Fire Hydrant Inspection Checklist (see Appendix 16) for reference. 6.3.3 HOIST AND CRANE SLING AND WIRE ROPE Slings and wire ropes of the mobile cranes, hoist and cranes, and hoist/lifting slings are regularly inspected within the first week of the month. The production operator together with the safety inspector and maintenance inspector will conduct the inspection. Colored adhesive vinyl tape will be placed at the end portion of the sling or at the hoist block to indicate the last monthly inspection. Color code changes every month as indicated in Table 1. Table 1 Sling and Wire Rope Inspection Color Code White Red Yellow January February March April May June July August September October November December

- 40. SAFETY AND HEALTH PROGRAM Document Title 00 1/1/2010 GED - 3001 40 of 119 Rev. No. Start Date Document No. Page ________________________________________________________________________________ Printed versions are UNCONTROLLED except when stamped “CONTROLLED COPY” in blue Coral Bay Nickel Corporation Wire rope and sling shall be taken out of service when any of the following conditions exist: o In running ropes, six randomly distributed broken wires in one lay or three broken wires in one strand in one lay. o When wire rope is kinking, crushing, bird caging, or any damage resulting in distortion of the rope structure. o Reduction of wire diameter of more than 7 % due to wear and corrosion. o All wire ropes and slings found to be unsafe for use shall be isolated and tagged appropriately. See Appendix 17 for the inspection sheet. 6.3.4 CONVEYOR PULL CORDS FUNCTION TEST Pull cords of belt conveyors at the Limestone, Ore Preparation, and Filtration areas are regularly inspected. Function test is conducted on a monthly basis. It is usually scheduled on the first week of the month. Function test will be witnessed by the Production Supervisor and Safety Personnel. During the function test, Field operator at first will advise DCS Operator for the function test activity. DCS operator will confirm that the test can be conducted. Field operation will initially check the condition of the pull cord. Cuts and damages along the pull cord will be noted and reported immediately for repair or replacement (see Appendix 18 and 19 for the function test Sheet). When the field operator pulls the emergency pull cord, he then confirms with DCS operator if PULLCORD alarm is triggered. The field operator will then reset the PULLCORD alarm using the corresponding reset switch of the belt conveyor and will confirm with the DCS operator if the alarm is reset. Results of confirmation are noted in the Function Test Sheet.

- 41. SAFETY AND HEALTH PROGRAM Document Title 00 1/1/2010 GED - 3001 41 of 119 Rev. No. Start Date Document No. Page ________________________________________________________________________________ Printed versions are UNCONTROLLED except when stamped “CONTROLLED COPY” in blue Coral Bay Nickel Corporation 6.3.5 MOTOR CENTRAL CONTROL (MCC) INSPECTION MCC Inspection will be conducted by the Safety Inspector on every last week of the month. The inspection will be based mainly on the cleanliness of the area and the safety equipment such as fire extinguishers. Scattered materials that can hinder the access to the motor switches will be coordinated with the concerned department managers. Result of this inspection will also be discussed during the CSHC Meeting. See Appendix 19 for the MCC Inspection Sheet. 6.3.6 SCABA INSPECTION Safety Inspection Team will conduct the SCABA and its accessories’ inspection on every third week of the month. Any part of SCABA or accessory found missing will be recovered or replaced immediately. Compressed air cylinder whose pressure is less than normal value will also be replaced immediately. Result of this inspection will be presented in the Secretariat Meeting or in the CSHC Meeting. See Appendix 20 for the SCABA Inspection Sheet. 6.3.7 AIR LINE MASK INSPECTION There are two sets of airline mask apparatus in the plant. One can be found in MS area while the other in H2S Plant area. This apparatus will be inspected on a monthly basis, usually on the first week of the month. Any damaged part or missing items will be properly coordinated with the concerned department manager for the immediate recovery or replacement. The result of this inspection will be discussed in the Secretariat Meeting. 6.3.8 FIRST AID KIT INSPECTION First Aid Kits are inspected regularly on the third week of the month. The inspection will be done to monitor the status and frequency of first aid medicine

- 42. SAFETY AND HEALTH PROGRAM Document Title 00 1/1/2010 GED - 3001 42 of 119 Rev. No. Start Date Document No. Page ________________________________________________________________________________ Printed versions are UNCONTROLLED except when stamped “CONTROLLED COPY” in blue Coral Bay Nickel Corporation consumption. Any consumed first aid medicine will be replenished immediately. See Appendix 21 for the First Aid Kit Checklist. 6.3.9 PIER SITE INSPECTION Pier Site Inspection will be done on weekly basis, usually every Monday. The inspection will cover all Pier Site facilities including trestle, causeway, tank farm, acid and methanol loading/unloading areas, various stockyards (slaked lime and coal), and pier warehouse. Any observed unsafe conditions will be reported accordingly through Sub Standard Report Format (Appendix 29). 6.3.10 TAILINGS DAM INSPECTION Tailings dam will be inspected on a monthly basis. Safety Inspection Team will do the inspection covering the effluent discharge operation, equipment and facilities, safety signs and boards, etc. The team will coordinate with the Engineering Section for any observed unsafe condition. Result of this inspection will also be presented in the Secretariat Meeting and/or CSCH Meeting. 6.3.11 INTAKE DAM Intake dam, the plant water source, will be inspected monthly. Safety Inspection Team will check if the dam contains materials such as trunk of the trees and dead animals that are trapped in the dam which will hamper the passage of water through the pipeline. Any unsafe condition found will be properly coordinated. Result of the inspection will be discussed during the Secretariat Meeting or CSHC Meeting. 6.3.12 FIRE TRUCK INSPECTION Fire truck and its facilities inspection will be conducted every Friday. The inspection will be made by the Work Shop Foreman and will be assisted by Safety Section. Any defective part found will be repaired or replaced immediately. This

- 43. SAFETY AND HEALTH PROGRAM Document Title 00 1/1/2010 GED - 3001 43 of 119 Rev. No. Start Date Document No. Page ________________________________________________________________________________ Printed versions are UNCONTROLLED except when stamped “CONTROLLED COPY” in blue Coral Bay Nickel Corporation inspection will be done to ensure that the fire fighting equipment is available and in good condition at all times. 6.3.13 EMERGENCY VEHICLE INSPECTION Emergency vehicle inspection and check-up will be conducted three times a week. It will be done on Tuesdays, Thursdays and Sundays. Checklist provided for this inspection is found in Appendix 28. The inspection also include test run for 15 minutes within the plant site premises only. The time of inspection will be between 12 am to 5 am. Safety Inspection Team will make work request and report any defect or abnormality observed on vehicles. 6.3.14 WEEKLY INSPECTION Safety Inspection Team is also conducting weekly inspections on the following subjects: a) safety and accessories, b) machinery and equipment, c) material handling/storage, and d) Environmental factors. Result of which is presented through Sub Standard Report format (appendix 24) 6.3.15 DAILY INSPECTION Safety Inspection Team is conducting inspections on a daily basis. The daily general inspection covers, but not limited to, the personal protective equipment worn by employees, activities done by the operations crew and other plant activities. See Sub Standard Report format in Appendix 24. The concerned supervisor / section head will be informed of all findings, unsafe acts and/or conditions and the corrective actions must be initiated immediately. Reporting of the unsafe acts/conditions will be in a standard format. See Appendix 25 for the Reporting Format.

- 44. SAFETY AND HEALTH PROGRAM Document Title 00 1/1/2010 GED - 3001 44 of 119 Rev. No. Start Date Document No. Page ________________________________________________________________________________ Printed versions are UNCONTROLLED except when stamped “CONTROLLED COPY” in blue Coral Bay Nickel Corporation 7 SAFETY TRAINING 7.1 SAFETY ORIENTATION It is the policy of CBNC that all newly hired and regularized employees, contractors and visitors undergo safety orientations to be conducted by the Safety Section before allowing them to move around the plant. Orientations that will be given to the newcomers differ according to the particular assignment of the personnel or the reason why such the contractors/ visitors are here in CBNC. 7.1.1 FOR NEWLY HIRED/REGULARIZED CBNC EMPLOYEES Safety orientation for the newly hired employees covers the general Company Safety Policy, General Plant Rules, Plant Operation / General Safety Rule, Personal Protective Equipment Usage, Area Restrictions, Safety Cards: KY, HHK, Unusual KY & 4RKY, Radiation Safety Orientation and Material Safety Data Sheet (MSDS). For newly regularized employees, the re-orientation covers Company Safety Policy and General Plant Rules and accidents that happened with their corresponding countermeasure. 7.1.2 FOR CONTRACTORS Safety orientation for the contractors may include the following subjects: Company Safety Policy, General Plant Rules, and Restricted Areas. Other safety matters will be discussed by their respective safety personnel. 7.1.3 FOR VISITORS Safety orientation for the visitors covers the discussions on the restricted areas, PPE requirements, and evacuation routes in case of emergency, locations of the hazardous chemicals, and locations where they are allowed to take pictures.

- 45. SAFETY AND HEALTH PROGRAM Document Title 00 1/1/2010 GED - 3001 45 of 119 Rev. No. Start Date Document No. Page ________________________________________________________________________________ Printed versions are UNCONTROLLED except when stamped “CONTROLLED COPY” in blue Coral Bay Nickel Corporation 7.2 SAFETY CARDS Orientation about the use of safety cards will be given to the newly hired employee by the safety personnel. Every employee shall be given exercises on the making of these cards during the discussion for records. It is expected that the employee should practice the use of safety cards right after the orientation. 8 PERSONNEL SAFETY DEVELOPMENT 8.1 SAFETY TRAININGS To enhance the ability of the Plant Safety Personnel, safety trainings and seminars must be constantly given. The following trainings are necessary: a) Occupational Safety and Health, b) Loss Control Management, c) Safety Auditing, (d) Advanced Safety Management, (e) Fire Safety, (f) First Aid and Basic Life Support, and (g) Safety in the Use of Radioactive Equipments and Devices (SUNED). 8.1.1 SAFETY CONVENTIONS Safety personnel are also encouraged to participate in safety conventions in order for them to be aware of new developments in safety and benchmark on programs from outside of the company premises. Applicable practices and programs learned from conventions and conferences can be applied to CBNC. This way, CBNC will improve its operations and continue with its business safely. 8.1.2 FIRST AID TRAINING COURSES First Aid Training Course will be conducted once a year and a monthly refresher will be initiated. This training will be scheduled depending on personnel availability and that of invited accredited lecturer. The training duration is approximately 5 days or 40 hours. This training includes, but not limited to, responding emergency cases, first aid treatment of wounds and fractures, proper wearing of SCABA, and responding to (CPR, AR, etc.) and transporting accident victims. The refresher will be facilitated by the Safety Section and it will take only three hours per month.

- 46. SAFETY AND HEALTH PROGRAM Document Title 00 1/1/2010 GED - 3001 46 of 119 Rev. No. Start Date Document No. Page ________________________________________________________________________________ Printed versions are UNCONTROLLED except when stamped “CONTROLLED COPY” in blue Coral Bay Nickel Corporation 8.1.3 RADIATION SAFETY This is a three-hour lecture conducted by the Assistant Radiological Health and Safety Officer. Radiation Awareness lecture is included in the Safety Orientation Program for a newly hired employee. Everyone will be expected to be aware of the presence of radioactive materials in the plant and mindful on the radiation safety and precautions after the lecture. 8.1.4 FIRE FIGHTING TRAINING Training for responding fire, fire fighting equipment and facilities will be done twice a year. As scheduled, it will be conducted on March and September. Fire Fighting Chairman will make the training program and it will be assisted by the Safety Section. Every department, at least a representative, is required to participate in the said training. 8.1.5 DEFENSIVE DRIVING Defensive Driving Training is scheduled twice a month. This training will be facilitated by the Safety Section. The participant of this training must be: a) Recommended by the foreman or supervisor b) Has a valid professional LTO license, and c) With a justifiable reason that he/she is required to operate a specified company vehicle. This training will also include written and actual driving test. Upon successfully passing both examinations, the trainee will be given an “Authorized Driver’s Card” which serves as his/her permit to operate specified company vehicle. In case the trainee failed in the written test, he will be required to take the course again. In case he failed the actual driving test, he will either be deprived of the authorization or will be required to take the actual driving test again.. 8.1.6 SAFETY PROFICIENCY / KNOWLEDGE TEST This safety proficiency and knowledge test is given to assess the level of safety awareness and practice in the plant. This is given once a year usually in January

- 47. SAFETY AND HEALTH PROGRAM Document Title 00 1/1/2010 GED - 3001 47 of 119 Rev. No. Start Date Document No. Page ________________________________________________________________________________ Printed versions are UNCONTROLLED except when stamped “CONTROLLED COPY” in blue Coral Bay Nickel Corporation for three (3) consecutive years. This is self-appraisal type and a written test, respectively. The result would determine the safety education program of the company for the employees. This is being facilitated by the Safety Office. 8.1.7 MOBILE AND LIFTING EQUIPMENT SAFETY TRAINING This training/orientation aims to enhance employees’ safety awareness in operating forklifts and overhead cranes. This consists of a lecture, a written test and actual equipment operation. Passers are given authority to operate the equipment. Attendees are those regularly operating the equipment and those who are expected to be operating the equipment. New users are given proper supervision by authorized user. The training/re-orientation will be on monthly basis and will take three hours to finish. 9 ACCIDENT/INCIDENT ANALYSIS 9.1 ACCIDENT REPORTING 9.1.1 Production If the personnel involved in the accident come from Production Department, the discoverer reports the accident to the Production Operator, who will then inform the Production Foreman. The Production Foreman will inform the Production Superintendent. Simultaneously, the Production Foreman will proceed to the scene of the accident and assess the situation. If there is a need to bring the victim to the hospital, the Production Shift Superintendent reports the accident to the Production Manager and the RTNFI Hospital condition of the patient. The Production Manager will report the accident to the General Affairs Manager. The General Affairs Manager will instruct the Ambulance Driver to bring the injured personnel to the RTNFI Hospital for treatment. The General Affairs Manager will then go to the RTNFI Hospital. And finally, the Production Manager will inform the Plant Manager and Safety Head about the accident. See Appendix 25 for the communication flow.

- 48. SAFETY AND HEALTH PROGRAM Document Title 00 1/1/2010 GED - 3001 48 of 119 Rev. No. Start Date Document No. Page ________________________________________________________________________________ Printed versions are UNCONTROLLED except when stamped “CONTROLLED COPY” in blue Coral Bay Nickel Corporation 9.1.2 UTILITY If the accident involves personnel from Utility Department, the discoverer must report the accident to the Utility Operator, who will then inform the Utility Foreman. The Utility Foreman will inform the Utility Manager and Production Shift Superintendent. Simultaneously, Utility Foreman will proceed to the accident site and will assess the situation. The Utility Manager will report the accident to the General Affairs Manager. In the absence of Utility Manager, the Production Shift Superintendent will inform the General Affairs Manager. The General Affairs Manager will instruct the Ambulance Driver to bring the injured personnel to the RTNFI Hospital for immediate treatment. The General Affairs Manager will follow to the hospital. The Utility Manager will then inform the Plant Manager and Safety head about the accident. See Appendix 25 for the communication flow. 9.1.3 MAINTENANCE If the accident involves personnel from Maintenance Department, the discoverer must report the accident to the Maintenance Inspector. Maintenance Inspector will then report to the Maintenance Foreman. Maintenance Foreman will inform the Maintenance Superintendent and he will then proceed to the accident site and will assess the situation. Maintenance Superintendent will then inform the Maintenance Manager. Maintenance Manager will inform the General Affairs Manager. The General Affairs Manager will instruct the Ambulance Driver to bring the injured personnel to RTNFI Hospital for treatment. The Maintenance Superintendent will inform the RTNFI Hospital condition of the patient. The Admin Manager will follow to the RTNFI Hospital. Maintenance Manager will finally inform Plant Manager and Safety Head about the accident. See Appendix 25 for the communication flow. 9.1.4 LABORATORY If the accident involves personnel from Laboratory, the discoverer must report the accident to the Chemist-In-Charge, who will then inform the laboratory Manager.